Preparation method of PPR (polypropylene random copolymer) pipe with copper metal effect

A copper metal and pipe technology, applied in the field of PPR pipe preparation, can solve the problems of poor low-temperature toughness, single visual effect, and poor heat resistance of PPR pipes, so as to improve compatibility, reduce fracture probability, and avoid embrittlement aggravation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

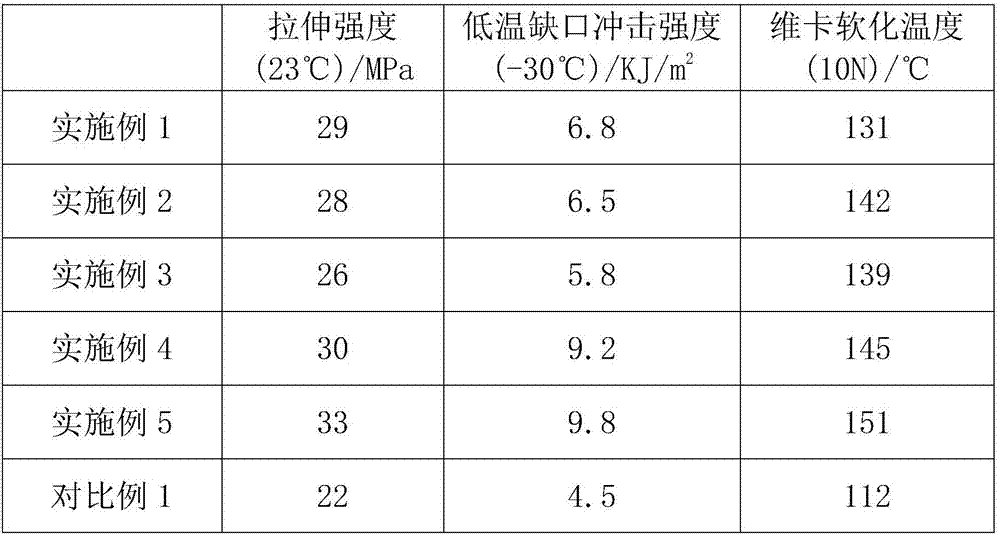

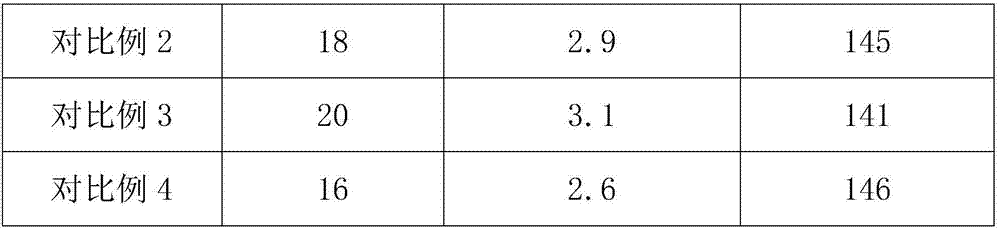

Examples

Embodiment 1

[0037] This embodiment provides a method for preparing a PPR pipe with a copper metal effect, comprising the following steps:

[0038] Prepare the following raw materials by weight: 100 parts of PPR, 15 parts of granular copper powder, 5 parts of scaly copper powder, 12 parts of dispersant, 8 parts of carbon fiber, 1 part of coupling agent, soft-core hard-shell core-shell copolymer 8 parts of toughening agent, 1.5 parts of antioxidant; Described carbon fiber is polyacrylonitrile-based carbon fiber, and described soft-core hard-shell type core-shell copolymer is methyl methacrylate-butyl acrylate core-shell copolymer, and described The dispersant is stearic acid, the coupling agent is γ-(2,3-glycidoxy)propyltrimethoxysilane, and the antioxidant is β-(3, 5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate and three [2,4-di-tert-butylphenyl] phosphite, the granular copper powder is 400 mesh, the The flaky copper powder is 700 mesh;

[0039] Prepare the dispersant solution with ...

Embodiment 2

[0046] This embodiment provides a method for preparing a PPR pipe with a copper metal effect, comprising the following steps:

[0047] Prepare the following raw materials by weight: 100 parts of PPR, 30 parts of granular copper powder, 1 part of scaly copper powder, 15 parts of dispersant, 15 parts of carbon fiber, 2 parts of coupling agent, soft-core hard-shell core-shell copolymer 12 parts of toughening agent, 1.3 parts of antioxidant; The carbon fiber is a pitch-based carbon fiber, and the soft-core hard-shell type core-shell copolymer is methyl methacrylate-butadiene-styrene core-shell copolymer , the dispersant is lauric acid, the coupling agent is γ-mercaptopropyltrimethoxysilane, and the antioxidant is tetrakis[β-(3,5-di-tert-butyl with a mass ratio of 1:1 base-4-hydroxyphenyl)propionic acid]pentaerythritol ester and bis(2,4-di-tert-butylphenol)pentaerythritol diphosphite, the granular copper powder is 500 mesh, and the flaky copper powder is 600 head;

[0048] Prepar...

Embodiment 3

[0055] This embodiment provides a method for preparing a PPR pipe with a copper metal effect, comprising the following steps:

[0056] Prepare the following raw materials by weight: 100 parts of PPR, 20 parts of granular copper powder, 2 parts of scaly copper powder, 10 parts of dispersant, 10 parts of carbon fiber, 1.5 parts of coupling agent, soft core and hard shell core-shell copolymer 5 parts of toughening agent, 2.5 parts of antioxidant; The carbon fiber is viscose-based carbon fiber, the soft-core hard-shell type core-shell copolymer is methyl methacrylate-butyl acrylate core-shell copolymer, and the dispersed The agent is glyceryl tristearate, the coupling agent is isopropyl tris(dioctylpyrophosphoryloxy) titanate, and the antioxidant is 4,6-tris (3,5-di-tert-butyl-4-hydroxybenzyl) benzene and tris[2,4-di-tert-butylphenyl] phosphite, the granular copper powder is 800 mesh, and the flaky copper Powder is 500 mesh;

[0057] Prepare dispersant solution with chloroform; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com