A method for preparing a high-toughness thermally conductive functional composite material

A technology for functional composite materials and thermally conductive fillers is applied in the field of preparing high-toughness and thermally conductive functional composite materials, which can solve the problems of poor surface finish of composite products, damage to polymer material properties, and reduced impact strength, so as to increase added value and improve processing. The effect of performance, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

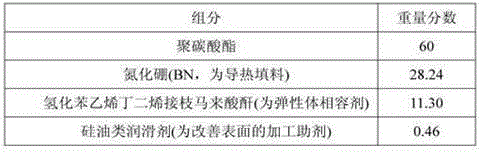

Embodiment 1

[0026] The method for preparing a high-toughness heat-conducting composite material in this embodiment uses polycarbonate as a substrate and boron nitride as a heat-conducting filler, including the following steps:

[0027] (1) Boron nitride is calcined at a high temperature of 800°C, cooled to room temperature, treated with a silane coupling agent, and then dried in a blast oven at 60°C for 6 hours;

[0028] (2) The boron nitride, hydrogenated styrene-butadiene-styrene block copolymer grafted with maleic anhydride and silicone oil lubricant after the coupling agent treatment and drying in step (1) is The ratio of 250:100:4 is pre-mixed in a high-speed mixer, and then melt-blended, extruded, and granulated by a twin-screw extruder to prepare a heat-conducting elastomer masterbatch with a "core-shell" structure, and then in The heat-conducting elastomer masterbatch was placed in a blast oven at 80° C. and dried for 2 hours to obtain a dried heat-conducting elastomer masterbatch...

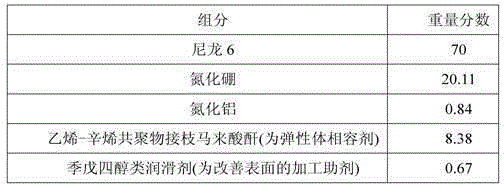

Embodiment 2

[0041] The method for preparing a high-toughness thermally conductive composite material in this embodiment uses nylon 6 as the substrate and boron nitride as the thermally conductive filler, including the following steps:

[0042] (1) Boron nitride is calcined at a high temperature of 800°C, cooled to room temperature, treated with a silane coupling agent, and then dried in a blast oven at 70°C for 5 hours;

[0043] (2) Put the boron nitride and ethylene octene copolymer grafted maleic anhydride and pentaerythritol lubricant after the coupling agent treatment and drying in the step (1) at a weight ratio of 250:100:8. Pre-mixed in the mixer, and then melt blended, extruded, and granulated by a twin-screw extruder to prepare a heat-conducting elastomer masterbatch with a "core-shell" structure, and then place the heat-conducting elastomer masterbatch in the blast Dry in an oven at 80° C. for 2 hours to obtain dry heat-conducting elastomer masterbatches. Among them, the tempera...

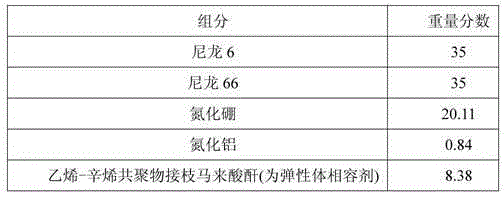

Embodiment 3

[0056] The method for preparing a high-toughness thermally conductive composite material in this embodiment uses nylon 6 as the substrate, and boron nitride and aluminum nitride as thermally conductive fillers, including the following steps:

[0057] (1) Boron nitride and aluminum nitride are calcined at a high temperature of 800°C, cooled to room temperature, treated with a silane coupling agent, and then dried in a blast oven at 70°C for 5 hours;

[0058] (2) The boron nitride, aluminum nitride and ethylene octene copolymer grafted with maleic anhydride and pentaerythritol lubricant after the coupling agent treatment and drying in step (1) are 240:10:100 by weight :8 (the ratio of the total amount of the two fillers, the elastomer compatibilizer and the processing aid is 250:100:8) is pre-mixed in a high-mixer, and then melted and blended by a twin-screw extruder, Extrude and granulate to prepare a thermally conductive elastomer masterbatch with a "core-shell" structure, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com