Heat-dissipating aluminum-based circuit board

A technology for circuit boards and aluminum substrates, applied in the direction of circuit substrate materials, printed circuit components, etc., can solve problems such as the inability to meet the development requirements of high-power LEDs, and achieve the effects of simple structure, high insulation breakdown voltage, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

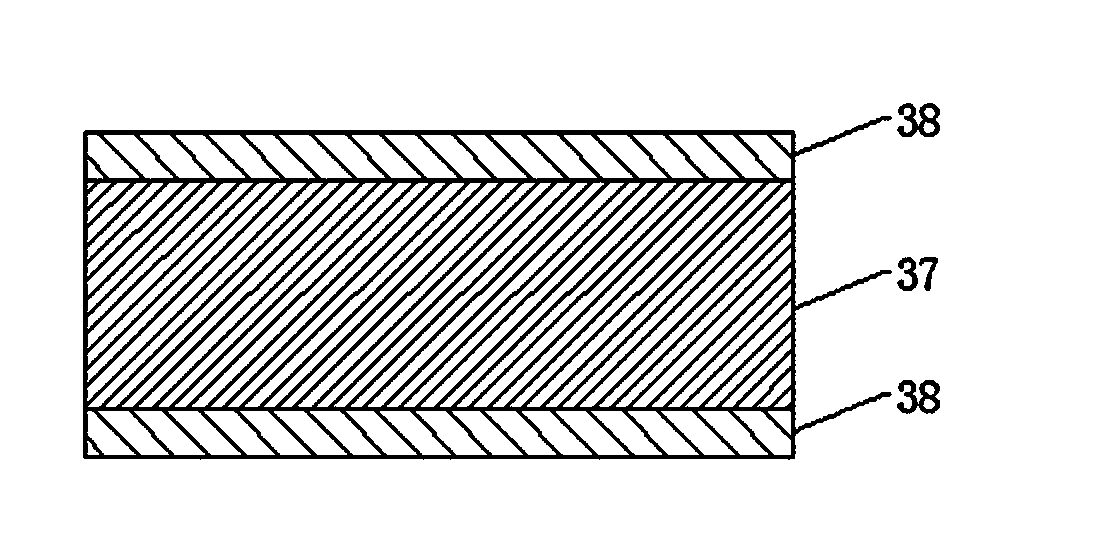

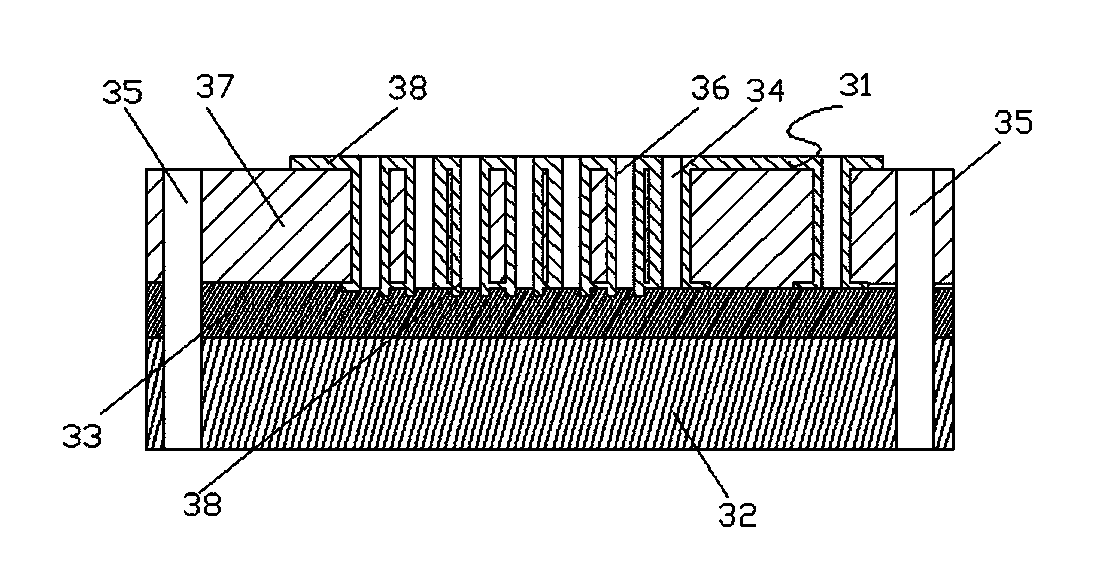

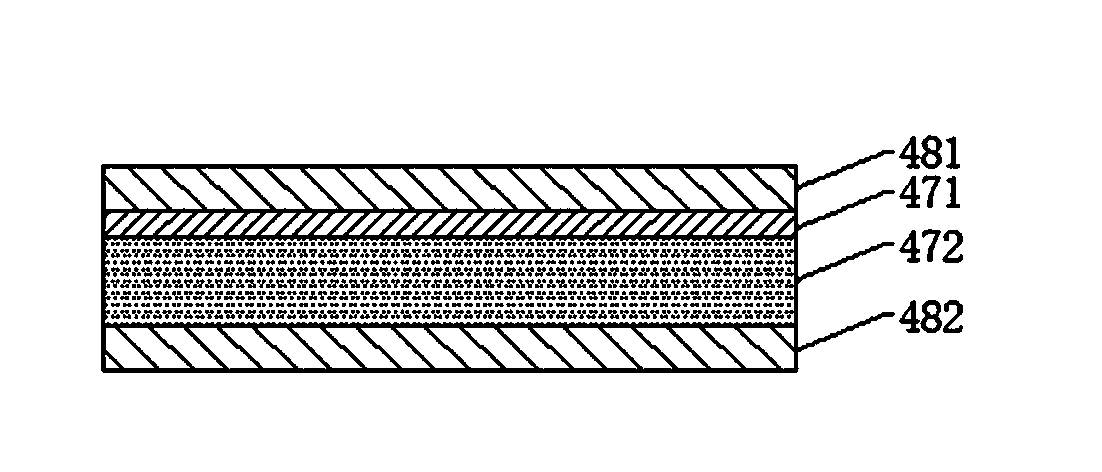

[0021] Embodiment: A heat-dissipating aluminum-based circuit board, which is formed by pressing a double-sided copper foil substrate 41, a dielectric layer 43 and an aluminum substrate 42, and the dielectric layer 43 is located between the double-sided copper foil substrate 41 and the Between the aluminum substrates 42, the double-sided copper foil substrate is a flexible copper foil thermally conductive substrate 41, and the flexible copper foil thermally conductive substrate is composed of a first copper foil layer 481, an insulating polymer layer 471, and a thermally conductive adhesive layer dispersed with heat dissipation powder. layer 472 and a second copper foil layer 482, the insulating polymer layer 471 is located between the first copper foil layer 481 and the thermally conductive adhesive layer 472, and the thermally conductive adhesive layer 472 is located on the insulating polymer layer 471 and the second copper foil layer 482, the flexible copper foil heat conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com