Method for preparing polylactic acid, bamboo nano-cellulose whisker and ultrafine bamboo charcoal composite material film

A composite material film and nanocellulose technology, which is applied in the field of preparation of polylactic acid/bamboo nanocellulose whiskers/ultrafine bamboo charcoal composite material film, can solve the problem of reduced tensile strength, low mechanical properties, and high tensile strength of the film. problem, to achieve the effect of improving the brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0068] Embodiment 1-1, a kind of preparation method of polylactic acid bamboo nano cellulose whisker bamboo charcoal composite material film, carries out following steps successively:

[0069] 1), bamboo nanocellulose whiskers carry out surface modification treatment:

[0070] ①. Add the silane coupling agent KH-590 as a surface modifier to the methanol / water solution (methanol / water: 80 / 20, volume ratio), adjust the pH to 4~5 with acetic acid, and test the magnetic force at 50°C Stir and hydrolyze for 30 minutes to obtain a hydrolyzed silane coupling agent solution; the solid-liquid ratio of the silane coupling agent to methanol / water solution is 1g / 25ml;

[0071] 2. According to the mass ratio of silane coupling agent:bamboo nanocellulose whiskers=8%, add bamboo nanocellulose whiskers to the silane coupling agent solution after hydrolysis, keep stirring at 45°C for 2h, wash with methanol / water solution Afterwards, drying (drying at 75° C. for 24 hours) to obtain the modifie...

Embodiment 1-2~ Embodiment 1-6

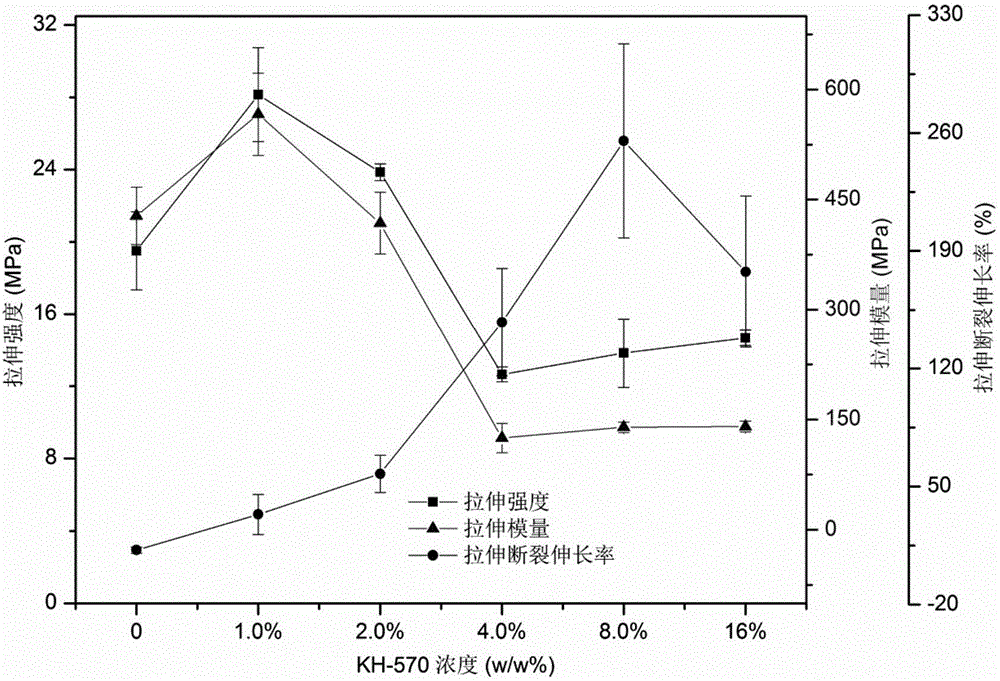

[0081] The mass ratio of silane coupling agent and bamboo nanocellulose whisker in the step 1) of embodiment 1-1 is changed into 0%, 1.0%, 2.0%, 4.0%, 16% respectively by 8%; All the other are equal to implementing Example 1-1; thus correspondingly obtain Example 1-2 to Example 1-6.

[0082] Gained composite material film is detected according to the method described in embodiment 1-1, and its tensile strength, tensile modulus and tensile elongation at break are as follows: Figure 4 mentioned.

Embodiment 2-1~2-6

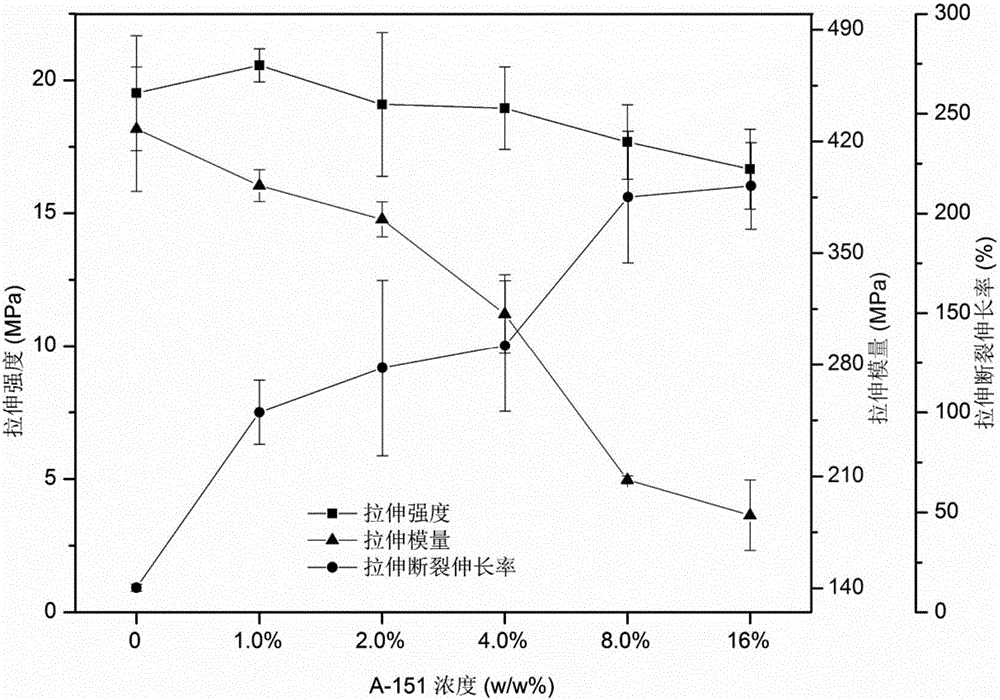

[0084] Change the silane coupling agent in Example 1-1 to Example 1-6 from KH-590 to A-151; step 1) and step 2) in "methanol / water solution (methanol / water: 80 / 20, Volume ratio)" are correspondingly changed to "ethanol / water solution (ethanol / water: 80 / 20, volume ratio)"; the rest are the same.

[0085] Gained composite material film is detected according to the method described in embodiment 1-1, and its tensile strength, tensile modulus and tensile elongation at break are as follows: figure 1 mentioned.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile elongation at break | aaaaa | aaaaa |

| Tensile elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com