Method for preparing low-shrinkage-factor copper clad laminate by applying nano-stuffing

A technology of copper-clad laminates and low shrinkage, which is applied in lamination, lamination devices, lamination auxiliary operations, etc., can solve the problems of inaccurate installation of components, large differences in thermal expansion coefficients, and changes in board flexibility. Poor and other problems, to achieve the effect of improved dimensional stability, lower thermal expansion coefficient, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

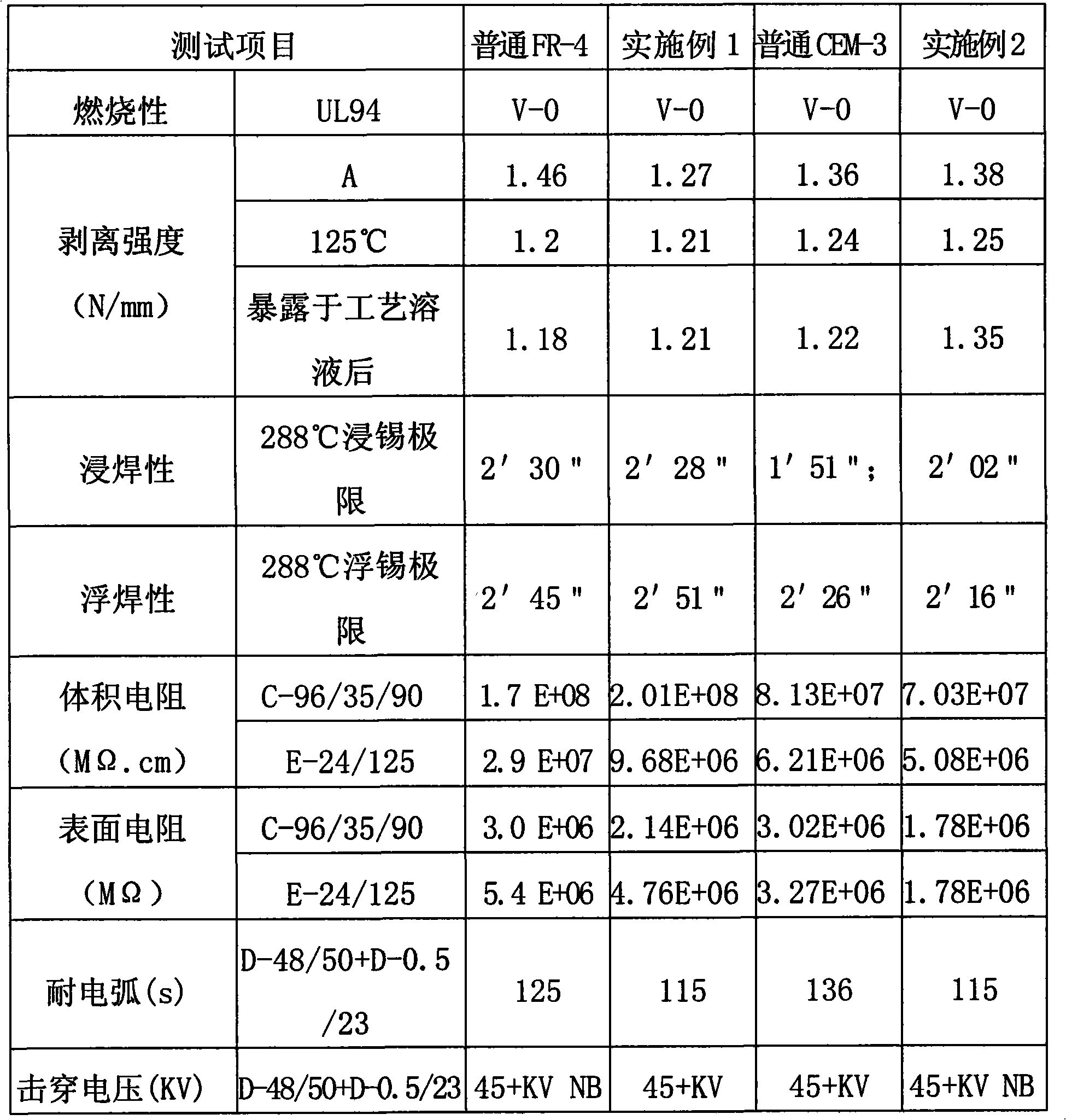

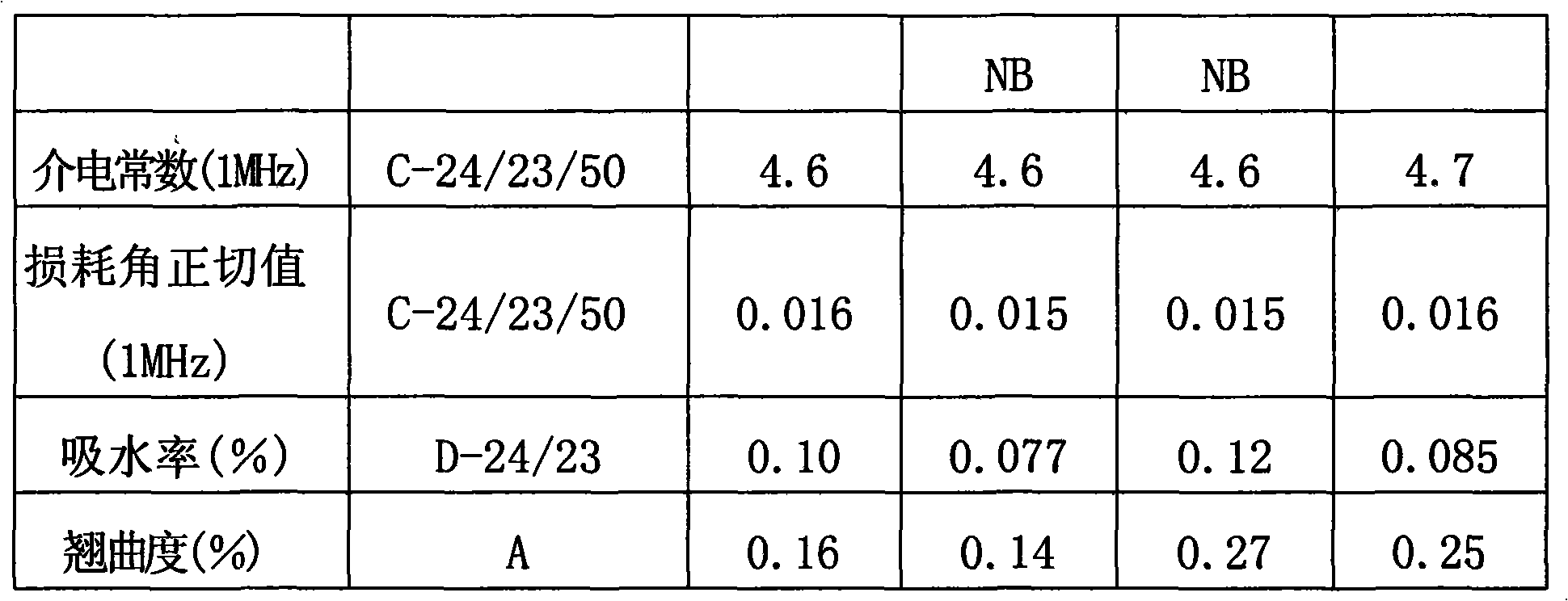

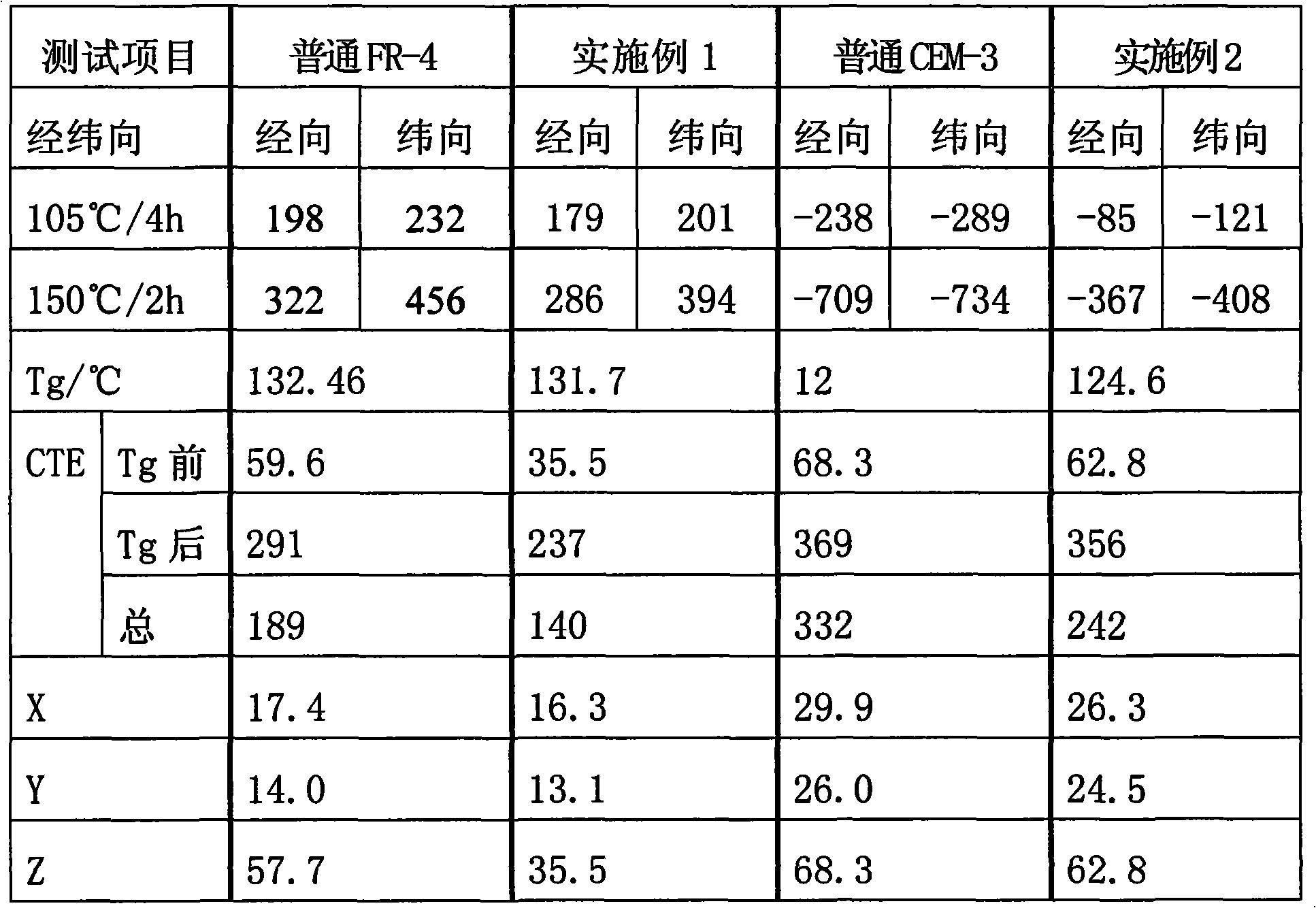

Examples

Embodiment 1

[0012] a. prepare FR-4 glue, its component parts by weight are:

[0013] 100 parts of bisphenol A type epoxy resin, 3 parts of dicyandiamide,

