A radiation-curable quantum dot material sealant composition

A quantum dot material, radiation curing technology, applied in the field of sealants, can solve problems such as performance degradation, and achieve the effect of effective protection function, high bonding strength and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

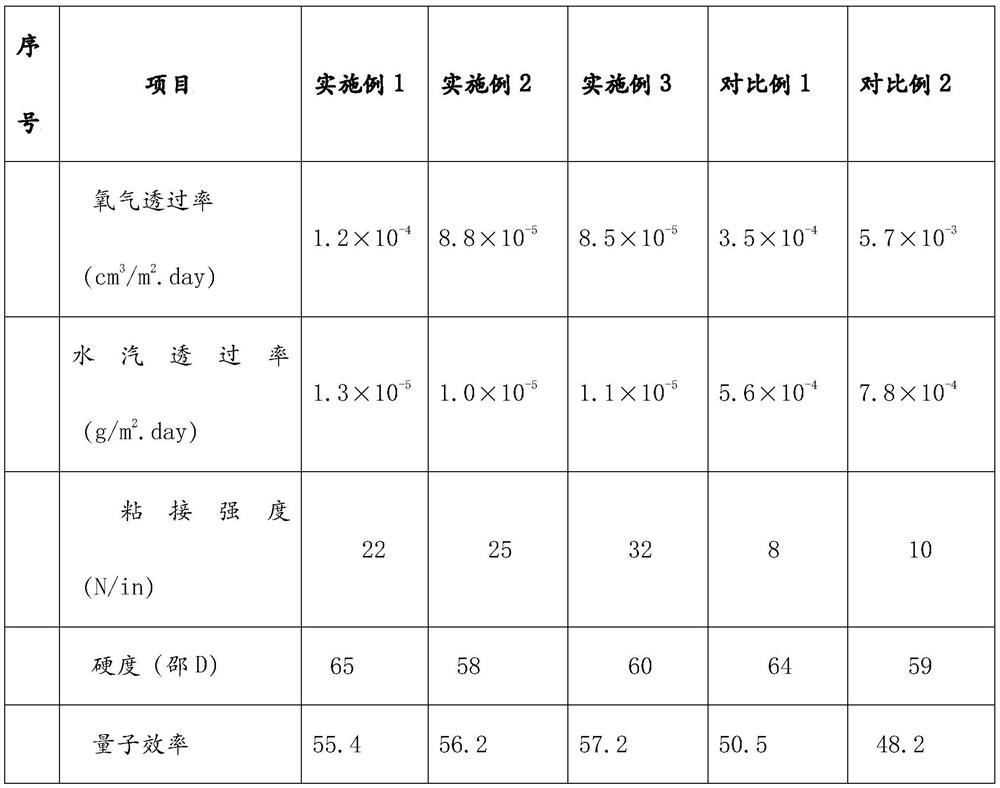

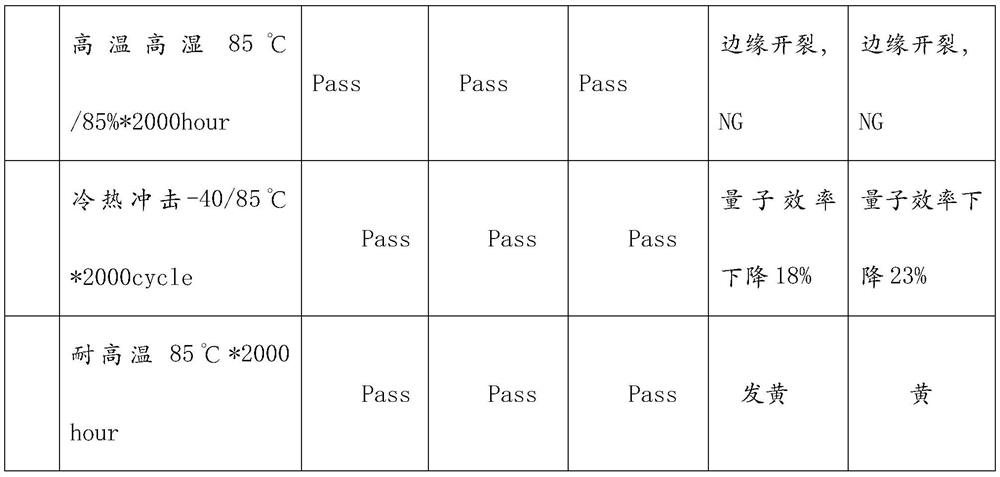

Embodiment 1

[0042] A radiation-curable quantum dot material sealant provided in Embodiment 1, by weight, contains components and the percentages of each component are as follows:

