Patents

Literature

95 results about "FR-4" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

FR-4 (or FR4) is a NEMA grade designation for glass-reinforced epoxy laminate material. FR-4 is a composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant (self-extinguishing).

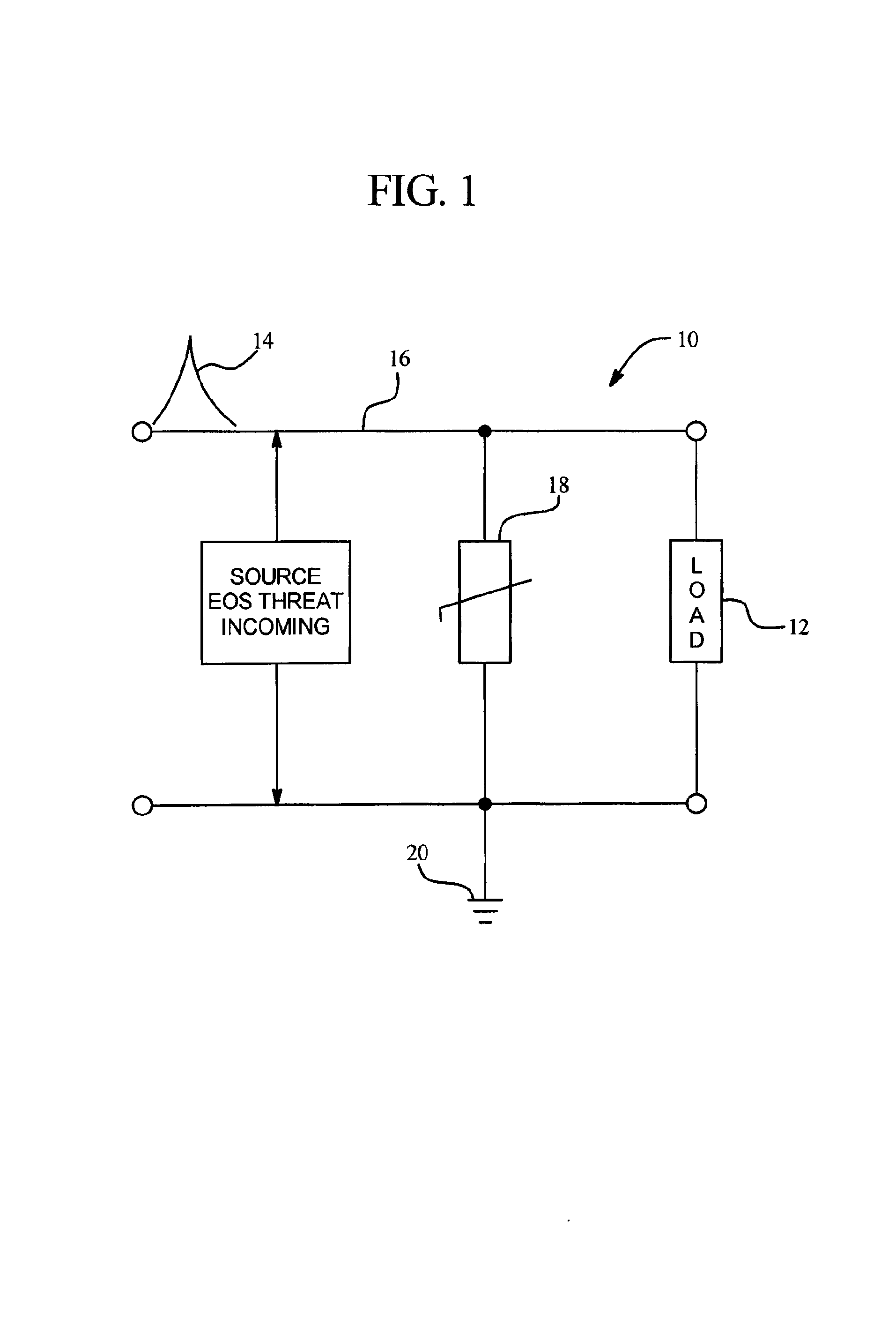

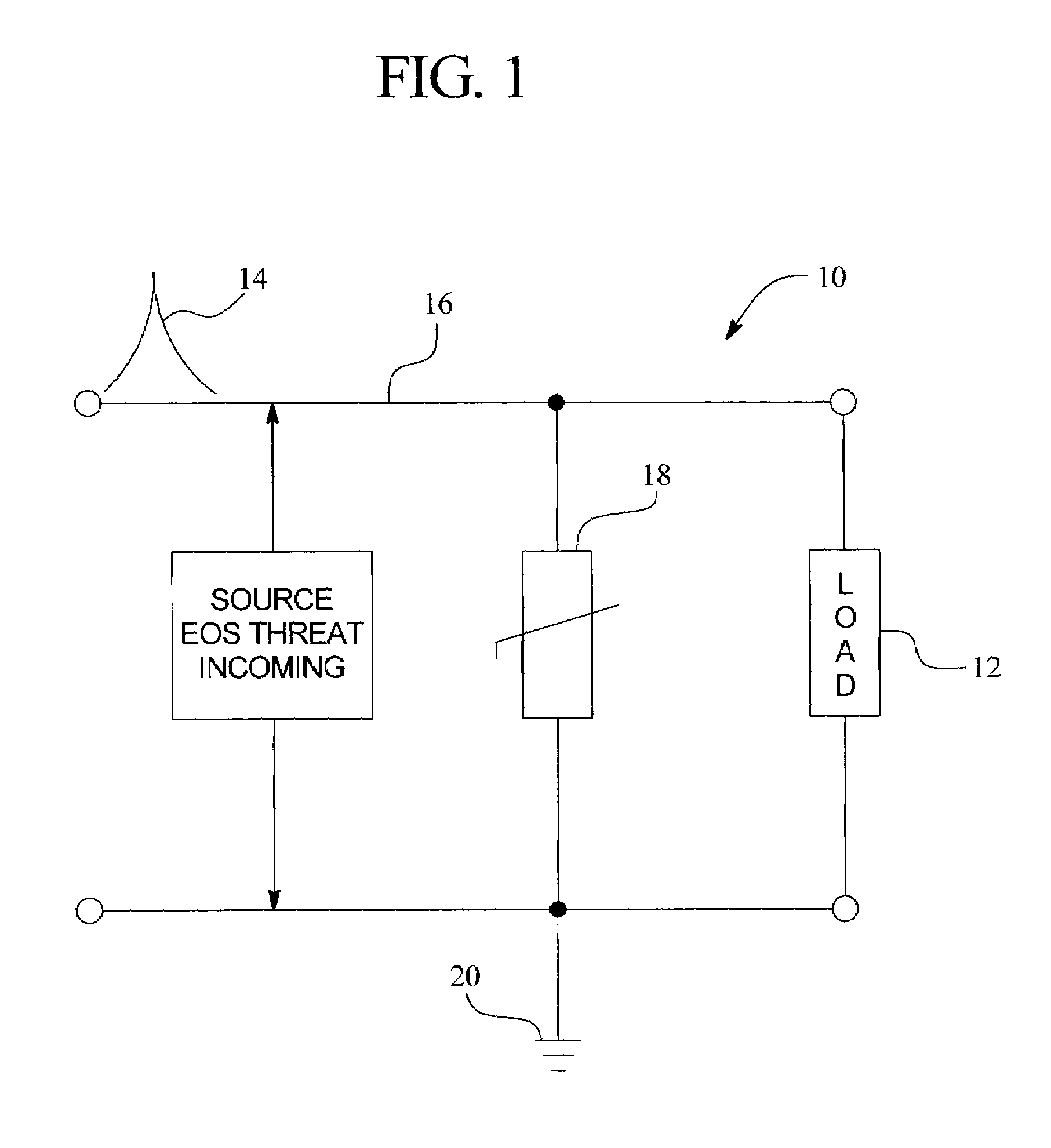

Direct application voltage variable material, devices employing same and methods of manufacturing such devices

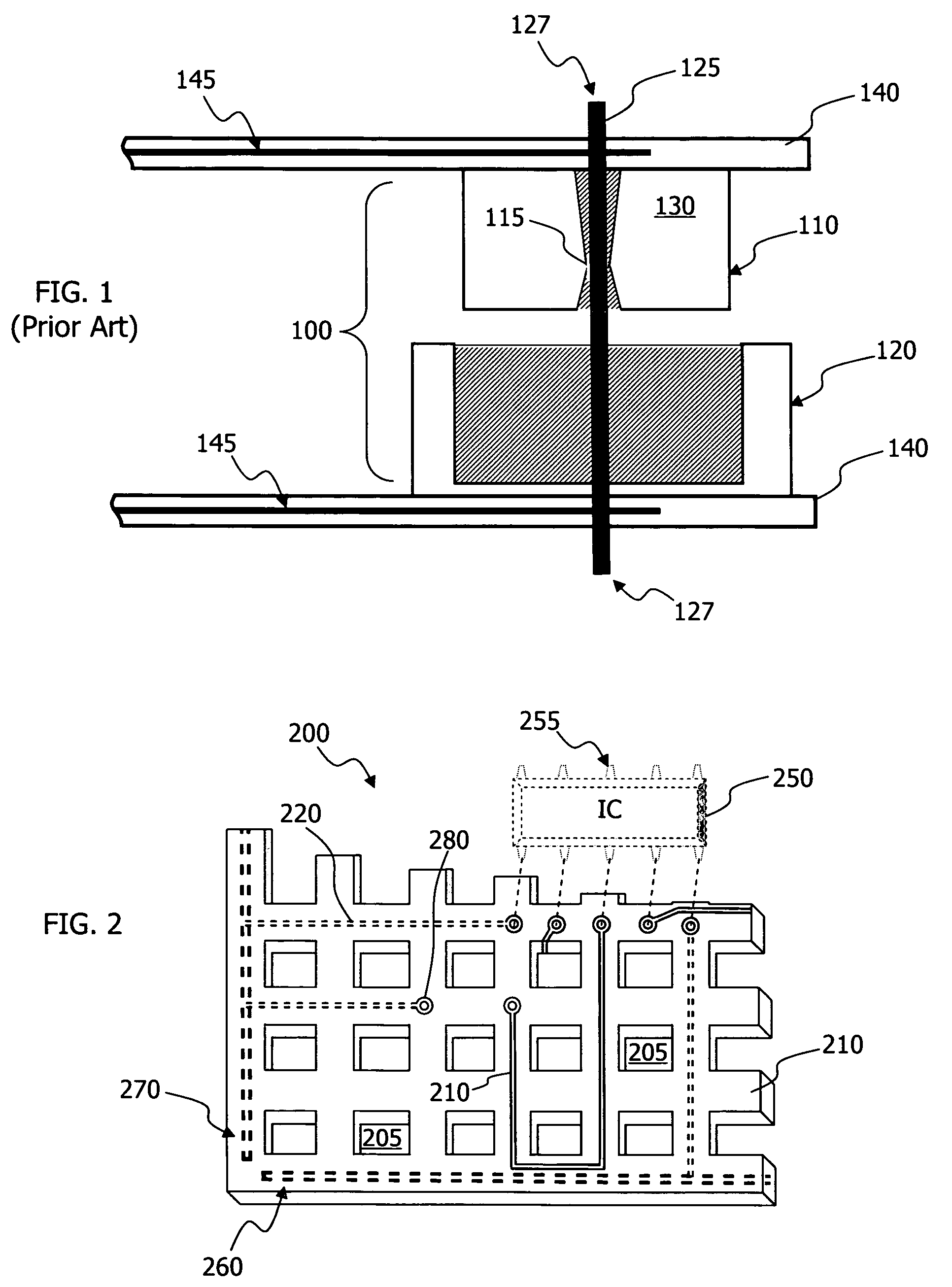

InactiveUS7183891B2Directly appliedCurrent responsive resistorsPrinted circuit aspectsScreen printingStencil printing

