Mixed passenger and freight railway rubber adapter plate

A technology of rubber backing plate, passenger-cargo joint, applied in the field of passenger-cargo railroad rubber backing plate, can solve problems such as unsatisfactory, achieve improved shock absorption performance, simple preparation process, wear resistance and aging resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

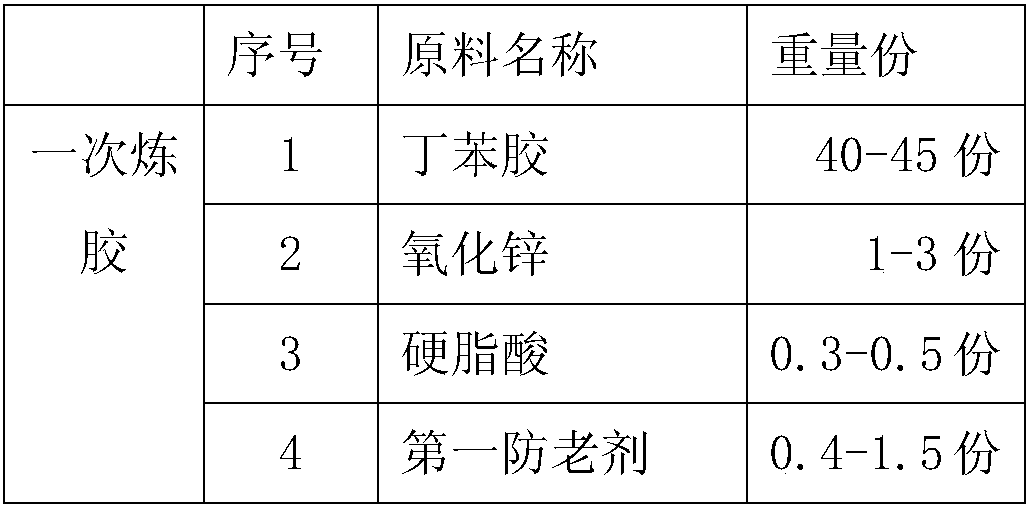

[0017] The passenger-cargo collinear railway rubber backing plate of the present embodiment, the rubber backing plate adopts a composite rubber material, and the composite rubber material adopts the following components by weight as raw materials:

[0018]

[0019] The preparation method of railway rubber backing plate material of the present invention comprises primary rubber mixing, secondary rubber mixing, tertiary rubber mixing, vulcanization production, concrete operation steps are as follows:

[0020] Primary rubber mixing: Weigh the above weight parts of styrene-butadiene rubber, zinc oxide, stearic acid, anti-aging agent 4010A, anti-aging agent RD, silane coupling agent 4C, and mix them in an internal mixer for rubber mixing, and the temperature rises To 120°C, the mixing time is controlled within 10 minutes, after the end of the mixing, the temperature of the glue is lowered to below 100°C to discharge the glue, and it is cooled to room temperature.

[0021] Second...

Embodiment 2

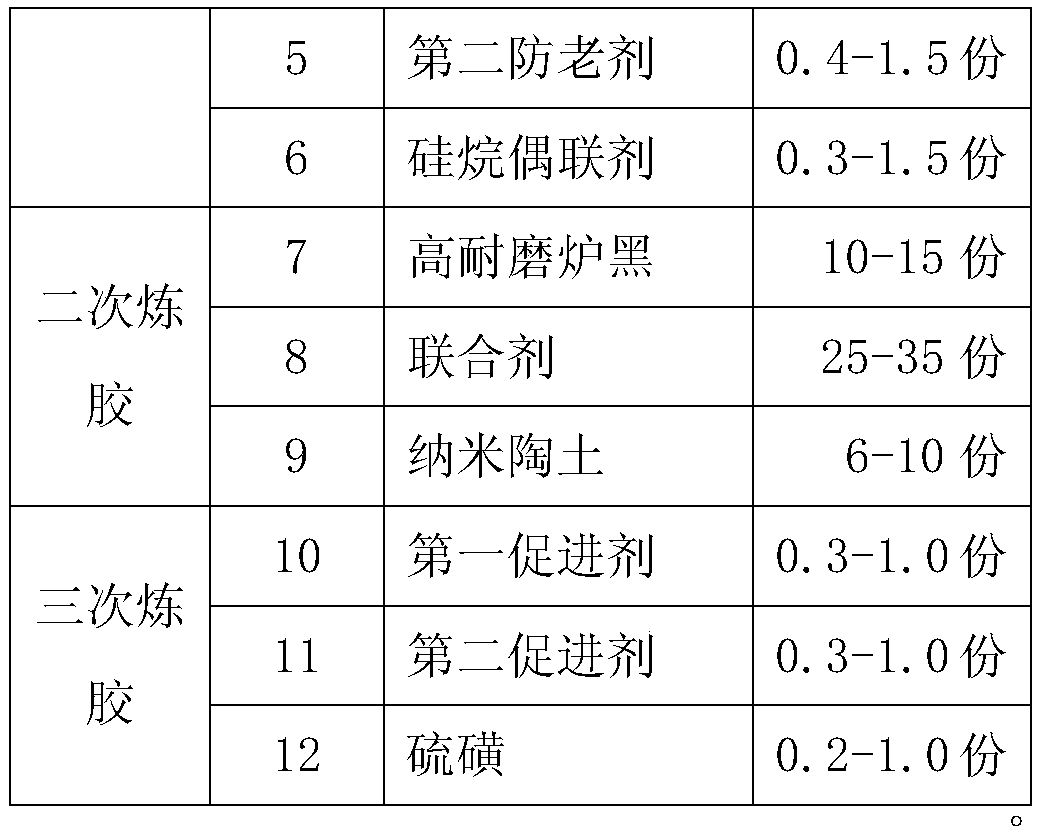

[0025] The passenger-cargo collinear railway rubber backing plate of the present embodiment, the rubber backing plate adopts a composite rubber material, and the composite rubber material adopts the following components by weight as raw materials:

