Method for producing printed circuit board for local region high frequency circuit by half-addition method

A technology for printed circuit boards and local areas, applied in the direction of circuit substrate materials, printed circuit manufacturing, printed circuits, etc., can solve the problems of low loss, high price, low dielectric, etc., and achieve the effect of reducing use and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

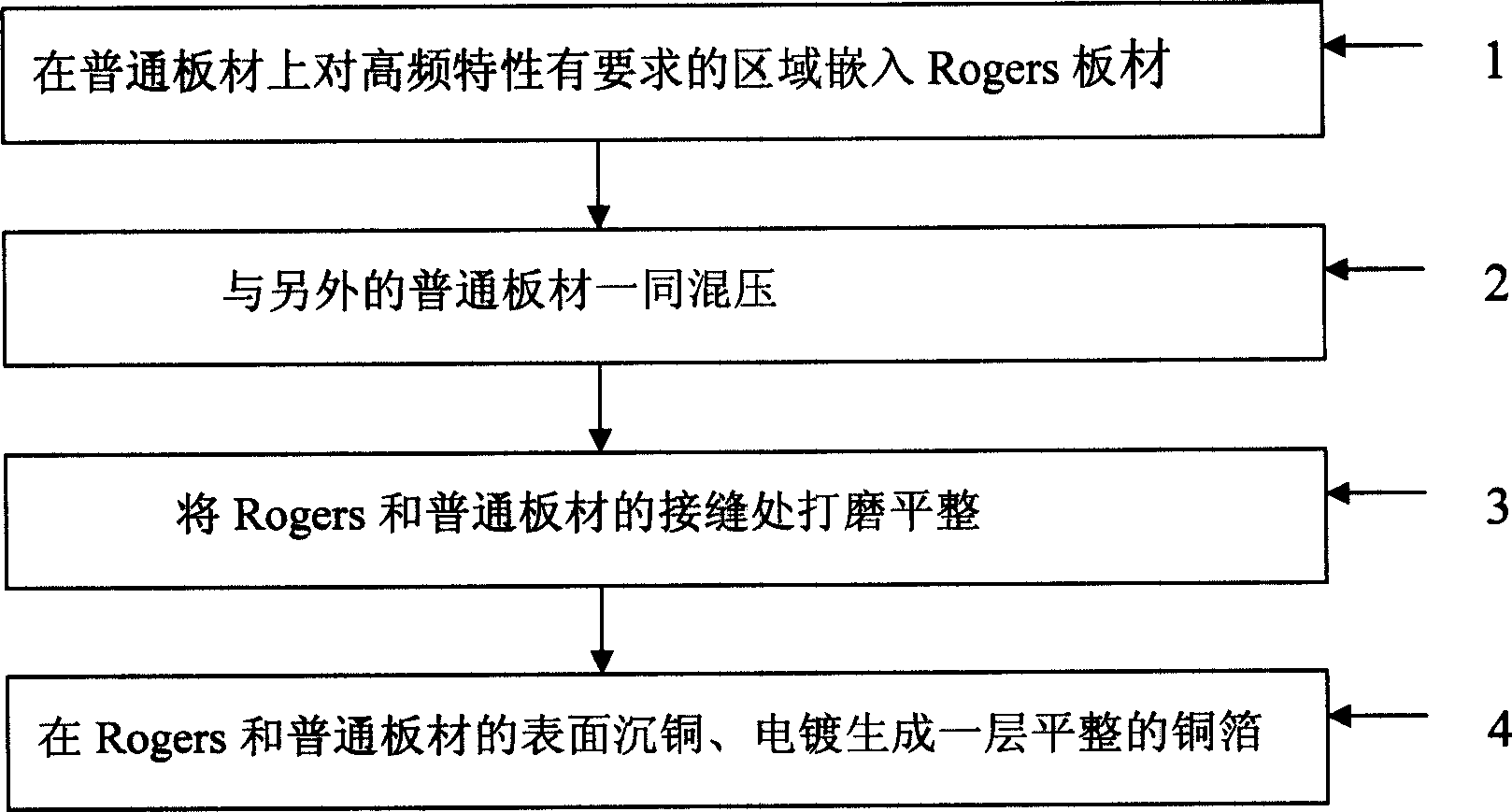

[0018] Such as figure 1 Shown, the semi-additive method of the present invention makes the method for the high-frequency circuit printed circuit board of local area, comprises the following steps:

