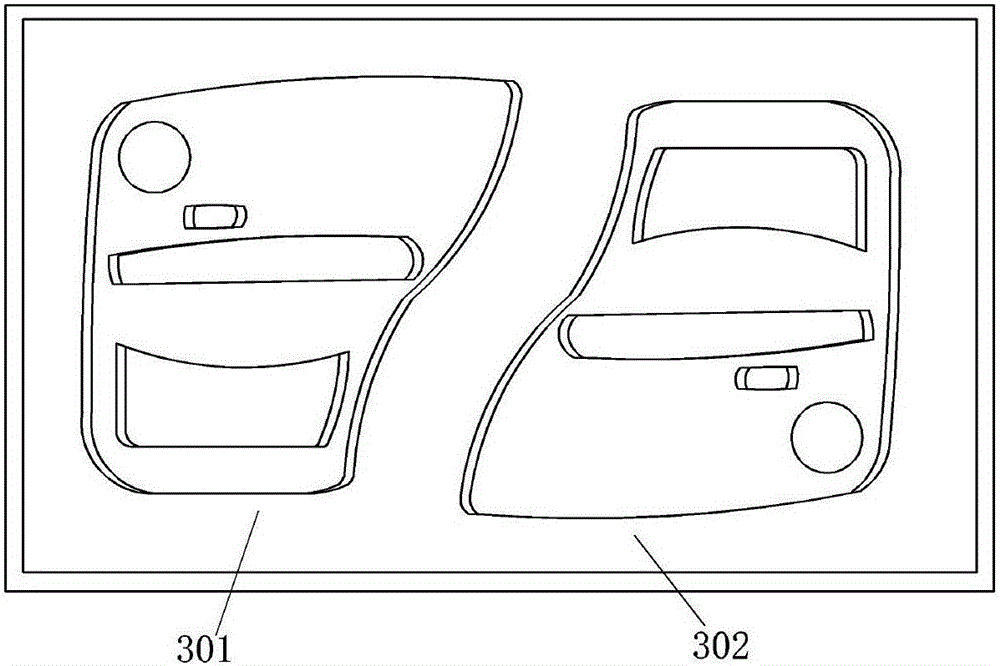

Vacuum plastic sucking molding process and vacuum plastic sucking molding device for regenerated leather skins of automobile door panels

A technology of vacuum blister and regenerated leather, which is applied to household appliances, other household appliances, household components, etc. It can solve problems such as uneven deformation, damage, and wrinkles, so as to avoid uneven deformation, avoid local wrinkles, and solve stretching problems. The effect of poor strength and tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Evenly mix 4080 fiber and kraft fiber in a certain proportion, wherein the mass fraction of 4080 fiber is 13%. Then the mixed fibers are carded into a web, and then the regenerated leather 101 is produced through 7 spunlace non-woven processes. The thickness of the prepared regenerated leather was kept at 1.2 mm.

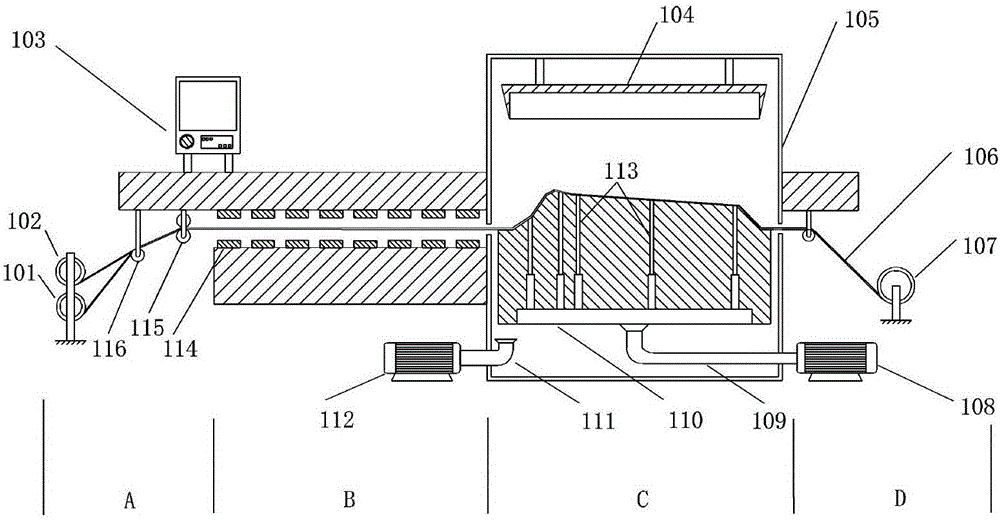

[0056] (2) Select the male mold for vacuum forming, uncoil the reclaimed leather obtained in (1) and the 0.5mm thick PU film coil 102 of the prefabricated pattern at the unfolding station A at the same time, and transfer it to the heating station through the conveyor belt b.