[0026]

[0027] The preparation method of railway rubber backing plate material of the present invention comprises primary rubber mixing, secondary rubber mixing, tertiary rubber mixing, vulcanization production, concrete operation steps are as follows:

[0028] Primary rubber mixing: Weigh the above weight parts of styrene-butadiene rubber, zinc oxide, stearic acid, anti-aging agent 4010A, anti-aging agent RD, silane coupling agent 4C, and mix them in an internal mixer for rubber mixing, and the temperature rises To 160°C, the mixing time is controlled within 10 minutes, after the end of the mixing, the temperature of the glue is lowered to below 100°C to discharge the glue, and it is cooled to room temperature.

[0029] Second...

Embodiment 3

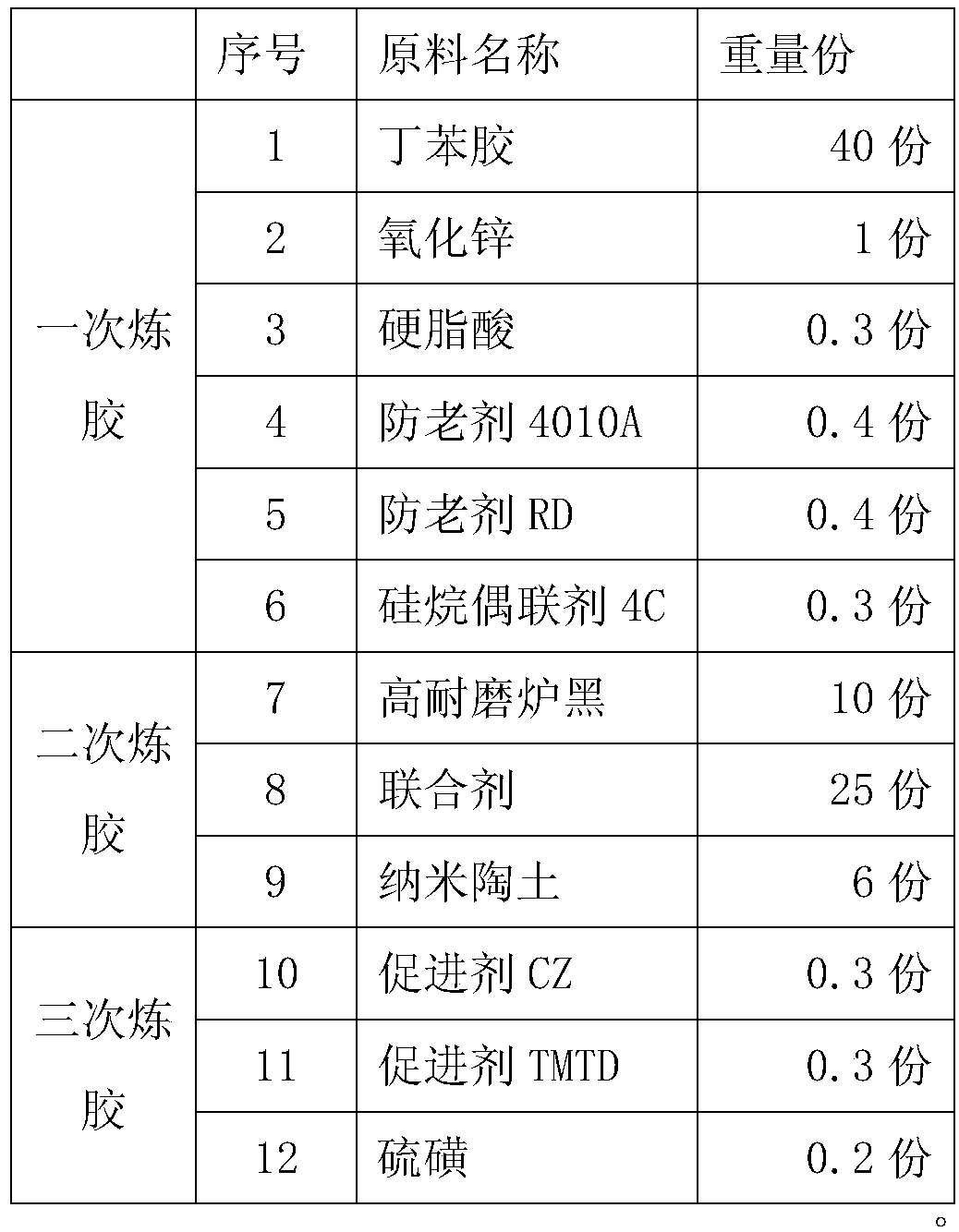

[0033] The passenger-cargo collinear railway rubber backing plate of the present embodiment, the rubber backing plate adopts a composite rubber material, and the composite rubber material adopts the following components by weight as raw materials:

[0034]

[0035] The preparation method of railway rubber backing plate material of the present invention comprises primary rubber mixing, secondary rubber mixing, tertiary rubber mixing, vulcanization production, concrete operation steps are as follows:

[0036] Primary rubber mixing: Weigh the above weight parts of styrene-butadiene rubber, zinc oxide, stearic acid, anti-aging agent 4010A, anti-aging agent RD, silane coupling agent 4C, and mix them in an internal mixer for rubber mixing, and the temperature rises To 140°C, the mixing time is controlled within 10 minutes, after the end of the mixing, the temperature of the glue is lowered to below 100°C to discharge the glue, and it is cooled to room temperature.

[0037] Second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com