Chip on board (COB) aluminum substrate with high reflectivity and good heat dissipation performance and manufacturing process thereof

A technology with high reflectivity and manufacturing process, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low light utilization rate, affecting the consistency of light output direction, and difficult to guarantee the flatness of the bottom cup, so as to improve the reflectivity and The effect of light extraction efficiency, improving export rate and heat dissipation capacity, and improving heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings of the description.

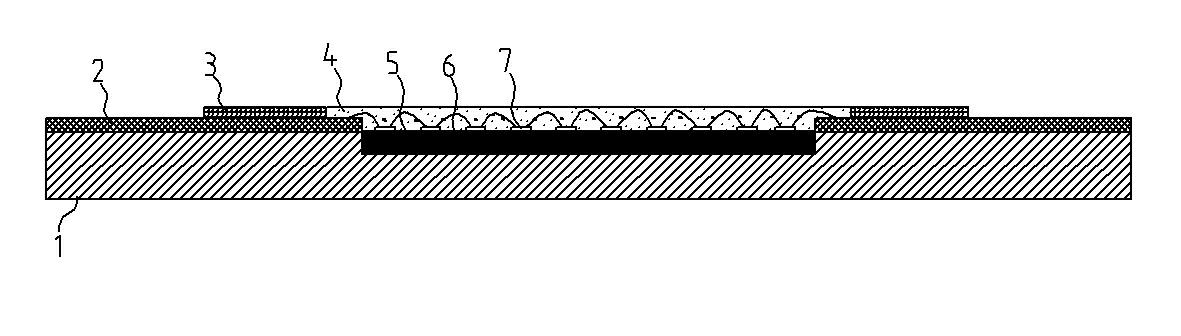

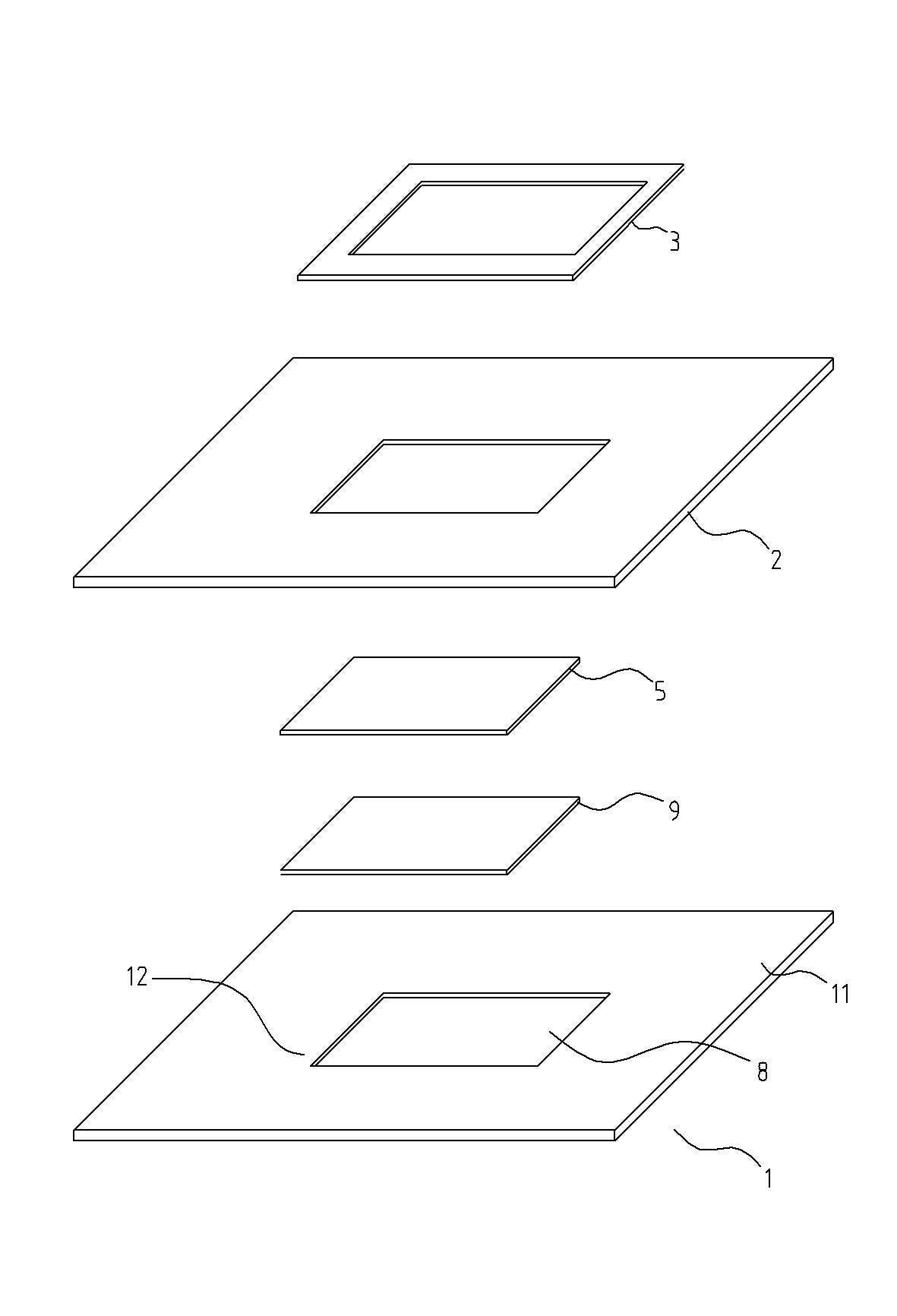

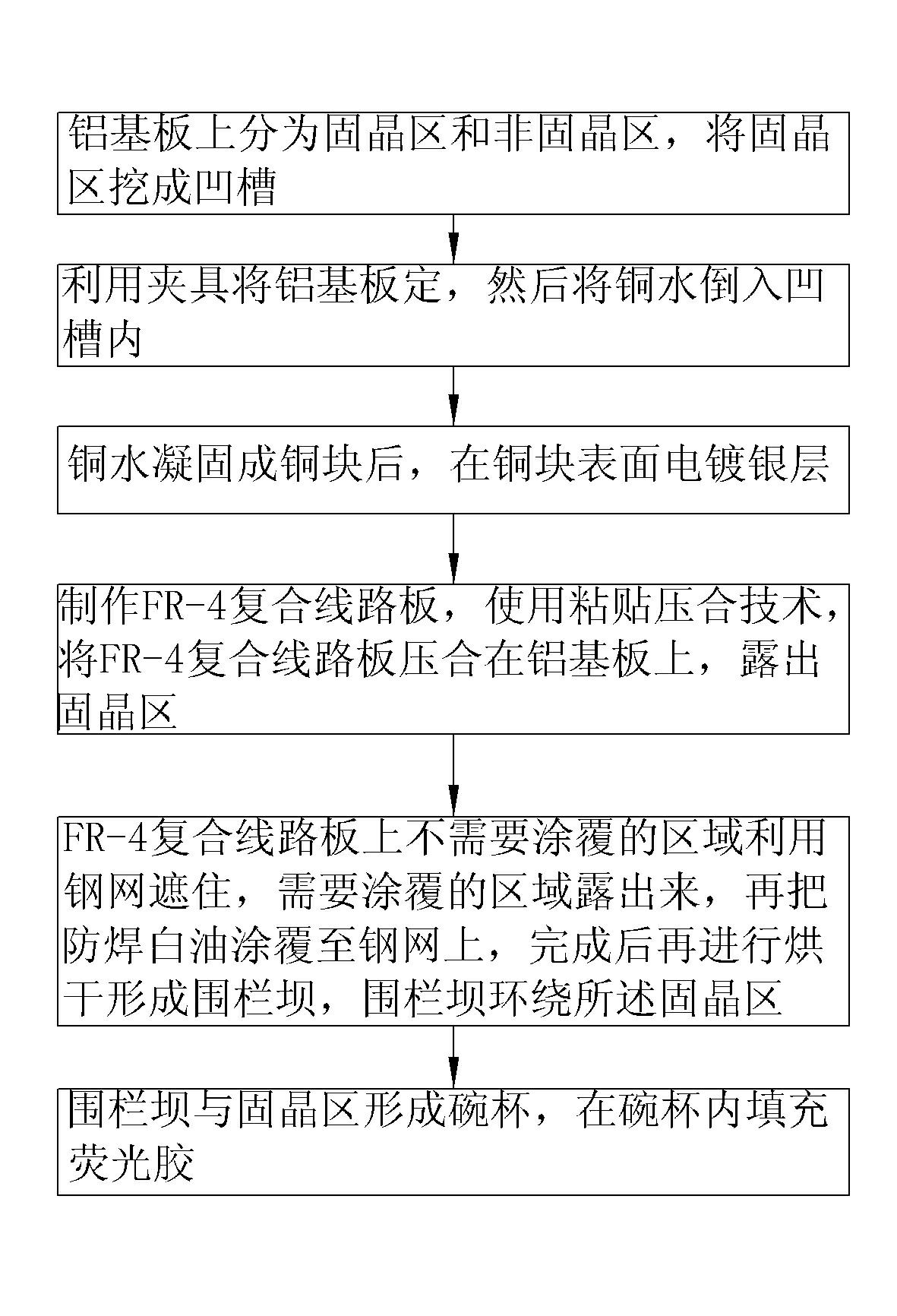

[0033] Such as figure 1 , 2 As shown, a COB aluminum substrate with high reflectivity and good heat dissipation, the aluminum substrate 1 is divided into a crystal-bonding area 12 and a non-crystal-bonding area 11, the crystal-bonding area 12 is provided with a groove 8, and the concave The slot 8 is provided with a copper block 6 for fixing the LED chip 7, the surface of the copper block 6 is flush with the surface of the aluminum substrate 1, the surface of the copper block 6 is provided with a nickel-plated layer 9, and the nickel-plated layer 9 is provided with a silver-plated layer 5. A layer of FR-4 composite circuit board 2 is provided on the non-crystal-bonding area 11, and the FR-4 composite circuit board 2 is formed by combining FR-4 fiberboard and a circuit layer provided on its surface. The FR-4 composite circuit board 2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com