Aramid fiber surface metallization treatment method

A technology of aramid fiber and surface metal, which is applied in fiber processing, textiles and papermaking, etc., to achieve the effects of improving mechanical properties, improving electrical conductivity, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

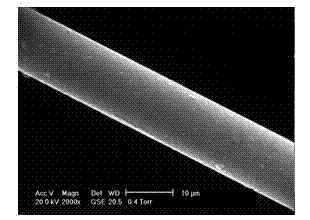

[0025] Embodiment 1 (single-layer nickel coating): the specific steps of the method for metallizing the surface of aramid fibers in this embodiment are:

[0026] (1) Treat the aramid fiber with alcohol containing NaOH concentration of 20wt% at a temperature of 35°C for 30 minutes for degreasing and roughening, then sensitize it with stannous chloride sensitizing solution for 3 minutes, Then use palladium chloride activation solution to activate for 3 minutes; the formula of stannous chloride sensitization solution is stannous chloride SnCl 2 2H 2 O: 15g / l, hydrochloric acid HCl: 45g / l, tin Sn: 5g / l; the formula of palladium chloride activation solution is palladium chloride PdCl 2 : 0.1g / l, hydrochloric acid HCl: 20ml / l;

[0027] (2) Pre-plate the aramid fibers treated in step (1) in the pre-plating solution, the composition of the pre-plating solution is nickel sulfate: 15 g / l, sodium hypophosphite: 40 g / l, sodium acetate: 15 g / l, sodium potassium tartrate: 1m g / l, adjust...

Embodiment 2

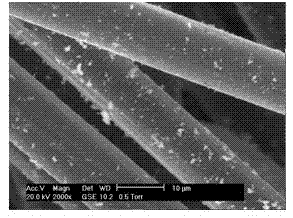

[0030] Embodiment 2 (double-layer nickel-copper coating): the specific steps of the method for metallizing the surface of the aramid fiber of the present embodiment are:

[0031] (1) Treat the aramid fiber with alcohol with an alkali concentration of 15wt% at a temperature of 30°C for 50 minutes for degreasing and roughening, and then sensitize it with stannous chloride sensitizing solution for 4 minutes , and then use palladium chloride activation solution to activate for 4 minutes; the formula of stannous chloride sensitization solution is stannous chloride SnCl 2 2H 2 O: 10g / l, hydrochloric acid HCl: 30g / l, tin Sn: 3g / l; the formula of silver nitrate activation solution is silver nitrate AgNO 3 : 6g / l, hydrochloric acid HCl: 25ml / l.

[0032] (2) Pre-plate the aramid fiber treated in step (1) in the pre-plating solution, the composition of the pre-plating solution is nickel chloride: 20g / l, potassium phosphite: 30g / l, sodium acetate: 18g / l , Potassium sodium tartrate: 1.5...

Embodiment 3

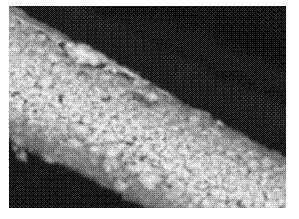

[0036] Embodiment 3: The specific steps of the metallization treatment method on the surface of the aramid fiber of the present embodiment are:

[0037] (1) Treat the aramid fiber with alcohol with an alkali concentration of 45wt% at a temperature of 45°C for 90 minutes for degreasing and roughening, and then sensitize it with stannous chloride sensitizing solution for 5 minutes , and then activated by palladium chloride activation solution for 8 minutes; the formula of stannous chloride sensitization solution is stannous chloride SnCl 2 2H 2 O: 20g / l, hydrochloric acid HCl: 25g / l, tin Sn: 4g / l; the formula of palladium chloride activation solution is palladium chloride PdCl 2 : 0.5g / l, hydrochloric acid HCl: 35ml / l.

[0038] (2) Pre-plate the aramid fiber treated in step (1) in the pre-plating solution, the composition of the pre-plating solution is copper chloride: 30 g / l, sodium hypophosphite: 20 g / l, sodium acetate : 20 g / l, sodium potassium tartrate: 2m g / l, adjust the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com