A modified polycarbonate material applied to 3D printing

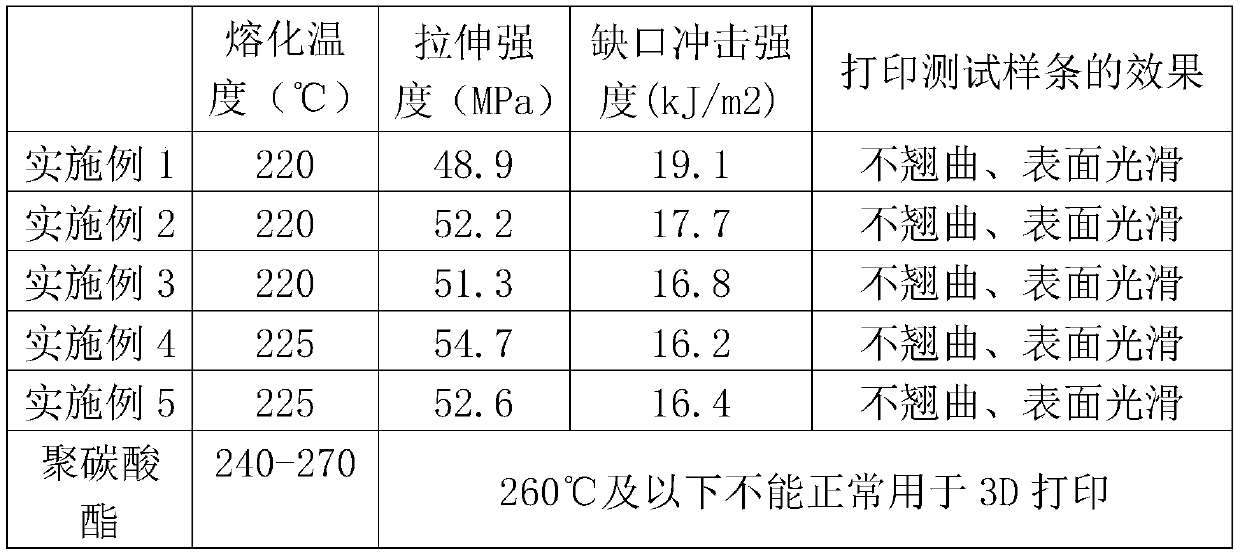

A polycarbonate, 3D printing technology, applied in additive processing and other directions, can solve the problems of polycarbonate materials cannot be printed, and printed products are warped and deformed, so as to reduce warpage and cracking, improve shrinkage, stretch The effect of high tensile strength and notched impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This example provides a modified polycarbonate material for 3D printing, which contains the following components in parts by weight: 100 parts of general-purpose polycarbonate, 20 parts of polycaprolactone, 10 parts of toughening agent, hindered phenolic anti- 0.5 part of oxygen agent, 0.2 part of phosphite antioxidant; the general-purpose polycarbonate is selected from Covestro XT5010, the polycaprolactone selects Capa TM 6500, the toughening agent is methyl methacrylate-styrene-butadiene core-shell copolymer, and the hindered phenolic antioxidant is β-(3,5-di-tert-butyl-4-hydroxybenzene base) octadecyl propionate, and the phosphite antioxidant is three [2,4-di-tert-butylphenyl] phosphite.

[0034] The preparation method of the above-mentioned modified polycarbonate material applied to 3D printing comprises the following steps:

[0035] Dry the polycarbonate at 110°C until the water content does not exceed 0.05%, then cool to room temperature for later use;

[003...

Embodiment 2

[0040] This embodiment provides a modified polycarbonate material for 3D printing, comprising the following components by weight: 100 parts of general-purpose polycarbonate, 10 parts of thermotropic liquid crystal polymer, 25 parts of polycaprolactone, toughened 12 parts, hydrophobic fumed silica, 0.3 parts of hindered phenolic antioxidant, and 0.2 part of phosphite antioxidant; the general-purpose polycarbonate is Chi Mei PC-122, and the thermally induced liquid crystal polymerization Celanese A950, the polycaprolactone selects Capa TM 6506, the toughening agent is methyl methacrylate-styrene-butadiene core-shell copolymer, and the hydrophobic fumed silica is Evonik Degussa hydrophobic fumed silica R974, the hindered phenolic antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, and the phosphite antioxidant is tris[2 , 4-di-tert-butylphenyl] phosphite.

[0041] The preparation method of the above-mentioned modified polycarbonate material applied ...

Embodiment 3

[0047] This embodiment provides a modified polycarbonate material for 3D printing, which includes the following components in parts by weight: 80 parts of general-purpose polycarbonate, 20 parts of disc grade polycarbonate, 5 parts of thermotropic liquid crystal polymer, polycarbonate 15 parts of caprolactone, 8 parts of toughening agent, 2 parts of hydrophobic fumed silica, 0.5 part of hindered phenolic antioxidant, 0.2 part of phosphite antioxidant; the general-purpose polycarbonate is selected from Covestro 2405, the disc grade polycarbonate is Covestro CD2005, and the thermotropic liquid crystal polymer is Celanese A900, the toughening agent is methyl methacrylate-butyl acrylate core-shell copolymer, and the polycaprolactone is selected from Capa TM 6500, the hydrophobic fumed silica is Evonik Degussa hydrophobic fumed silica R972, the hindered phenolic antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, and the phosphite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com