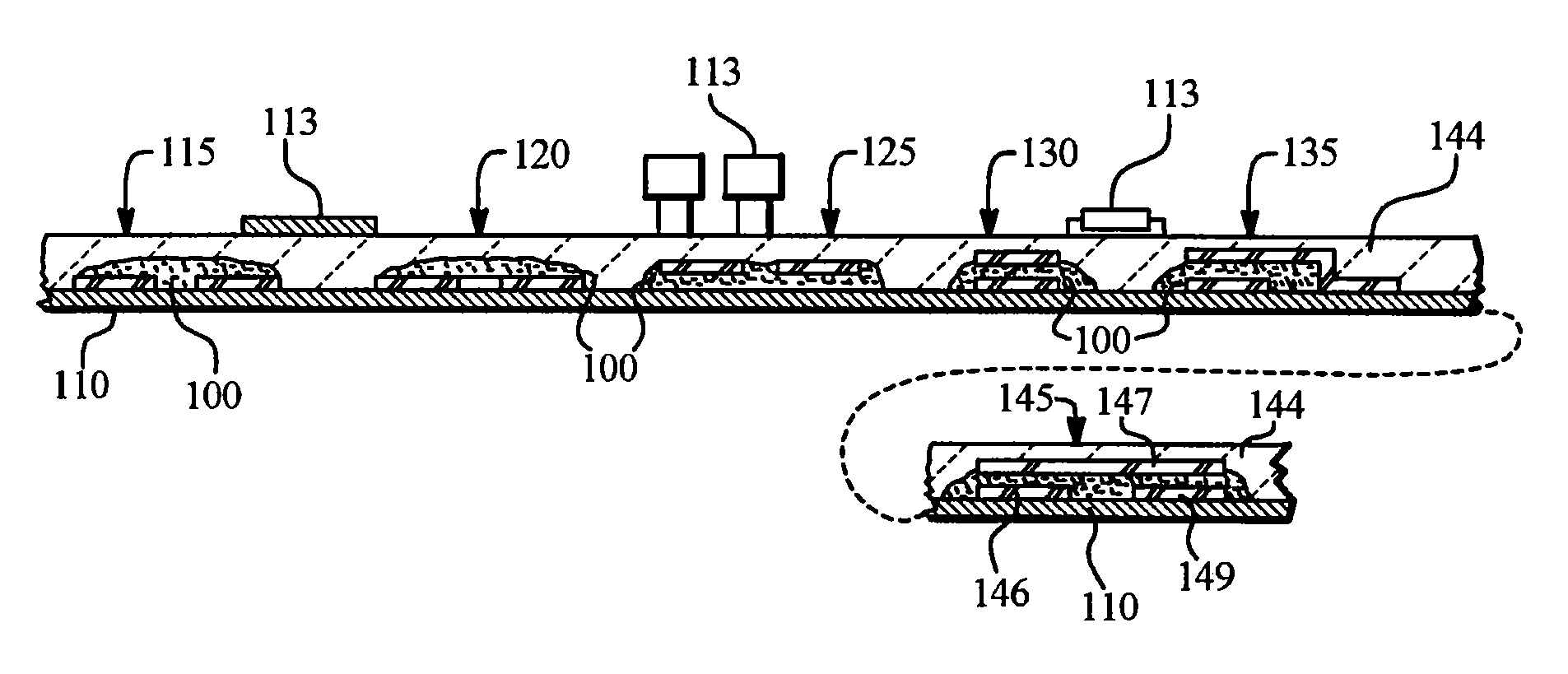

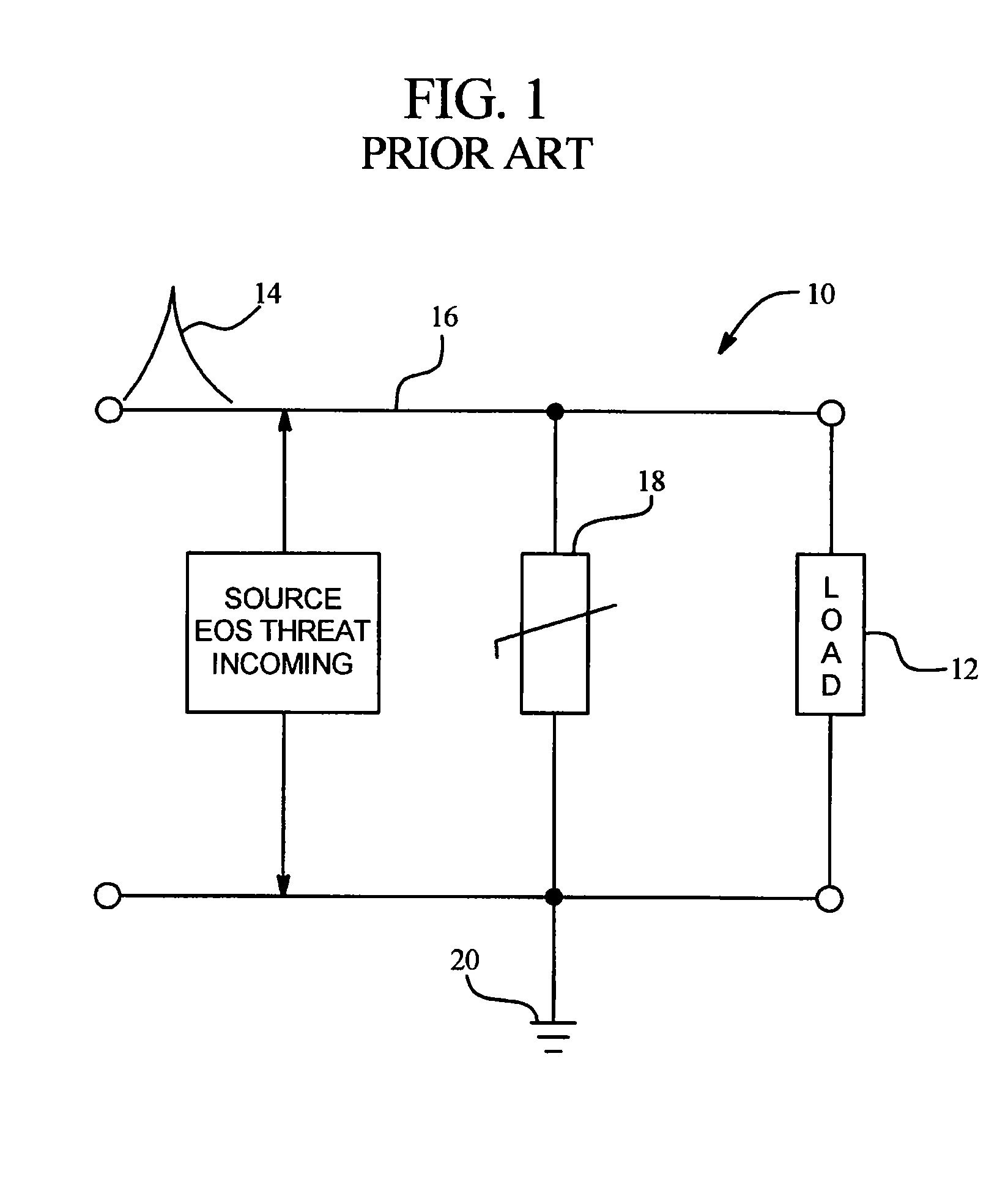

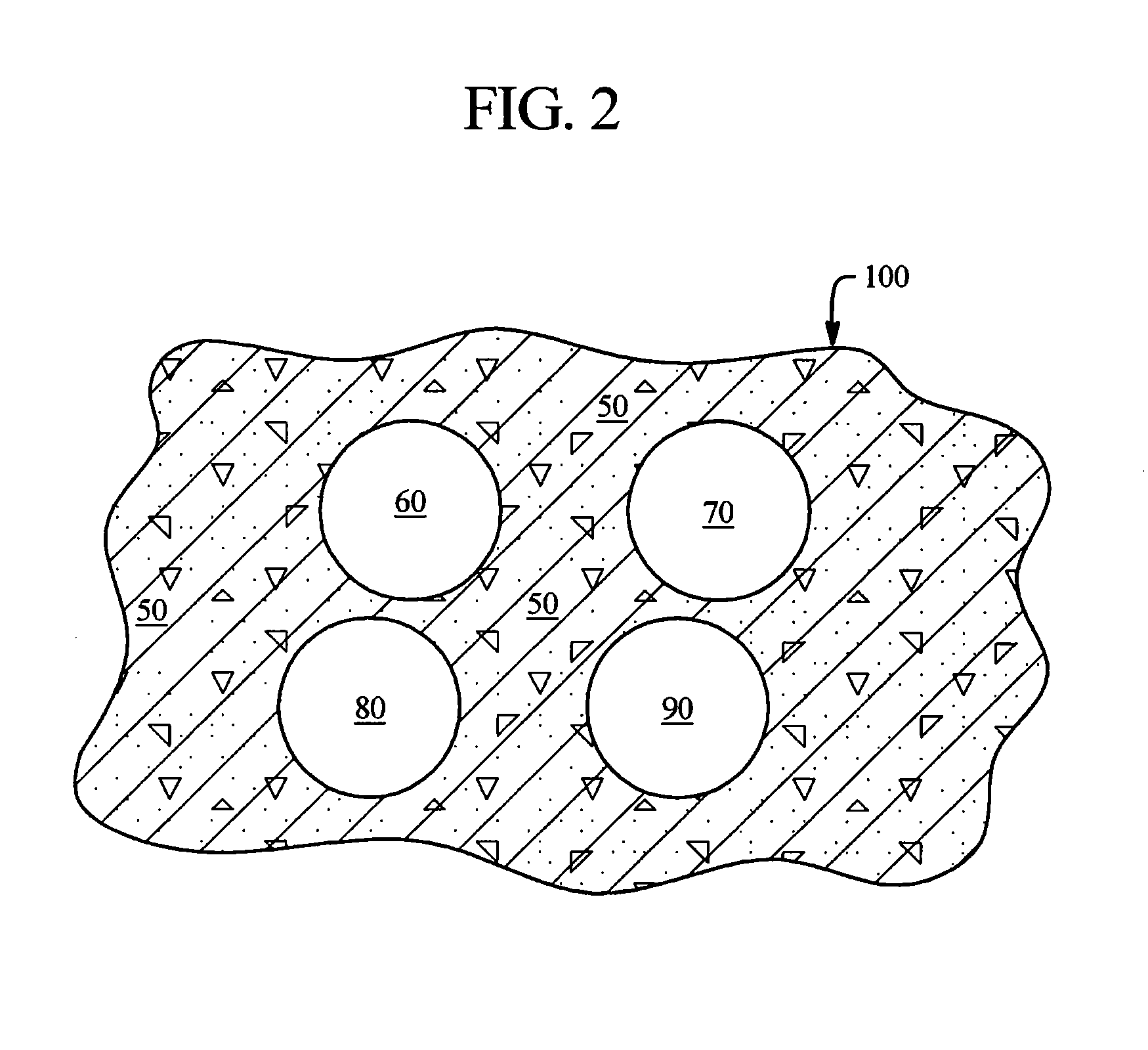

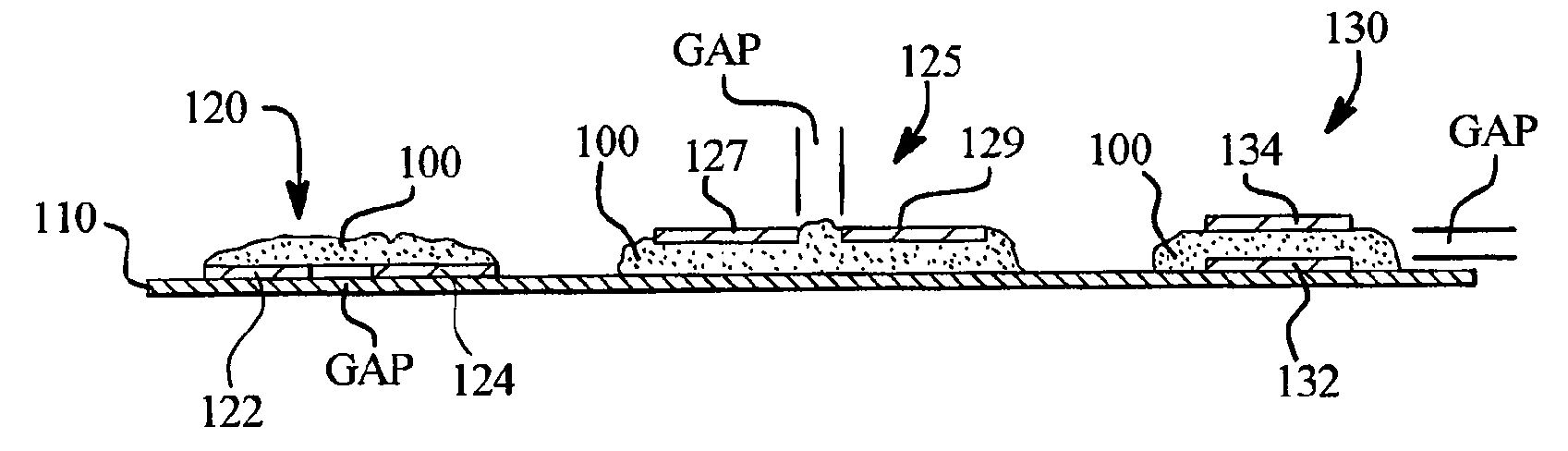

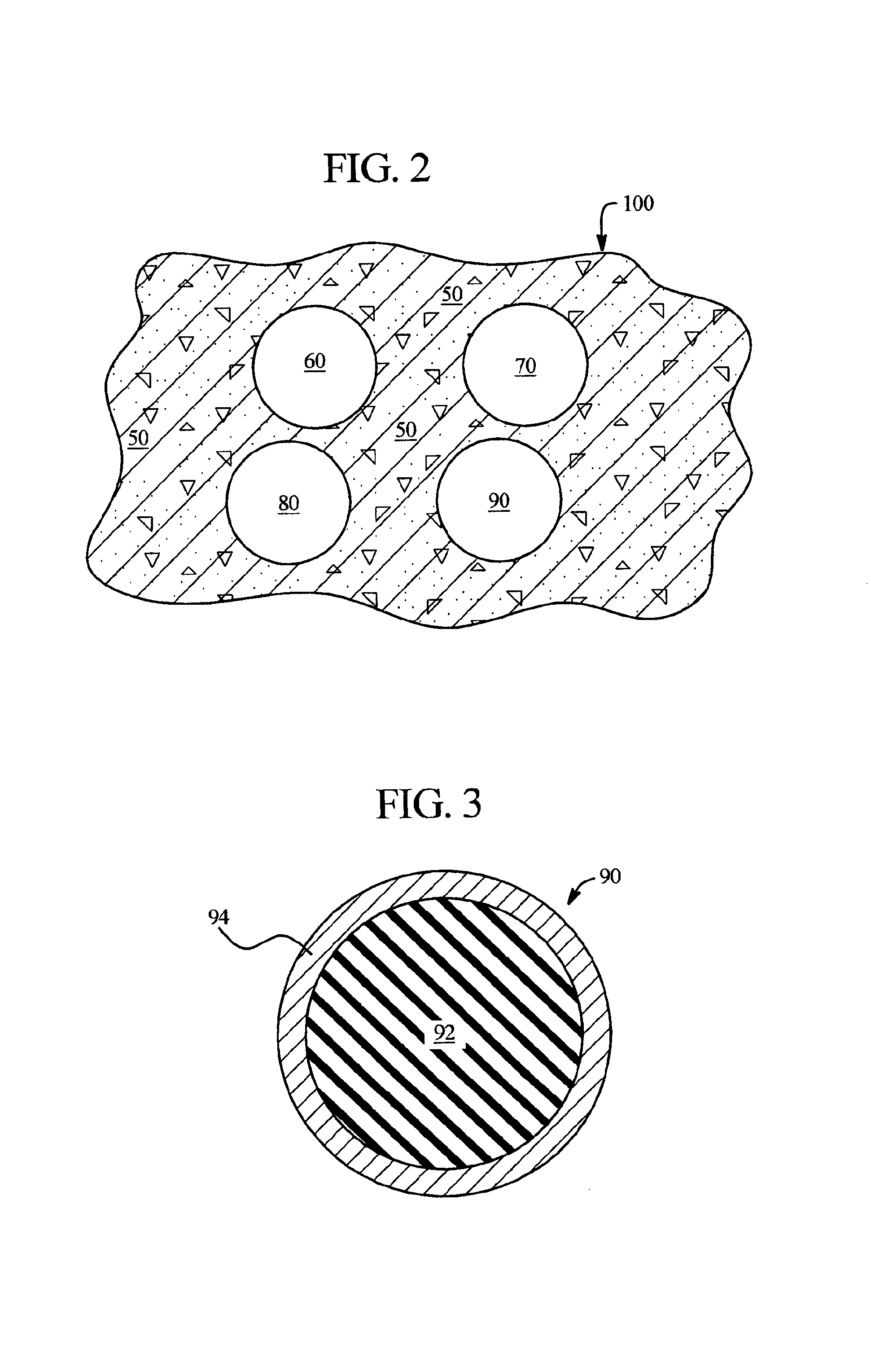

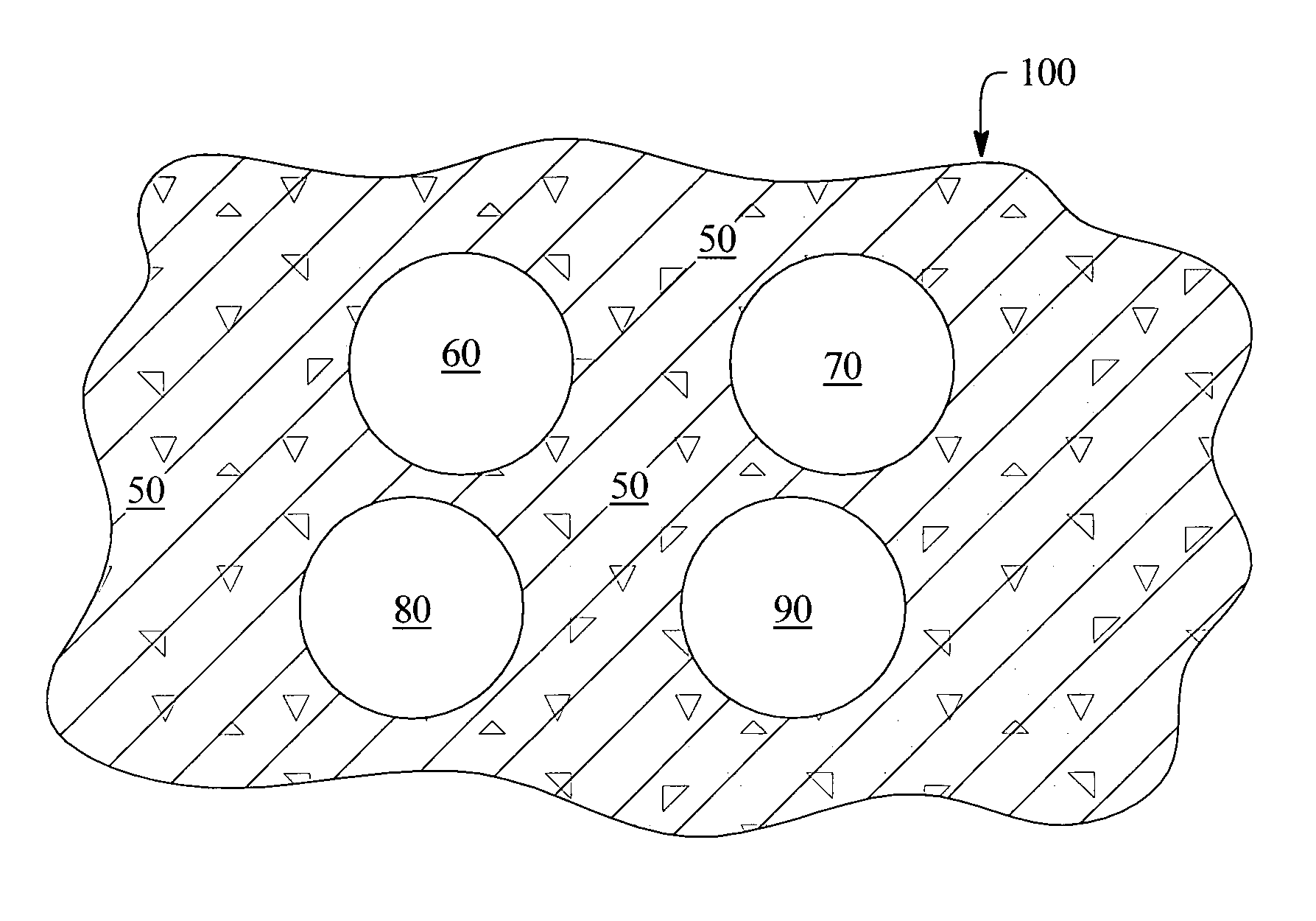

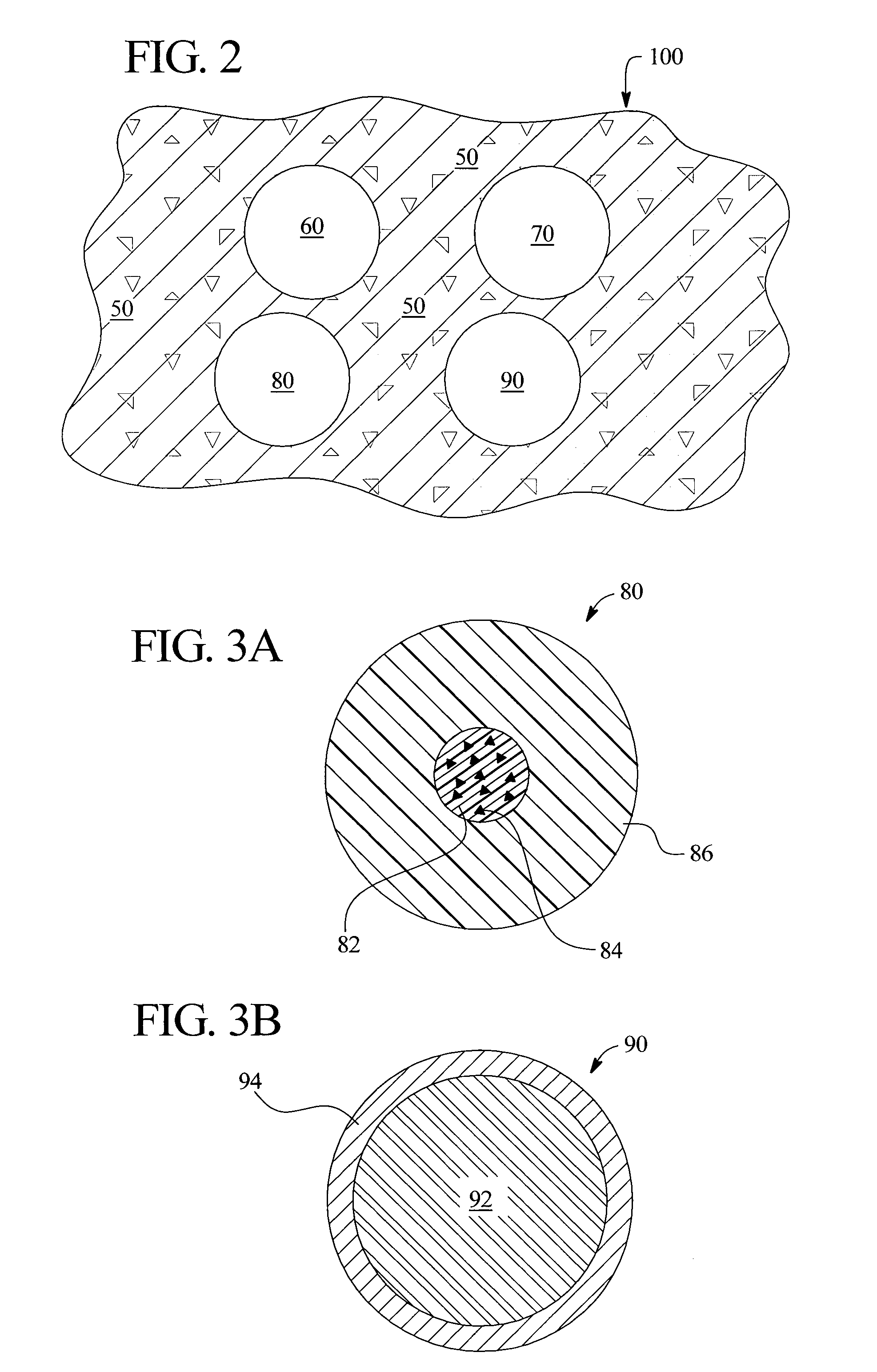

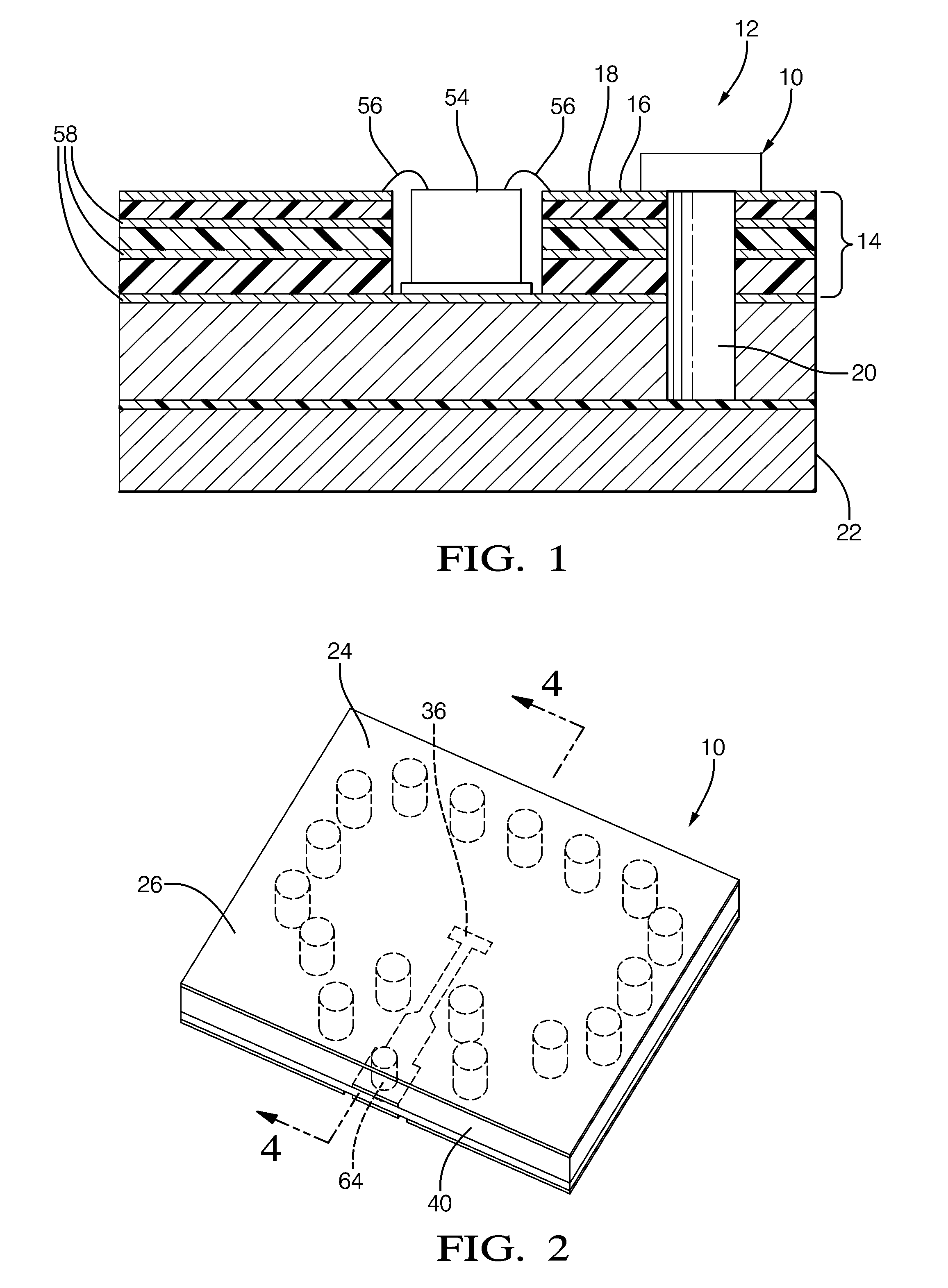

A voltage variable material (“VVM”) including an insulative binder that is formulated to intrinsically adhere to conductive and non-conductive surfaces is provided. The binder and thus the VVM is self-curable and applicable in a spreadable form that dries before use. The binder eliminates the need to place the VVM in a separate device or to provide separate printed circuit board pads on which to electrically connect the VVM. The binder and thus the VVM can be directly applied to many different types of substrates, such as a rigid FR-4 laminate, a polyimide, a polymer or a multilayer PCB via a process such as screen or stencil printing. In one embodiment, the VVM includes two types of conductive particles, one with a core and one without a core. The VVM can also have core-shell type semiconductive particles.

Owner:LITTELFUSE INC

Voltage variable material for direct application and devices employing same

InactiveUS7202770B2Directly appliedSemiconductor/solid-state device detailsSolid-state devicesOvervoltagePolymer

The present invention provides overvoltage circuit protection. Specifically, the present invention provides a voltage variable material (“VVM”) that includes an insulative binder that is formulated to intrinsically adhere to conductive and nonconductive surfaces. The binder and thus the VVM is self-curable and may be applied to an application in the form of an ink, which dries in a final form for use. The binder eliminates the need to place the VVM in a separate device or for separate printed circuit board pads on which to electrically connect the VVM. The binder and thus the VVM can be directly applied to many different types of substrates, such as a rigid (FR-4) laminate, a polyimide or a polymer. The VVM can also be directly applied to different types of substrates that are placed inside a device.

Owner:LITTELFUSE INC

Direct application voltage variable material, components thereof and devices employing same

InactiveUS7132922B2Directly appliedSemiconductor/solid-state device detailsSolid-state devicesSiliconPolymer

A voltage variable material (“VVM”) including an insulative binder that is formulated to intrinsically adhere to conductive and non-conductive surfaces is provided. The binder and thus the VVM is self-curable and applicable in a spreadable form that dries before use. The binder eliminates the need to place the VVM in a separate device or to provide separate printed circuit board pads on which to electrically connect the VVM. The binder and thus the VVM can be directly applied to many different types of substrates, such as a rigid (FR-4) laminate, a polyimide or a polymer. The VVM can also be directly applied to different types of substrates that are placed inside a device. In one embodiment, the VVM includes doped semiconductive particles having a core, such which can be silicon, and an inert coating, which can be an oxide. The particles are mixed in the binder with conductive particles.