[0014] 15 parts of nanometer calcium carbonate, 0.07 part of 2-methylimidazole,

[0015] The above materials are prepared with acetone / dimethylformamide to make a resin solution for fabrics,

[0016] b. Impregnate the above resin liquid with glass fiber cloth and dry it at 130-190°C to make a fabric;

[0017] c. Select 8 fabric combinations according to the thickness of the board, and cover the upper and lower sides with a piece of copper foil for superposition;

[0018] d. Molding temperature 170°C, unit pressure 40kgf / cm 2 , Vacuum degree -60mmHg, heat preservation and pressure holding for 60 minutes, made of FR-4 type copper clad laminate.

Embodiment 2

[0020] a. prepare CEM-3 core material glue, its component parts by weight are:

[0021] 100 parts of bisphenol A type epoxy resin, 3 parts of dicyandiamide, Al(OH) 3 40 copies,

[0022] 15 parts of nanometer calcium carbonate, 0.1 part of 2-methylimidazole,

[0023] Modulate the above materials with acetone / dimethylformamide to make a resin solution for the core material;

[0024] b. impregnate the above-mentioned core material glue with glass fiber paper, and make the core material after drying at 130-190°C;

[0025] c. Choose 1-20 pieces of core material according to the thickness of the board, stick a piece of fabric on each side, and cover a piece of copper foil on the upper and lower sides;

[0026] d. Molding temperature 170°C, unit pressure 40kgf / cm 2 , Vacuum degree -60mmHg, heat preservation and pressure holding for 60 minutes, made of CEM-3 type copper clad laminate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com