Preparation of homogeneous mischcrystal cerium-zirconium-aluminum coating material by coprecipitation method and technique thereof

A technology of co-precipitation method and process method, applied in the field of automobile exhaust gas purification, can solve the problem of not mentioning oxygen storage performance parameters, etc., and achieve the effects of good high temperature resistance performance, simple production process, and reduction of specific surface area loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0026] Dissolve 3.86g of cerous nitrate and 1.23g of zirconyl nitrate in 12.7mL of deionized water, the molar ratio Ce:Zr=7:3, the molar concentration is [Ce+Zr]=1mol / L, use 4mol / L under rapid stirring NH 3 ·H 2 O for precipitation, adjust the pH to 10, add 0.1g of polyethylene glycol, stir thoroughly for 30min, let it stand at room temperature for 1h, and age at 70°C for 3h; take 14.72g of aluminum nitrate and dissolve it in 39.23mL of deionized water, and use 4mol under vigorous stirring / L NH 3 ·H 2 O for precipitation, the titration end point is pH 9, add polyethylene glycol 0.1g, fully stir for 30min, let stand at room temperature for 1h, and age at 70°C for 3h; stir and mix the two suspensions thoroughly, and carry out the second step at 70°C Secondary aging, the aging time is 12h. Use vacuum filtration to obtain a precipitate, and use deionized water to wash the precipitate until the filtrate is neutral, then dry the obtained filter cake at 120°C for 12h, pre-calcin...

Embodiment 3

[0028] Put 2#f in a tube-type aging furnace, pass through air containing 10% water vapor and heat-treat at 950°C for 10 hours, and obtain an aging sample of 2#f catalyst after cooling in the furnace, which is marked as 2#a950. Put 2#f in a tube-type aging furnace, pass in air containing 10% water vapor and heat-treat at 1050°C for 10 hours, and obtain an aging sample of 2#f catalyst after cooling in the furnace, which is marked as 2#a1050.