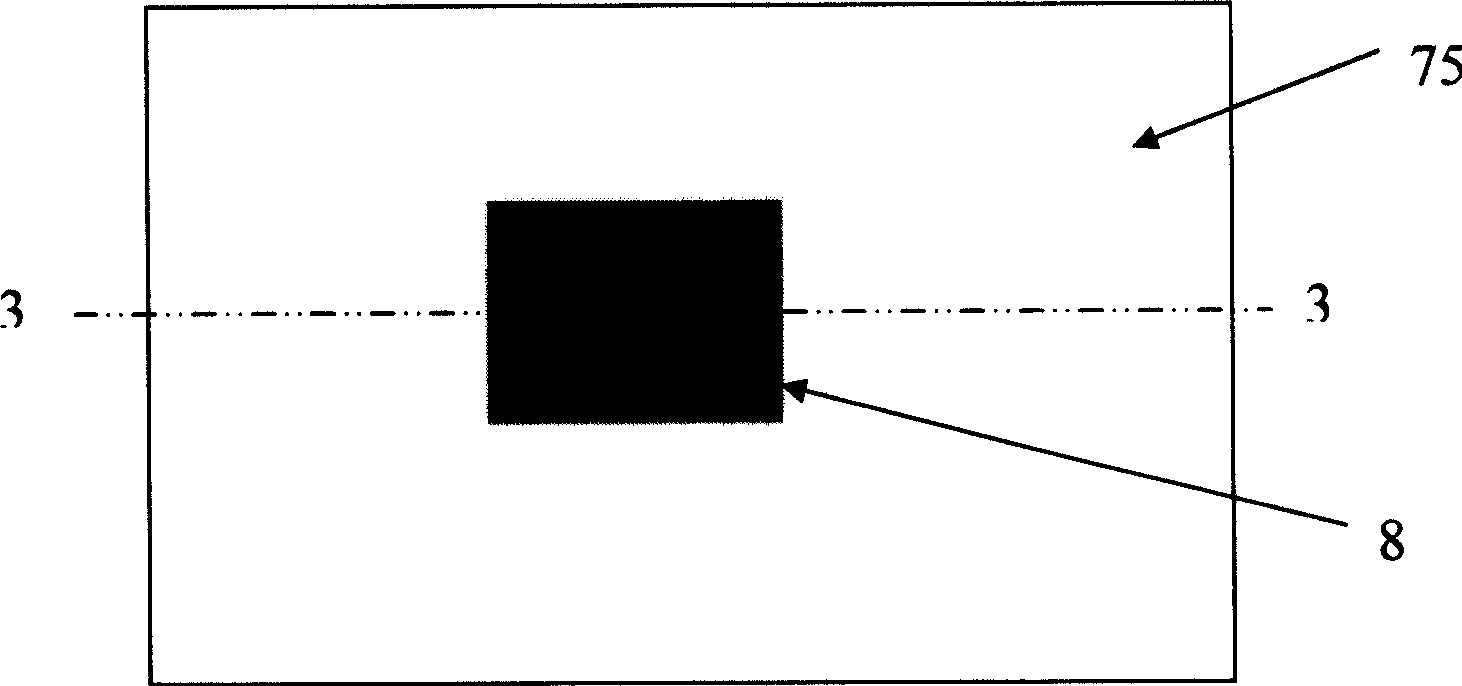

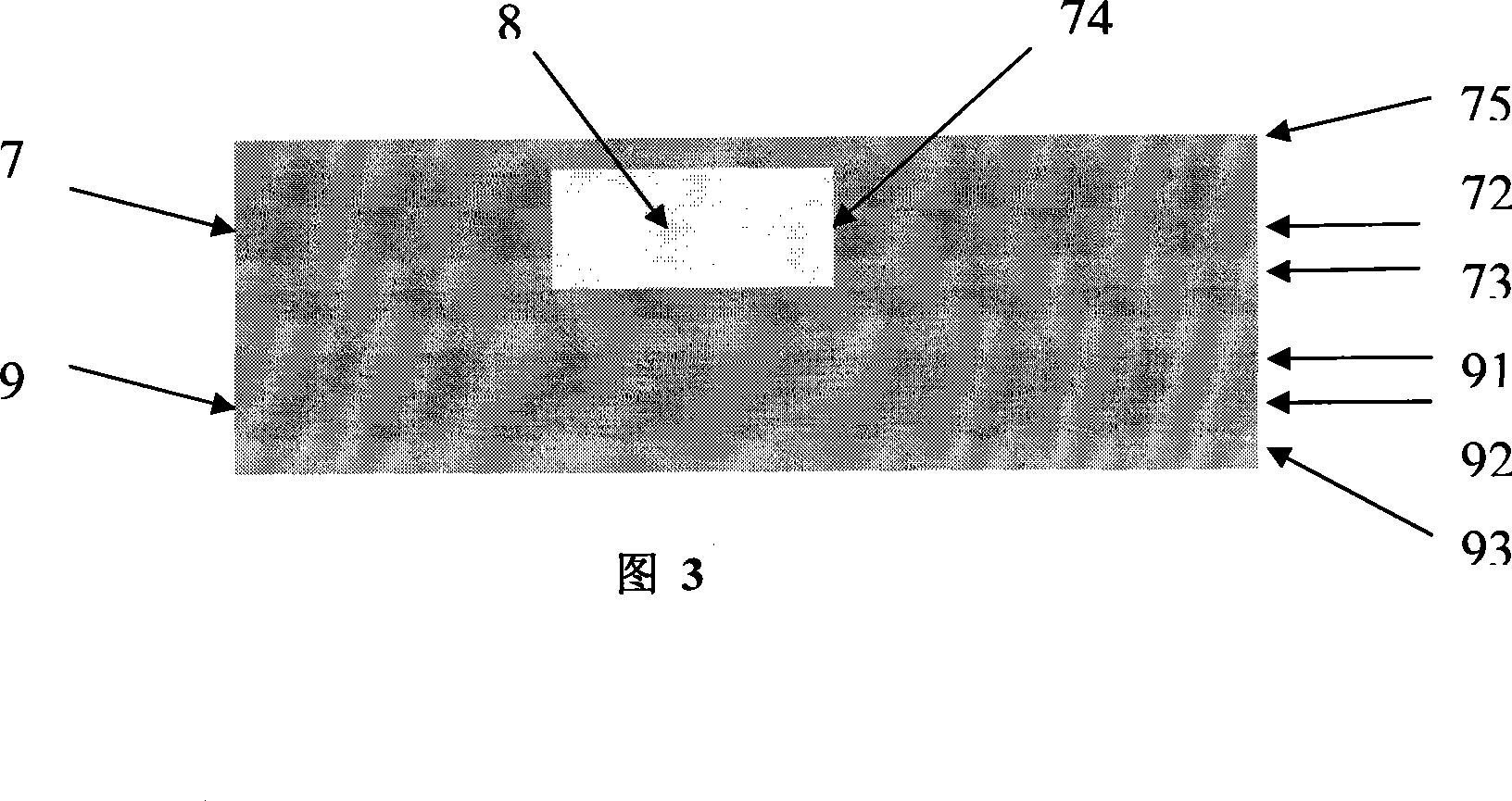

[0019] Step 1: Embed the Rogers plate in the area that requires high-frequency characteristics on a common plate; Position, mill out the groove on the ordinary plate, and then mill out the shape of the Rogers plate corresponding to the groove and etch the copper foil on its surface, and then embed it in the groove; figure 2 As shown, the common plate 7 includes an L2 layer 71 and an L1 layer (not shown) and an L3 layer 73 disposed on both surfaces of the L2 layer 71. The L2 layer 71 is the base material, and the L1 layer (not shown) and the L3 layer 73 are Copper foil, etch the L1 layer (not shown), and mill out the groove 74 in the area where the high-frequency charac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com