Glass fiber enhanced flame retardant polypropylene composite material for upper cover of battery pack and preparation method thereof

A technology of flame-retardant polypropylene and composite materials, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of complicated processing procedures, large man-hours, and increased material costs, and achieve improved bonding effects, reduced procedures, and reduced The effect of processing costs

Active Publication Date: 2019-01-11

中广核俊尔(上海)新材料有限公司

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the current production of glass fiber reinforced flame-retardant polypropylene composite materials, the processing procedures are complicated and the production capacity is low, resulting in large man-

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

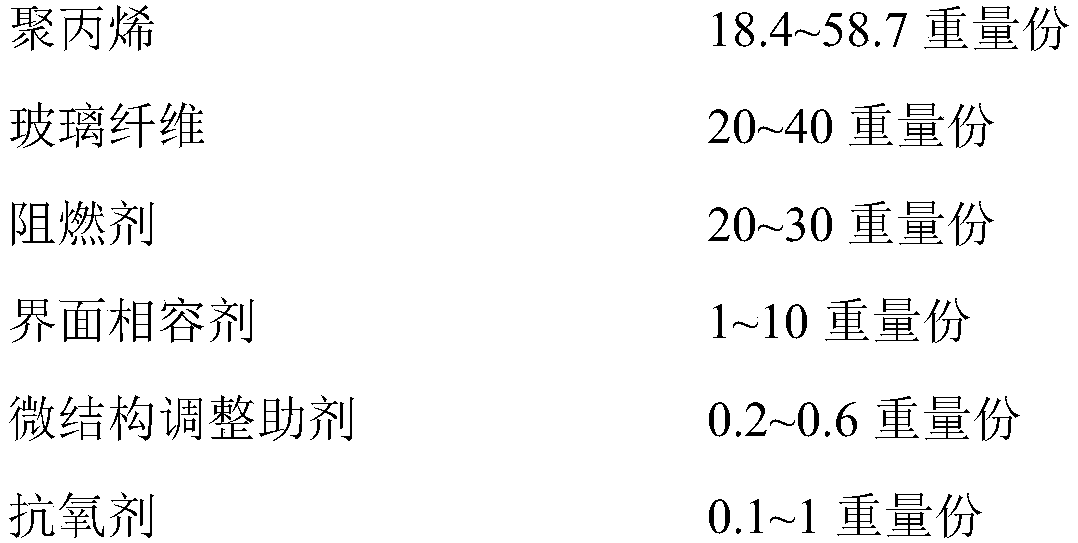

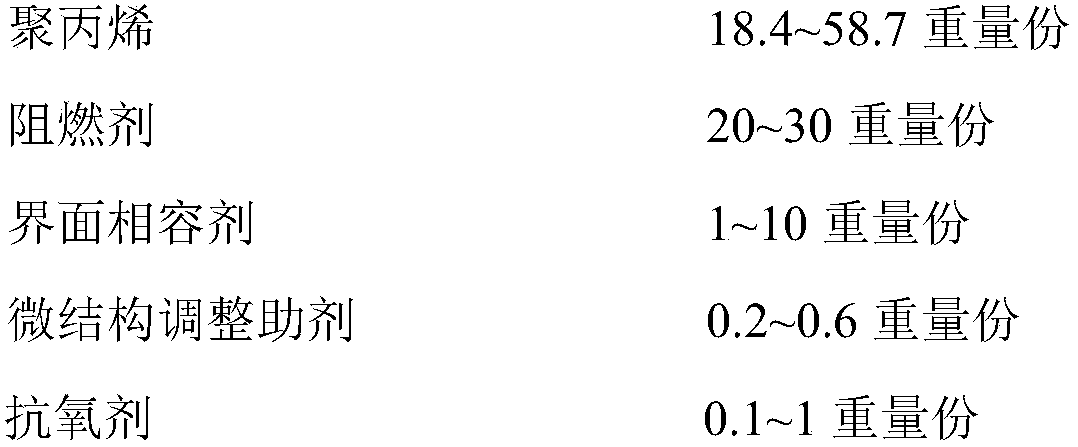

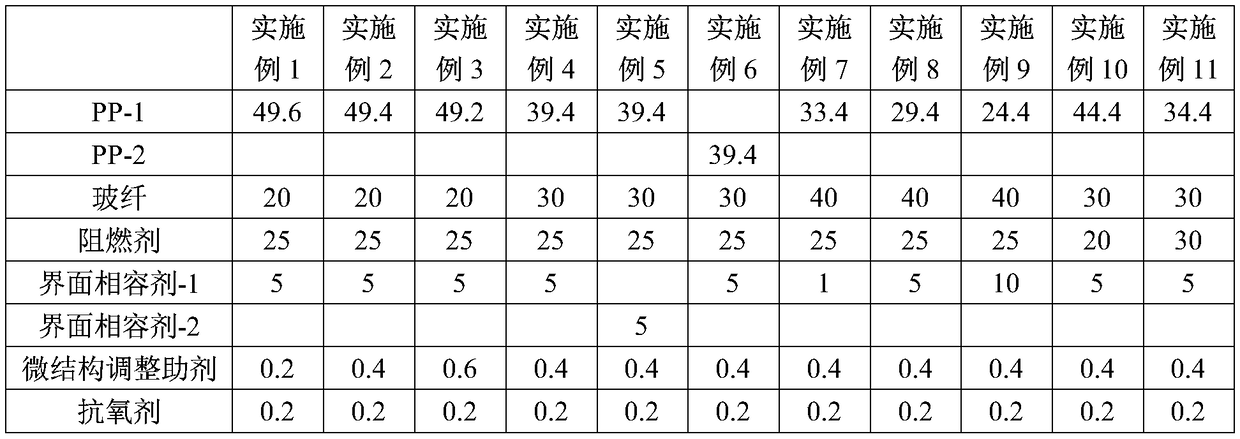

The invention relates to a glass fiber enhanced flame retardant polypropylene composite material for an upper cover of a battery pack and a preparation method thereof. The composite material is prepared from the following raw materials in parts by weight: 18.4-58.7 parts of polypropylene, 20-40 parts of glass fibers, 20-30 parts of a flame retardant, 1-10 parts of an interface compatilizer, 0.2-0.6 part of a microstructure adjusting aid and 0.1-1 part of an antioxidant. The material is produced by a processing mode of preimpregnating a melt into continuous long fibers, so that the demand on performance of the material is met, and the problem that it is hard to process and low