Owner:LITTELFUSE INC

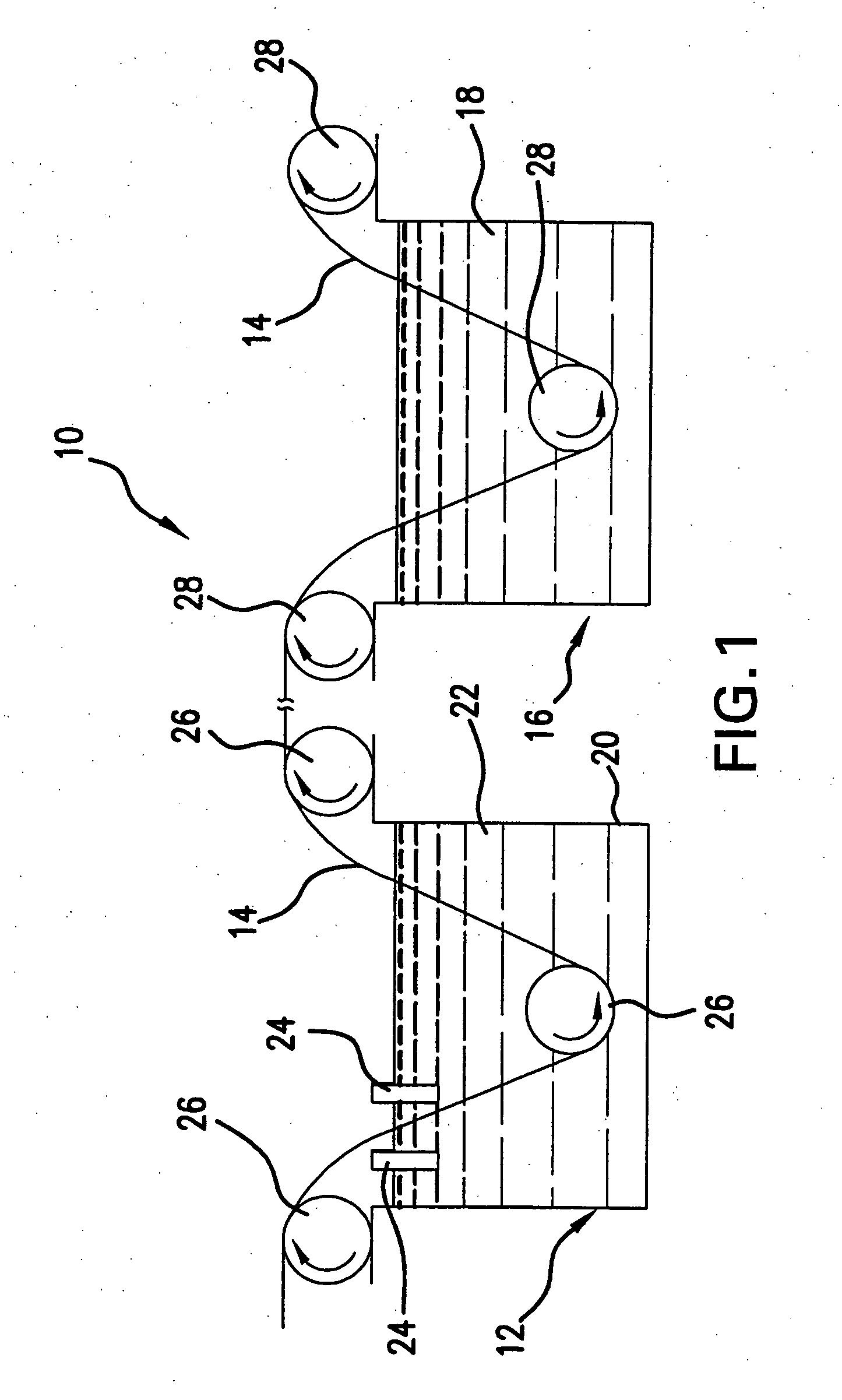

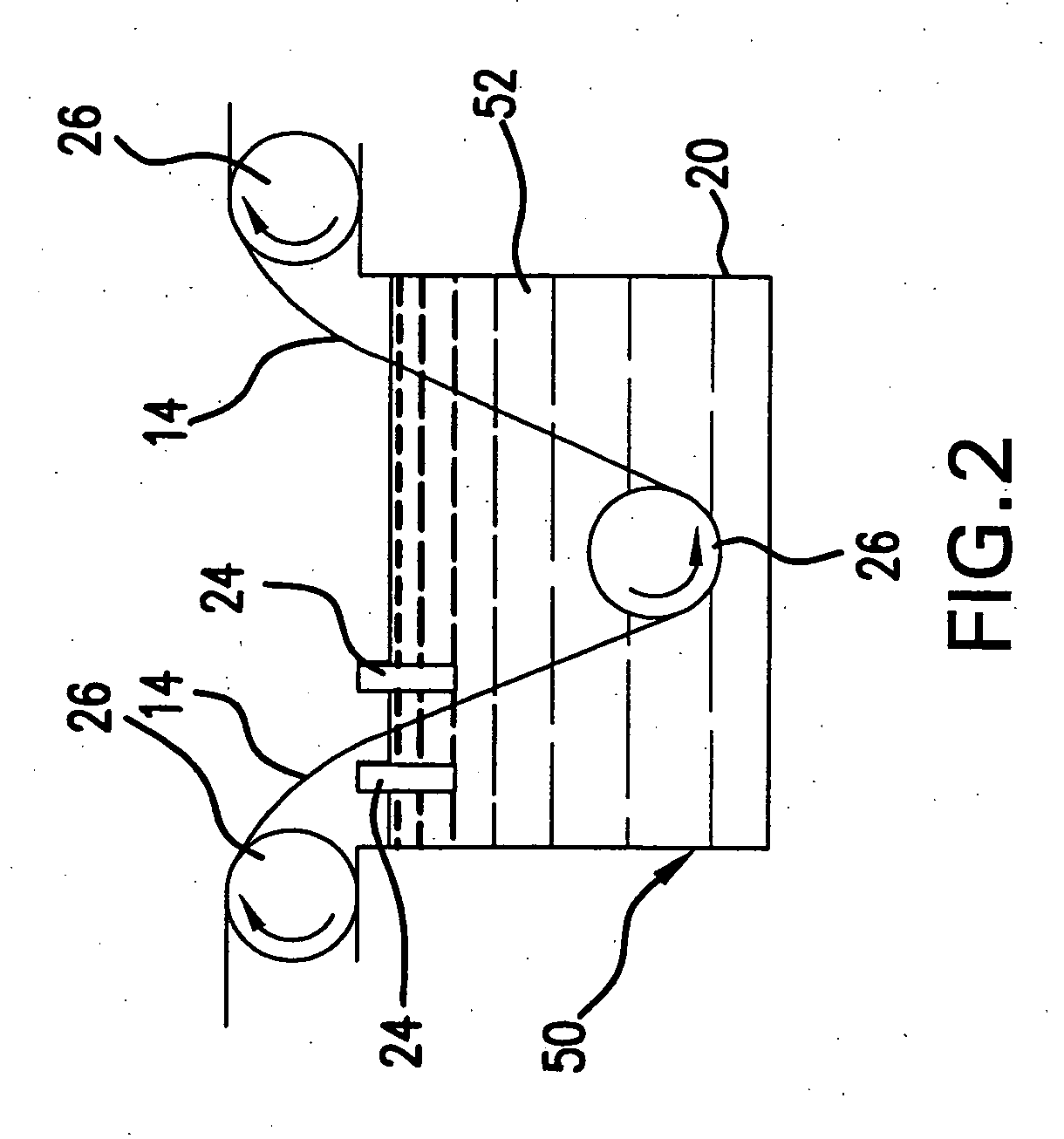

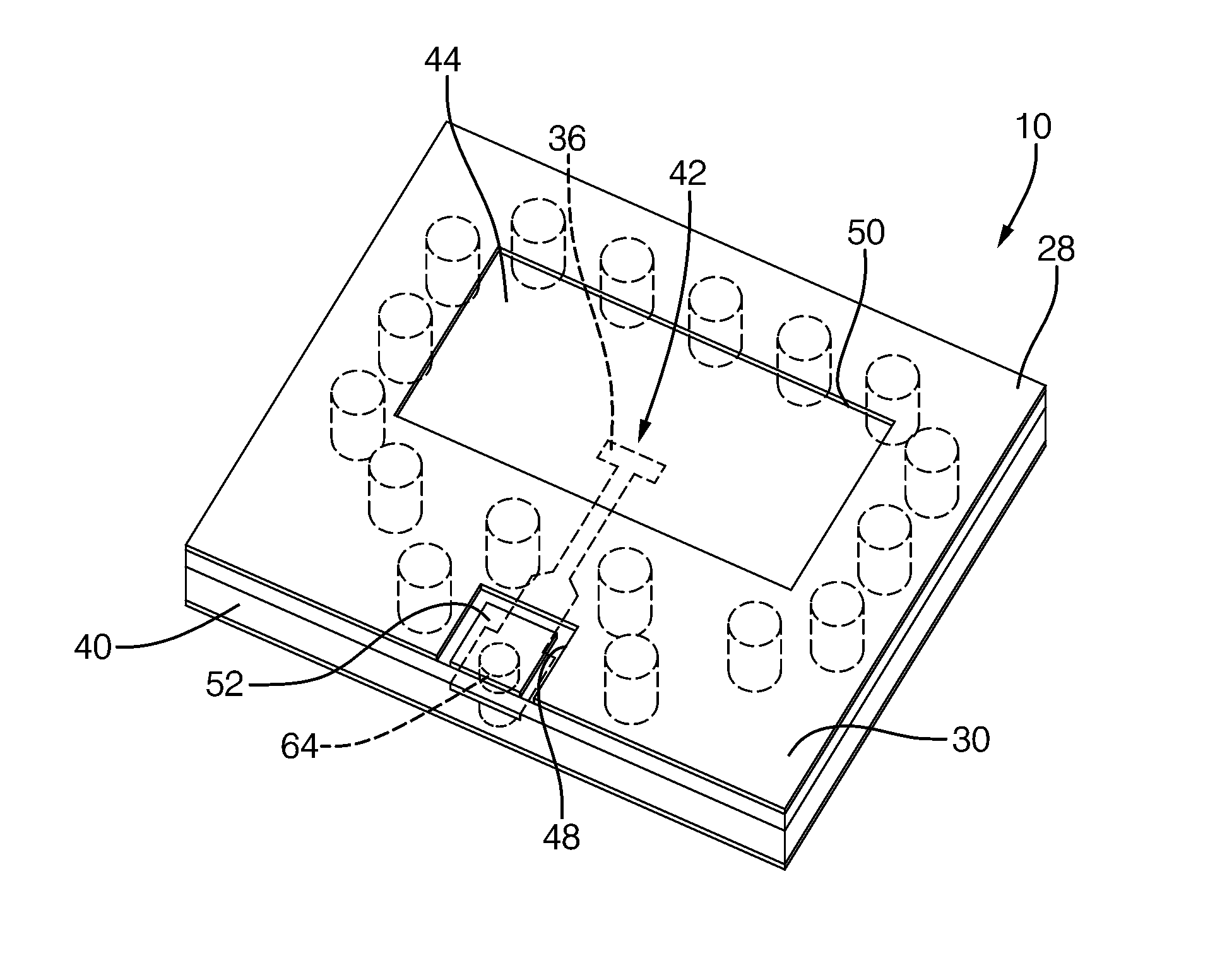

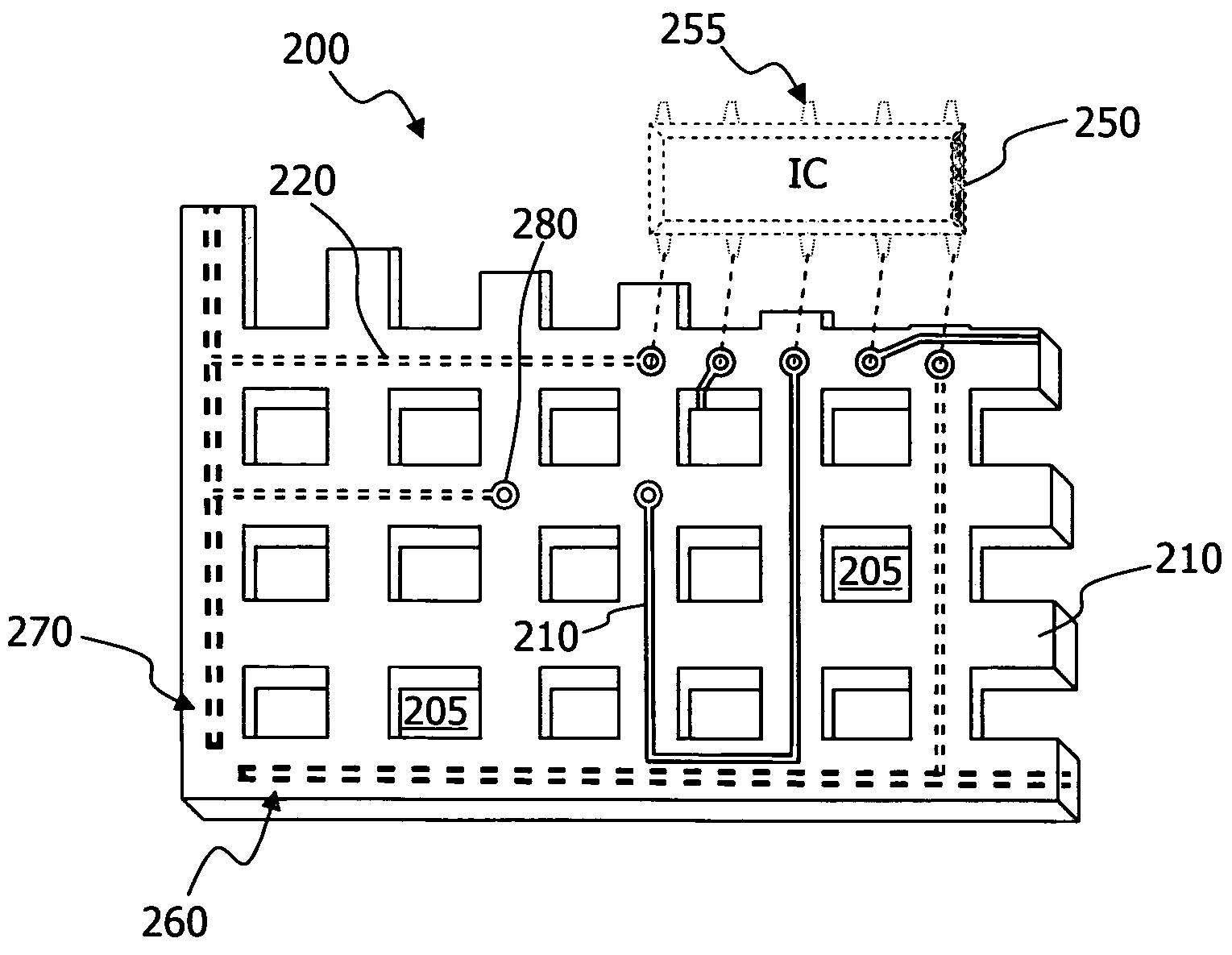

Electronic component connection support structures including air as a dielectric

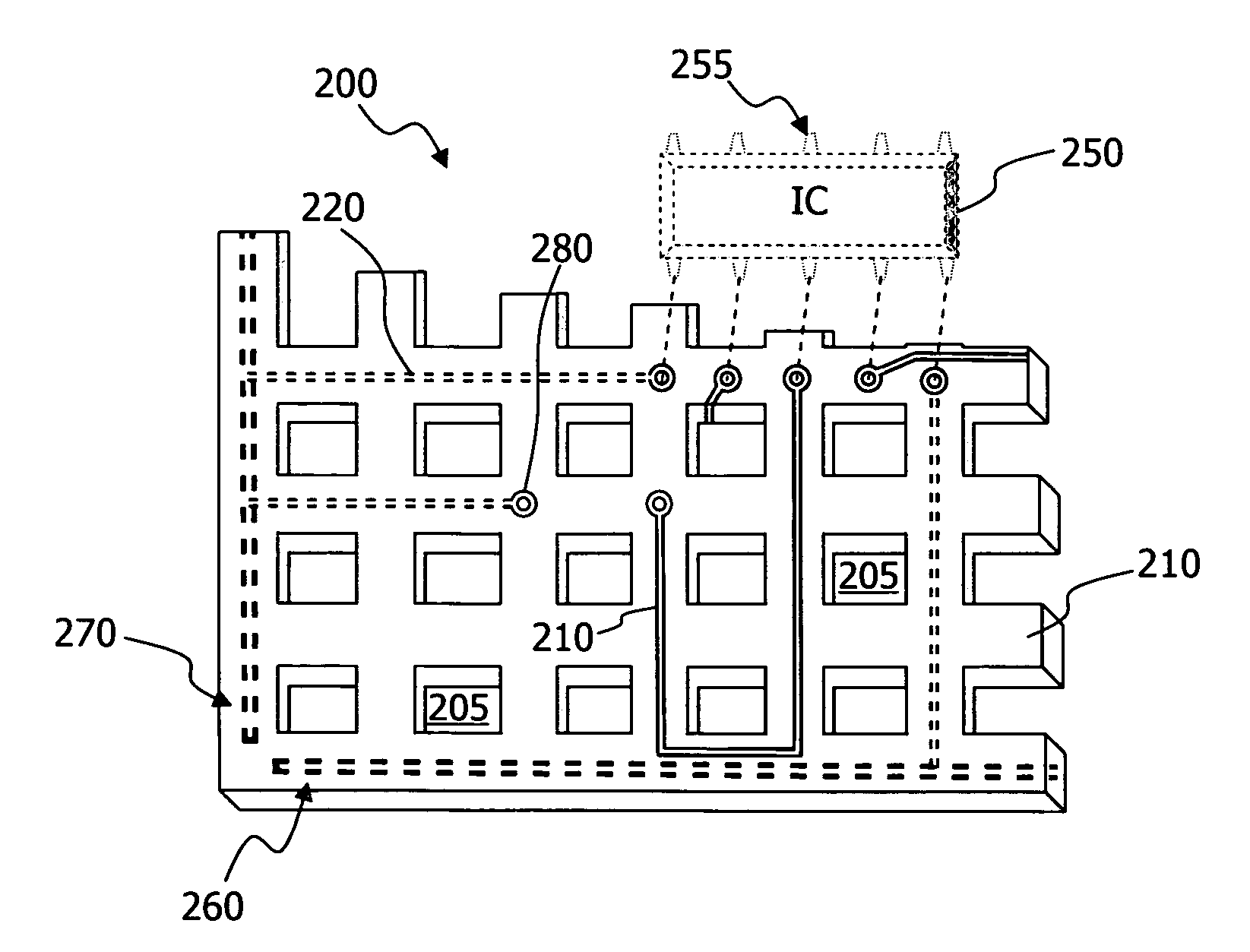

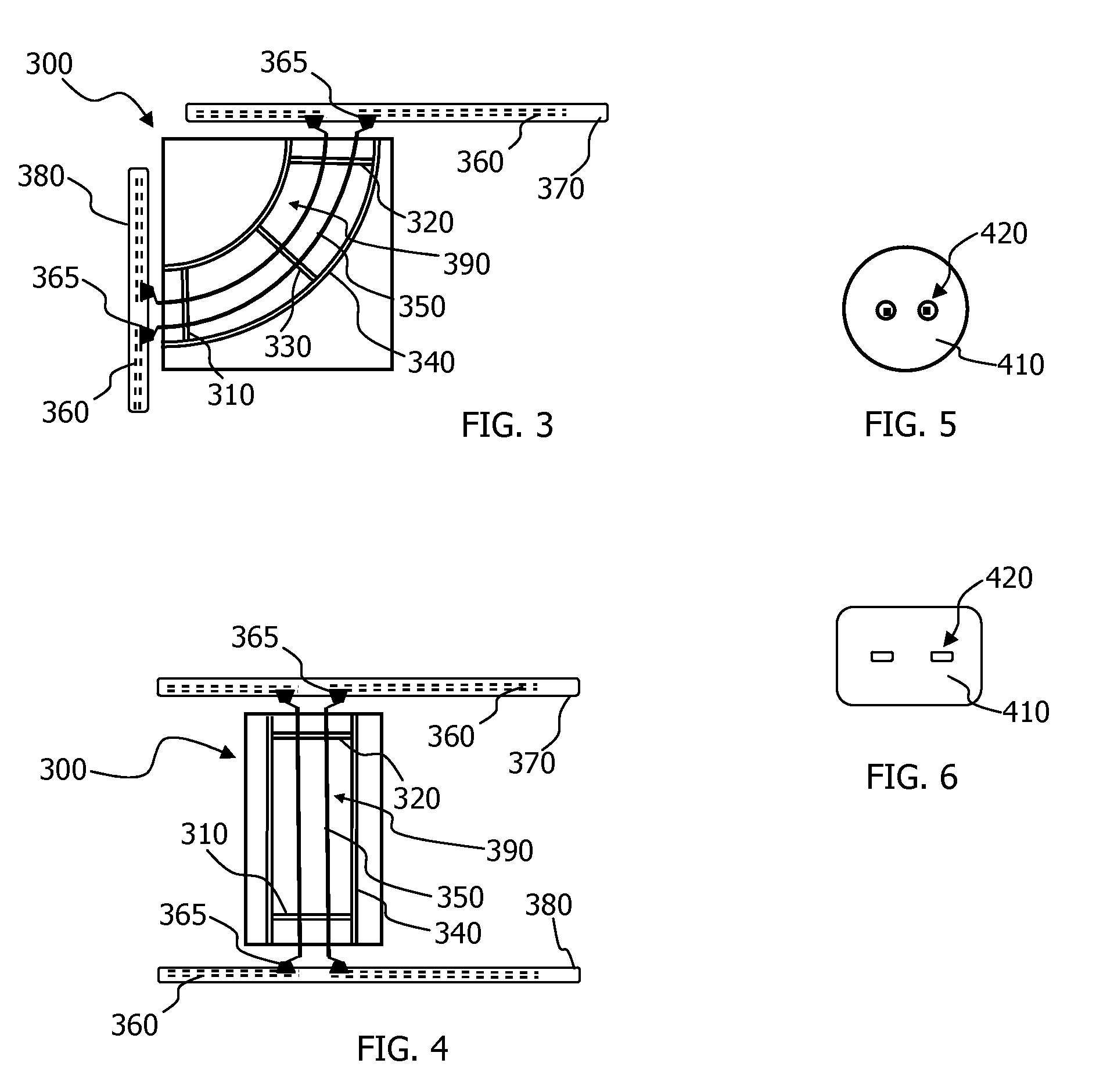

ActiveUS20080142250A1High frequency propagationEnergy lossPrinted circuit aspectsHigh frequency circuit adaptationsFR-4Electricity

Electronic component supporting mediums includes dielectric support material having voids adapted to include the use of air as a dielectric, which is commonly used in printed circuit boards and electrical connectors. The support medium provides physical support to conductive connections and a mechanical structure to enable electrical connections between electronic components. Support structures including air as a dielectric can be provided in the form of printed circuit boards and electrical connectors. The printed circuit board of claim 16 wherein said dielectric material comprises a low loss material. The support medium can comprise a low loss material such as air, FR-4, Teflon material, and plastic.

Owner:BELL SEMICON LLC

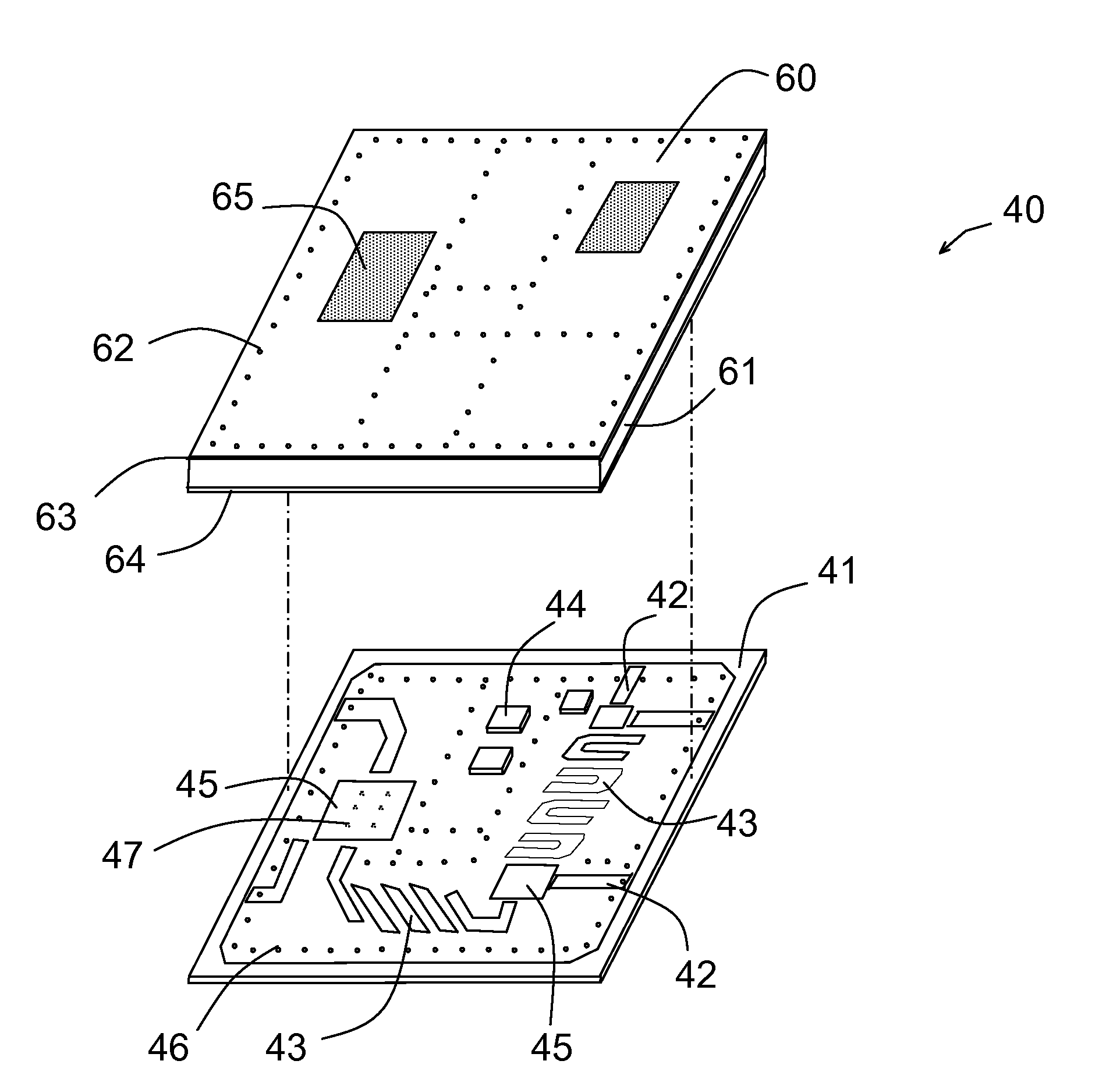

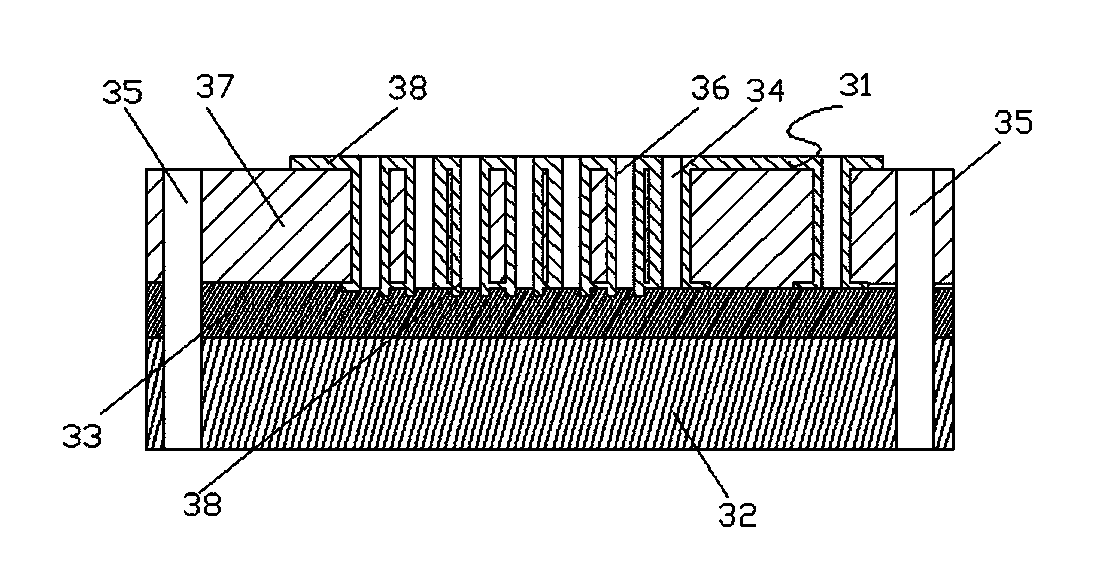

Highly Integrated Miniature Radio Frequency Module

ActiveUS20110051375A1Low costHighly integratedLine/current collector detailsSemiconductor/solid-state device detailsElectricityDielectric substrate

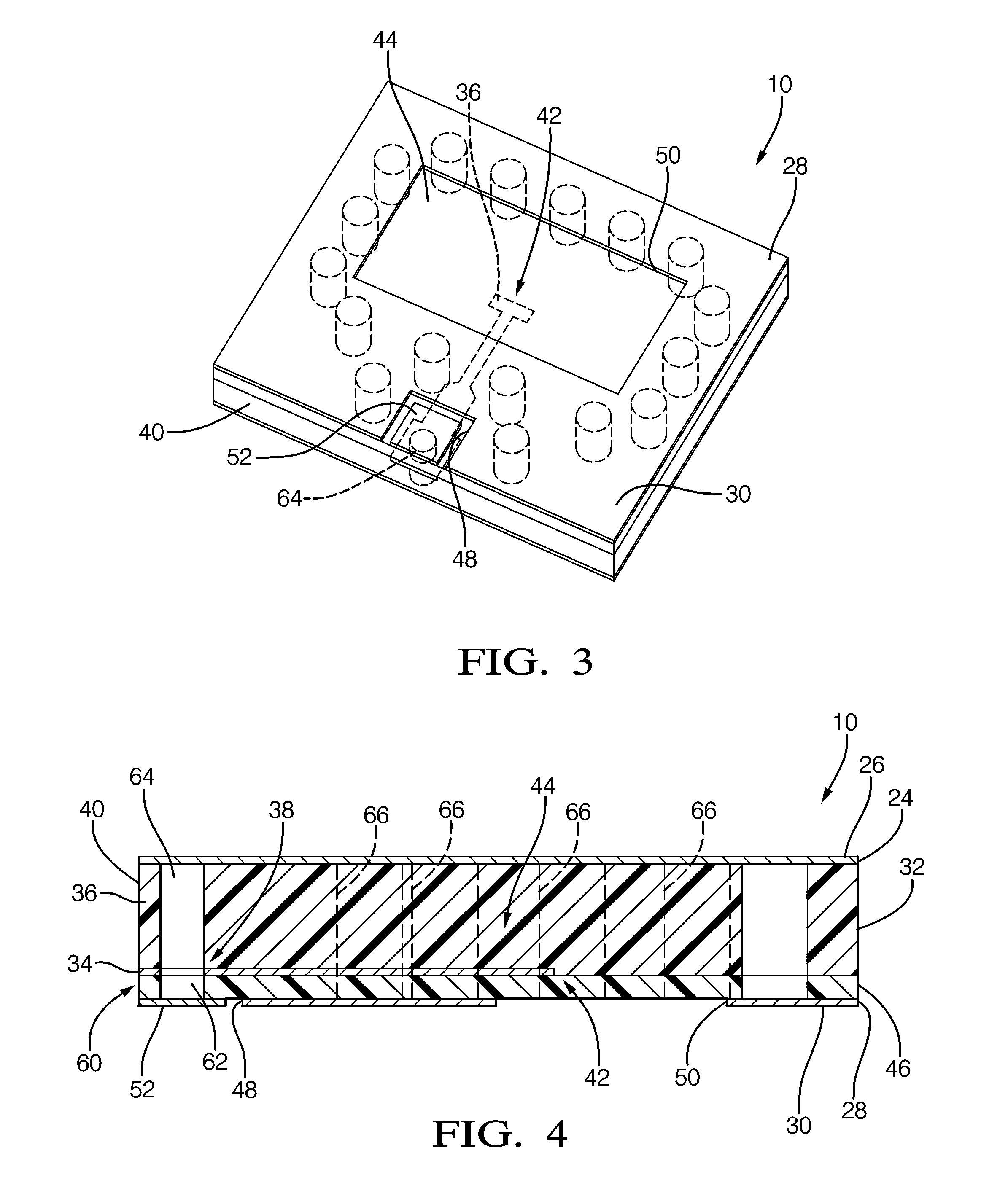

A highly integrated miniature RF module includes a dielectric base board with opposing top and bottom metal layers and having interconnects traces, radio frequency (RF) circuits and semiconductor chips at the top metal layer and ground and signal pads at the bottom metal layer. Metalized vias extending through the dielectric material connect the top and bottom layers. A top cover made out of laminate material, such as FR-4, with opposing top and bottom metal layers and having machined compartments and channels, surrounded with arrays of metal plated vias extending through the laminate material, protects the RF circuits and chips and provide the required isolation and wave propagation.

Owner:VU SYST LLC

Epoxy resin glue solution, prepreg and copper clad panel containing epoxy resin glue solution, and preparation method thereof

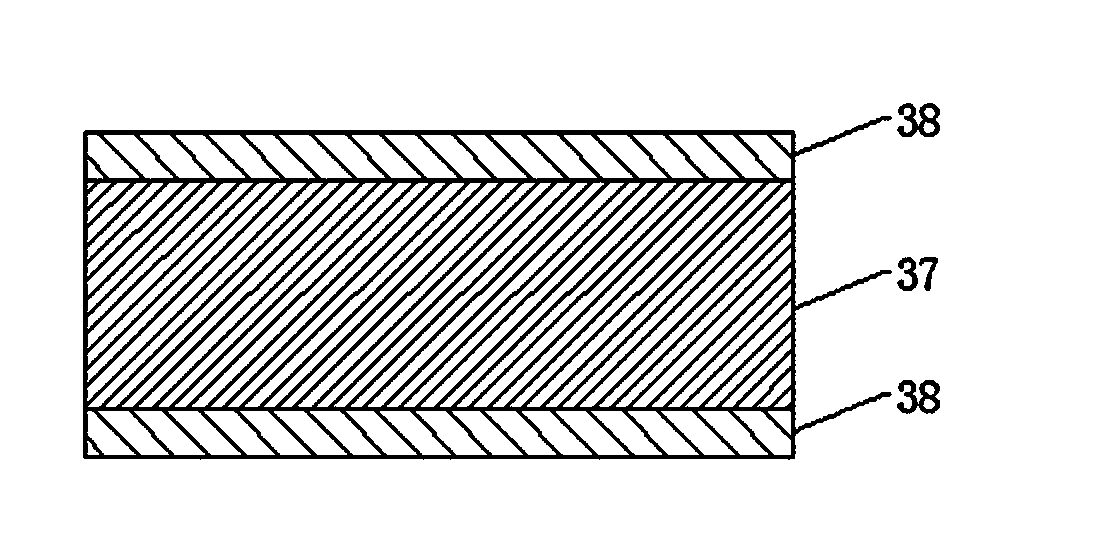

ActiveCN102190865AGood shading effectGood chemical resistanceGlass/slag layered productsCircuit susbtrate materialsFilling materialsAluminium hydroxide

The invention provides an epoxy resin glue solution comprising brominated bisphenol A resin, dicyandiamide, dimethylimidazole, inorganic filling materials, aniline and solvents, wherein, the inorganic filling materials comprise aluminium hydroxide. The invention also provides a preparation method for the epoxy resin glue solution, and an application of the epoxy resin glue solution for preparing a prepreg and a FR-4 copper-clad panel. The invention further provides the prepreg and FR-4 copper-clad panel prepared by using the epoxy resin glue solution, and a preparation method for the prepreg and FR-4 copper-clad panel. According to the invention, the defect of energy wasting caused by high light transmittance existing in the copper-clad panel in the prior art is overcome. The prepreg and FR-4 copper-clad panel prepared by using the epoxy resin glue solution disclosed in the invention can be used as a black substrate without affecting other performances of the substrate. The copper-clad panel can reduce the light transmittance and is suitable for using as an LED substrate.

Owner:SHANGHAI GUOJI ELECTRONICS MATERIALS CO LTD

Press fit method for high-voltage-resistant PCB with thick copper plate

InactiveCN105472912AMeet reliabilityImprove liquidityMultilayer circuit manufactureCircuit laminationHigh resistanceVitrification

The invention discloses a press fit method for a high-voltage-resistant PCB with a thick copper plate. The method includes the following steps: S1, cutting, i.e., cutting an outer-layer copper foil, a polyimide medium, pure-glue prepreg and a polyimide copper-clad plate according to required dimensions; S2, inner-layer pattern making; and S3, conducting press fit after plate lamination, the press fit including the first heating stage at the temperature of 100-140 DEG C, the second heating stage at the temperature of 140-180 DEG C, the third heating stage at the temperature of 180-220 DEG C, a warm-keeping stage, the first cooling stage at the temperature of 220-150 DEG C and the second cooling stage at the temperature of 150-100 DEG C. Conventional FR-4 prepreg is replaced by a polyimide material that has higher glass transition temperature and exhibits higher resistance to voltage, so a PCB with a thick copper plate is made to have the excellent resistance to voltage, and polyimide having high glass transition temperature can effectively ensure that resin is fully filled among lines during press fit. Moreover, press fit parameters can be adjusted and the operating time of a high-temperature and high-voltage stage can be prolonged, thus helping polyimide materials to fully fill line gaps in a high-temperature and high-voltage condition.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

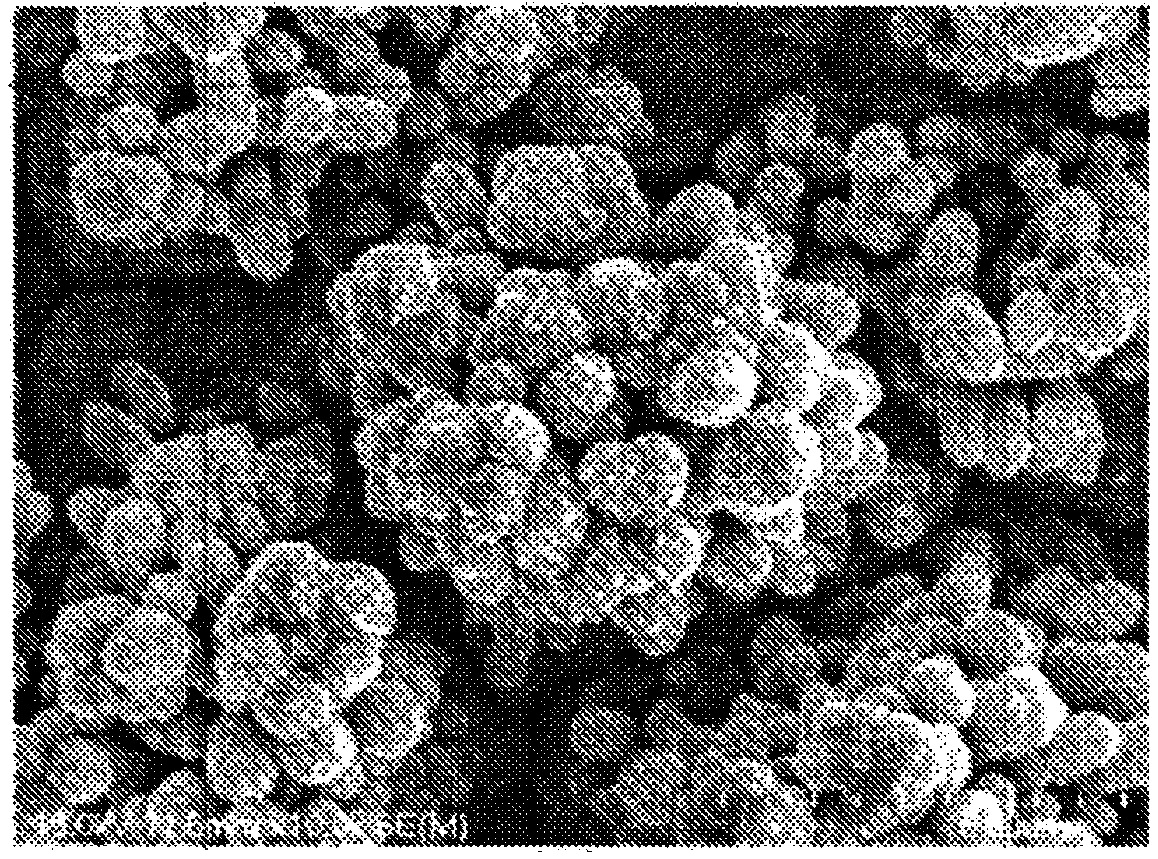

Copper foil excellent in adhesion with resin, method for manufacturing same, and printed wiring board or battery negative electrode material using electrolytic copper foil

ActiveCN103857833AHigh peel strengthHigh bonding strengthInsulating substrate metal adhesion improvementElectrode carriers/collectorsEpoxyElectrolysis

An electrolytic copper foil is characterized by having a roughened surface (M surface) on which roughening particles are formed, wherein the roughening particles have an average size of 0.1 to 1.0 mum. Provided is the electrolytic copper foil capable of, without deteriorating various characteristics of the electrolytic copper foil, improving a roughening treatment layer on the copper foil and enhancing the adhesion strength between the copper foil and a resin substrate, especially, capable of obtaining a stronger peeling strength in comparison with a general-purpose epoxy resin substrate (FR-4 and the like) when used in combination with a semiconductor package substrate having a generally low adhesion with a copper foil and a liquid crystal polymer substrate, and also provided is a method for manufacturing the electrolytic copper foil. The present invention addresses the problem of providing the electrolytic copper foil useful as an electrolytic copper foil to be used for a printed wiring board or a battery (LiB and the like) negative electrode material.