[0043] Silicone modified hyperbranched acrylate (self-made) 50 parts, silicone modified polyurethane acrylate CN1963 15 parts, isobornyl acrylate (IBOA) 10 parts, 1,6 hexanediol diacrylate (HDDA)

[0044] 20 parts, 3 parts of photoinitiator 184, 0.8 part of octadecenylamine acetate, 0.2 part of antioxidant 1010, 1 part of γ-methacryloxypropyl trimethoxysilane (KH570).

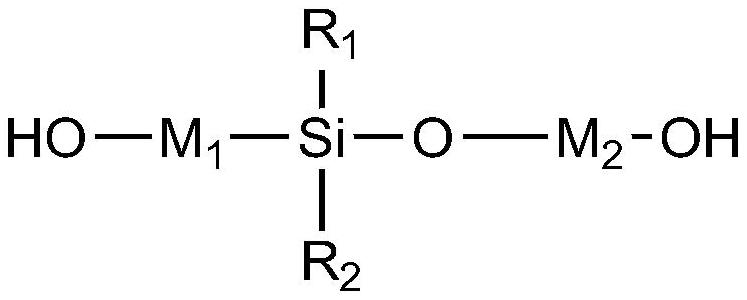

[0045] Wherein, the silicone-modified hyperbranched acrylate is self-made, and by weight, the materials required for the resin synthesis reaction are: 40 parts of isophorone diisocyanate (IPDI) trimer, 40 parts of dialkylhydroxyphenylpolysilane 10 parts, 10 parts of hydroxyethyl acrylate, 10 parts of absolute ethanol, 0.2 parts of a catalyst, and 0.3 parts of a polymerization inhibitor, wherein the catalyst is a tertiary amine, and the polymeriz...

Embodiment 2

[0051] A radiation-curable quantum dot material sealant provided in Embodiment 2, by weight, contains components and the percentages of each component are as follows:

[0052] Silicone modified hyperbranched acrylate (self-made) 45 parts, silicone modified polyurethane acrylate (self-made) 25 parts, isobornyl methacrylate (MIBOA) 10 parts, tripropylene glycol diacrylate (TPGDA) 10 parts Parts, 5 parts of lauryl methacrylate, 2 parts of photoinitiator 184, 2 parts of photoinitiator TPO, 0.1 part of oleyl amino oleate, 0.4 part of antioxidant 2246, γ-methacryloxypropyl trimethyl 0.5 parts of oxysilane (KH570).

[0053] The organosilicon-modified hyperbranched acrylate is the organosilicon-modified hyperbranched acrylate prepared in Example 1, and the organosilicon-modified polyurethane acrylate is self-made. By weight, the materials required for the resin synthesis reaction are : 20 parts of isophorone diisocyanate (IPDI), 65 parts of hydroxyl-terminated polysiloxane, 10 parts ...

Embodiment 3

[0058] A radiation-curable quantum dot material sealant, by weight, contains components and the percentages of each component include: 40 parts of organosilicon-modified hyperbranched acrylate (self-made), organosilicon-modified polyurethane acrylate (Homemade) 10, 25 parts of isobornyl methacrylate (MIBOA), 22 parts of 1,6 hexanediol diacrylate, 2 parts of photoinitiator TPO, 0.5 parts of octadecylamine acetate, antioxidant 10100.2 parts, 0.2 parts of vinyltrimethylsilane, 0.1 part of 3-methacryloxypropyl trimethoxysilane, wherein, the organosilicon modified hyperbranched acrylate is the organic Silicon-modified hyperbranched acrylate; the organosilicon-modified urethane acrylate is the organosilicon-modified urethane acrylate prepared in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com