Full-automatic screen printing machine

A screen printing machine, fully automatic technology, applied in the direction of screen printing machine, printing machine, rotary printing machine, etc., can solve the problems of high oven cost, limited oven load capacity, high cost of operating oven equipment, etc., to achieve low design cost , high assembly efficiency, and the effect of reducing costs and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

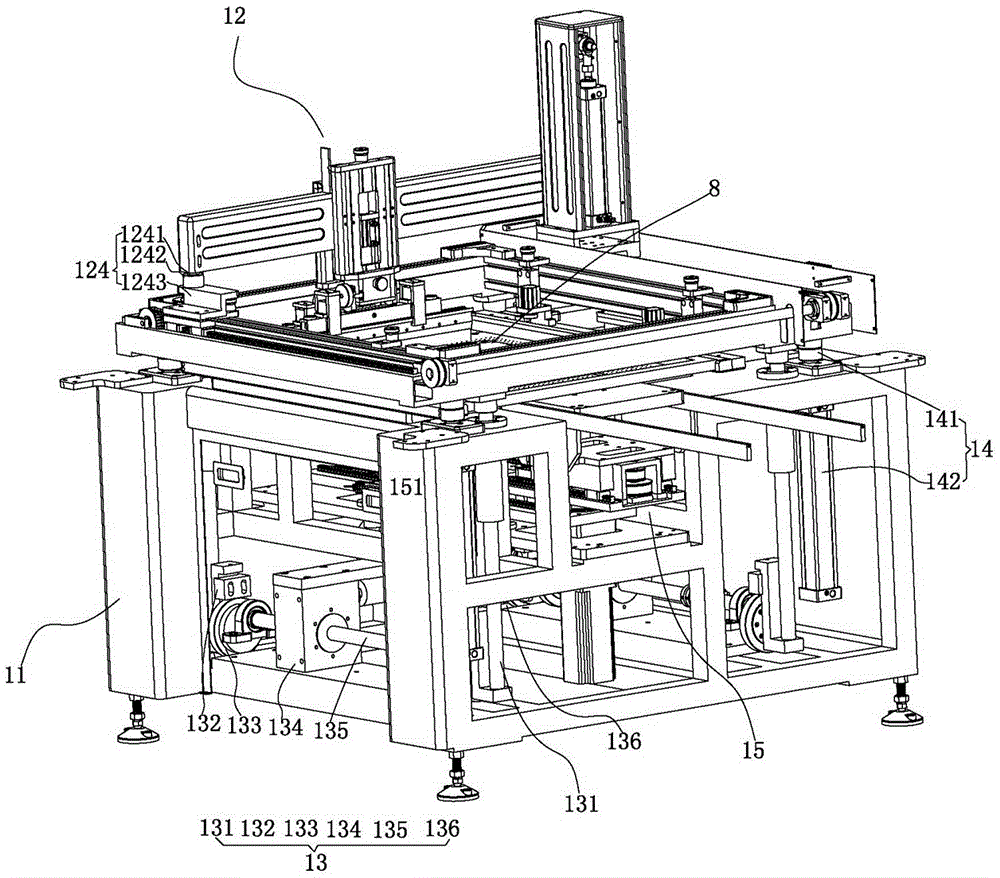

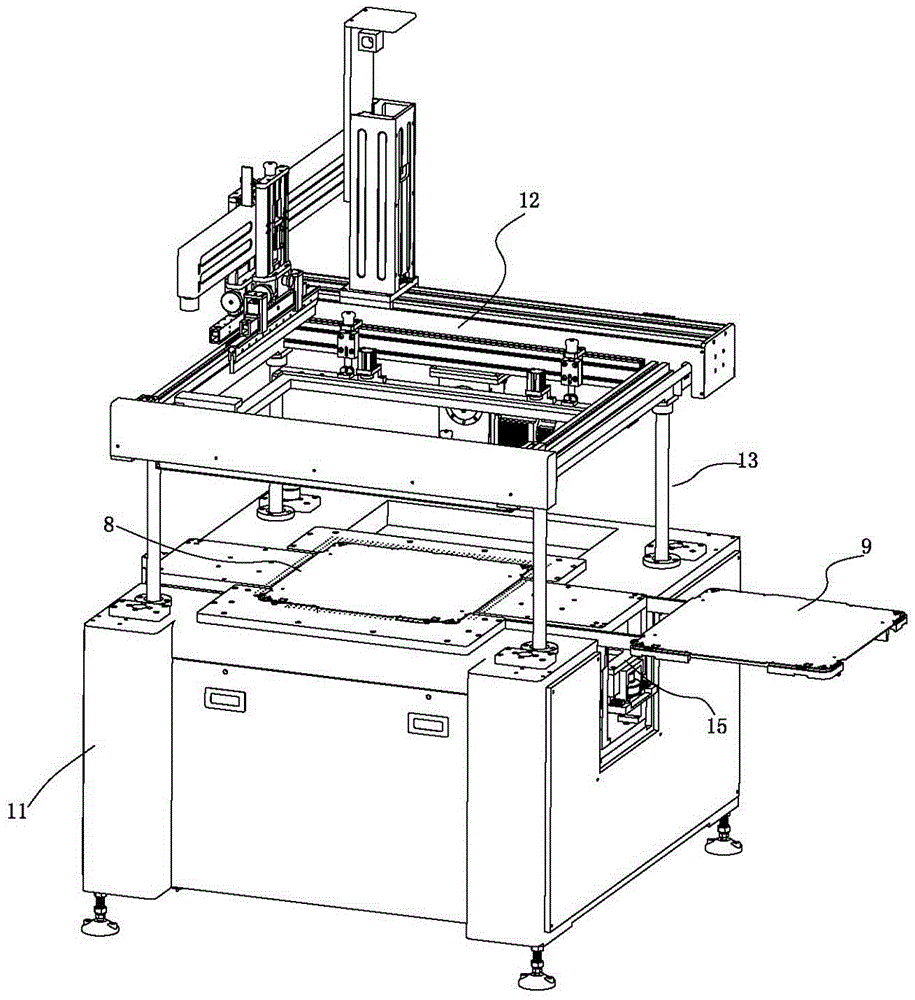

[0036] Attached below Figure 1-9 The present invention is described in further detail.

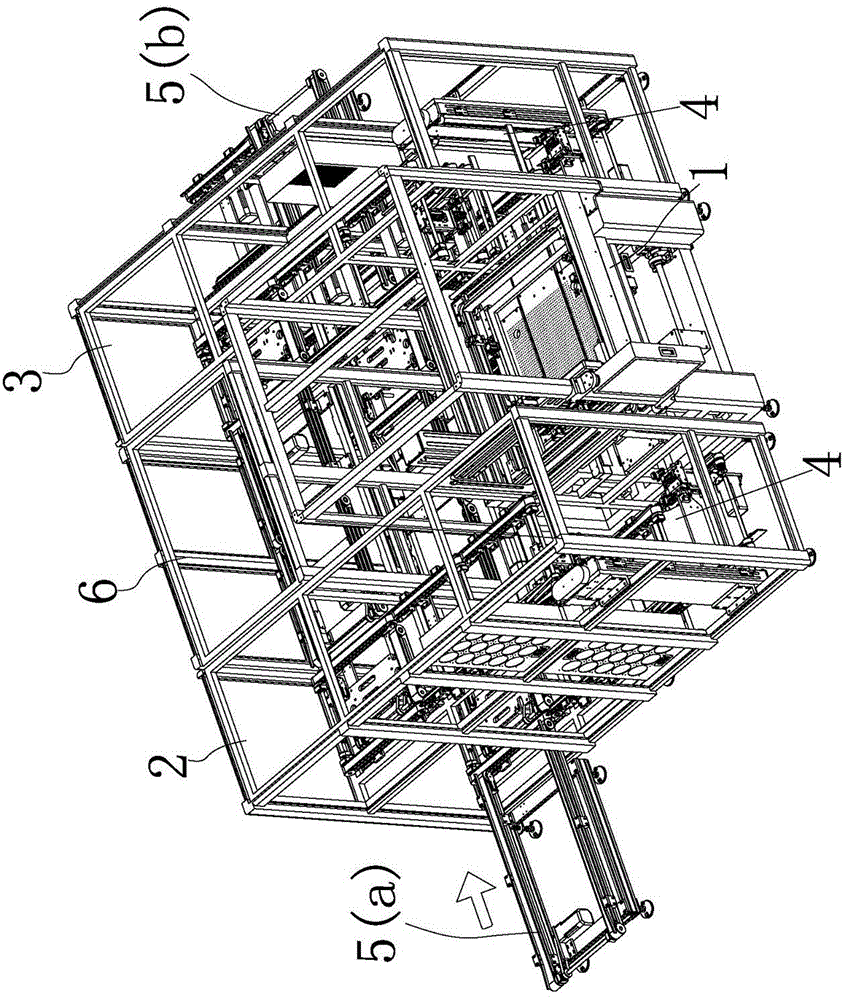

[0037] Such as Figure 1-9 As shown, a fully automatic screen printing machine includes a control system, a frame 11, a printing assembly 12 arranged on the frame 11 for printing and can be raised and lowered, symmetrically arranged on both sides of the printing assembly 12 and equipped with a baking The feeding mechanism 2 and the receiving mechanism 3 of the device 7 and the circular conveying mechanism 6 that movably connect the feeding mechanism 2 and the receiving mechanism 3, the feeding mechanism 2 and the receiving mechanism 3 are provided with parallel and vertically installed Several layers of transmission lanes 10 (in this embodiment, two layers are selected, of course, different layers of transmission lanes 10 can be set according to actual needs and others), and the transmission lanes 10 are used for horizontal transfer of the carrier plate 9. A vertical transfer device 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com