Owner:JX NIPPON MINING & METALS CO LTD

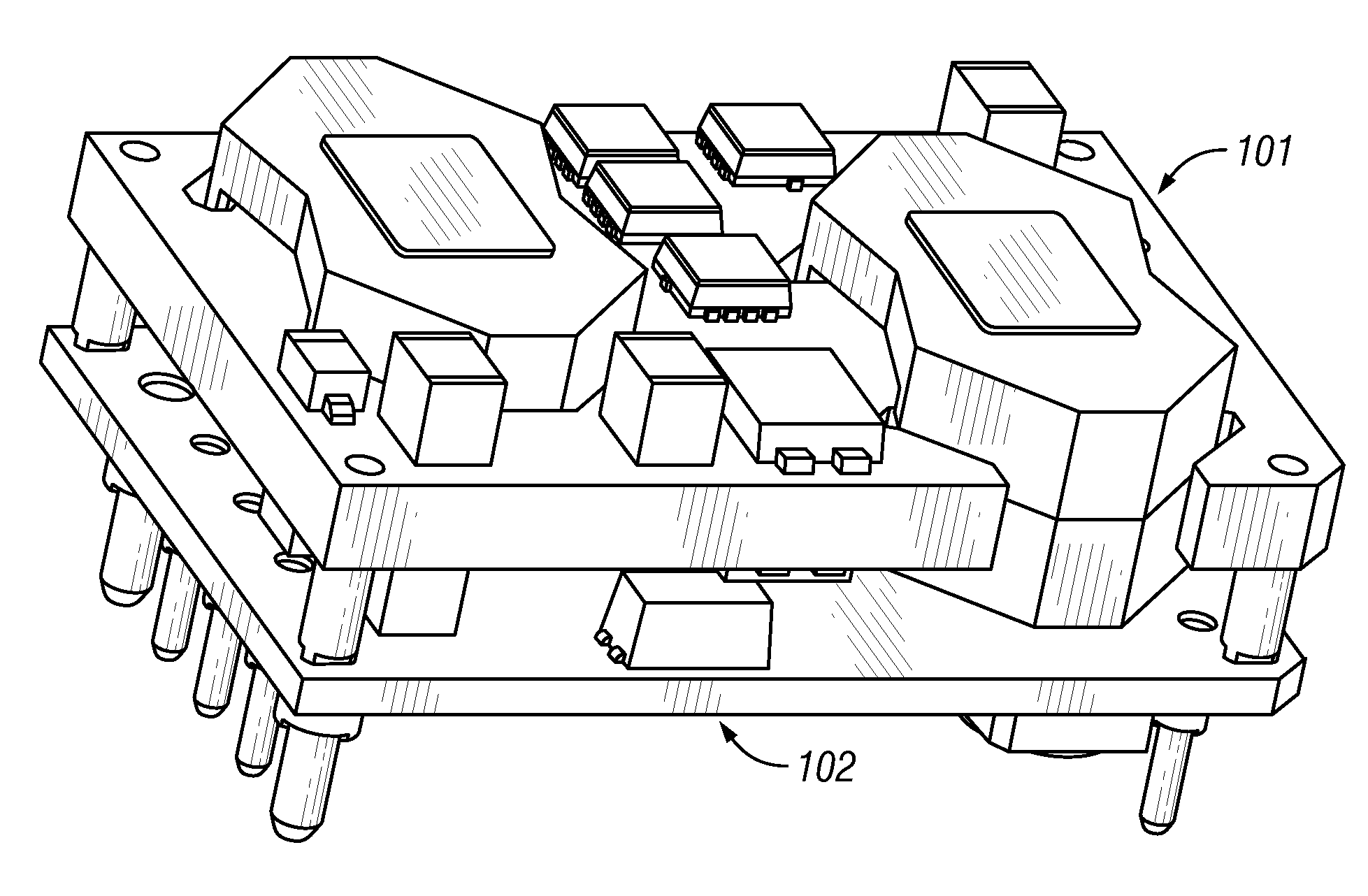

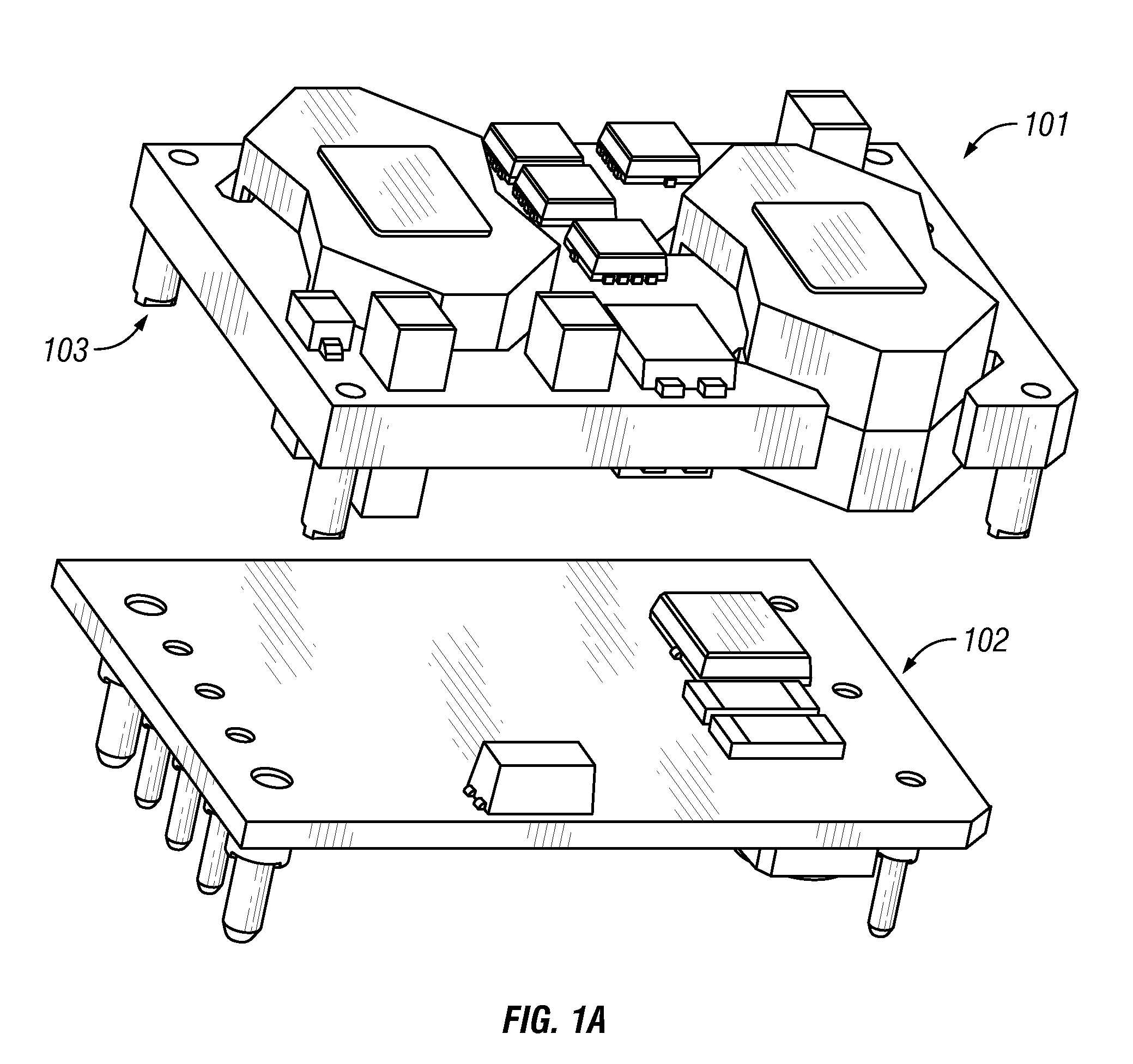

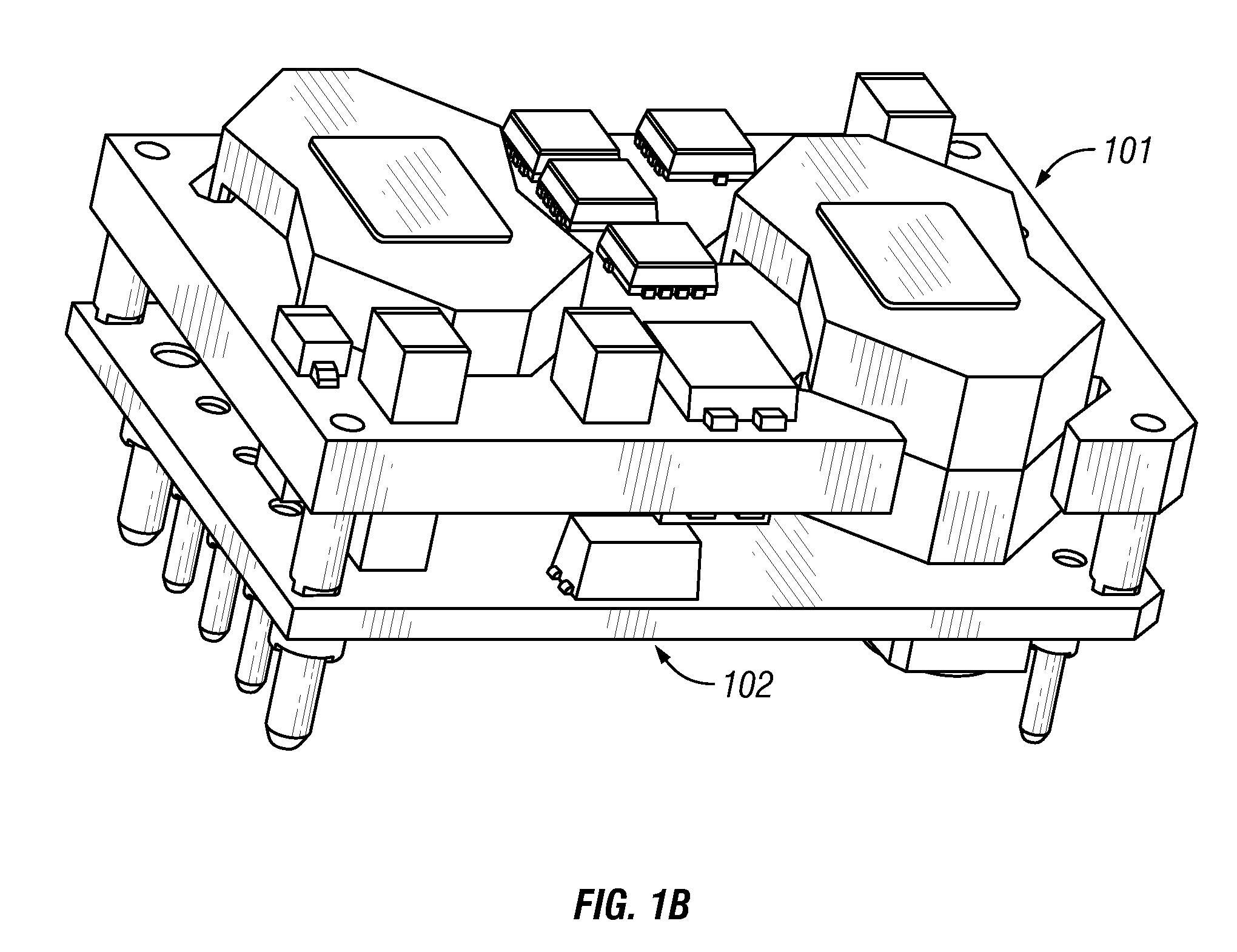

Multiple-board power converter

The present invention provides a DC-DC power converter that comprises two or more Printed Wiring Boards (PWB) mounted parallel to one another and without encapsulation. Electronic components can be mounted on both sides of each board. The open design and parallel orientation of the PWBs allow airflow over components mounted on the PWBs. The PWBs are preferable made of FR-4 with copper foils, with one thicker board being comprised of more copper layers and the other boards comprised of less copper layers. In the preferred embodiment, the power processing elements are housed in the thicker PWB, while the thinner boards house the control circuitry.

Owner:TDK LAMBDA CORP

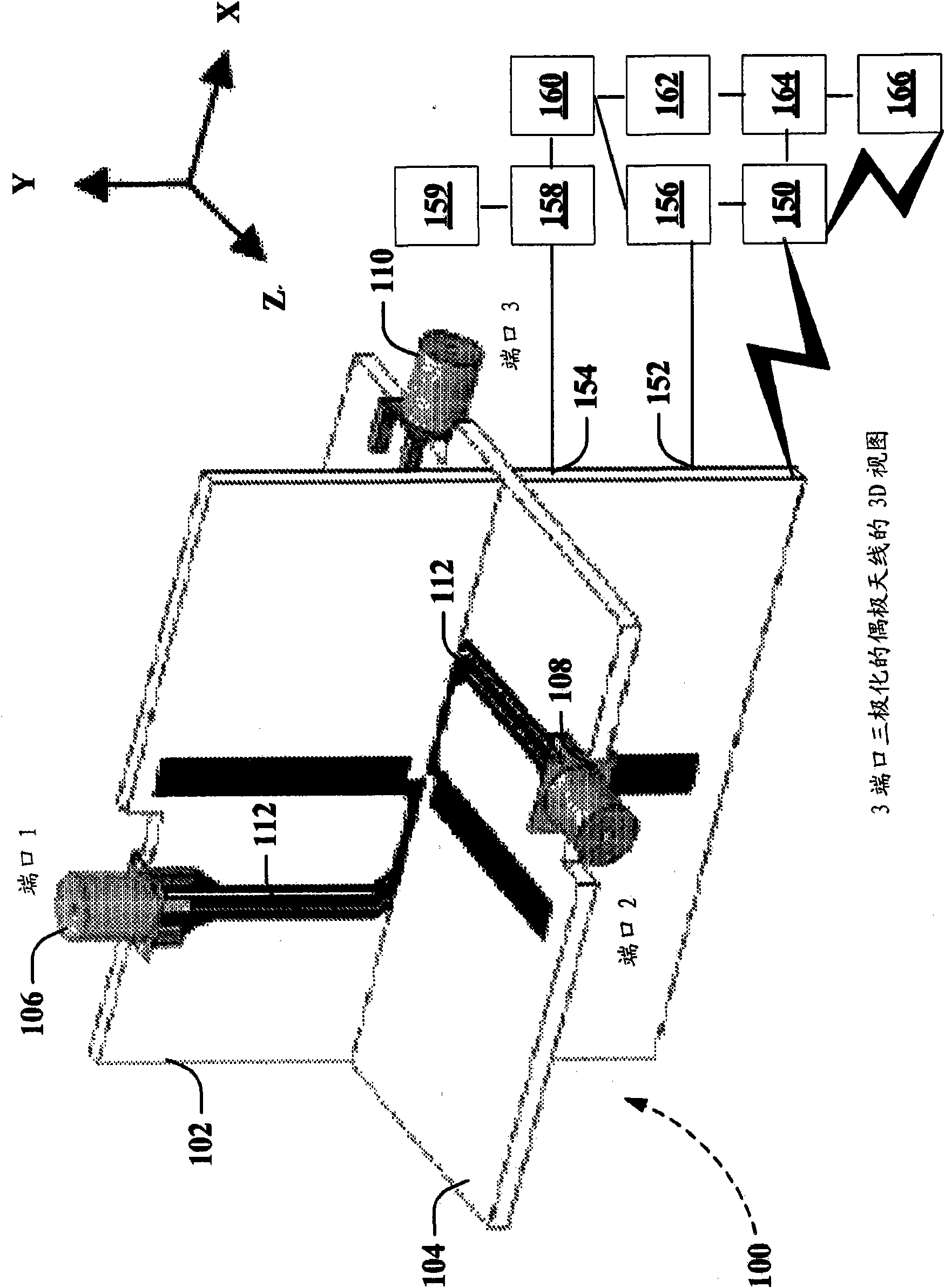

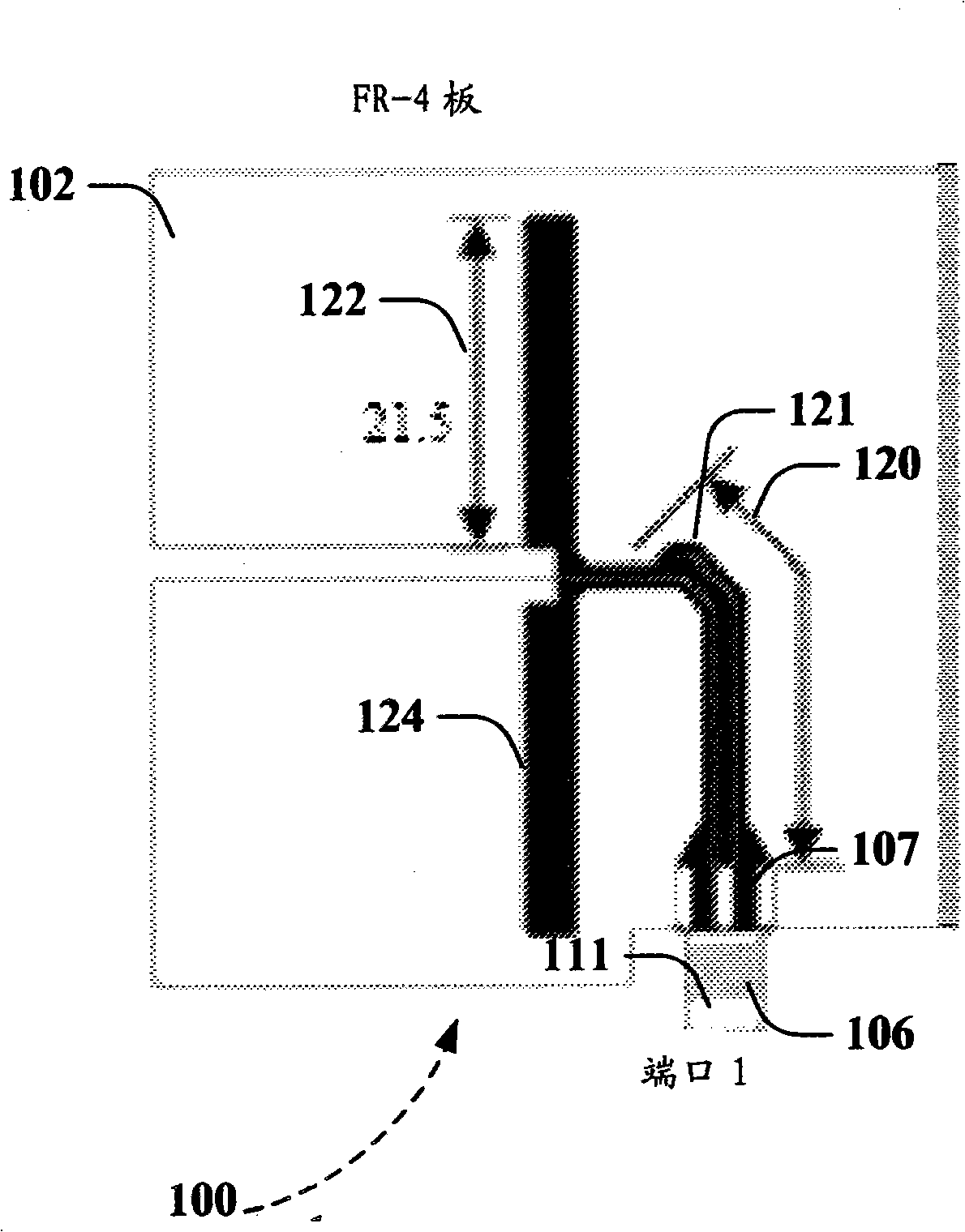

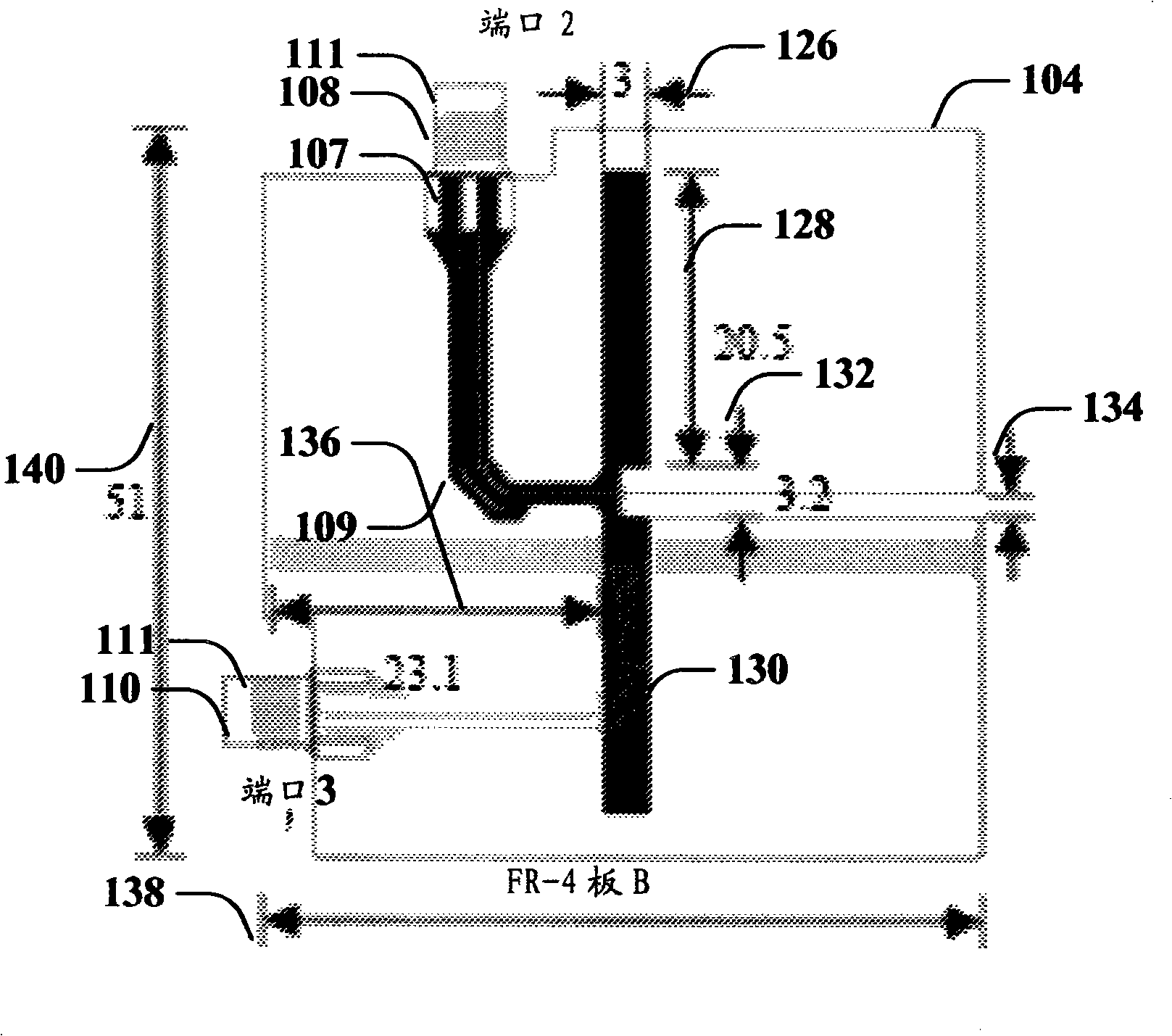

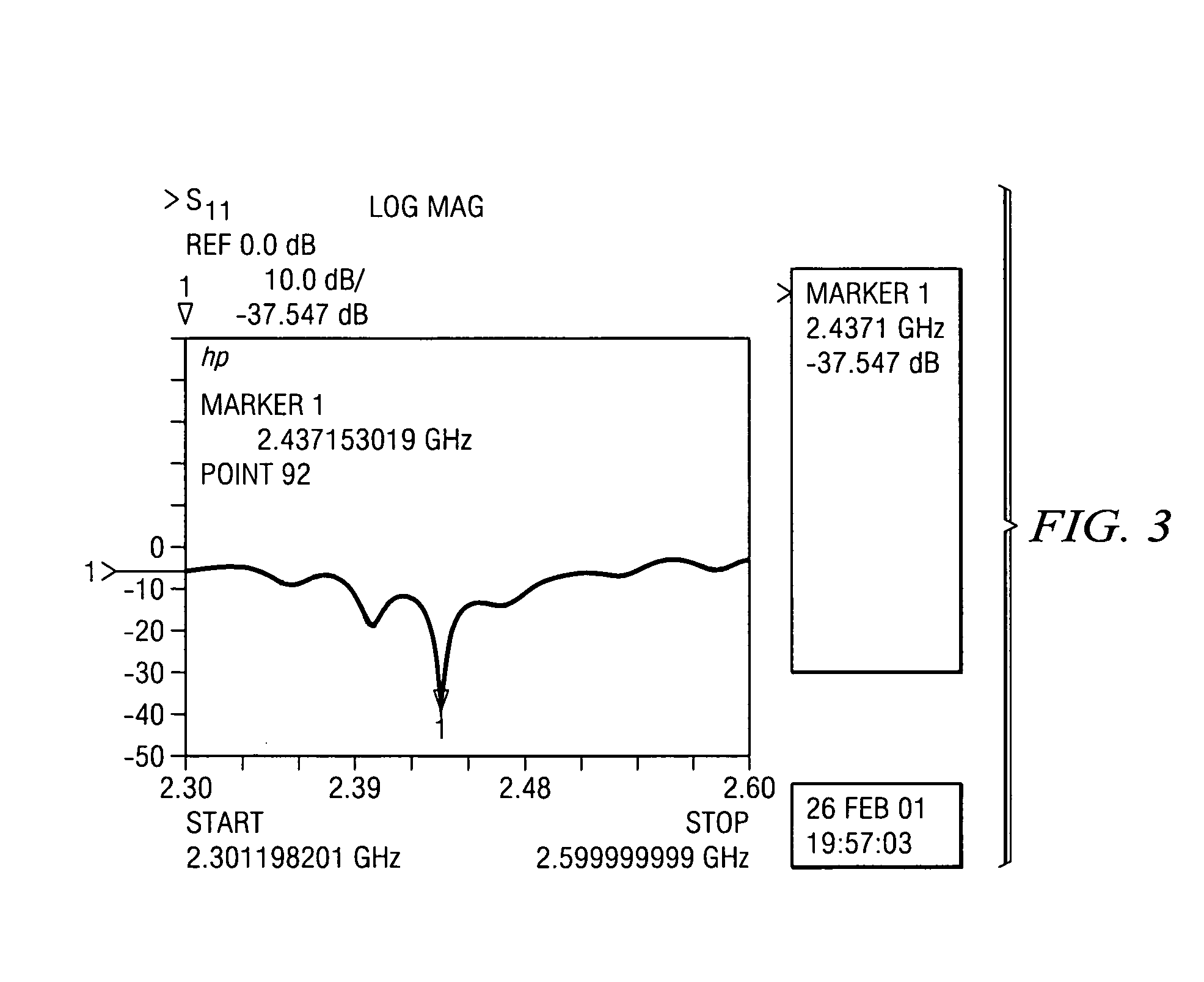

Compact 3-port orthogonally polarized mimo antennas

InactiveCN101884183ARadiating elements structural formsFrequency-division multiplexCouplingSignal correlation

Generalized non-limiting embodiments include employing a dipole antenna and / or a half slot antenna. Each of the antennas constitutes three mutually perpendicular radiating elements to achieve good isolation and low antenna signal correlation between the three ports. In one generalized non-limiting embodiment the antennas are fabricated on FR-4 epoxy boards. Experimental results show that the antennas resonate a reasonable frequency and have a desired mutual coupling. In addition experimental results for the diversity performance and the MIMO channel capacity are also provided for these antennas and these results show that the herein described antennas offer good diversity gain and the channel capacity can be increased by as much as three times by using these antennas over conventional antennas.

