Nameplate with strong durability and manufacturing method thereof

A manufacturing method and durability technology, applied in the field of signs, can solve the problems of acid and alkali, poor moisture resistance, short service life, blurred writing, etc., achieve strong acid and alkali resistance and moisture resistance, reduce production costs, and waste utilization saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Although the present invention has been described with reference to specific embodiments, those skilled in the art will be able to make obvious modifications and modifications to the present invention after reading the above description without departing from the intent and essence of the present invention. The present invention intends to include such modifications and modifications within the scope of the claims.

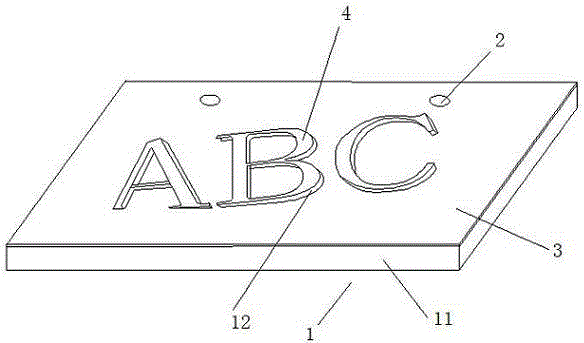

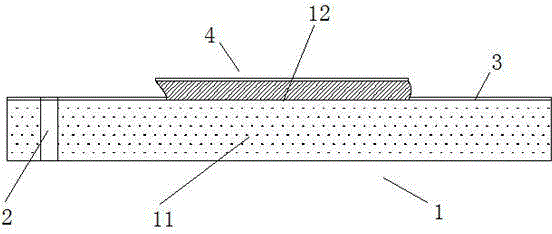

[0030] A durable signage such as figure 1 , figure 2 As shown, a durable nameplate includes a base plate 1, and at least one mounting hole 2 is provided on the base plate 1. The mounting hole 2 is a hanger hole or a nail hole, and the marking can be placed through the mounting hole 2. The signboard is fixed on various occasions, and the signboard of the present invention does not need to be provided with the installation hole 2, and can be directly adhered to the object or wall surface with an adhesive material. In this embodiment, two Mounting hole 2. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com