Copper-clad board and production method thereof

A manufacturing method and technology of copper clad laminates, applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve the problem of affecting the heat resistance and electrical reliability of printed circuit boards of copper clad laminates, and the white spots of substrate texture , Low resin content and other issues, to achieve the effect of improving heat resistance and electrical reliability, low bending strength, good bendability and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

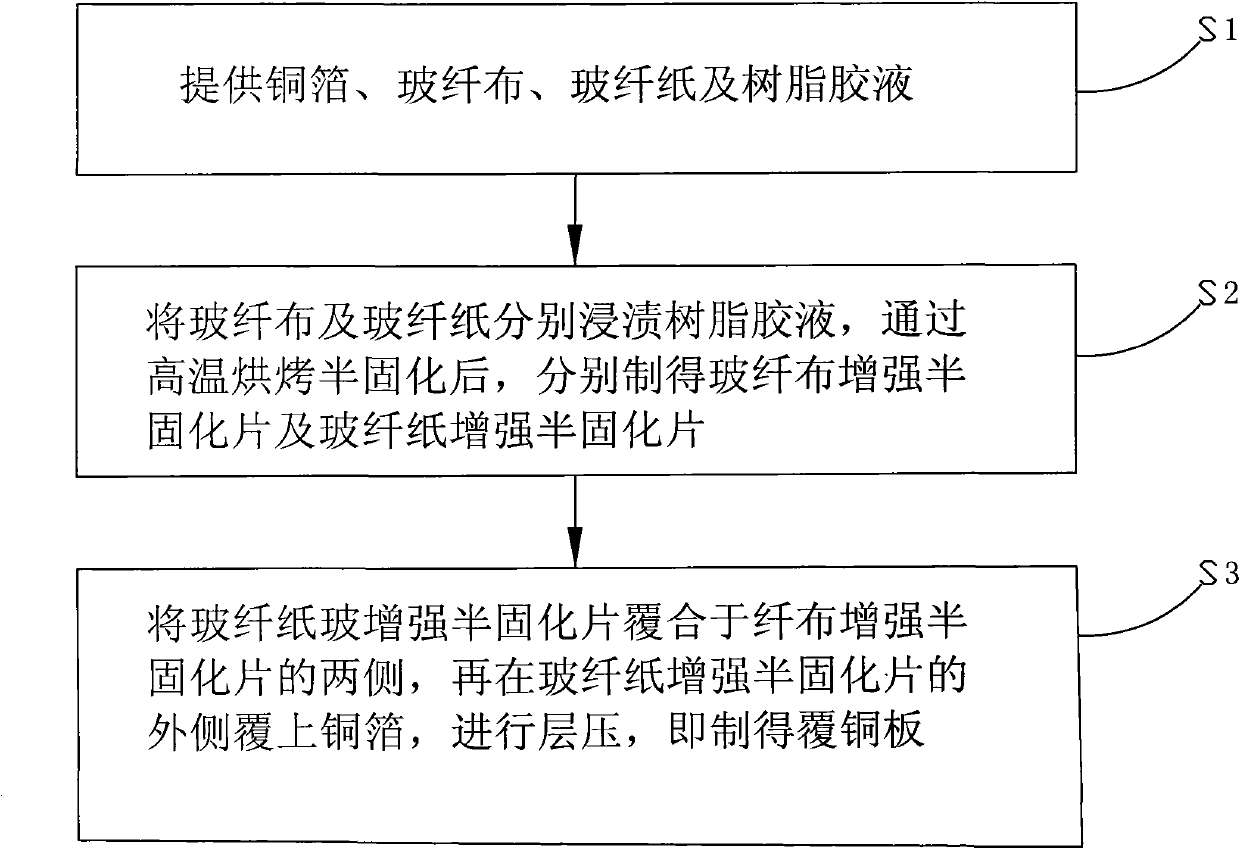

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

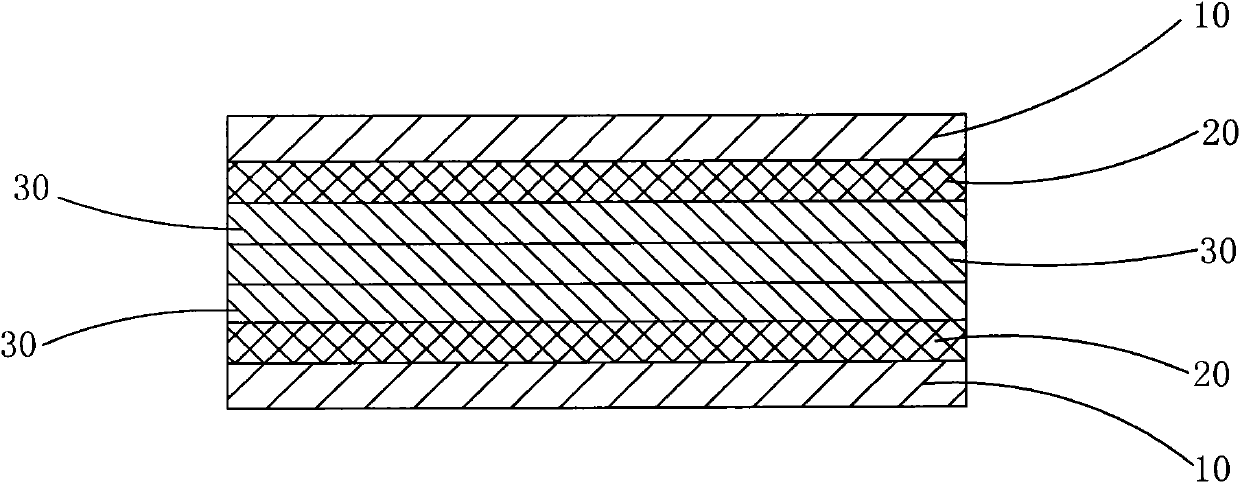

[0026] Such as figure 1 As shown, the copper clad laminate of an embodiment of the present invention includes: at least one layer of glass fiber cloth reinforced prepreg 30, glass fiber paper reinforced prepreg 20 coated on both sides of the glass fiber cloth reinforced prepreg 30, and coated on the glass fiber cloth reinforced prepreg 30. The fiber paper reinforces the copper foil 10 on both sides of the prepreg 20 . In this embodiment, the glass fiber cloth reinforced prepreg 30 has three layers. The copper clad laminate has a low bending strength of 40000-60000PSI (276-414MPa).

[0027] The glass fiber cloth reinforced prepreg 30 includes glass fiber cloth and resin attached thereto after being impregnated and dried, and the glass fiber paper reinforced prepreg 20 includes glass fiber paper and resin attached thereto after impregnated and dried. The resin conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com