Owner:HONG KONG TECH GROUP

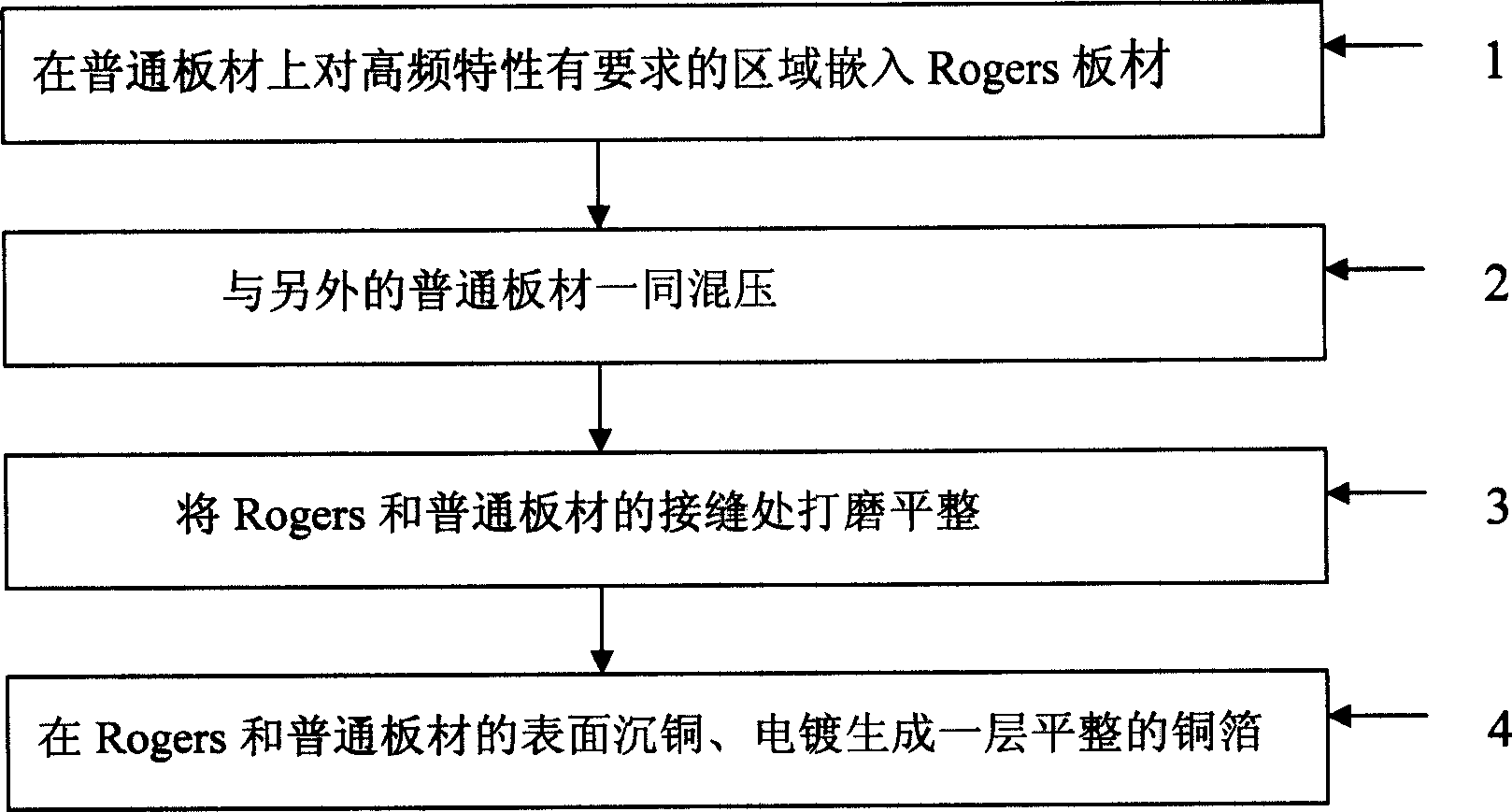

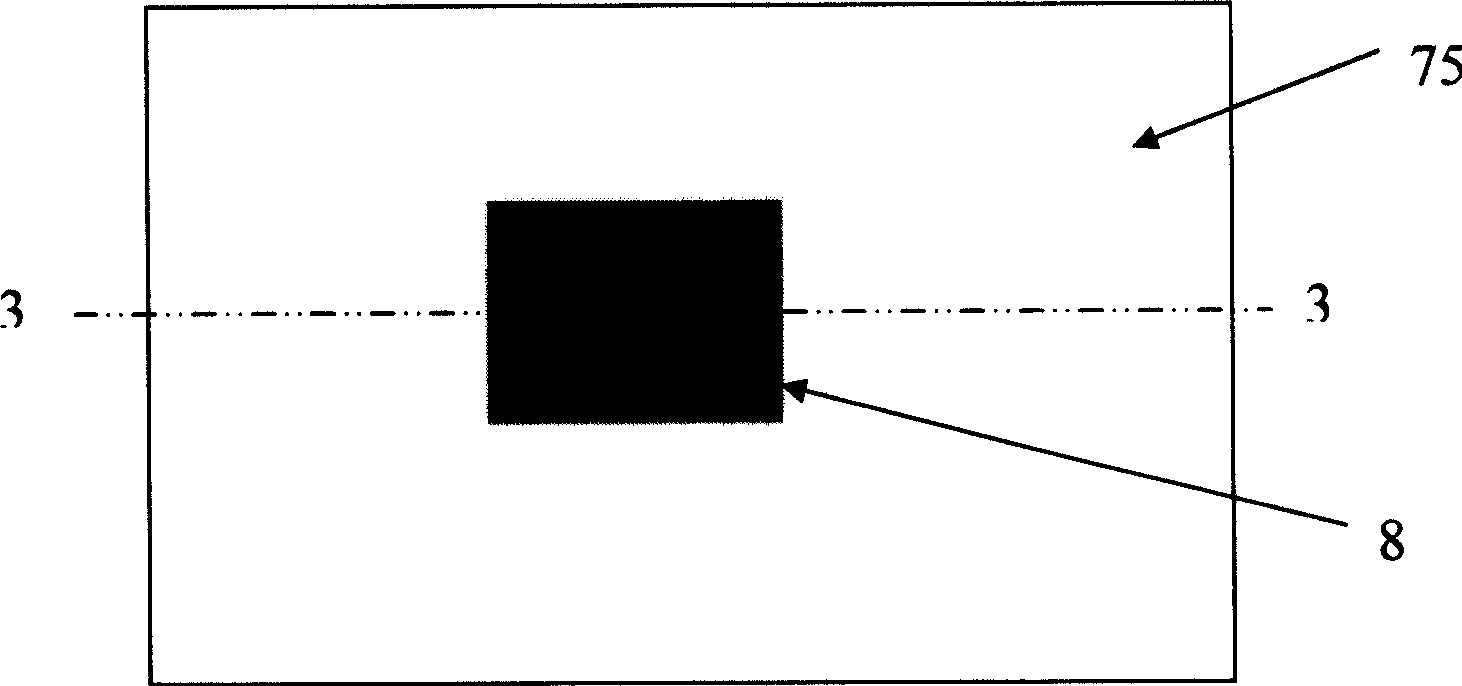

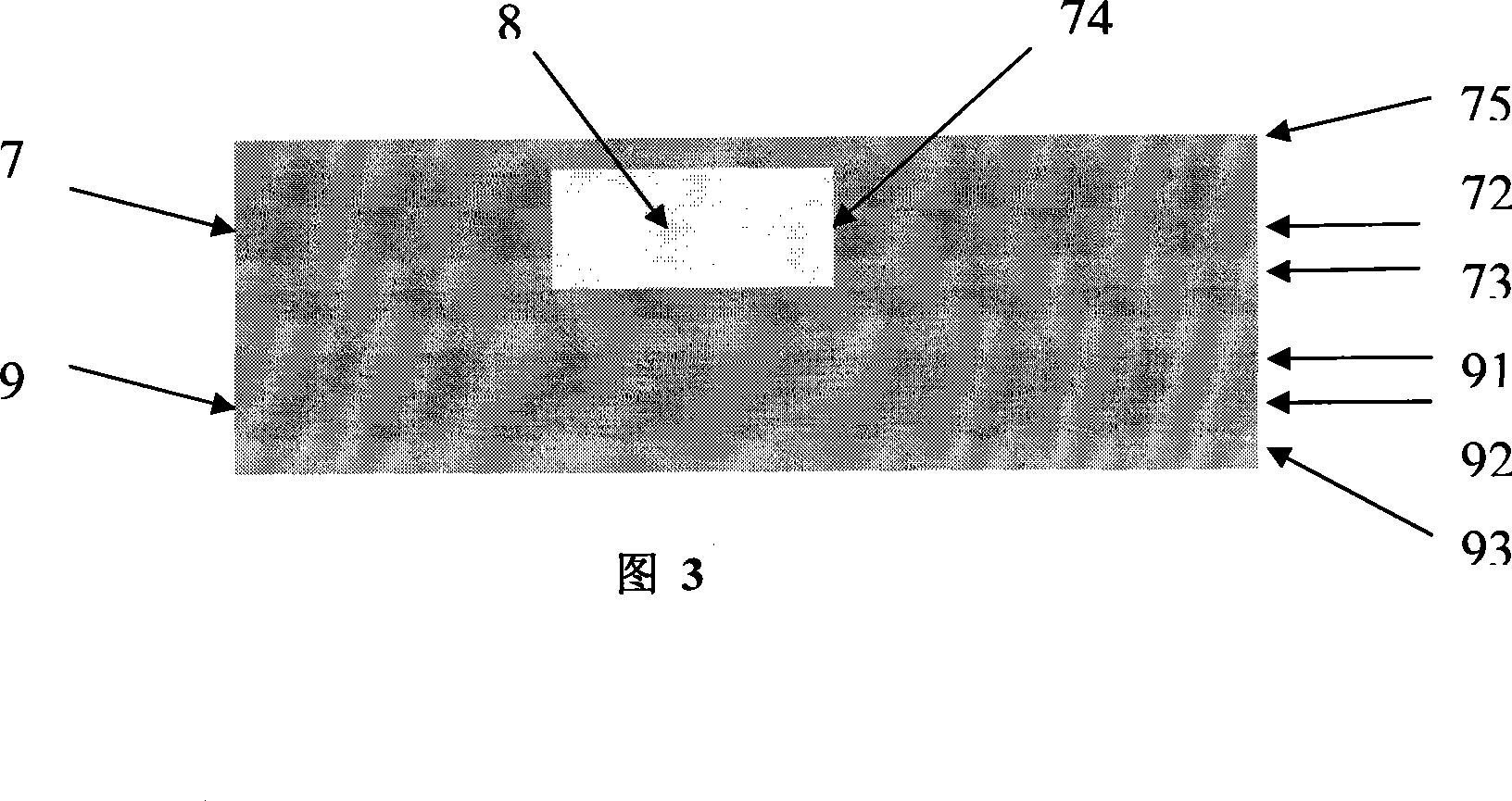

Method for producing printed circuit board for local region high frequency circuit by half-addition method

ActiveCN101400212AReduce usageActive connectionPrinted circuit manufactureCircuit susbtrate materialsCopper foilElectric signal

The present invention relates to a method for manufacturing a localized region high frequency circuit printed circuit board by a semi-additive method, including the following steps: embedding a Rogers sheet at regions of common sheet which has requirements to the high-frequency characteristics; mixing and pressing with additional common sheet; sanding well the seam crossing of the Rogers sheet and common sheet; and depositing copper and plating to generate a layer of level copper foil on the surface of the Rogers sheet and common sheet. The present invention adopts an embedded stitching method for pressing a high-frequency material Rogers into regions having high-frequency characteristic requirement, and then adopts a semi-additive method to plate a layer of copper on the shared surface of the Rogers and ordinary FR-4 for wire laying, for implementing effective connection of electric signals, thereby minimizing the use of Rogers material, and saving cost under the precondition of guaranteeing functions.

Owner:DONGGUAN SHENGYI ELECTRONICS

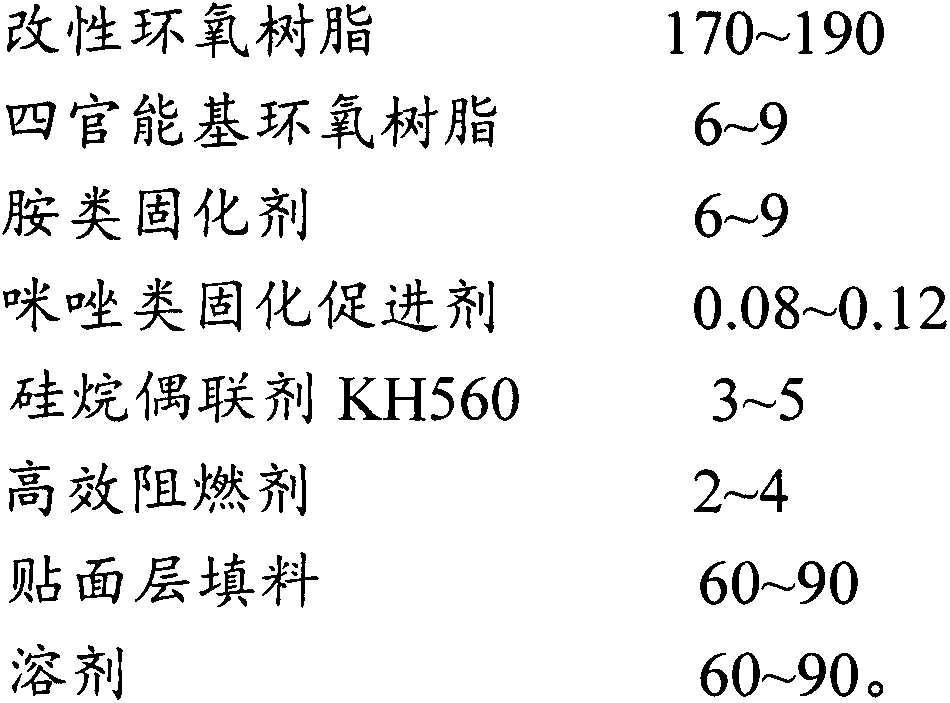

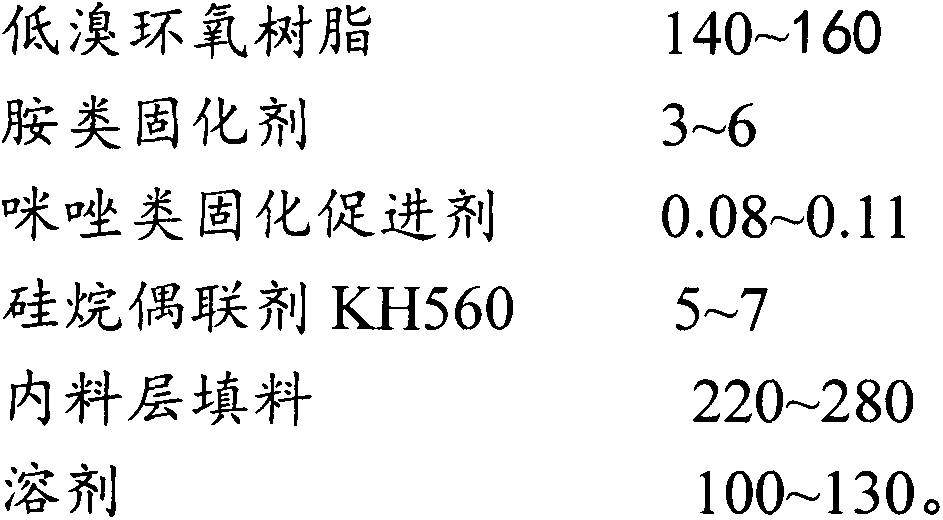

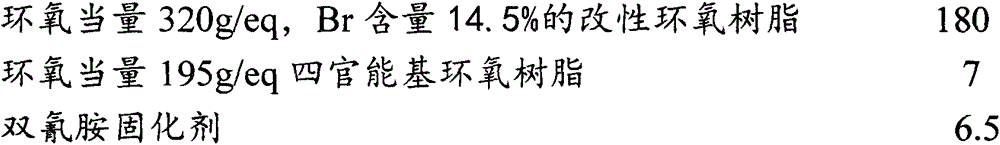

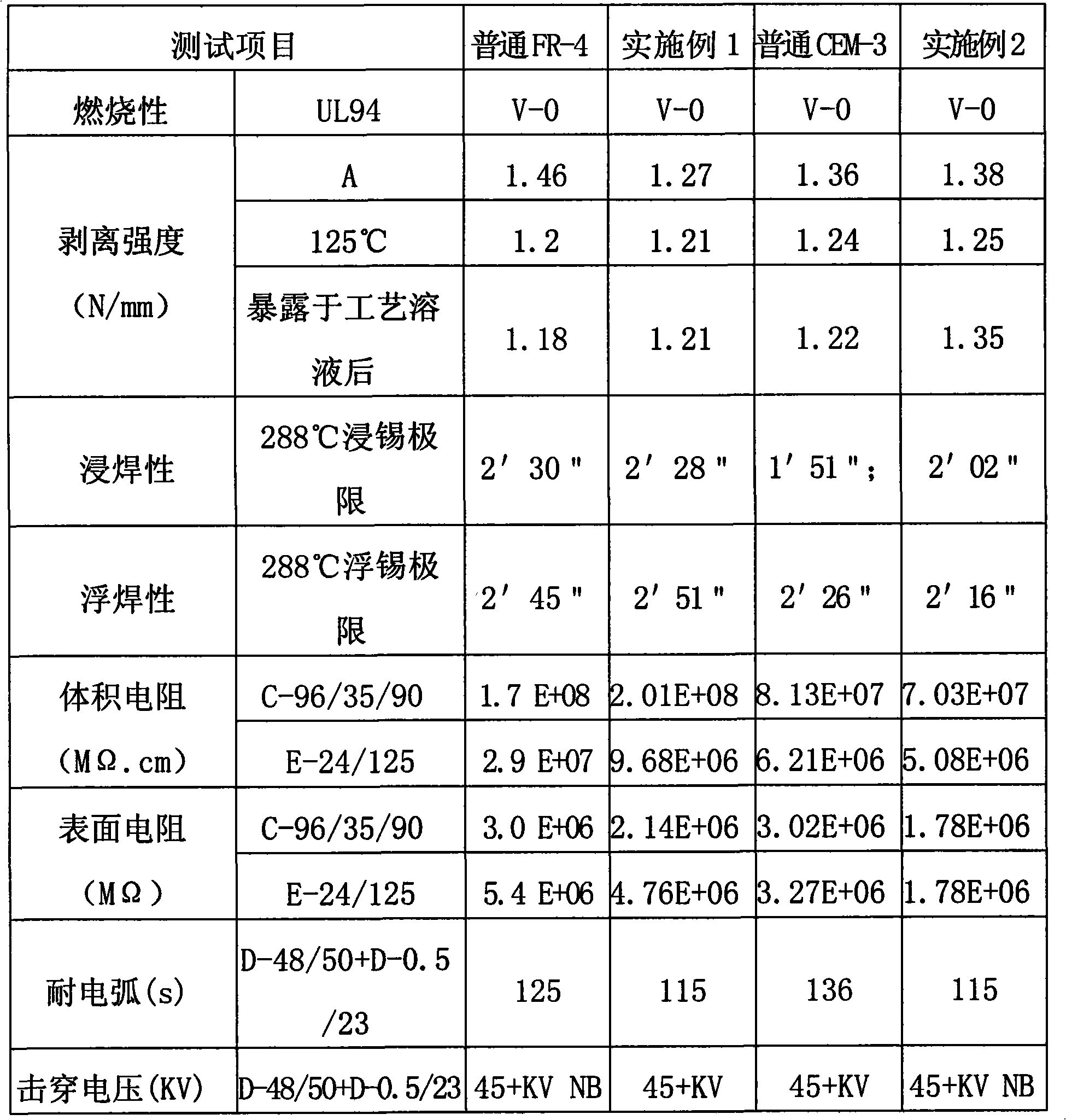

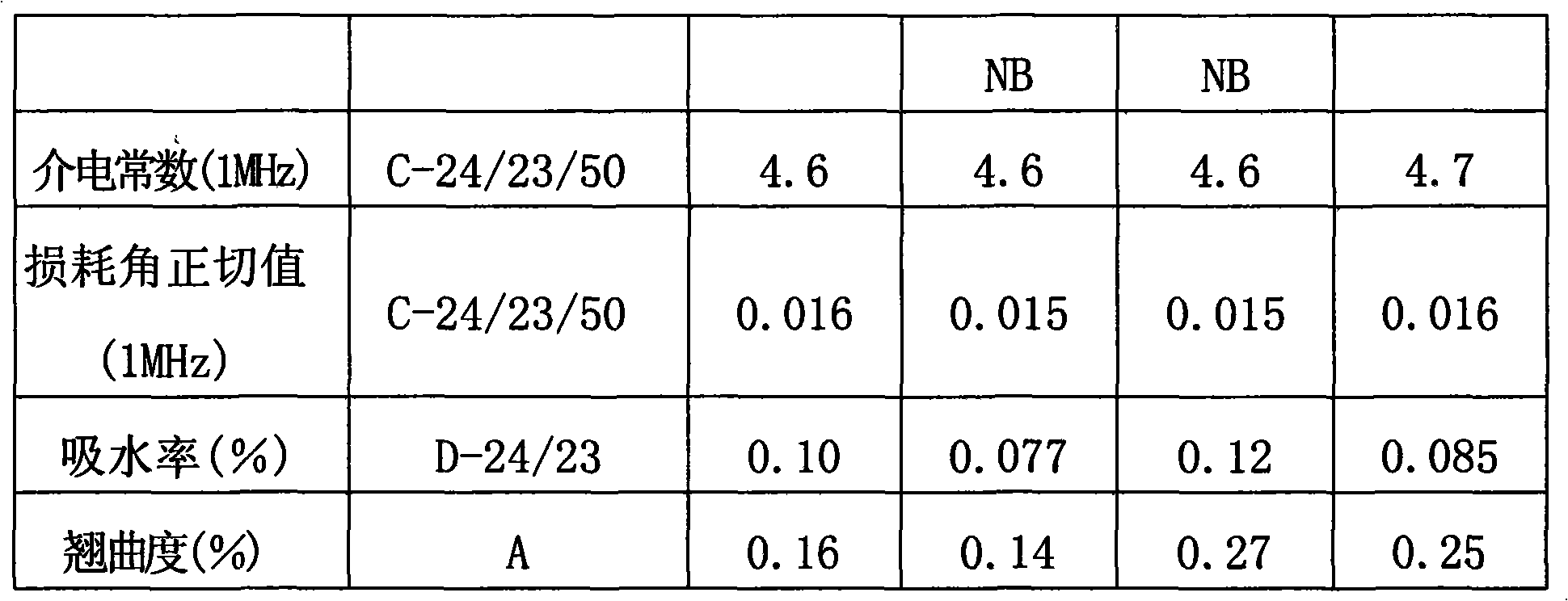

Making method for high thermal conductive, high heat resistant and high CTI FR-4 copper-clad plate

InactiveCN104002524AImprove thermal conductivityImprove heat resistanceSynthetic resin layered productsLaminationEpoxyHeat conducting

The invention discloses a making method for a high thermal conductive, high heat resistant and high CTI FR-4 copper-clad plate. The method comprises the steps of: preparation of a veneer layer glue solution and an inner material layer glue solution respectively, cementing, superimposition, and hot pressing. The veneer layer glue solution comprises the ingredients of: modified epoxy resin, tetrafunctional epoxy resin, an amine curing agent, an imidazole curing accelerator, a silane coupling agent KH560, an efficient flame retardant and a veneer layer filler; and any one of or a composition of over one of acetone, butanone, and dimethylformamide is taken as the solvent for preparation. The inner material layer glue solution comprises the ingredients of: low bromine epoxy resin, an amine curing agent, an imidazole curing accelerator, a silane coupling agent KH560, and an inner material layer filler; and any one of or a composition of over one of acetone, butanone, and dimethylformamide is taken as the solvent for preparation. The copper-clad plate prepared by the method provided by the invention has a CTI value of greater than or equal to 600V, efficient heat-conducting property, and thermal conductivity of greater than or equal to 1.7W / mk, thus meeting the use requirements of LED products for higher security. At the same time, the copper-clad plate also has excellent heat resistance.

Owner:NANTONG RODA ELECTRON

Method for manufacturing soft and hard combined board

The invention relates to a method for manufacturing a soft and hard combined board. The method comprises the following steps of: preparing the circuit of an inner-layer soft board; pre-cutting a gap on the surface of each inner-layer PP (Propene Polymer) film; adhering and pressing the inner-layer PP films onto the two sides of the inner-layer soft board; pre-cutting a gap on the surface of each FR-4 layer, pressing the FR-4 layers onto the inner-layer PP films through the pseudo-adhering and transferring processes; combining the inner-layer soft board and the FR-4 layers together through pressing, and then sequentially carrying out target hole punching, hole drilling, board copper depositing and electroplating processes; preparing the circuit of a secondary outer layer, combining the secondary outer layer with the FR-4 layers; pre-cutting a gap on the surface of each of PP films on the surfaces of the secondary outer layer, combining the PP films of the secondary outer layer and the secondary outer layer together by pressing and then sequentially carrying out target hole punching, hole drilling, board copper depositing and electroplating processes; preparing the circuit of an outer layer, combining the outer layer and the PP films of the secondary outer layer and then performing a green oil coating process; and removing the FR-4 layers out of a soft board area and then performing the subsequent processes, wherein the gap width is 0.01-0.05mm. According to the invention, a PAD is effectively prevented from being subjected to fretting corrosion, PI (polyimide) is ensured to have no chromatic aberration, and the surface of the board is flat, thereby being beneficial to the improvement of the yield of circuit boards.

Owner:HUIZHOU BLUEWAY ELECTRONICS

Method for preparing low-shrinkage-factor copper clad laminate by applying nano-stuffing

ActiveCN101564929ASmall coefficient of thermal expansionGood dimensional stabilityLamination ancillary operationsLaminationCopper foilNanometre

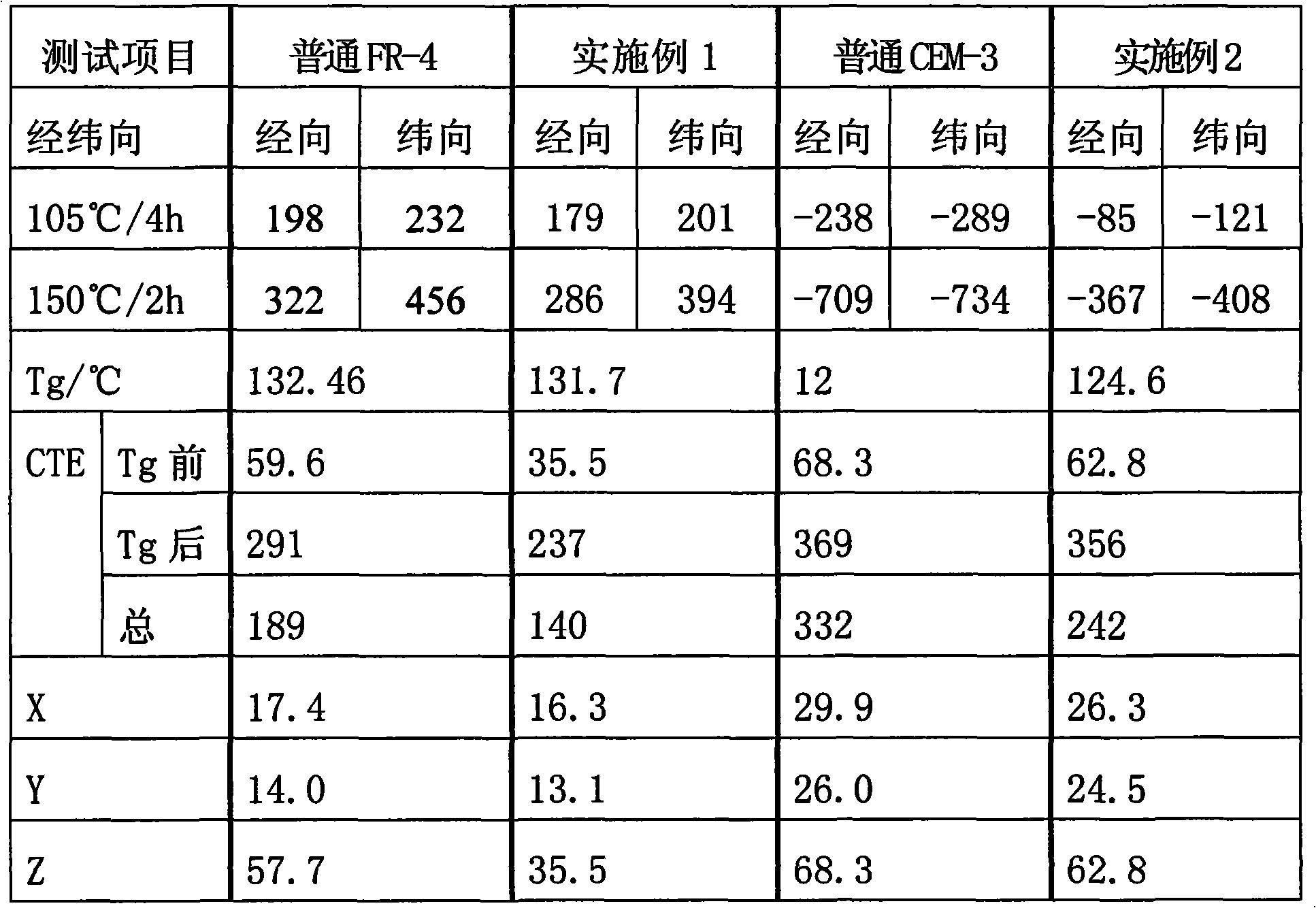

The invention discloses a method for preparing a low-shrinkage-factor copper clad laminate by applying a nano-stuffing, which comprises the following process flows: adding a nano-powder stuffing on a system of FR-4 / CEM-3, impregnating fiberglass cloth / fiberglass paper with a facing material and core material glue, and preparing the stuffing into a semi-solid state at a temperature of between 130 and 180 DEG C to prepare a facing material and a core material; superposing 1 to 20 sheets of the facing material according to the thickness requirement, and covering a copper foil on one side or both sides of the facing material to prepare an FR-4 sheet material; superposing 1 to 20 sheets of the core material, pasting the facing material on the upper surface and the lower surface of the core material, and covering a copper foil on one side or both sides of the core material to prepare a CEM-3 sheet material; and performing hot press molding on the combination of the FR-4 / CEM-3 at a temperature of between 90 and 180 DEG C, at a pressure of between 10 and 60 Kg / cm, and at a vacuum degree of -60 mmHg. The FR-4 / CEM-3 copper clad laminate prepared by the method obviously reduces the heat expansion coefficient, remarkably improves the dimensional stability, overcomes the defects that the FR-4 / CEM-3 sheet material prepared by the prior art has large CTE and poor dimensional stability, is more adaptable to the production of PCB and the assembly technique of electronic products, and remarkably improves the reliability.

