Making method for high thermal conductive, high heat resistant and high CTI FR-4 copper-clad plate

A technology of CTIFR-4 and manufacturing method, which is applied in the field of copper clad laminates, can solve the problems of affecting the service life of LED products, poor reliability of through-holes, poor moisture resistance, etc., and achieve rapid heat dissipation, high-efficiency thermal conductivity, and good heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below through specific examples.

[0032] The manufacturing method of high thermal conductivity, high heat resistance and high CTI FR-4 copper clad laminate provided by the present invention comprises the following steps: respectively preparing the glue solution for the veneer layer and the glue solution for the inner material layer—gluing—lamination, heat press.

[0033] S1: Prepare the glue solution for veneer layer

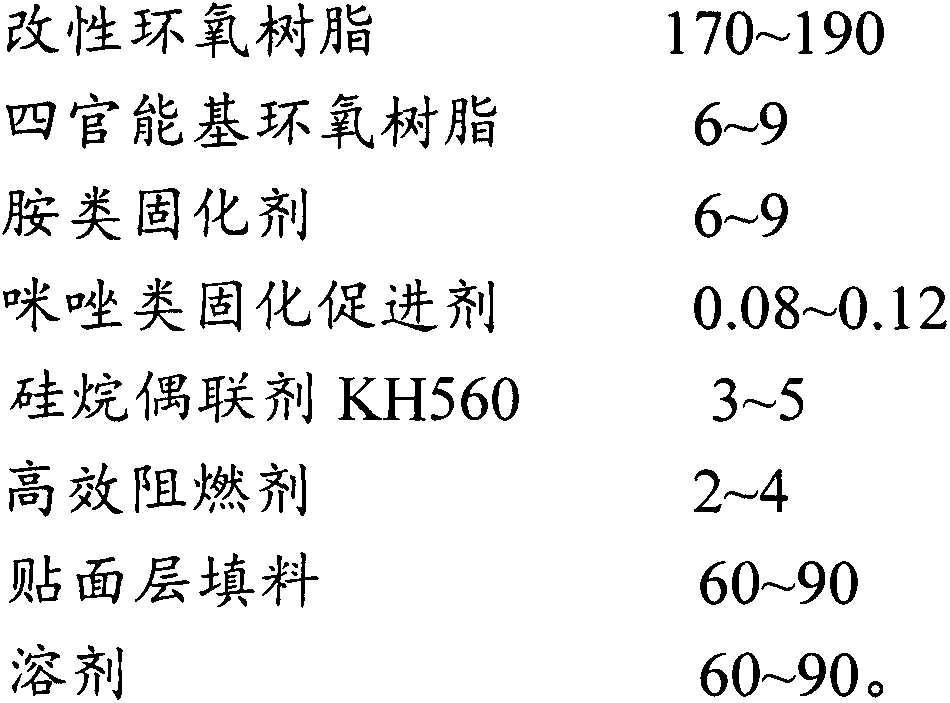

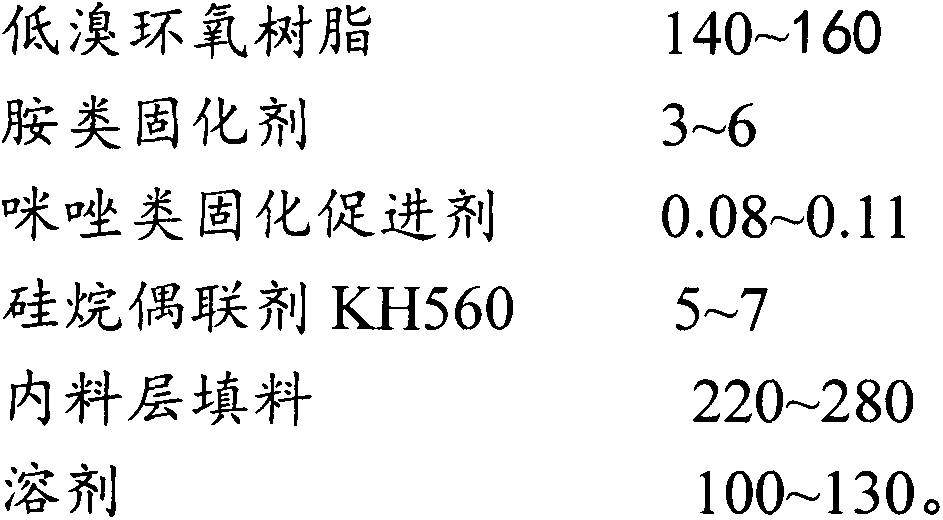

[0034] Glue for veneer layer comprises following composition (parts by weight):

[0035]

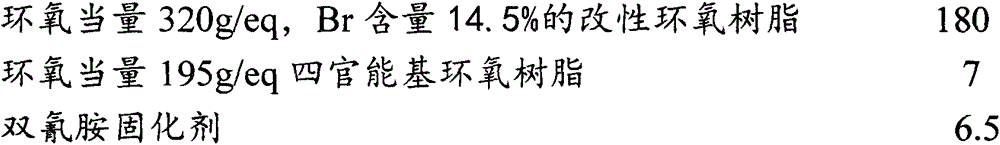

[0036]

[0037] According to the above ratio, the glue solution for the veneer layer is evenly stirred for 8 hours, and the gel time is 264S.

[0038] Among them, the epoxy equivalent is 320g / eq, and the bromine content is 14.5% modified epoxy resin (this resin is a copolymer of bisphenol A epoxy resin and brominated epoxy resin); the level of bromine content will directly affect the The value of CT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com