Quantum dot sealant containing macromolecular stabilizer and preparation method of quantum dot sealant

A macromolecular stabilizer, quantum dot technology, applied in applications, coatings, inks, etc., can solve the problems of quantum dot performance degradation and quantum dot instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

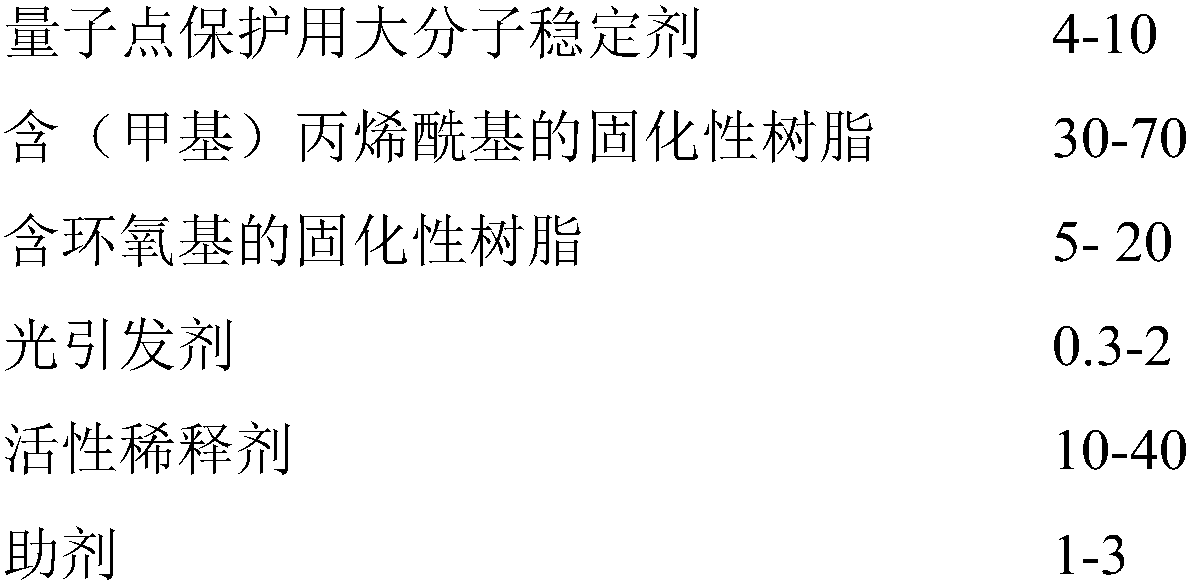

[0051] Embodiment 1: This embodiment provides a quantum dot sealant containing a macromolecular stabilizer, which is prepared by mixing the components in the following parts by weight:

[0052]

[0053] Wherein, the number average molecular weight of the macromolecule stabilizer for quantum dot protection is 3500-55000.

[0054] The macromolecular stabilizer for protecting quantum dots is a macromolecular copolymer having an A-b-B diblock structure, an A-b-B-b-A triblock structure, and an A-co-B copolymer structure.

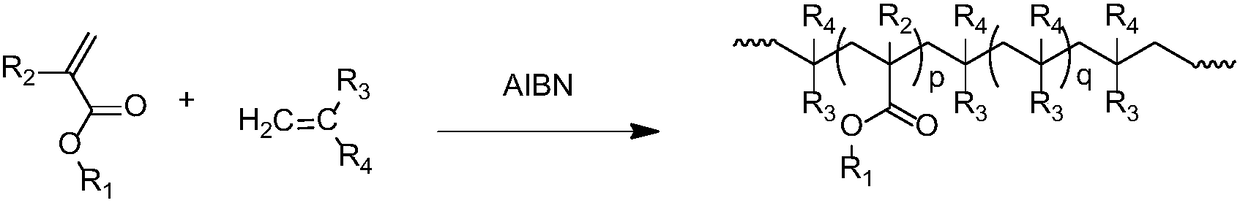

[0055] The macromolecular stabilizer for quantum dot protection with A-co-B copolymer structure is prepared by the following reaction formula:

[0056]

[0057] Among them, R 1It is a monofunctional acrylate group of an alkane chain segment with more than 10 carbon atoms, a monofunctional acrylate group of a polymer chain segment with a number average molecular weight of 600-3000, or a difunctional acrylate group. species; R 2 is a hydrogen atom or a met...

