Preparation method for metallic oxide loaded activated carbon

A technology of activated carbon preparation and metal loading, applied in catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of decreased activity, easy shedding of catalysts, and decreased catalyst life, and achieves good bonding degree and is not easy to be combined. The effect of catalyst falling off and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

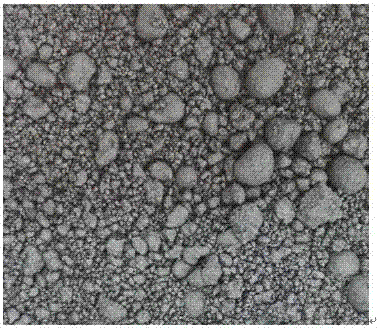

[0021] (1) The rice husk is crushed and screened, then carbonized at high temperature, and the mass fraction of the volatile matter of the carbonized product is determined to be 2%; the carbonized product is further crushed, and the particle size is preferably 20 to 100 microns; then the carbonized product is placed in dilute nitric acid, Boil and reflux, filter and wash until neutral; place acid-treated charcoal in potassium hydroxide solution, boil and reflux; filter and wash until neutral, and dry;

[0022] (2) Weigh sodium carboxymethyl cellulose and add deionized water to make an additive solution with an additive mass percentage of 1%; weigh cobalt chloride, add it to the additive solution, and dissolve it completely , the mass percentage of cobalt chloride is 10%;

[0023] (3) Weigh the charcoal and sodium hydroxide treated in step 1 according to the mass ratio of 1:2, and pulverize them together with a pulverizer; add the solution prepared in step (2) according to the ...

Embodiment 2

[0027] (1) After crushing and sieving the corncobs, and carbonizing at high temperature, the mass fraction of the volatile matter of the carbonized product is determined to be 3%; the carbonized product is further crushed, and the particle size is preferably 20-100 microns; then the carbonized product is placed in dilute hydrochloric acid, Boil and reflux, filter and wash until neutral; place acid-treated charcoal in potassium hydroxide solution, boil and reflux; filter and wash until neutral, and dry;

[0028] (2) Weigh sodium carboxymethyl cellulose and add deionized water to make an additive solution with an additive mass percentage of 2%; weigh cobalt chloride, add it to the additive solution, and dissolve it completely , the mass percentage of cobalt chloride is 10%;

[0029] (3) Weigh the charcoal and potassium hydroxide treated in step 1 according to the mass ratio of 1:2, and pulverize them together with a pulverizer; add the solution prepared in step (2) according to ...

Embodiment 3

[0033] (1) The rice husk is crushed and sieved, and carbonized at high temperature. The mass fraction of the volatile matter of the carbonized product is determined to be 1.4%; the carbonized product is further crushed, and the particle size is preferably 20-100 microns; then the carbonized product is placed in dilute sulfuric acid, Boil and reflux, filter and wash until neutral; place the acid-treated carbonized product in sodium hydroxide solution, boil and reflux; filter and wash until neutral, and dry;

[0034] (2) Weigh methyl cellulose, add deionized water to make an additive solution with an additive mass percentage of 0.8%; weigh manganese sulfate, and add it to the additive solution, dissolve it completely, manganese sulfate The mass percentage content is 8%;

[0035] (3) Weigh the carbide and potassium hydroxide treated in step 1 according to the mass ratio of 1:1.5, and pulverize them together with a pulverizer; add the solution prepared in step (2) according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com