Owner:SHAANXI SHENGYI TECH

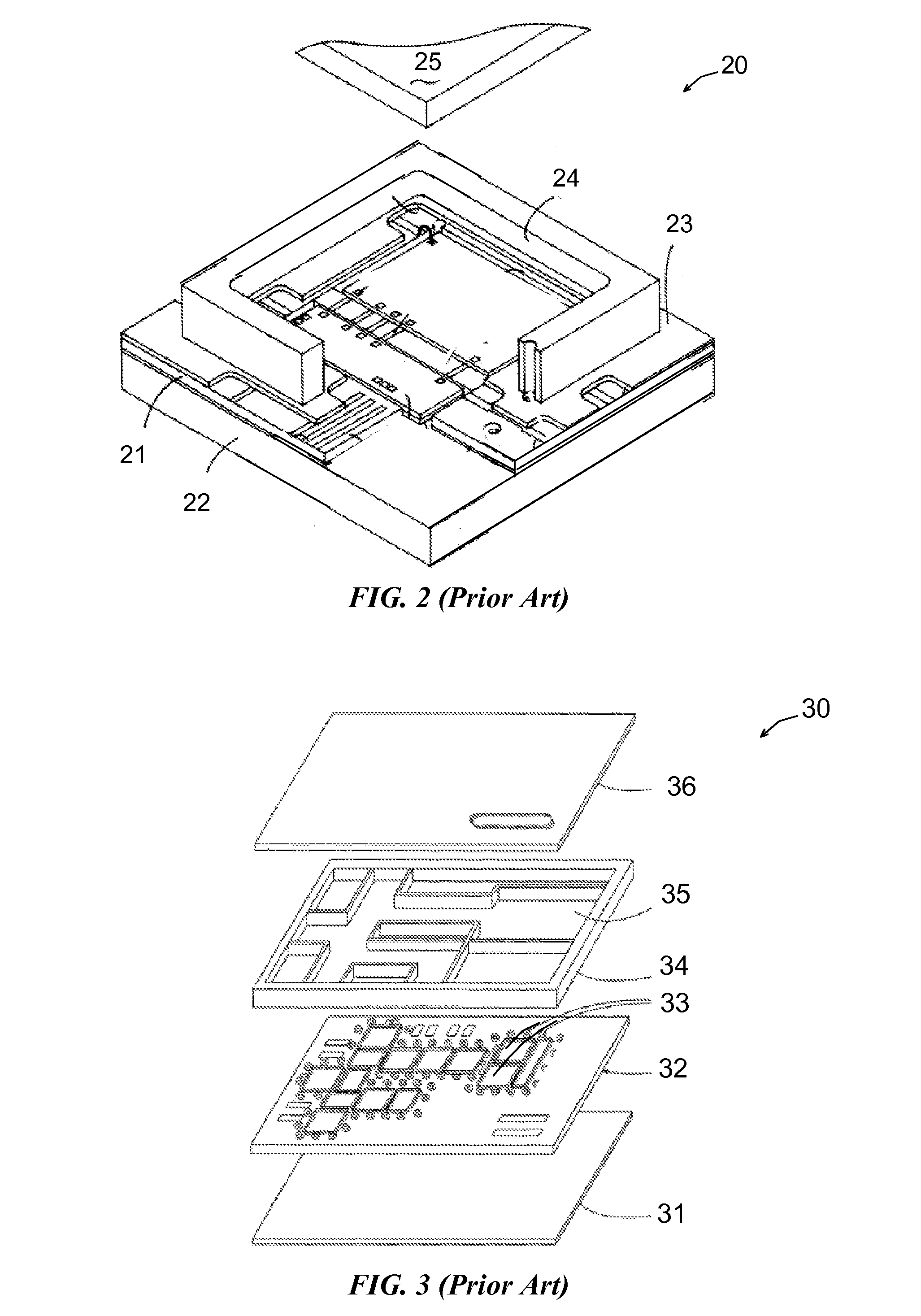

High density composite focal plane array

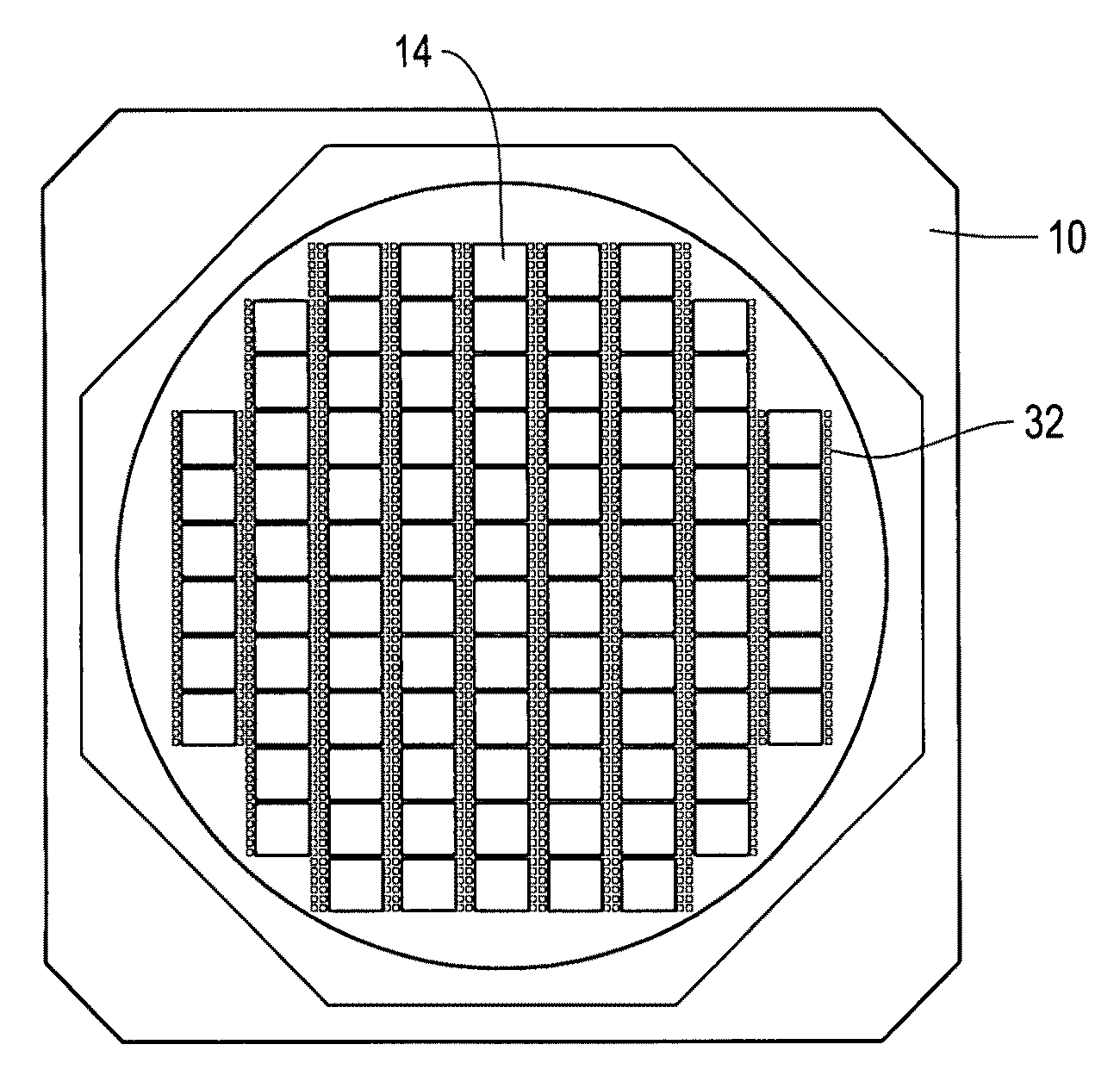

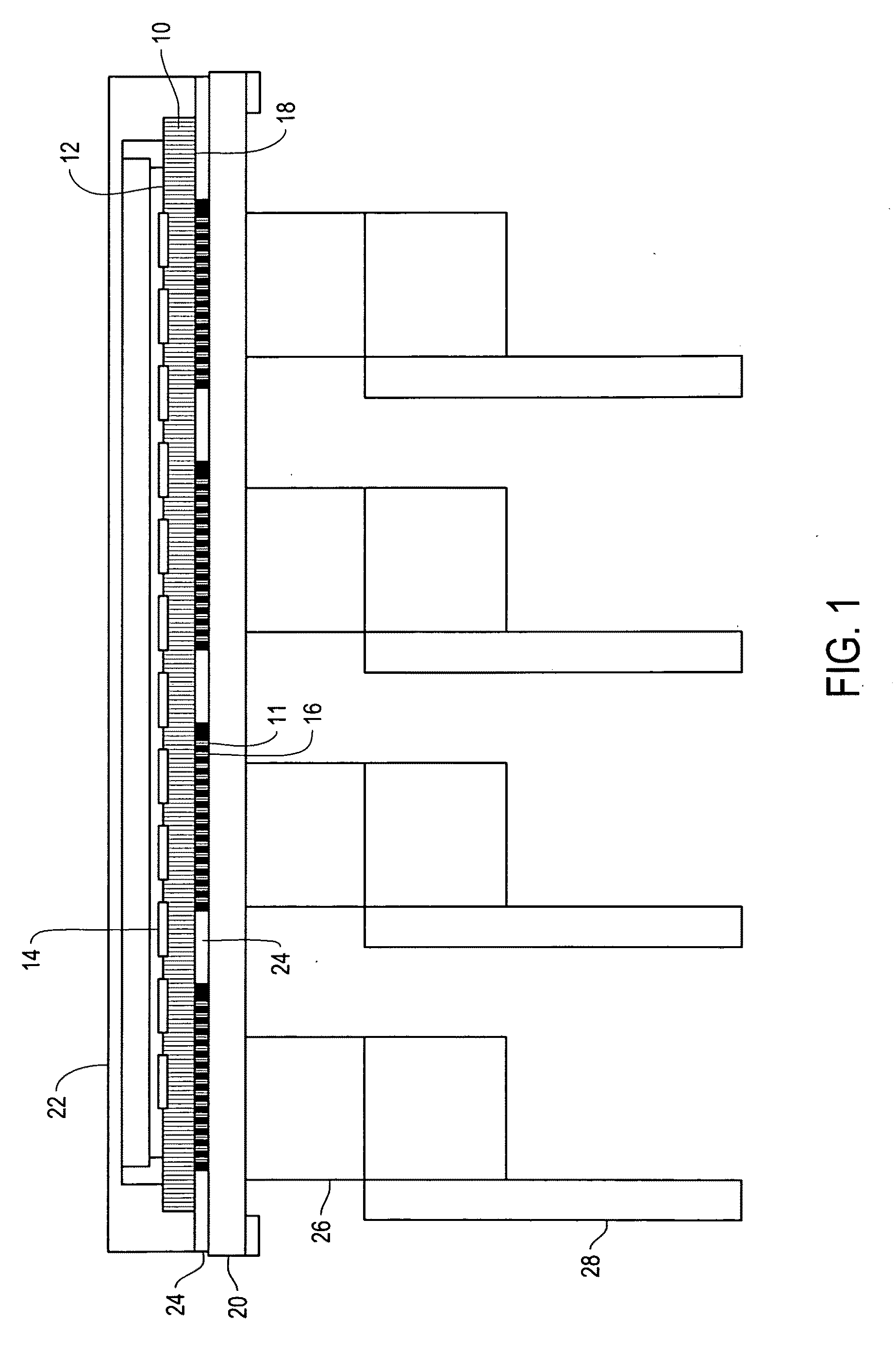

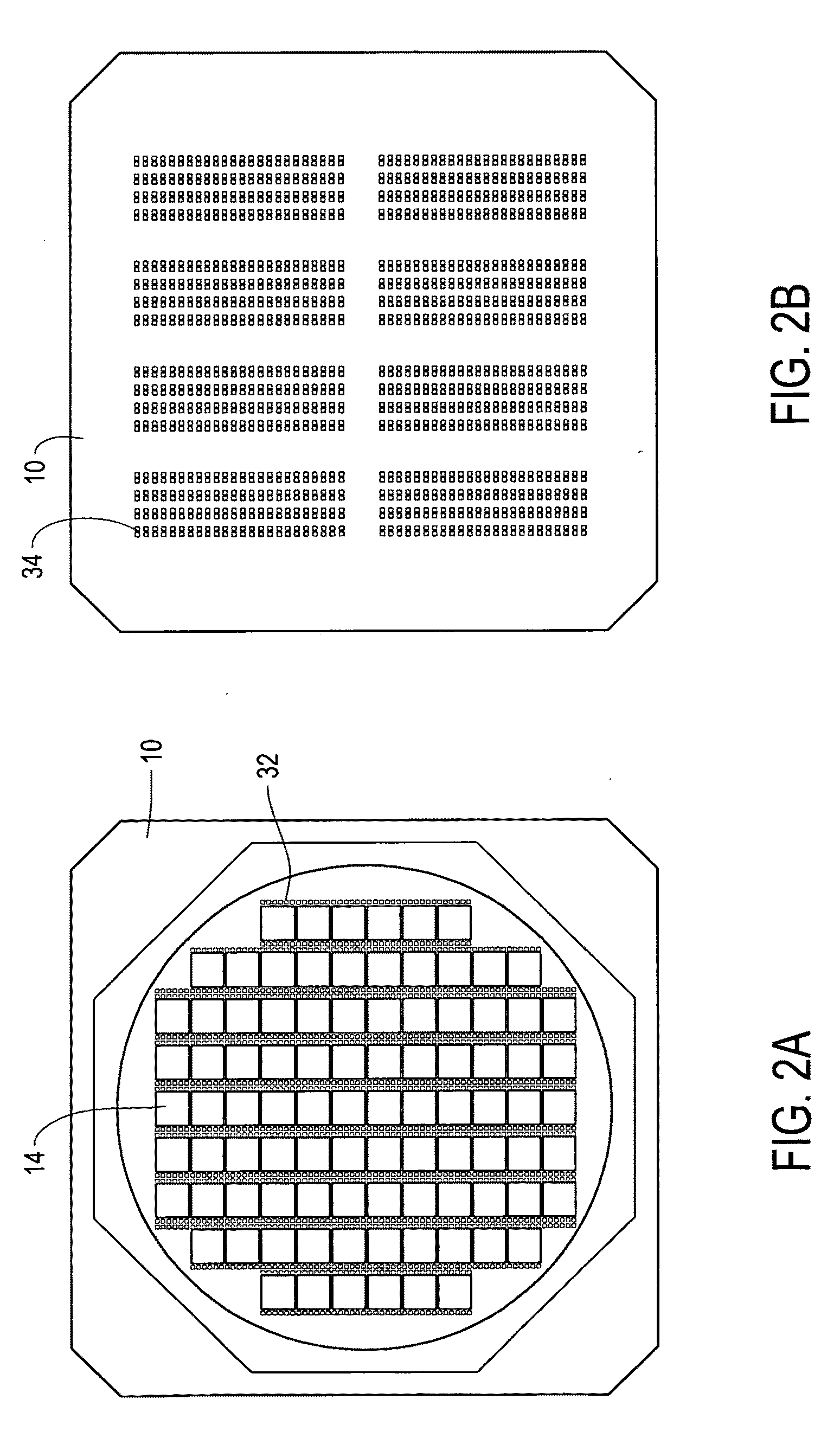

ActiveUS20100118168A1Reduction factorImprove thermal conductivityTelevision system detailsTelevision system scanning detailsHigh densityThermal expansion

A composite focal plane assembly with an expandable architecture has a multi-layer, double-sided aluminum nitride (AlN) substrate and vertical architecture to achieve the dual function of focal plane and electronics backplane. Imaging dice and other electrical components are mounted and wire bonded to one surface and then direct backplane connectivity is provided on the opposing surface through a matrix of electrical contacts. In one embodiment, a flexible connector is sandwiched between the AlN focal plane and a FR-4 backplane is used to compensate for differences in coefficient of thermal expansion (CTE) between the AlN and commercially available high density circuit card connectors that are commonly manufactured from materials with CTE properties more closely approximating FR-4. In an alternate embodiment, the FR-4 and flexible connectors are eliminated by using high density circuit card connectors that are fabricated out of materials more closely matching the CTE of AlN.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

Thermosetting resin composition, b graded resin film, metal foil, copper-clad board and multi-layer lamination substrate

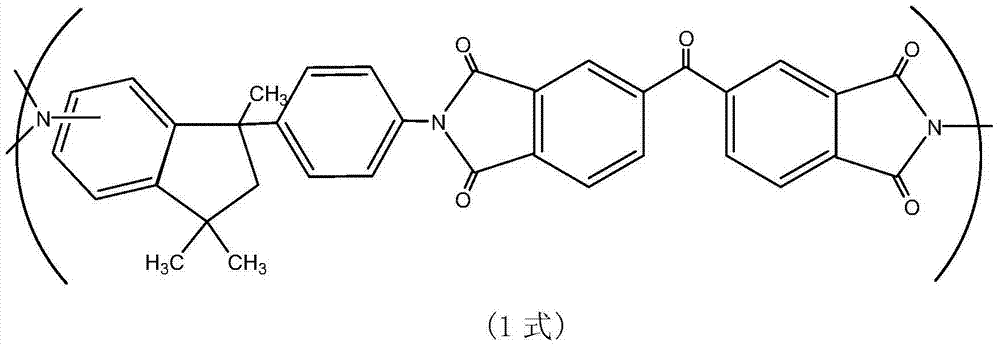

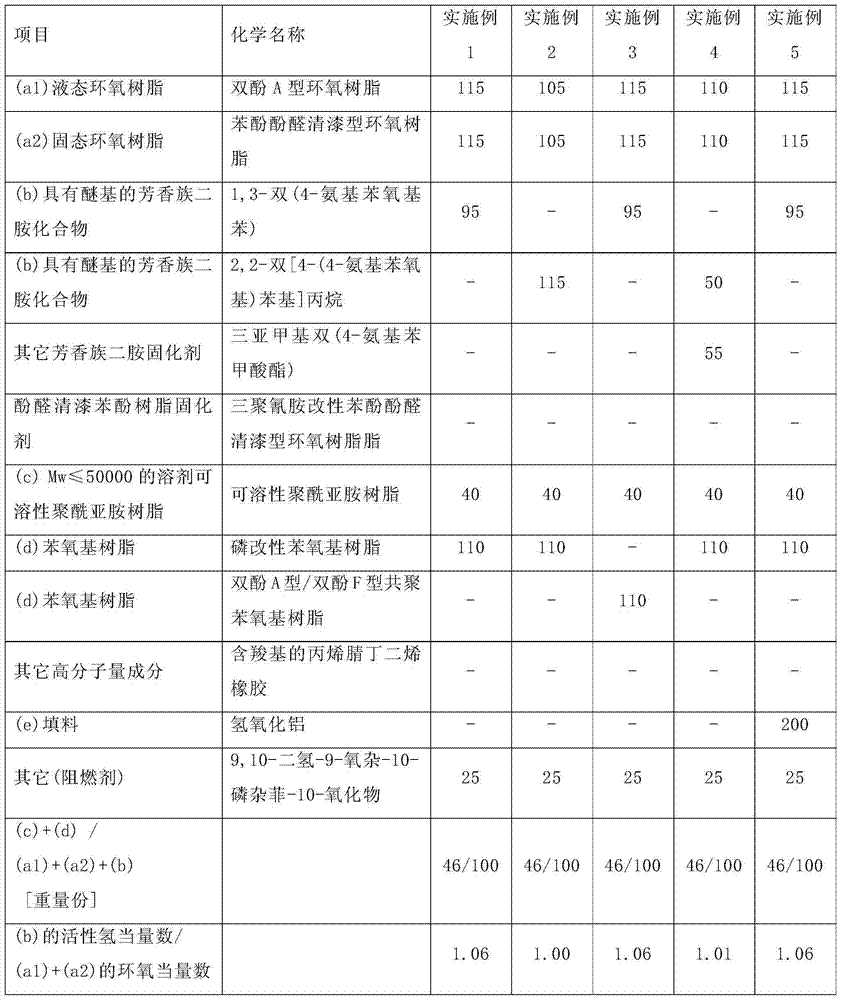

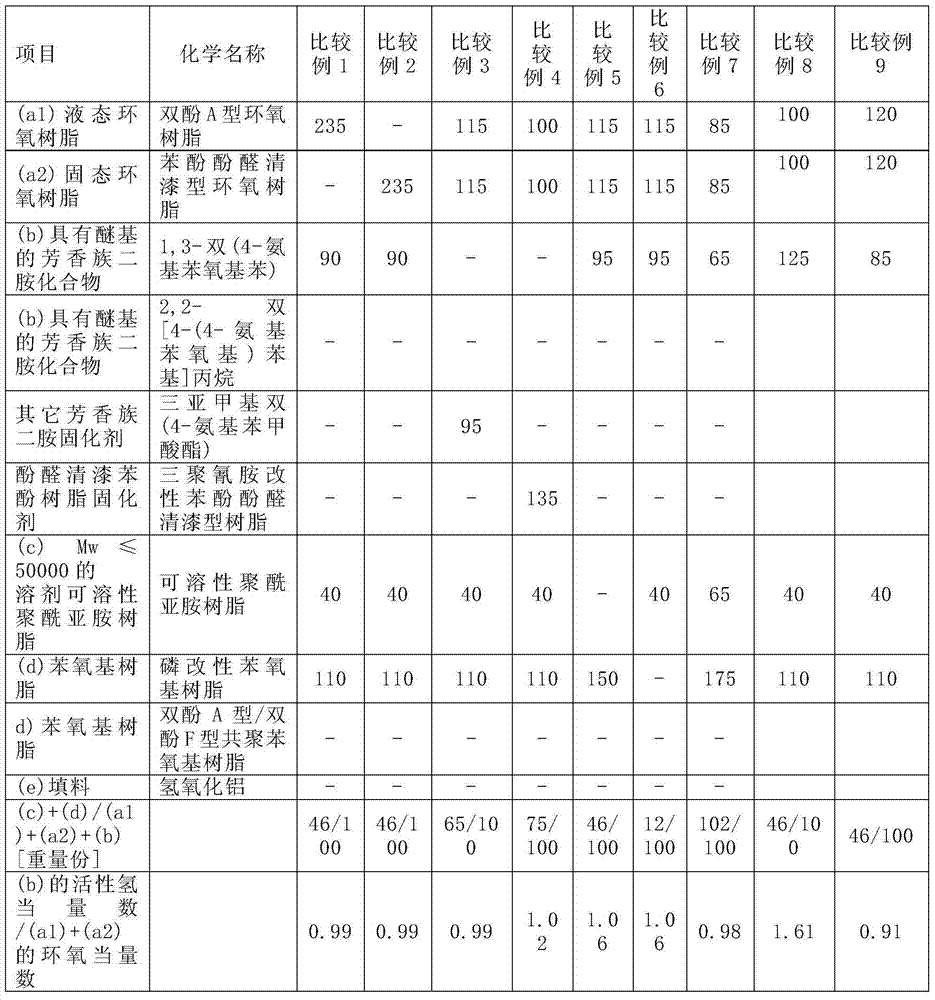

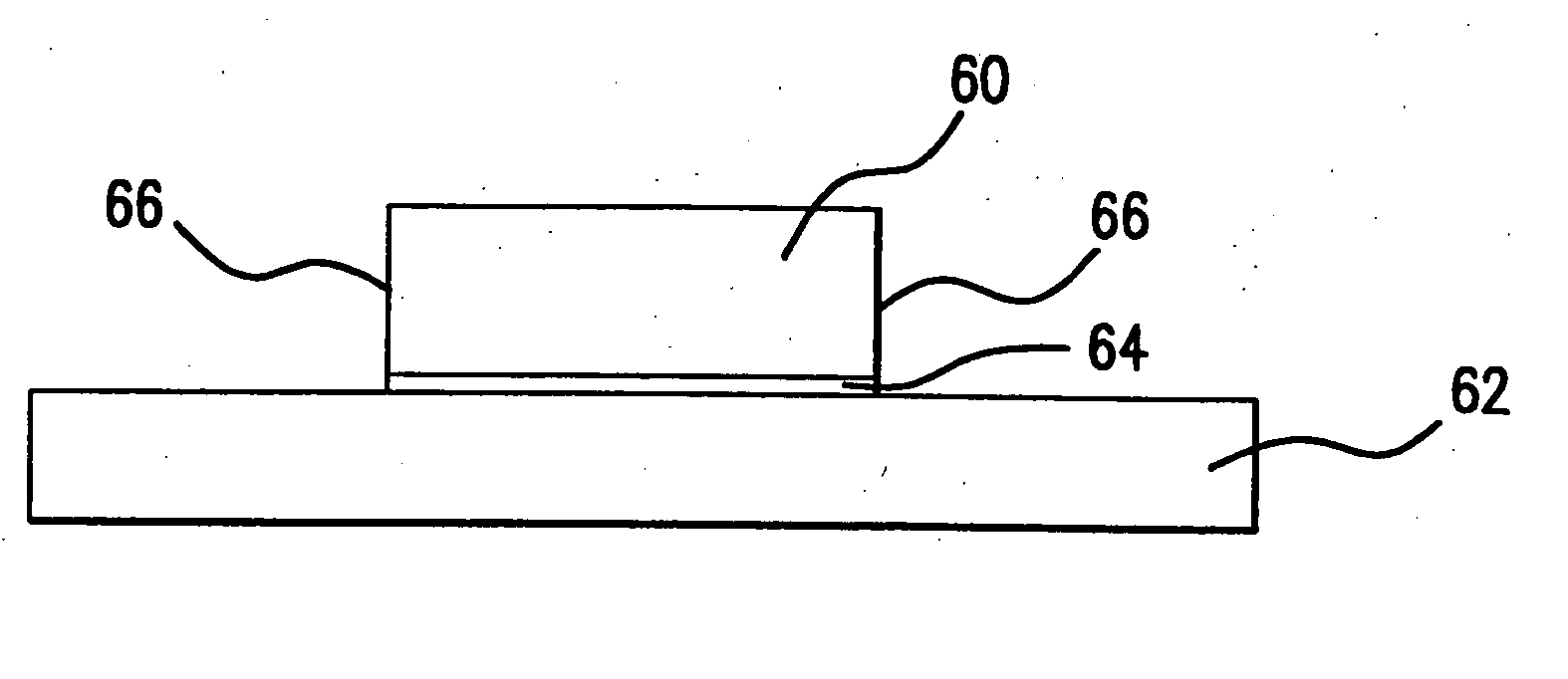

InactiveCN103665762AMeet bending performanceMeet reliabilitySynthetic resin layered productsMetal layered productsEpoxyInsulation layer

The invention aims to provide an epoxy thermosetting resin composition that can be bent and have a film insulation layer, has reliability and processing characteristic that compare favourably with halogen-free FR-4, and is low in fluidity in a vacuum pressing process. The thermosetting resin composition includes (a1) liquid epoxy resin; (a2) solid epoxy resin; (b) aromatic diamidogen compound with ether group; (c) solvent soluble polyimide resin with weight-average molecular weight below 50000; and (d) phenoxy resin. The amount of (c) solvent soluble polyimide resin with weight-average molecular weight below 50000 and (d) phenoxy resin is more than 15 parts by weight and less than 100 parts by weight when the total amount of the (a1) liquid epoxy resin, (a2) solid epoxy resin, (b) aromatic diamidogen compound is arranged to be 100 parts by weight.

Owner:TAMURA KK

Laser ablation resistant copper foil

InactiveUS20050118448A1Flat surfaceInsulating substrate metal adhesion improvementChromatisationEpoxyDielectric substrate

A copper foil for lamination to a dielectric substrate iscoated with a laser ablation inhibiting layer having an average surface roughness of less than 0.7 micron and an average nodule height of less than 0.75 micron that is effective to provide a lamination peel strength to FR-4 of at least 4.5 pounds per inch. The foil is typically laminated to a dielectric substrate, such as glass reinforced epoxy or polyimide and imaged into a plurality of circuit traces. Blind vias may be drilled through the dielectric terminating at an interface between the foil and the dielectric. The coated foil of the invention resists laser ablation, thereby resisting piercing of the foil by the laser during drilling.