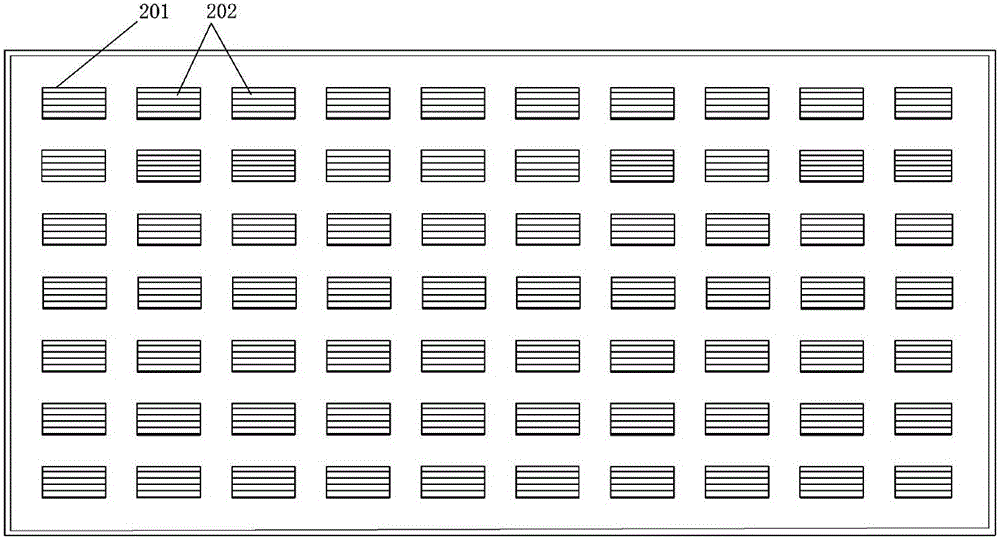

[0057] (3) by figure 2 The heating unit 201 arranged in a matrix is shown to conduct precise temperature control and heating on the regenerated leather sheet and the PU film. The temperature regulation is realized through the temperature control program 103 . Raise the overall temperature of the heating zone to 130°C, and adjust the temperature range to 130±20°C in areas with...

Embodiment 2

[0063] (1) Evenly mix N720 fiber and kraft fiber in a certain proportion, wherein the mass fraction of N720 fiber is 15%. Then the mixed fibers are air-laid into a six-pass needling process to produce regenerated leather 101 . The thickness of the prepared regenerated leather was kept at 1.2 mm.

[0064] (2) Select the male mold for vacuum blister forming, and unwind the regenerated leather obtained in (1) and the 0.3mm thick PU film roll material 102 of the prefabricated pattern at the unfolding station A simultaneously, wherein the PU film is positioned above the regenerated leather and Transfer to heating station B by conveyor belt.

[0065] (3) by figure 2 The matrix-arranged heating units shown in the figure conduct precise temperature-controlled heating on the regenerated leather preformed sheet. Each heating unit is composed of six heating sleeves 202 , and the temperature control is realized through the temperature control program 103 . Raise the overall temperatu...

Embodiment 3

[0071] (1) Evenly mix 4080 fiber and kraft fiber in a certain proportion, wherein the mass fraction of 4080 fiber is 17%. The uniformly mixed fibers are air-laid, and then subjected to six spunlace processes to obtain regenerated leather 101 .

[0072] (2) Vacuum forming with a female mold is selected, and the obtained regenerated leather sheet is compounded with a layer of thermoplastic PU film 102. The thickness of the PU film is about 0.5mm, and it is located under the regenerated leather sheet. The PU film does not need to be processed in advance. The rolled composite sheet is transported to the unfolding station A for uncoiling, in which the PU film is located under the regenerated leather, and is transported to the heating station B through the conveyor belt.

[0073] (3) The heating station composed of heating units 201 arranged in a matrix realizes precise temperature-controlled heating of the preformed sheet.

[0074] (4) The heated preformed sheet is transported to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com