Glass fiber reinforced polypropylene material used for thin-wall injection molding and preparation method of glass fiber reinforced polypropylene material

A polypropylene material and polypropylene resin technology, applied in the field of glass fiber reinforced polypropylene material for thin-wall injection molding and its preparation, can solve the problems of glass fiber exposure and fluidity to be improved, and achieve reduced orientation and better compatibility. Excellent, tightly combined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

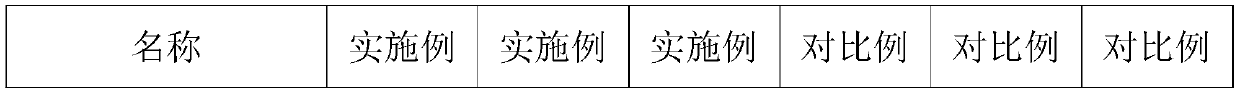

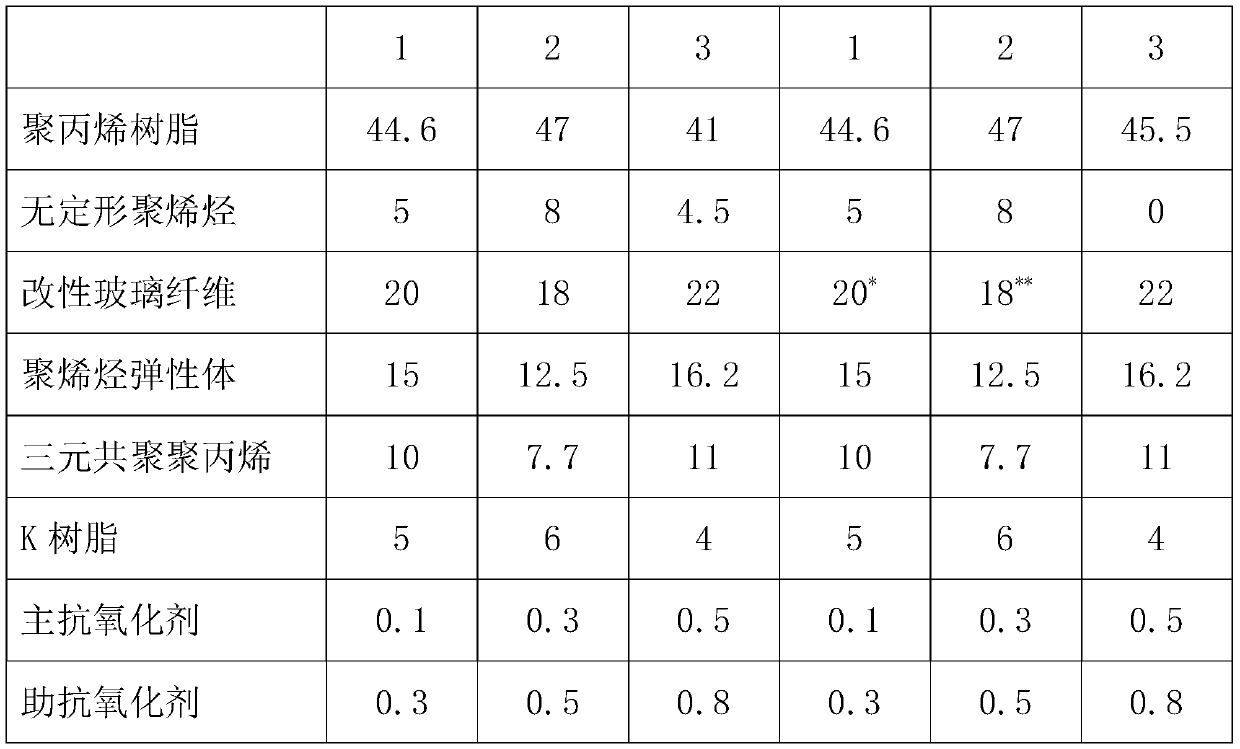

[0026] The invention provides a glass fiber-reinforced polypropylene material for thin-wall injection molding. The raw material composition of the material is shown in Table 1.

[0027] Wherein: the flow rate of the polypropylene resin under a load of 2.16kg is 40-55g / min at a temperature of 230°C.

[0028] The addition of amorphous polyolefin materials can change the crystallization rate and crystallinity of polypropylene, thereby reducing the wall shrinkage phenomenon on the surface of polypropylene composite materials and improving impact resistance.

[0029] Surface-modified glass fiber is glass fiber with oval cross-section, and its density is 2.2-2.66g / cm 3 ; Compared with the conventional circular cross-section, the elliptical cross-section reduces the orientation of the glass fiber and reduces the anisotropy of the glass fiber, thereby improving the warping deformation of the glass fiber-reinforced polypropylene material on the one hand, and on the other hand The phys...

Embodiment 2

[0041] The preparation method of this example is the same as that of Example 1, except that the raw material composition for preparing the glass fiber reinforced polypropylene material for thin-wall injection molding is different from that of Example 1, see Table 1 for details.

Embodiment 3

[0043] The preparation method of this example is the same as that of Example 1, except that the raw material composition for preparing the glass fiber reinforced polypropylene material for thin-wall injection molding is different from that of Example 1, see Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com