in yield in a high powder filling condition is solved. The original two-step method process method is simplified toone-step method processing, so that the processing course is simplified, the yield of the material is improved and the manufacturing cost is lowered.

Description

technical field [0001] The invention belongs to the technical field of polymer materials, and in particular relates to a high flame-retardant, high-rigidity and easy-to-process glass fiber reinforced flame-retardant polypropylene composite material for the upper cover of a battery pack and a preparation method thereof. Background technique [0002] At present, with the enhancement of environmental protection awareness in various countries, the market share of new energy vehicles has gradually increased, and the demand for materials around new energy vehicles in the material market has gradually increased. Compared with traditional fuel vehicle materials, new energy vehicle battery peripheral materials are a new market in the material market. Due to the particularity of the battery part of the new energy vehicle, the battery pack design has extremely high safety requirements for this part, so the materials used in the battery part, whether it is a structural part material or ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/12C08L23/14C08L51/06C08K13/04C08K7/14C08K5/134C08K5/526C08K5/098C08J5/04H01M2/04H01M50/155

CPCC08J5/043C08J2323/12C08J2323/14C08J2451/06C08K5/526C08K5/1345C08K5/098C08K13/04C08K7/14H01M50/155Y02E60/10

Inventor 付光屈国梁黄志杰王海华杨仓先

Owner 中广核俊尔(上海)新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com