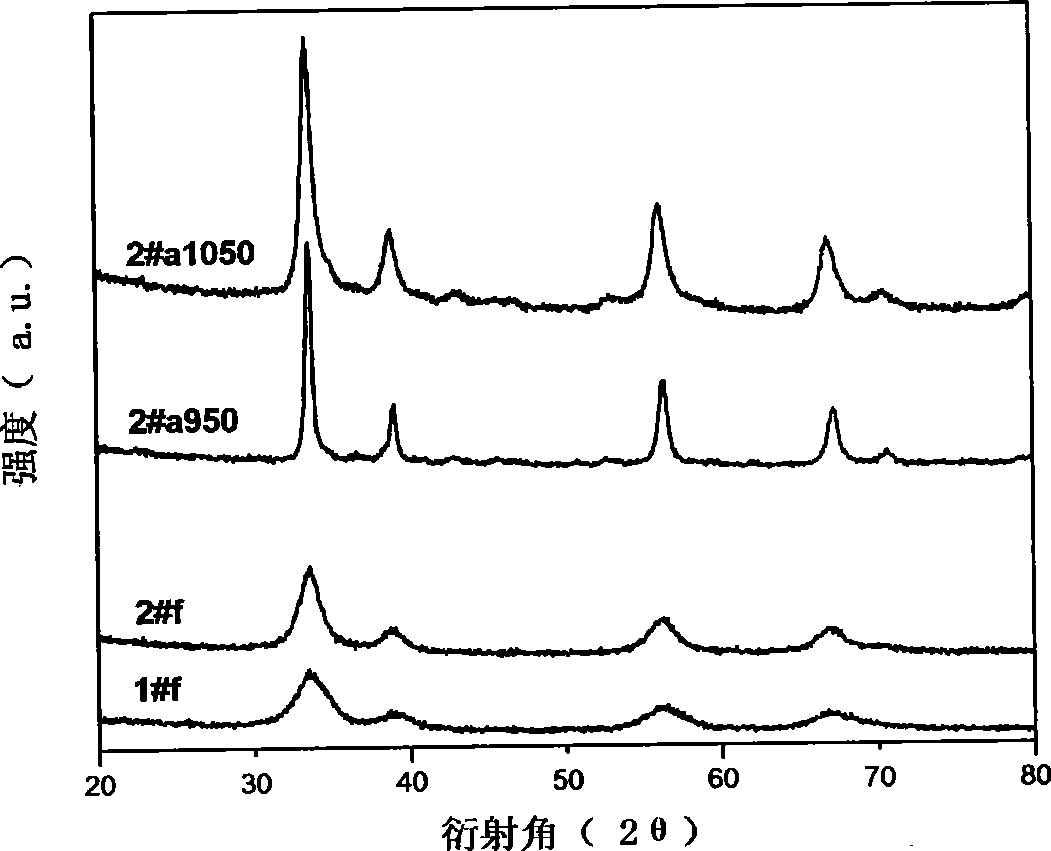

[0029] figure 1 Among them are the fresh coating material 1#f that embodiment 1 obtains, the fresh coating material 2#f that embodiment 2 obtains, the aging coating material 2#a of 950 ℃ hydrothermal treatment 10h in embodiment 3 and 1050 ℃ The X-ray diffraction curve of 10h aged coating material 2#a after hydrothermal treatment can prove the formation of three-phase solid solution of cerium, zirconium and aluminum.

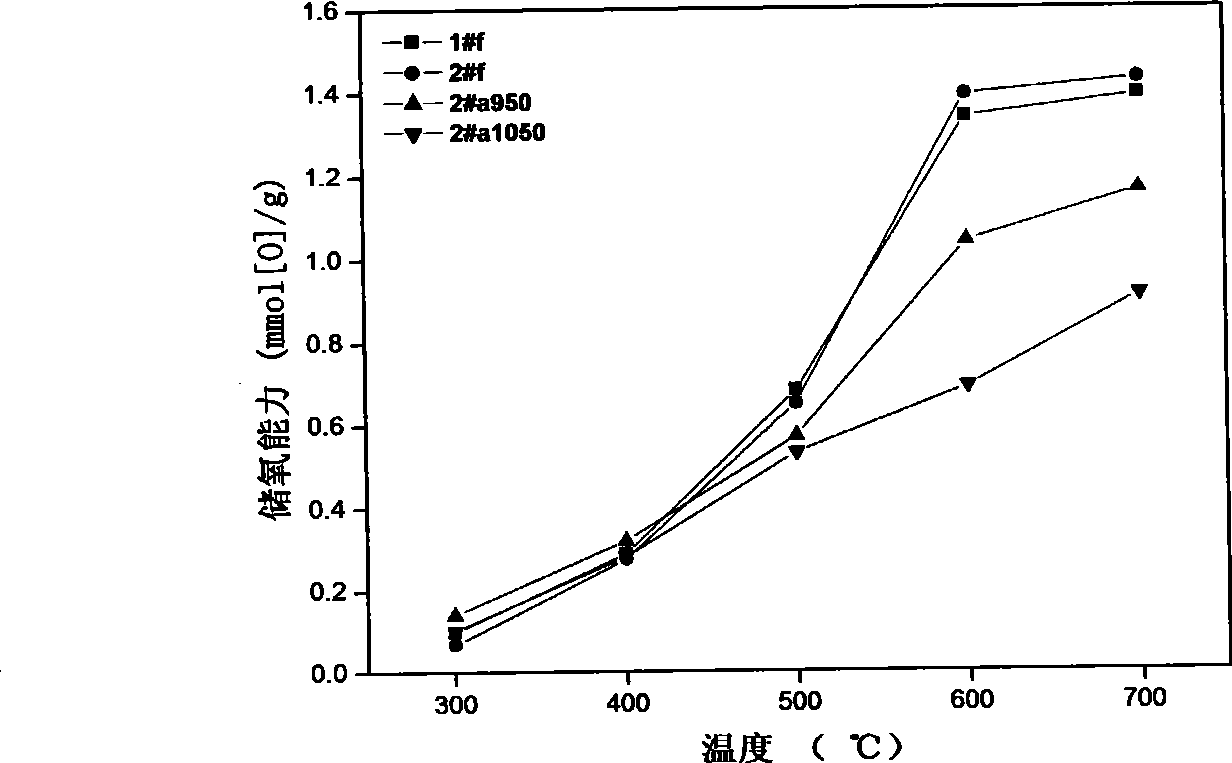

[0030] figure 2 They are the oxygen storage performance curves of the fresh coating material in Example 1, the fresh coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com