Embodiment 2

[0079] Embodiment 2: This embodiment provides a quantum dot sealant containing a macromolecular stabilizer, and a preparation method thereof. Its components and steps are basically the same as in Embodiment 1, except that:

[0080] It is prepared by mixing the components according to the following parts by weight:

[0081]

[0082] A kind of preparation method of the described quantum dot sealant containing macromolecular stabilizer, it may further comprise the steps:

[0083] (1) Preparation of polylauryl methacrylate-co-polyacrylonitrile (PLMA-co-PAN);

[0084] (2) preparing curable resin containing (meth)acryloyl group;

[0085] (3) prepare curable resin containing epoxy group;

[0086] (4) Prepare each component by following parts by weight:

[0087]

[0088] (5) Prepare a planetary vacuum mixer, place each component prepared in step (4) in a planetary vacuum mixer, and stir at a temperature of 40°C to 50°C to obtain a mixture;

[0089] (6) Filter the mixture obt...

Embodiment 3

[0092] Embodiment 3: This embodiment provides a quantum dot sealant containing a macromolecular stabilizer, and a preparation method thereof. Its components and steps are basically the same as those in Embodiment 1 and 2, except that:

[0093] It is prepared by mixing the components according to the following parts by weight:

[0094]

[0095] A kind of preparation method of the described quantum dot sealant containing macromolecular stabilizer, it may further comprise the steps:

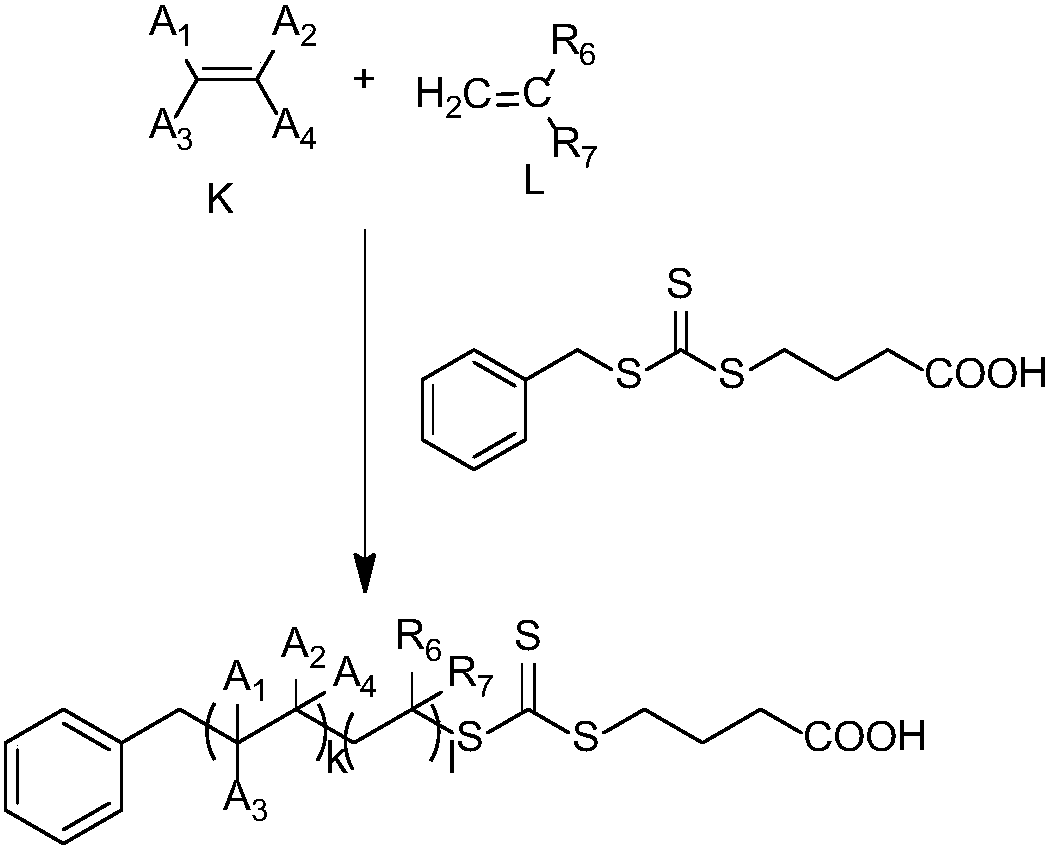

[0096] (1) Preparation of polystyrene-b-polyacrylic acid (PS-b-PMAA);

[0097] (2) preparing curable resin containing (meth)acryloyl group;

[0098] (3) prepare curable resin containing epoxy group;

[0099] (4) Prepare each component by following parts by weight:

[0100]

[0101] (5) Prepare a planetary vacuum mixer, place each component prepared in step (4) in a planetary vacuum mixer, and stir at a temperature of 40°C to 50°C to obtain a mixture;

[0102] (6) Filter the mixture obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com