Toughened silicon carbide ceramic and preparation method thereof

A technology of silicon carbide ceramics and toughened silicon carbide, which is applied in the field of toughened silicon carbide ceramics and its preparation, can solve the problems of high cost, affecting the quality uniformity of toughened silicon carbide ceramics, and rising costs, so as to achieve good hardness and overcome The effect of uneven ceramic quality and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

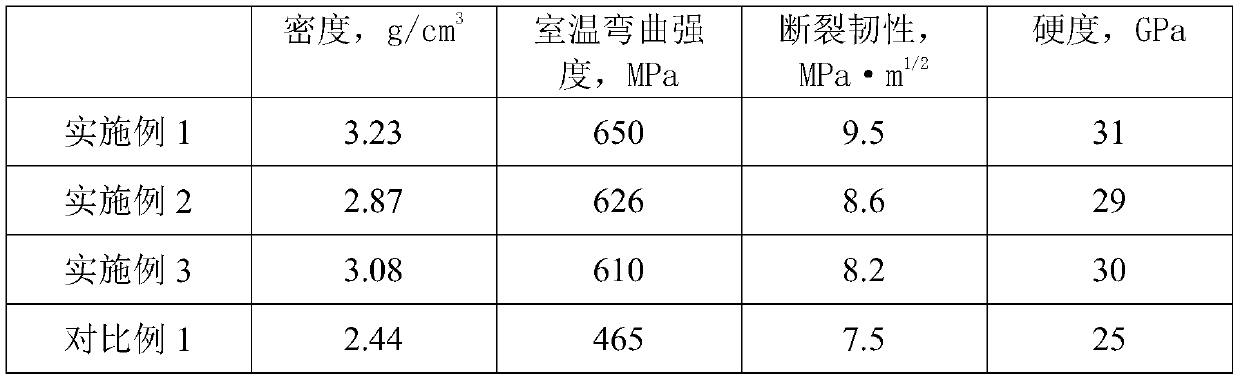

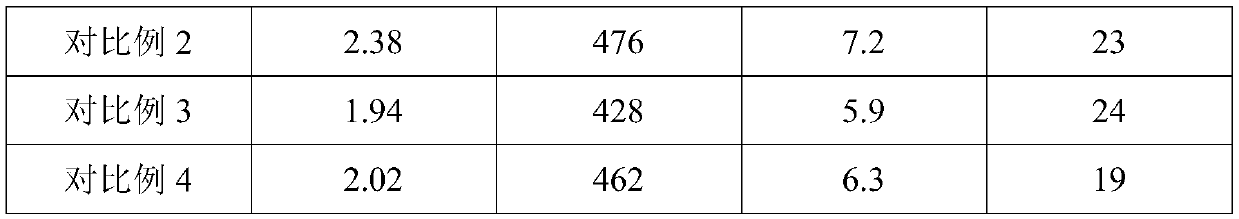

Examples

Embodiment 1

[0032] A toughened silicon carbide ceramics, in parts by weight, comprising the following components:

[0033] 90 parts of silicon carbide powder, 2 parts of boron carbide powder, 23 parts of carbon black, 3 parts of flaky alumina, 2 parts of magnesium fluoride, 0.8 parts of lanthanum oxide, 23 parts of carbon nanotubes, 4 parts of reinforcing fibers, Ti-Si- 4 parts of Fe alloy powder.

[0034] The particle size of silicon carbide powder is 1-3μm, the particle size of boron carbide powder is 0.5-1μm, the particle size of Ti-Si-Fe alloy powder is 0.2-0.8μm, and the reinforcing fiber is silicon carbide whisker and zirconia whisker The carbon nanotubes are carbon nanotubes with OD 1-2nm, length 1-30nm, CNTs purity>90wt%, Ash<1.5wt%.

[0035] The above-mentioned preparation method of toughened silicon carbide ceramics comprises the following steps:

[0036] (1) adding silicon carbide micropowder, carbon black, boron carbide micropowder and carbon nanotubes into ethanol for ultra...

Embodiment 2

[0043] A toughened silicon carbide ceramics, in parts by weight, comprising the following components:

[0044] 80 parts of silicon carbide micropowder, 3 parts of boron carbide micropowder, 15 parts of carbon black, 4 parts of flake alumina, 1 part of magnesium fluoride, 1 part of lanthanum oxide, 15 parts of carbon nanotube, 5 parts of reinforcing fiber, Ti-Si- 3 parts of Fe alloy powder.

[0045] The particle size of silicon carbide powder is 1-3μm, the particle size of boron carbide powder is 0.5-1μm, the particle size of Ti-Si-Fe alloy powder is 0.2-0.8μm, the reinforcing fiber is silicon carbide whisker, and the carbon nanotube is Carbon nanotubes with OD 1-2nm, length 1-30nm, CNTspurity>90wt%, Ash<1.5wt%.

[0046] The above-mentioned preparation method of toughened silicon carbide ceramics comprises the following steps:

[0047] (1) adding silicon carbide micropowder, carbon black, boron carbide micropowder and carbon nanotubes into ethanol for ultrasonication, the vol...

Embodiment 3

[0054] A toughened silicon carbide ceramics, in parts by weight, comprising the following components:

[0055] 100 parts of silicon carbide micropowder, 1 part of boron carbide micropowder, 30 parts of carbon black, 2 parts of flake alumina, 3 parts of magnesium fluoride, 0.5 part of lanthanum oxide, 30 parts of carbon nanotube, 3 parts of reinforcing fiber, Ti-Si- 5 parts of Fe alloy powder.

[0056] The particle size of silicon carbide powder is 1-3μm, the particle size of boron carbide powder is 0.5-1μm, the particle size of Ti-Si-Fe alloy powder is 0.2-0.8μm, the reinforcing fiber is titanium dioxide whisker, and the carbon nanotube is OD 1-2nm, length 1-30nm, CNTspurity>90wt%, Ash<1.5wt% carbon nanotubes.

[0057] The above-mentioned preparation method of toughened silicon carbide ceramics comprises the following steps:

[0058] (1) adding silicon carbide micropowder, carbon black, boron carbide micropowder and carbon nanotubes into ethanol for ultrasonication, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com