Owner:OLIN CORP

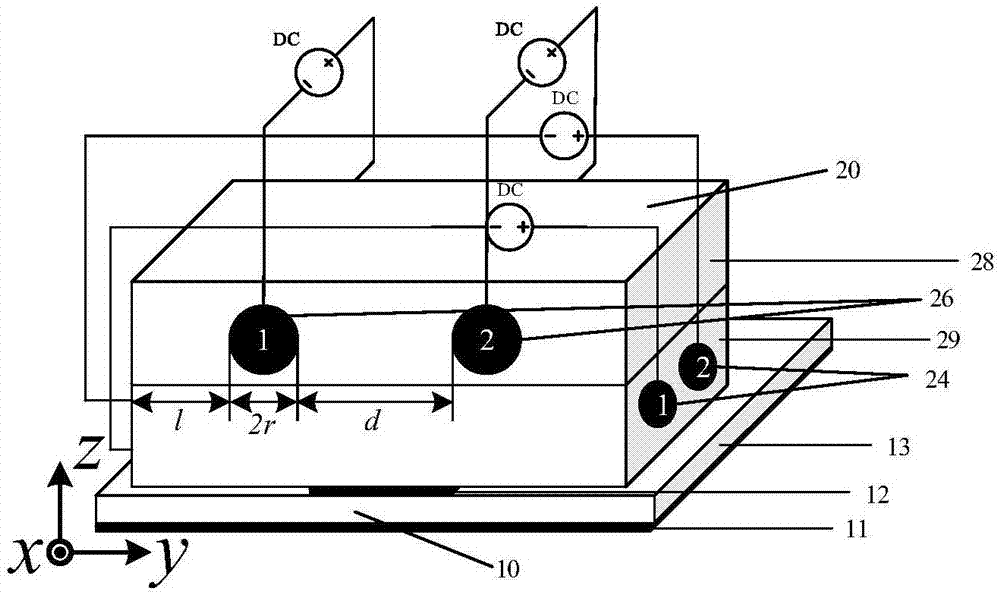

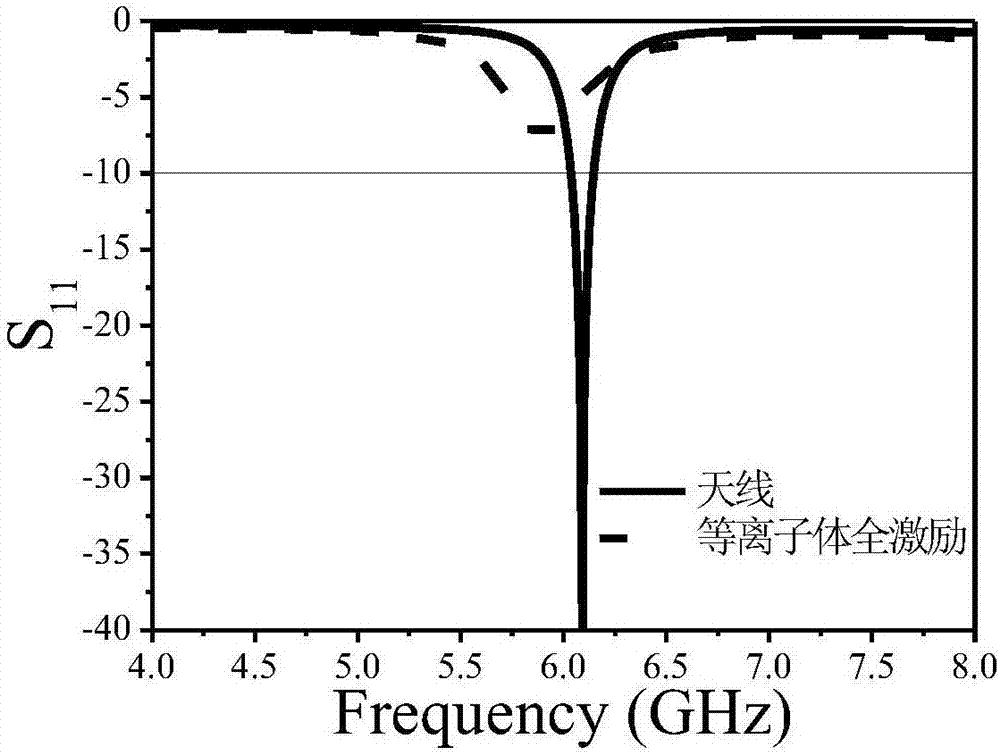

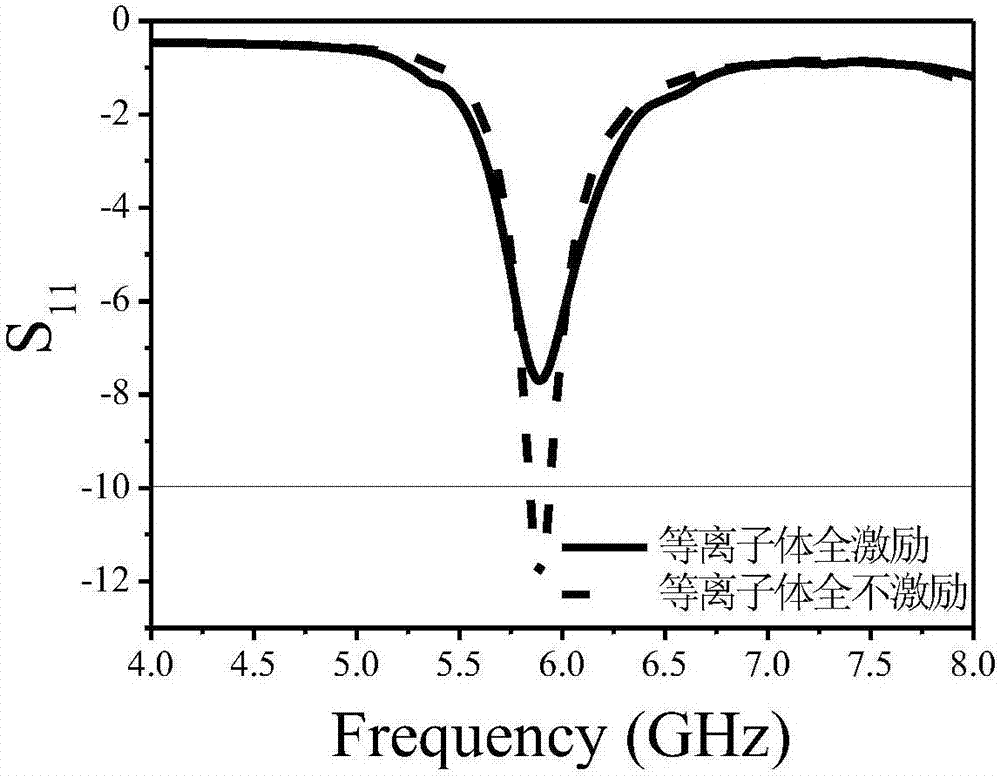

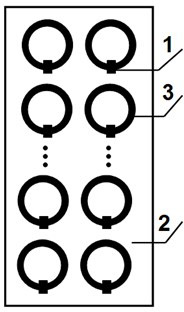

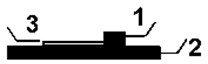

Programmable plasma dielectric antenna

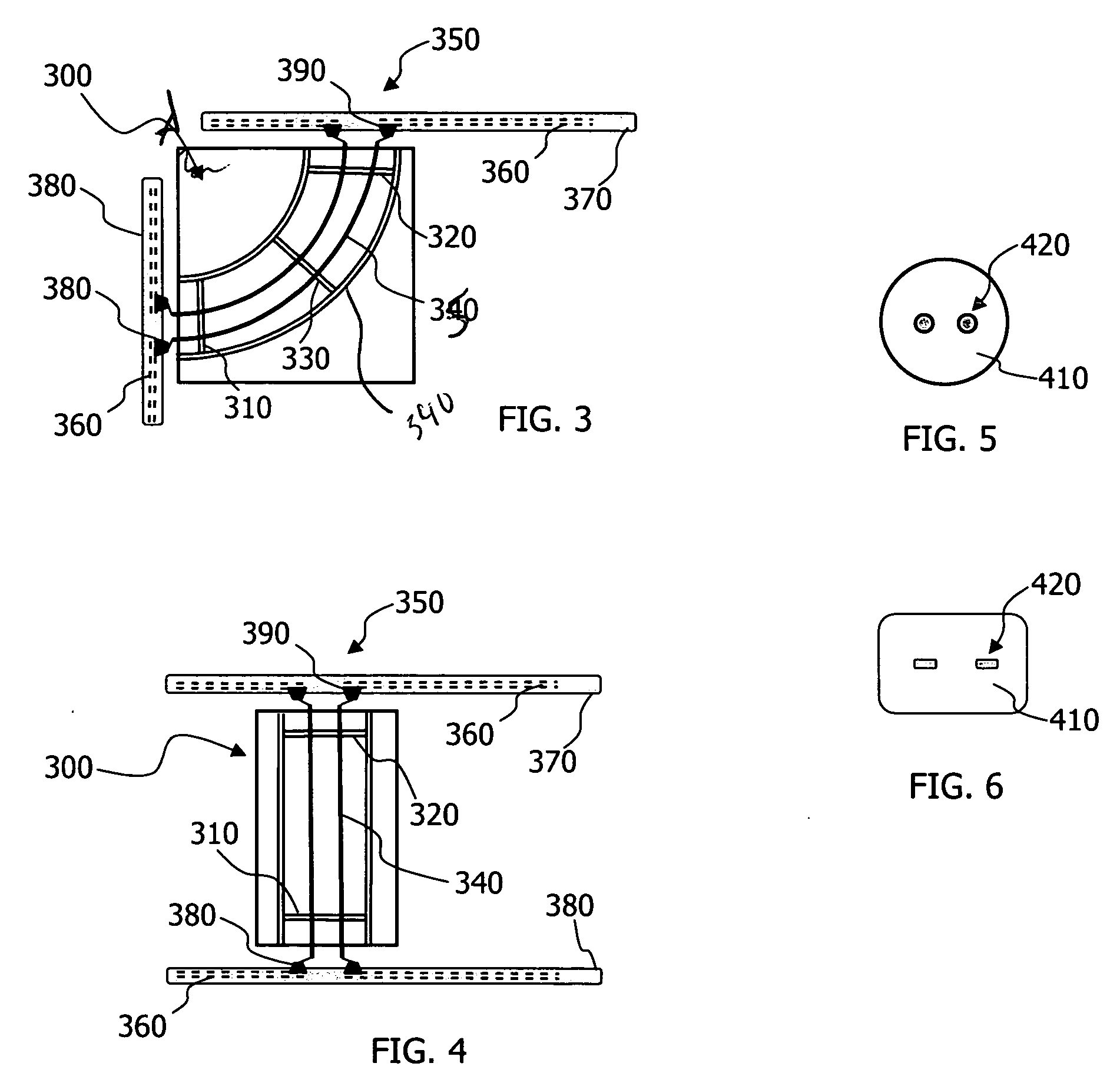

ActiveCN107230831AReconfigurableFlexible designSimultaneous aerial operationsRadiating elements structural formsMode controlControl line

The present invention discloses a programmable plasma dielectric antenna. The antenna comprises a patch antenna and a dielectric resonator. The dielectric resonator comprises at least two layers of solid-state FR-4 dielectrics, wherein the solid-state FR-4 dielectrics are arranged in an up-and-down manner; and multiple gas-state plasma column dielectrics. An upper layer FR-4 dielectric is provided with at least two upper layer FR-4 dielectric perforations, a lower layer FR-4 dielectric is provided with at least two lower layer FR-4 dielectric perforations, the plasma column dielectrics are embedded in the upper layer FR-4 dielectric perforations and the lower layer FR-4 dielectric perforations, and each of the upper layer plasma column dielectrics and lower layer plasma column dielectrics is connected with an excitation power supply via control lines separately. By using a double terminal excitation mode controlled by an independent power supply, excitation states of every plasma column dielectric are controlled; voltages of every excitation power supply are changed to control plasma frequency of the plasma column dielectrics, so that the reconstruction of the working state and frequency of the programmable plasma dielectric antenna is realized. The programmable plasma dielectric antenna has the advantages of simple structure, easiness for mass production, adjustable frequency and unlimited working bandwidth.

Owner:NANJING UNIV OF POSTS & TELECOMM +1

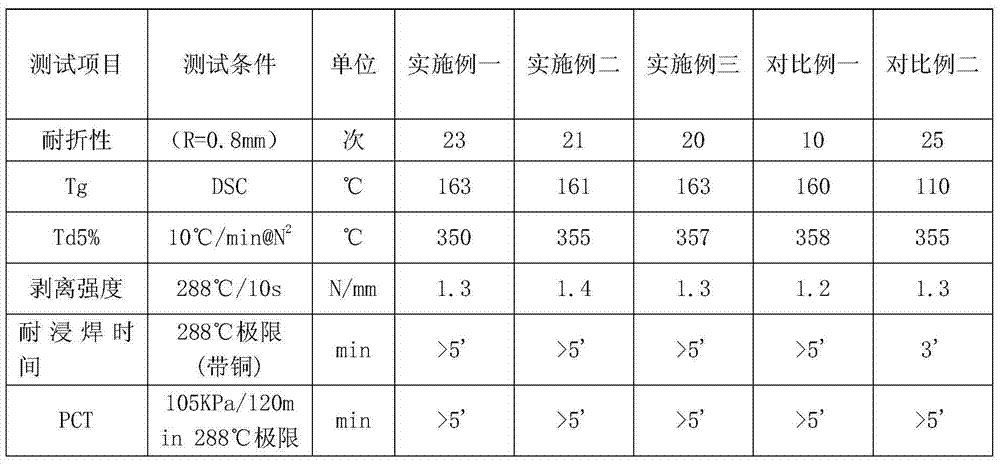

Resin composition and semi-flexible copper-clad plate made from resin composition

ActiveCN103571157AHigh bonding strengthHigh peel strengthLaminationLamination apparatusDimer acidCopper

The invention provides a resin composition and a semi-flexible copper-clad plate prepared from the resin composition. The resin composition comprises the following components in parts by weight of: 60-70 parts of phosphorus-containing epoxy resin, 5-10 parts of novolac epoxy resin, 10-20 parts of bisphenol A epoxy resin modified through dimer acid addition, 10-20 parts of polyurethane modified epoxy resin and 2-4 parts of dicyandiamide. The resin composition is characterized in that the polyurethane modified epoxy resin and the bisphenol A epoxy resin modified through dimer acid addition are introduced so that the tenacity of the system is enhanced and the influence on the Tg of the system is low; as a result, the system is capable of achieving the balance between flexibility and Tg; the semi-flexible copper-clad plate made from resin composition has more excellent flexibility than common FR-4, and is capable of keeping a high Tg value.

Owner:GUANGDONG SHENGYI SCI TECH

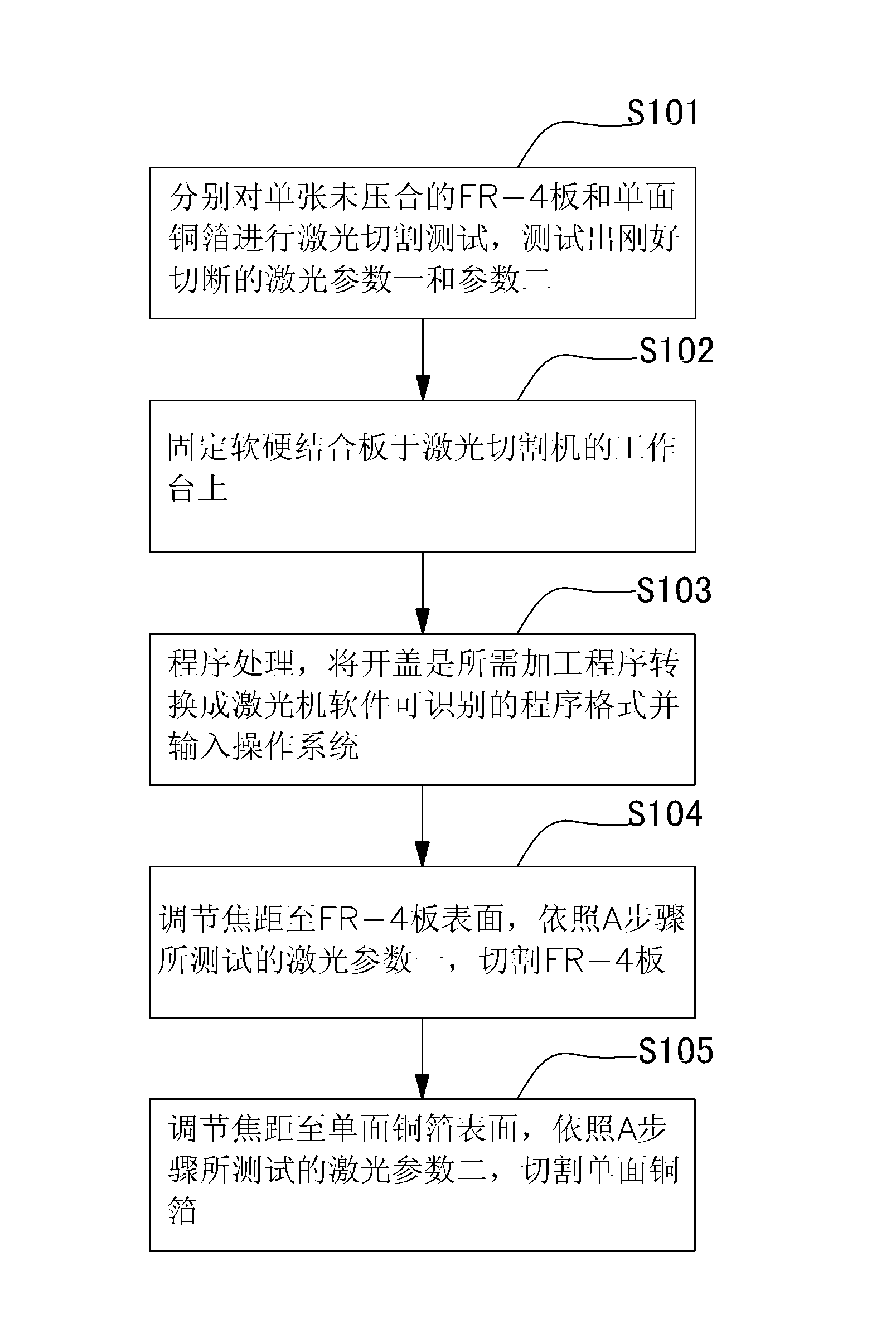

Uncapping method for soft and hard combined plate and operating system thereof

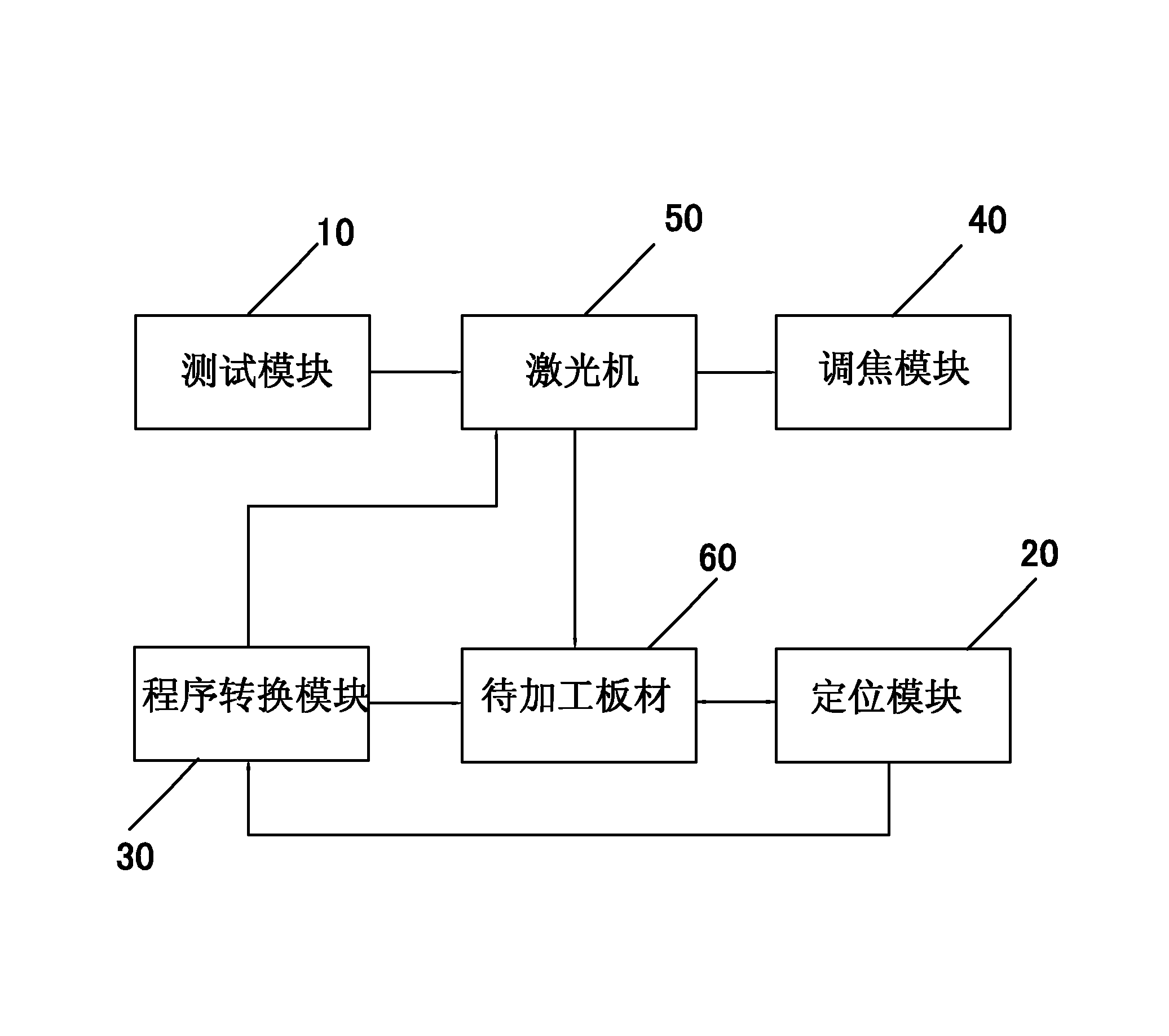

InactiveCN103179789AAvoid injuryImprove uniformityPrinted circuit manufactureLaser beam welding apparatusEngineeringLaser cutting

The invention provides an uncapping method for a soft and hard combined plate. The uncapping method comprises the operating steps of: laminating a layer of single-side copper foil at one side of a FR-4 plate which is near a soft plate and is located at the place where uncapping is necessary in advance; carrying out a laser cutting test on a single un-laminated FR-4 plate and the single-side copper foil respectively so as to obtain a first laser parameter and a second parameter for just cutting off; fixing the soft and hard combined plate on a workbench of a laser cutting machine; carrying out program processing to convert the processing program needed by uncapping into a program format identifiable by software of the laser machine and inputting the program to an operating system; adjusting a focal distance to reach to the surface of the FR-4 plate, and cutting the FR-4 plate based on the tested first laser parameter; and adjusting the focal distance to reach to the surface of the single-side copper foil, and cutting the single-side copper foil based on the tested second laser parameter. Meanwhile, the invention also provides the operating system corresponding to the method. The uncapping method for the soft and hard combined plate avoids damaging the soft plate part during the uncapping process to the maximum extent as the characteristics that the copper foil has good uniformity, and the processing depth is relatively easy to control when the copper foil is cut off are utilized.

Owner:HANS LASER TECH IND GRP CO LTD +1

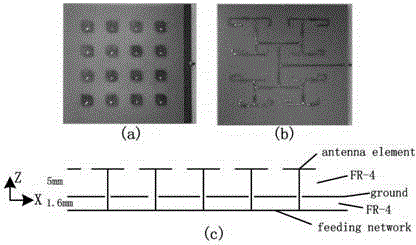

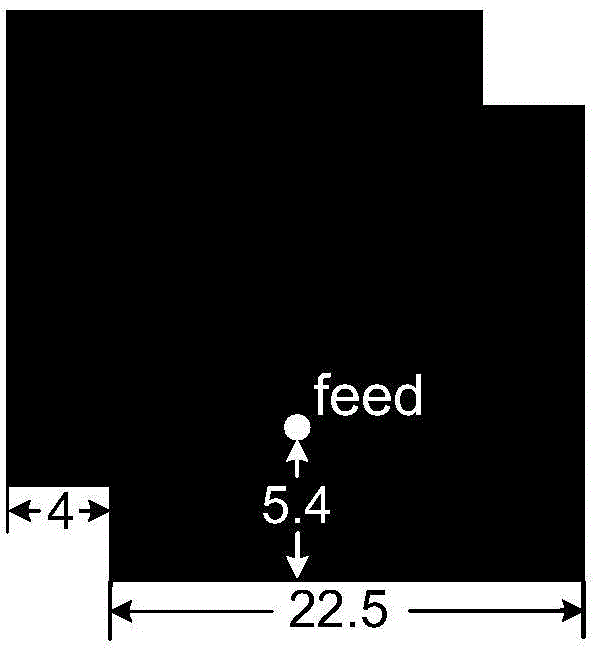

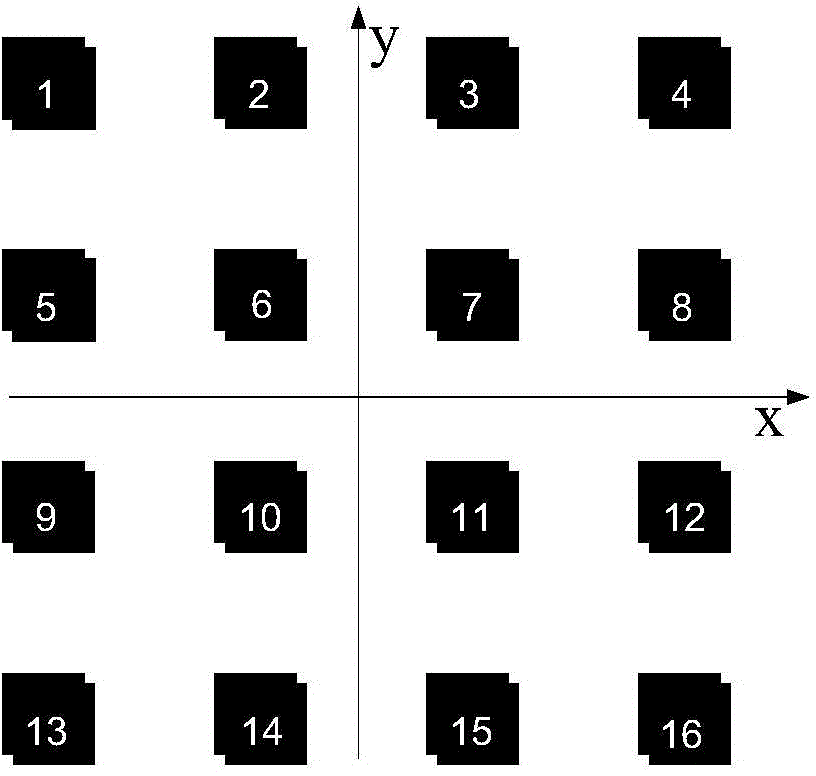

Microstrip array circularly-polarized focusing antenna

InactiveCN104900997AFocusReduce sidelobeAntenna arraysRadiating elements structural formsCircularly polarized antennaDielectric substrate

The invention discloses a microstrip array circularly-polarized focusing antenna. The antenna comprises two dielectric substrates, antenna elements and a feed network. The two dielectric substrates are both made of FR-4 and stacked, the antenna elements is arranged on the upper surface of the upper dielectric substrate; the metal radiation patch and the feed network share a metal grounding surface, and a contact surface is provided for the two dielectric substrates; and the feed network is arranged on the lower surface of the lower dielectric substrate. The circularly-polarized focusing antenna fulfills the purpose of focusing, has good focusing effect, good circular polarization property, good matching and high transmission efficiency, achieves a good focusing effect and enhances the anti-interference performance at the same time.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

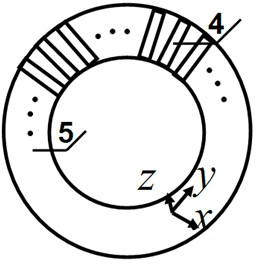

Superlens based on artificial electromagnetic structure in nuclear magnetic resonance imaging

InactiveCN102349831ASimple preparation processStructurally scalableDiagnostic recording/measuringSensorsCapacitanceEngineering

The invention relates to a superlens based on an artificial electromagnetic structure. Traditional equipment restricts the operating frequency and operating bandwidth of electromagnetic superlenses. The superlens comprises an inner fixed ring, an outer fixed ring and a plurality of resonance units, wherein the resonance units are vertically arranged between the inner fixed ring and the outer fixed ring; the inner and outer fixed rings are concentrically arranged; the plurality of resonance units are uniformly distributed with the circle center as the center; each resonance unit comprises an elongated FR-4 substrate, a plurality of LC loop resonance units and a plurality of nonmagnetic load capacitors; the LC loop resonance units are transversely and longitudinally distributed on the elongated FR-4 substrate uniformly; each LC loop resonance unit corresponds to a nonmagnetic load capacitor; and the nonmagnetic load capacitors are mounted at the openings of the LC loop resonance units. The superlens has the following beneficial effects: the manufacturing process is simple and the structure is extensile; and high spatial resolution and signal to noise ratio can be realized by introducing the resonance unit structures to the conventional nuclear magnetic resonance imaging equipment.

Owner:ZHEJIANG UNIV

Surface mountable microwave signal transition block for microstrip to perpendicular waveguide transition

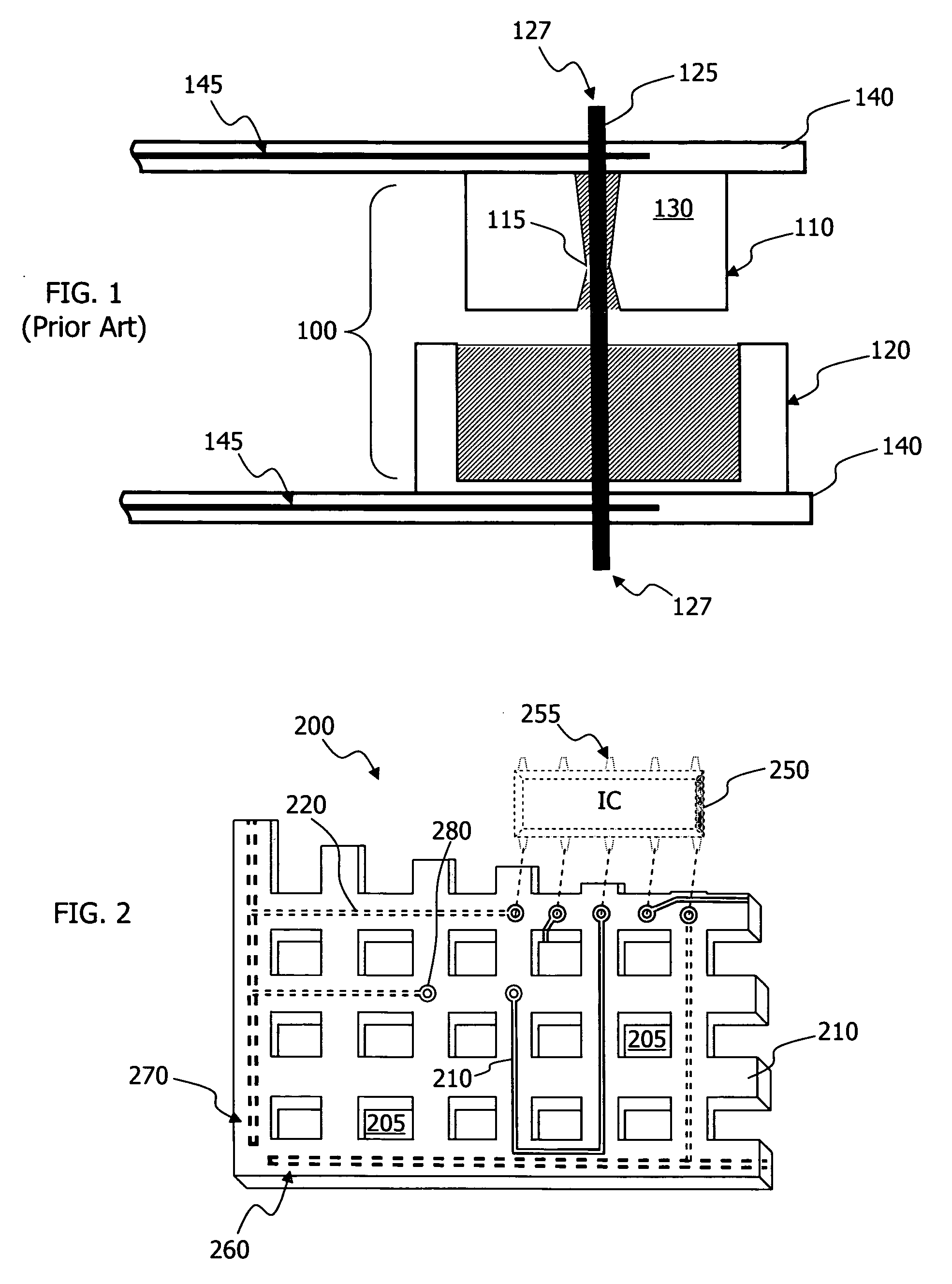

ActiveUS8680936B2One-port networksSemiconductor/solid-state device detailsSurface mountingBand shape

A surface mountable transition block for perpendicular transitions between a microstrip or stripline and a waveguide. The transition block configuration allows for a reduction in the overall cost of a microwave circuit assembly because the circuit board to which the transition block is attached can be an FR-4 type circuit board as opposed to more expensive microwave circuit board materials.

