Epoxy binder modified by micropowder of crosslinked rubber, and preparation method

A technology of epoxy adhesive and cross-linked rubber, applied in the direction of adhesive, epoxy resin, adhesive type, etc. Chemical properties and other issues, to achieve the effect of improving adhesive strength and heat resistance, small particle size, and enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

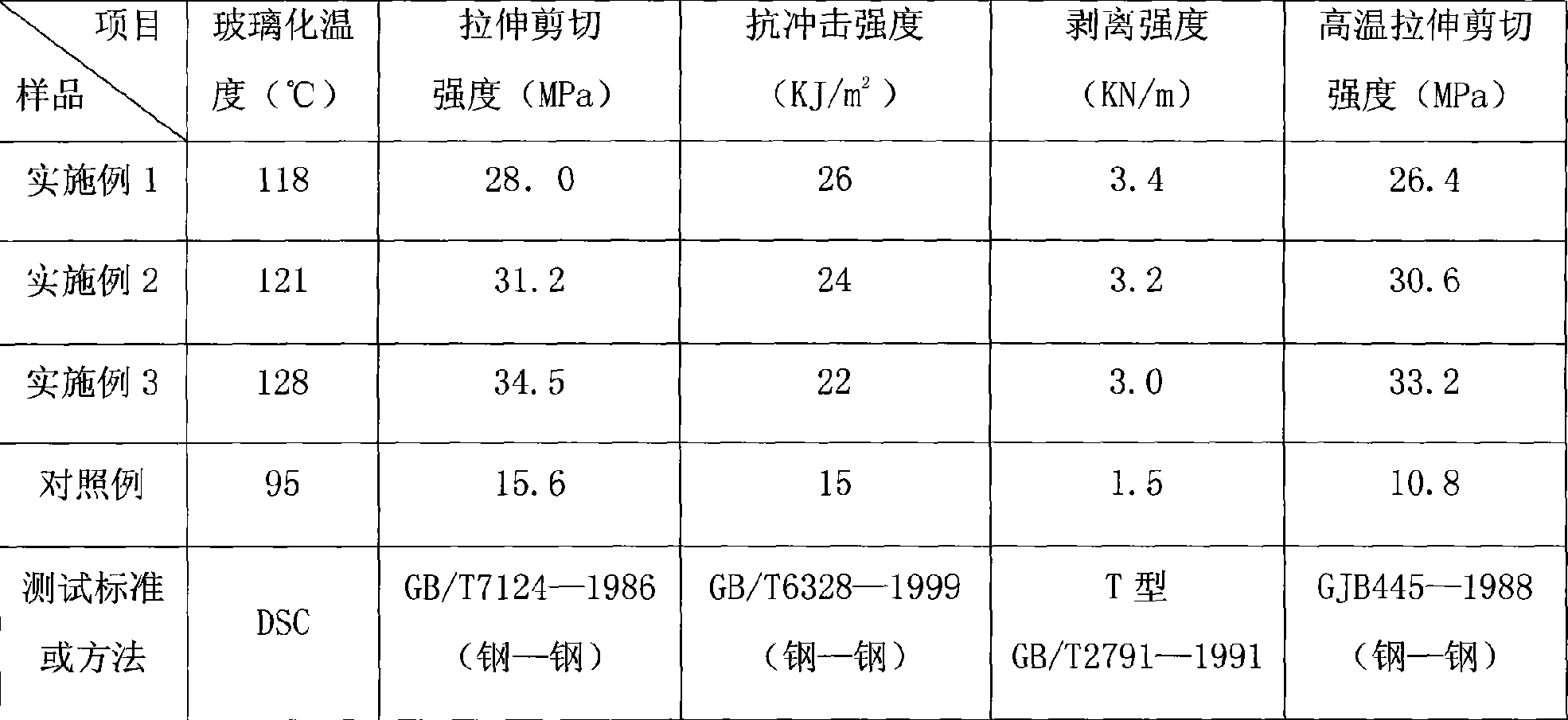

Examples

Embodiment 1

[0022] A: Preparation of epoxy components

[0023] Heat 60 parts of bisphenol A epoxy resin E-51 and 40 parts of E-44 to 60-80°C, after it becomes thin, turn on the high-speed disperser, adjust the speed to 6000 rpm, and slowly add nano-crosslinking Rubber powder VP-50115 parts, stirred for 60 minutes, put the material in a vacuum kneader, and added diluent C 12 ~C 13 5 parts of aliphatic glycidyl ether, the temperature is controlled at 40°C, the vacuum degree is 0.08-0.09MPa, and the kneading time is 2.5 hours to discharge.

[0024] B: Preparation of curing components

[0025] Add 40 parts of modified alicyclic amine and 13 parts of modified aromatic amine into the reaction kettle. After stirring for 15 minutes, add 2 parts of curing accelerator triethylenediamine, stir evenly, and then add silicone coupling agent r-aminopropyl 1 part of triethoxysilane, stirred for 30 minutes, and filtered out.

example 2

[0027] Among the raw material epoxy components used are 50 parts of epoxy resin E-51, 30 parts of E-44, 16 parts of nano-crosslinked rubber micropowder VP-501, and 4 parts of diluent o-cresol glycidyl ether. Among the curing components are 30 parts of modified alicyclic amine, 22 parts of modified fatty amine, 1.8 parts of curing accelerator triethylenediamine, and 1.2 parts of coupling agent r-aminopropyltriethoxysilane.

[0028] Manufacturing process condition is the same as embodiment 1

Embodiment 3

[0030] Among the raw material epoxy components used are 28 parts of epoxy resin E-51, 50 parts of E-44, 12 parts of nano-crosslinked rubber micropowder VP-701, and 6 parts of diluent trimethylolpropane triglycidyl ether. In the curing component, there are 30 parts of modified aromatic amines, 24 parts of modified aliphatic amines, 2.5 parts of curing accelerator 2,4,6-tris(dimethylaminomethyl)phenol, coupling agent N-(β-aminoethyl base)-r-aminopropyltrimethoxysilane 1.7 parts.

[0031] Manufacturing process condition is the same as embodiment 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com