High-performance high-flow polyamide composite material and preparation method thereof

A technology of high-flow polyamide and composite materials, applied in the field of polyamide composite materials, can solve the problems of high price of graphene, increased processing cost, etc., and achieve the effects of good economic benefits, improved gloss, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

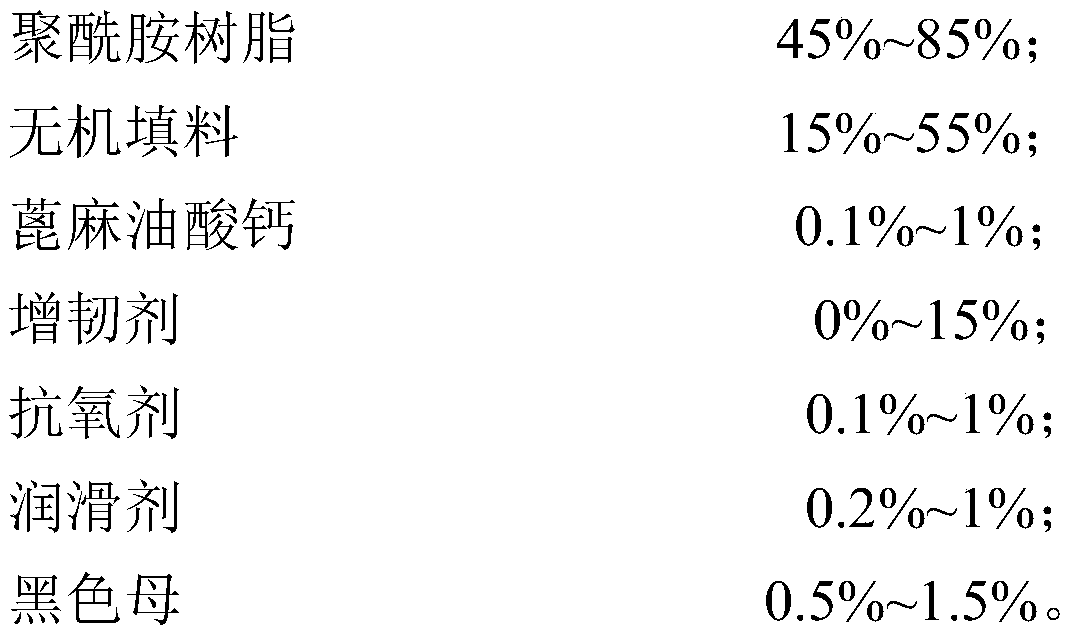

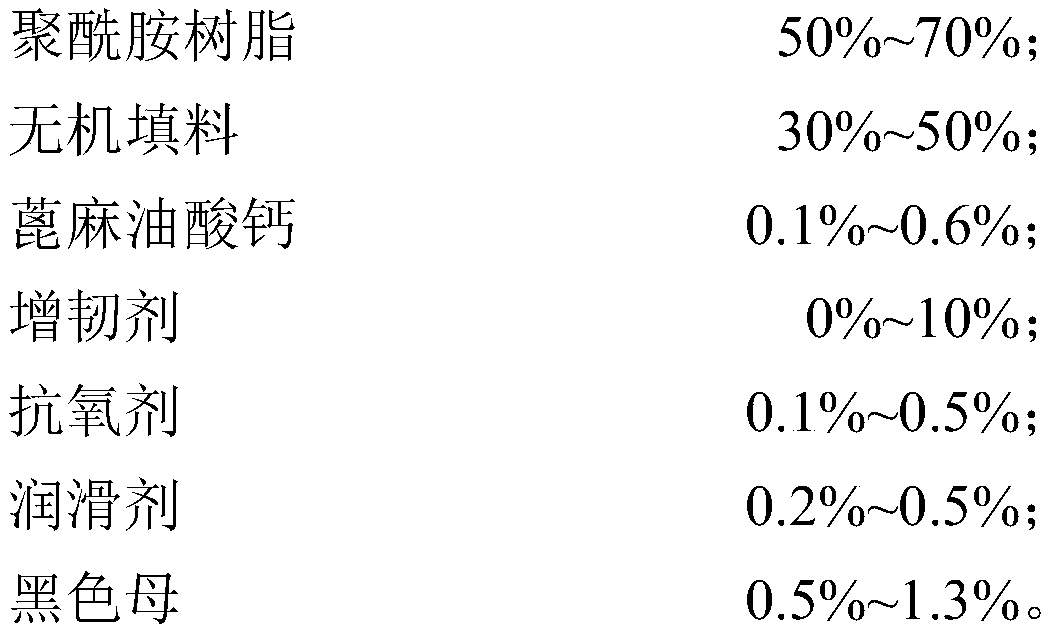

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific embodiments. It should be understood that these examples are only used to illustrate the present invention and not to limit the scope of the present invention. In the following examples, the experimental methods without specific conditions are usually in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer.

[0041] The specific preparation method is as follows:

[0042] Add nylon, calcium ricinoleate, toughening agent, black masterbatch, antioxidant and lubricant into the stirring pot, mix evenly for 7min, then add it to the twin-screw extruder from the main feeding hopper, and remove the glass fiber from the side. The feed hopper is added to the twin screw extruder. After being extruded by a twin-screw extruder at a specific temperature, water-cooled, pelletized and dried to obtain a polyamide composite material with high performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com