Underground anti-cracking and impermeable concrete with strength grade no more than C50 and preparation method thereof

A strength grade, concrete technology, applied in the field of new inorganic non-metallic materials, can solve the problems of insufficient concrete crack resistance, high concrete cost, concrete cracking, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The above-mentioned content of the present invention will be described in further detail below through the embodiment form, but this should not be interpreted as the scope of the above-mentioned theme of the present invention is limited to the following embodiments, all technologies realized based on the above-mentioned content of the present invention belong to this invention the scope of the invention.

[0035] 1. The best mix ratio of concrete with different strength grades mixed with mineral admixtures

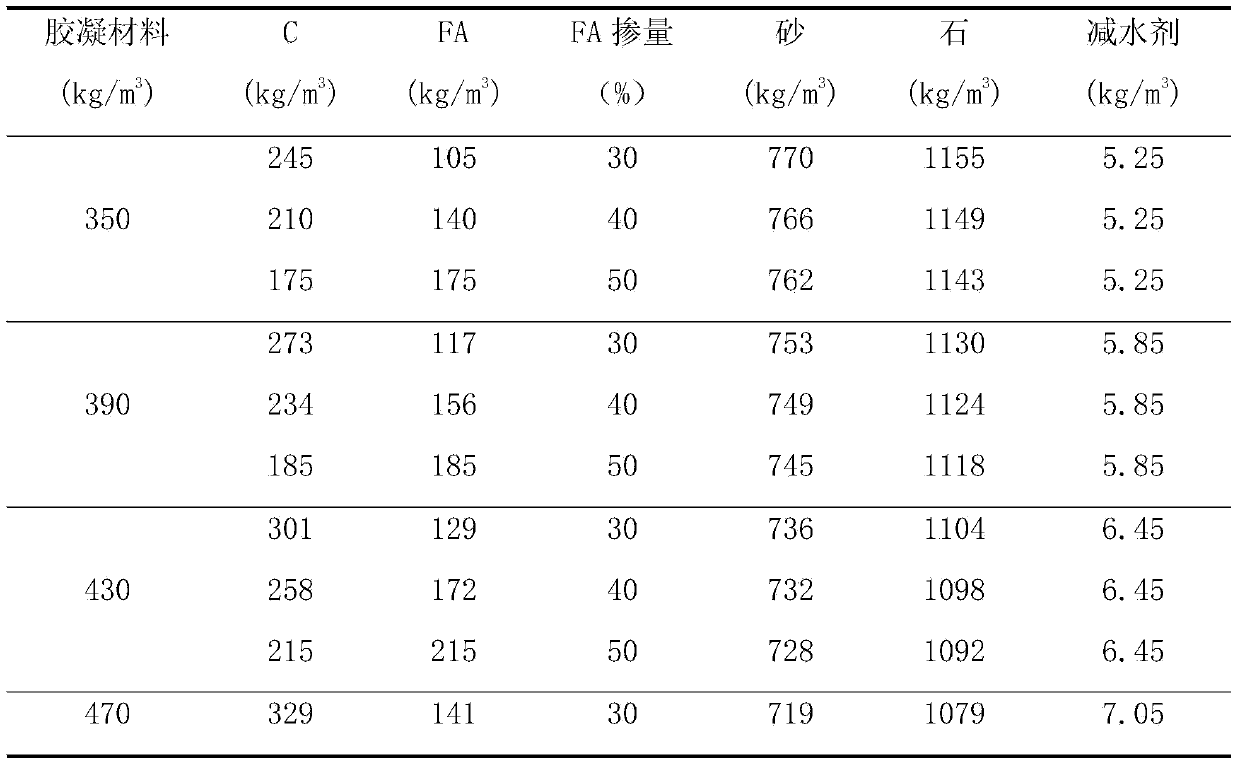

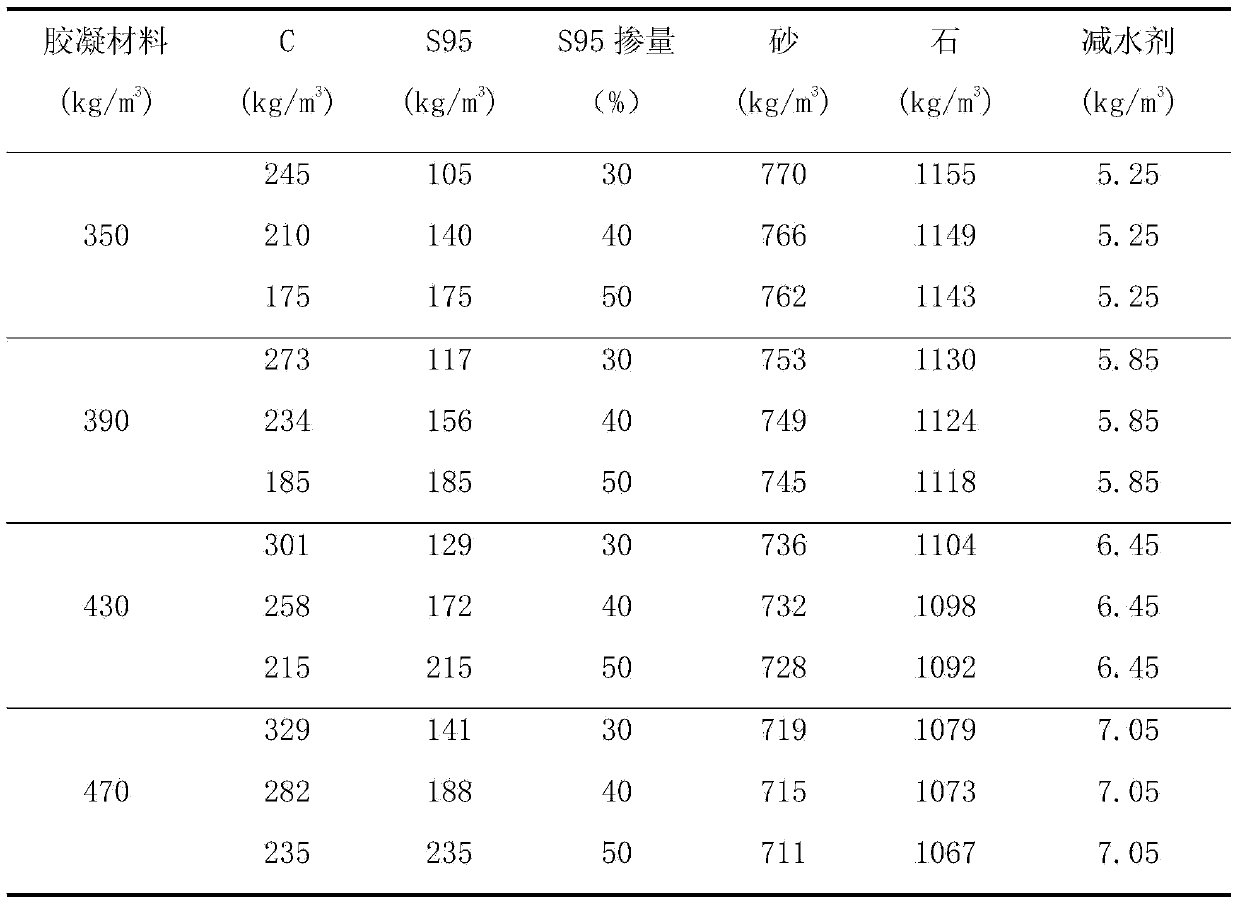

[0036]1.1 Experimental mix design of concrete with different cementitious material systems

[0037] Replacing cement with admixtures such as fly ash and mineral powder can not only reduce the production cost of concrete, but also reduce the crack resistance of concrete and improve the durability of concrete. The amount of gelling material used in this test is 350kg / m 3 、390kg / m 3 、430kg / m 3 and 470kg / m 3 The cementitious material system includes cement-fly ash,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com