Owner:APTIV TECH LTD

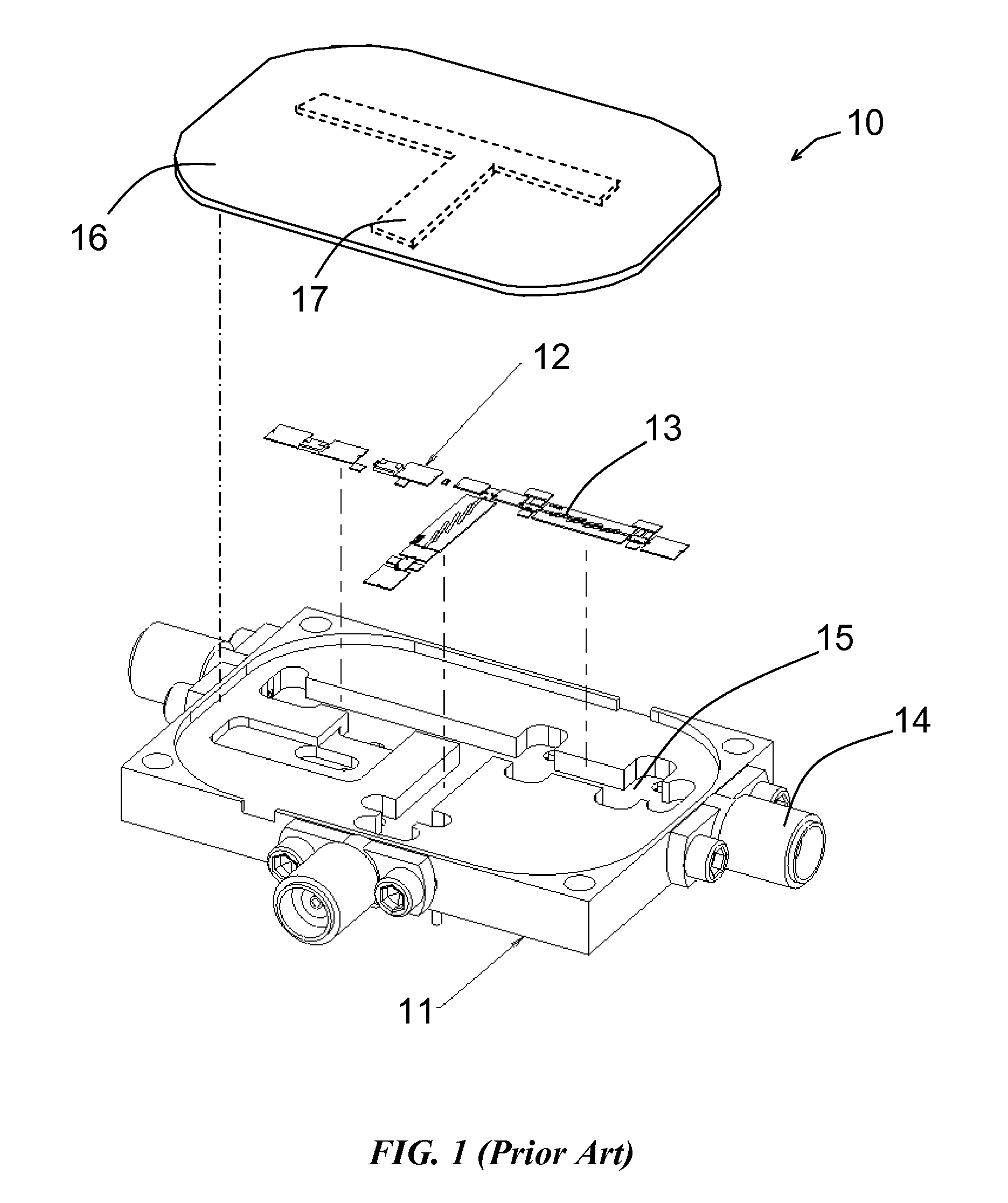

Set-top box having an improved patch antenna

InactiveUS7071883B2Reduces and eliminates interfering effectSolve the real problemSimultaneous aerial operationsAntenna supports/mountingsMetallic enclosureEngineering

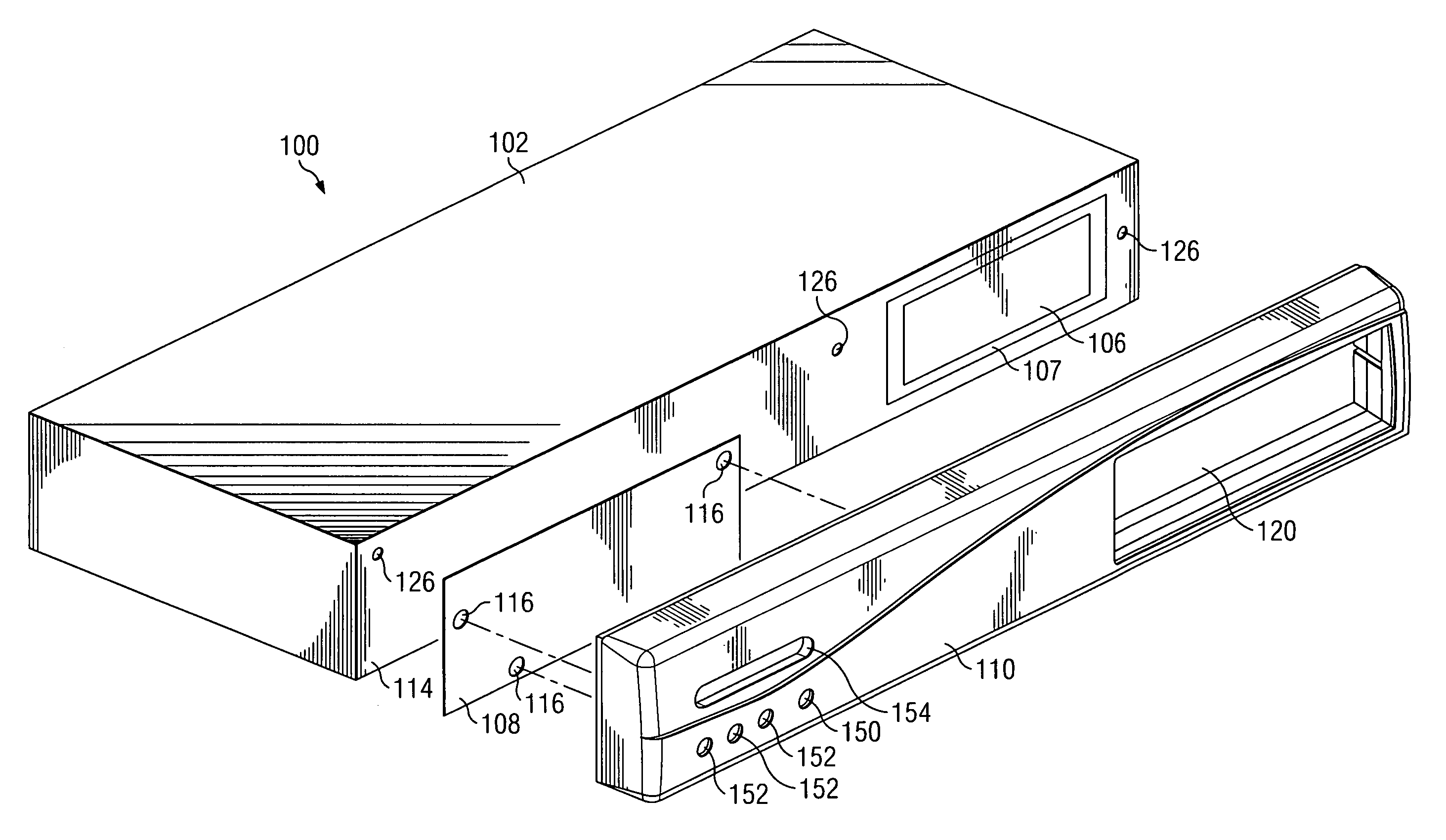

A set top box is provided with a patch antenna to wirelessly communicate with other devices. In one embodiment, the set top box has a metallic enclosure with a non-metallic bezel covering the front of the device. A communication circuit board with an imprinted patch antenna is located in the interstitial space between the metallic enclosure and the non-metallic bezel. The communications board preferably comprises a thin (0.06 inch) FR-4 circuit board with etched copper cladding. The patch antenna preferably comprises a ground plane on one side of the circuit board, and a rectangular patch on the opposite side of the circuit board. The patch is side-fed by a microstrip feed. The dimensions of the antenna are selected to optimize the antennas performance in frequency range between 2.400 and 2.483 GHz when located in the above-described interstitial space.

Owner:EAGLE BROADBAND

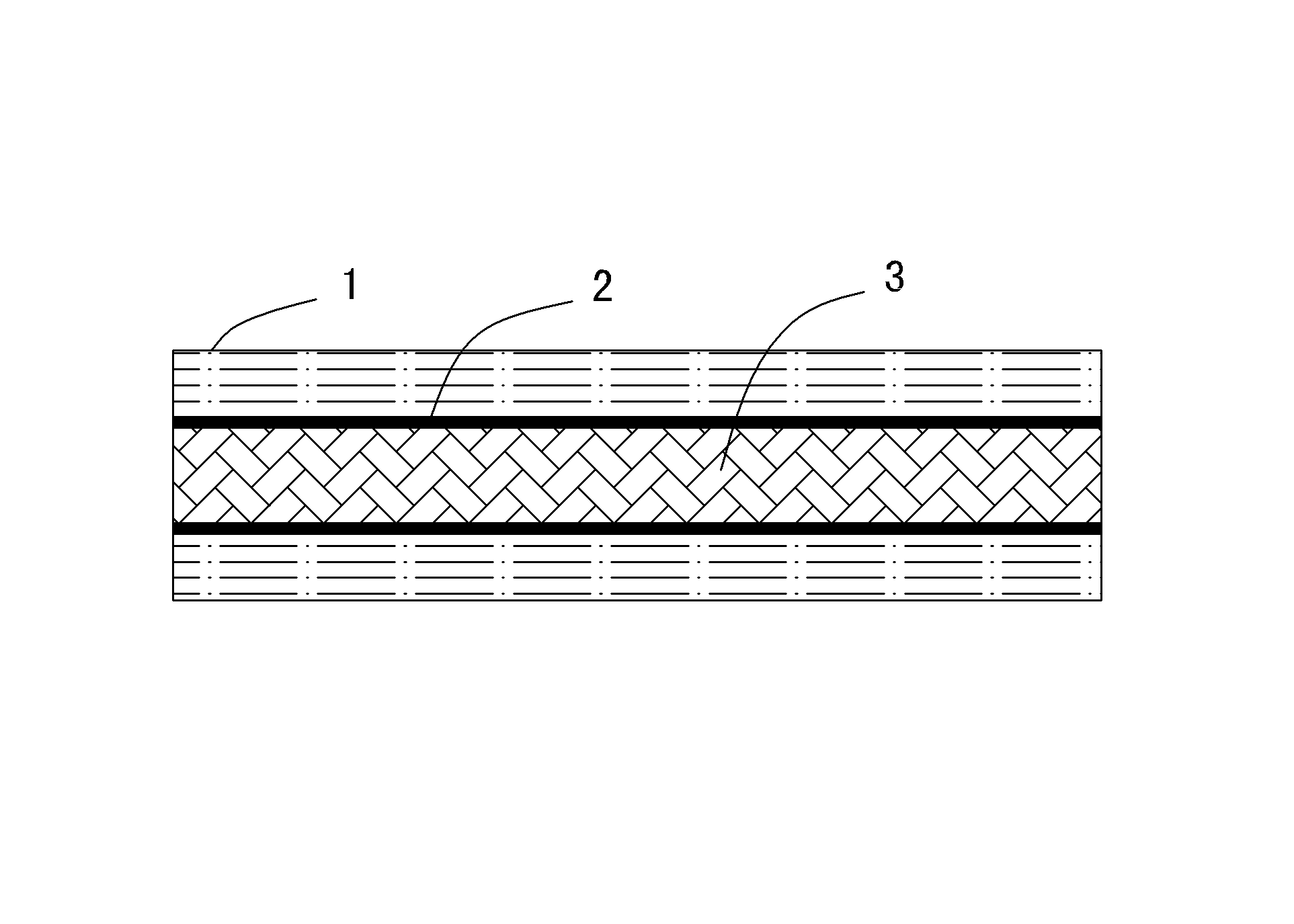

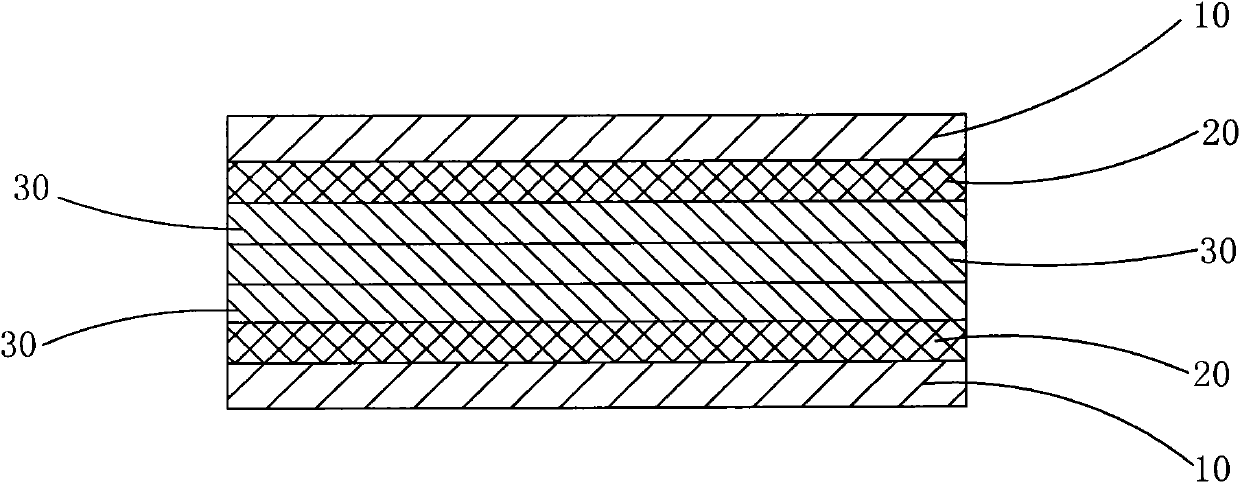

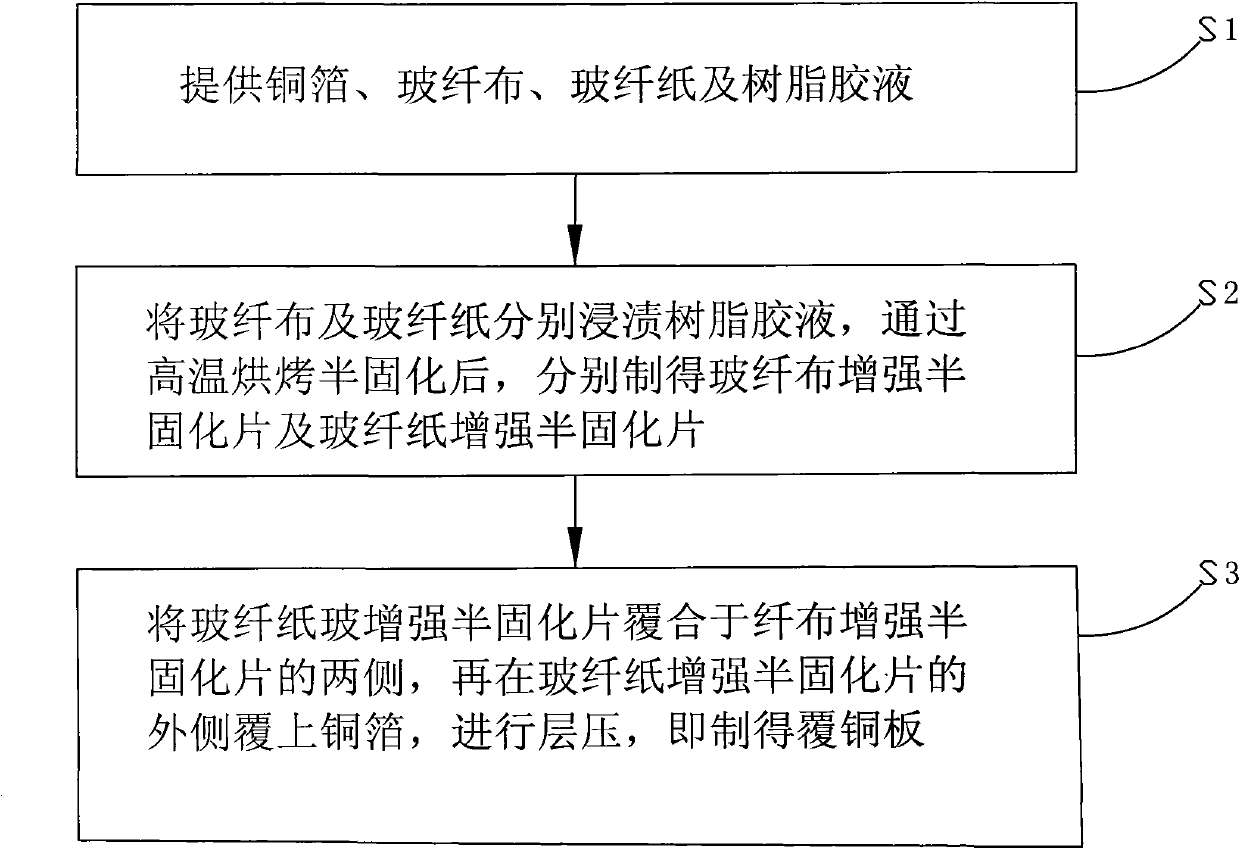

Copper-clad board and production method thereof

InactiveCN102029746AImprove heat resistanceImprove reliabilityLamination ancillary operationsLaminationGlass fiberFiber

The invention relates to a copper-clad board and a production method thereof. The copper-clad board comprises at least one layer of glass fiber-reinforced prepreg, glass fiber paper-reinforced prepregs and copper foils, wherein the glass fiber paper-reinforced prepregs are compounded on two sides of the glass fiber-reinforced prepreg; and the copper foils are compounded on the glass fiber-reinforced prepreg. The copper-clad board has a novel structure; compared with the traditional FR-4(Fiber Epoxy Resin-4), CEM-3 (Composite Epoxy Material Grade-3) and the like, the copper-clad board has the advantages that the probability of weavy grain white points of a substrate is greatly reduced and the heat resistance and the electrical reliability of the copper-clad board are improved; and the copper-clad board has lower bending strength and better bendability and flexibility and better meets the requirement for the development of the modern electronic technology. In addition, the production method of the copper-clad board is simple and feasible.

Owner:GUANGDONG SHENGYI SCI TECH

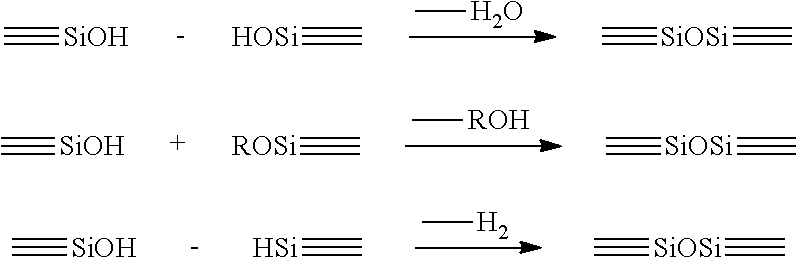

Ceramized Silicone Resin Composition and Pre-preg and Laminate that Use the Composition

ActiveUS20170355851A1Certain strengthImprove heat resistanceSynthetic resin layered productsVehicle componentsPassive fire protectionFire resistance

The present invention relates to a ceramized silicone resin composition and a pre-preg and a laminate that use the composition. The ceramized silicone resin composition comprises: 50-100 parts of a condensation-type silicone resin, 0.0001-2 parts of a catalyst, 5-80 parts of a ceramic-forming filler, and 0.01-50 parts of a flux. The pre-preg and the laminate manufactured using the ceramized silicone resin composition, when used in a sustained high temperature, can transform into complex ceramized structure thereby providing ceramic properties, thus providing great fireproof and flame retardant effects; also, manufacturing of the laminate is similar to that of a regular FR-4 laminate, where the process is easy to operate. The ceramized silicone resin composition, the pre-preg, and the laminate have the advantages of being halogen-free, low smoke, low toxicity, flame retardant, and fireproof, provide a novel concept and a novel method in terms of flame retardancy and fire resistance, accelerate the research progress in laminate passive fire protection technology, and have broad prospects in the field of fire protection and fire resistance.

Owner:GUANGDONG SHENGYI SCI TECH

Manufacturing process for ultra-thick copper PCB (printed circuit board)

InactiveCN105555043AGuaranteed alignmentEasy to shapePrinted circuit aspectsCircuit precursor manufactureCooking & bakingMaterials preparation

The invention relates to the technical field of production and manufacturing of a printed circuit board, and specifically to a manufacturing process for an ultra-thick copper PCB (printed circuit board). The manufacturing process comprises the following steps of (1) material preparation: taking FR-4 as the base material, wherein the plate is 1.6-1.7mm in thickness, and copper is 137-138um in thickness; (2) drilling and positioning; (3) performing pattern conversion; (4) performing pattern electroplating; (5) performing film removal and etching; (6) performing solder resist: manufacturing the plate by a way of two times of ink stamping, wherein a 43T screen printing plate is adopted in the first time, and a 77T screen printing plate is adopted after a pre-baking process is carried out for performing the second time of ink stamping; and then performing plate baking after a normal motionless state is achieved; (7) curing after solder resist: performing curing in different stages and further baking for 30-40 min at the maximum temperature; (8) regulating copper thickness; (9) hole modifying; (10) testing; (11) outline repairing; and (12) finished product checking. According to the manufacturing process, two times of dry film laminating for overlapping the circuits layer by layer are adopted for manufacturing the ultra-thick copper PCB so as to obtain a relatively ideal process route; and therefore, the alignment of the circuit can be ensured, and the phenomenon of a mushroom-shaped circuit also can be effectively avoided as well.

Owner:东莞翔国光电科技有限公司

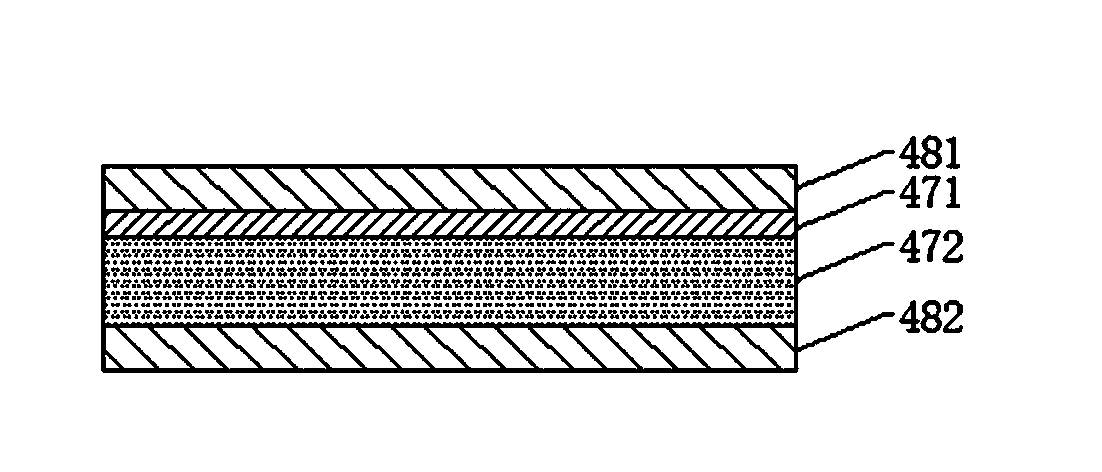

Heat-dissipating aluminum-based circuit board

InactiveCN103547066AImprove thermal efficiencySimple structureCircuit susbtrate materialsCopper foilAluminum substrate

The invention discloses a heat-dissipating aluminum-based circuit board which is formed by press fit of a double-faced copper clad laminate, a dielectric layer and an aluminum substrate. The double-faced copper clad laminate is a flexible copper foil heat-conductive substrate composed of a first foil layer, an insulating polymer layer, a heat-conductive adhering layer with dispersed heat-dissipating powder and a second foil layer. The dielectric layer is positioned between the second copper foil layer of the flexible copper foil heat-conductive substrate and the aluminum substrate. High heat conduction efficiency and high insulation breakdown voltage can be achieved while the overall thickness of the flexible copper foil heat-conductive substrate is reduced, and heat impedance of the flexible copper foil heat-conductive substrate is smaller than that of double-faced plates of T-preg, FR-4 and the like, so that the heat-dissipating aluminum-based circuit board has the advantages of simple structure, small overall thickness, low production cost, high heat conduction efficiency, low heat impedance and good insulation performance.

Owner:KUSN APLUS TEC CORP

Electronic component connection support structures including air as a dielectric

ActiveUS7557303B2High frequencyEasy to optimizeHigh frequency circuit adaptationsPrinted circuit aspectsDielectricElectricity

Electronic component supporting mediums includes dielectric support material having voids adapted to include the use of air as a dielectric, which is commonly used in printed circuit boards and electrical connectors. The support medium provides physical support to conductive connections and a mechanical structure to enable electrical connections between electronic components. Support structures including air as a dielectric can be provided in the form of printed circuit boards and electrical connectors. A printed circuit board wherein said dielectric material comprises a low loss material. The support medium can comprise a low loss material such as air, FR-4, Teflon material, and plastic.

Owner:BELL SEMICON LLC

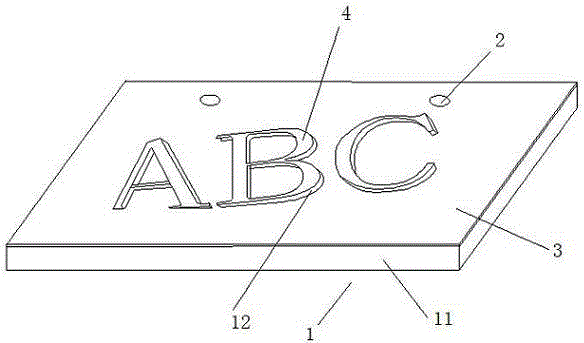

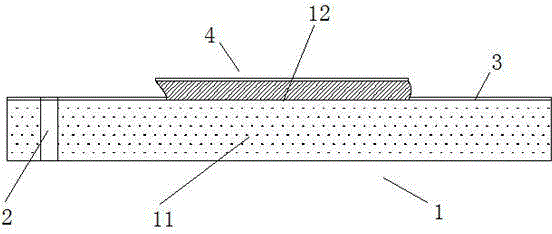

Nameplate with strong durability and manufacturing method thereof

The invention discloses a nameplate with strong durability. The nameplate comprises a base plate. The base plate comprises a bottom plate and a copper foil layer where words or patterns are etched. The base plate is made of FR-4-grade materials composed of epoxy resin and glass fibers. The surface of the bottom plate is coated with photosensitive ink, the copper foil layer is arranged on one side of the bottom plate, and the surface of the copper foil layer is coated with heat solidification type ink. Meanwhile, the invention provides a manufacturing method of the nameplate with strong durability. The nameplate with strong durability is durable in use, strong in corrosion resistance, acid and alkali resistance and wet resistance, not prone to color fading or deformation, firm and stable, clear in name, long in service life, low in cost and capable of utilizing waste materials and saving social resources. The manufacturing method of the nameplate with strong durability is simple in technology and convenient to operate and effectively reduces the production cost.

Owner:BOMIN ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com