Preparation method of titanium-dioxide-modified carbon-fiber-reinforced resin-base composite material

A fiber-reinforced resin and titanium dioxide technology is applied in the field of preparation of titanium dioxide-modified carbon fiber-reinforced resin-based composite materials, which can solve the problems of insufficient synergy, insufficient reinforcement effect, and inability to ensure uniformity, etc. Chemical properties, excellent mechanical strength, the effect of increasing surface roughness and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

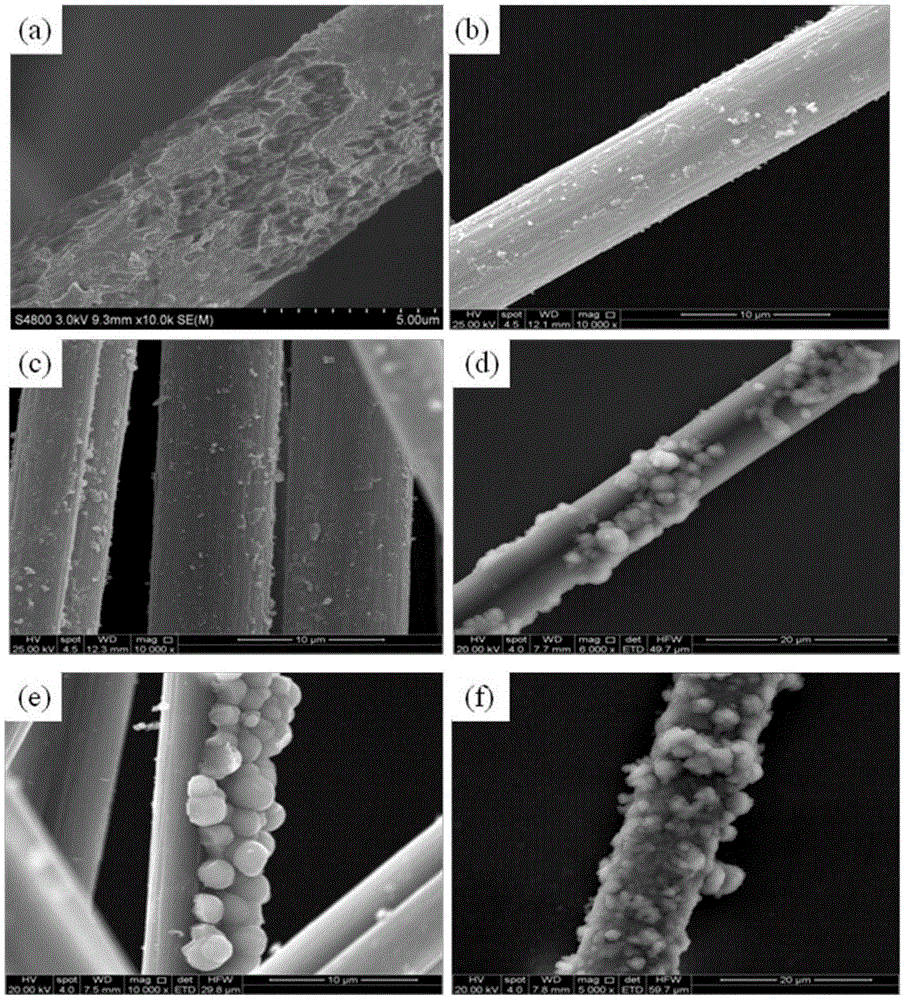

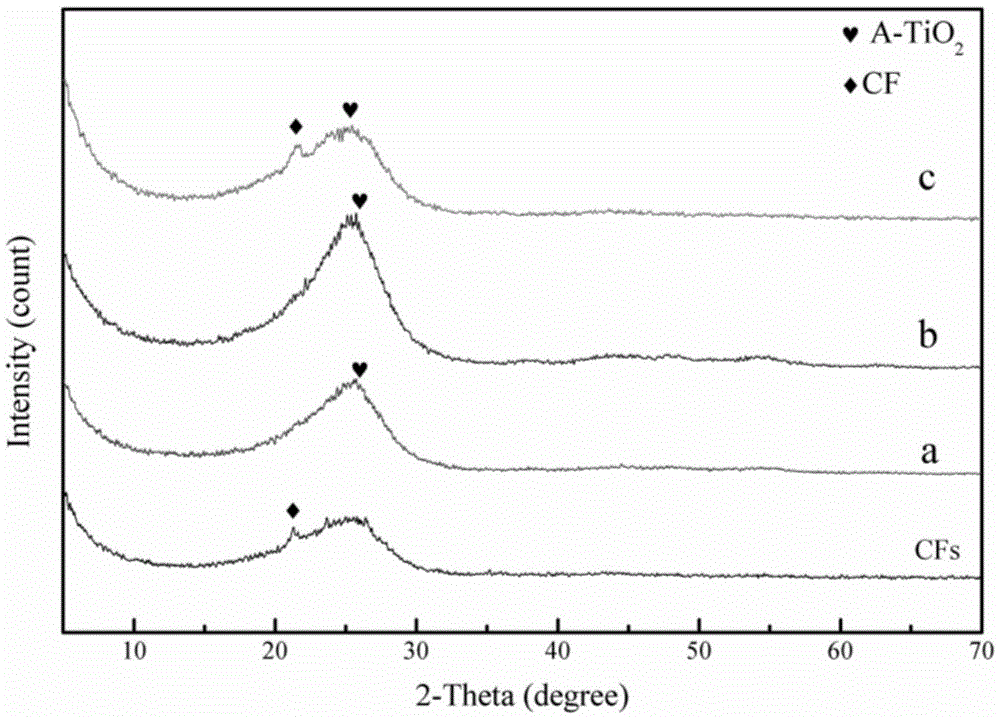

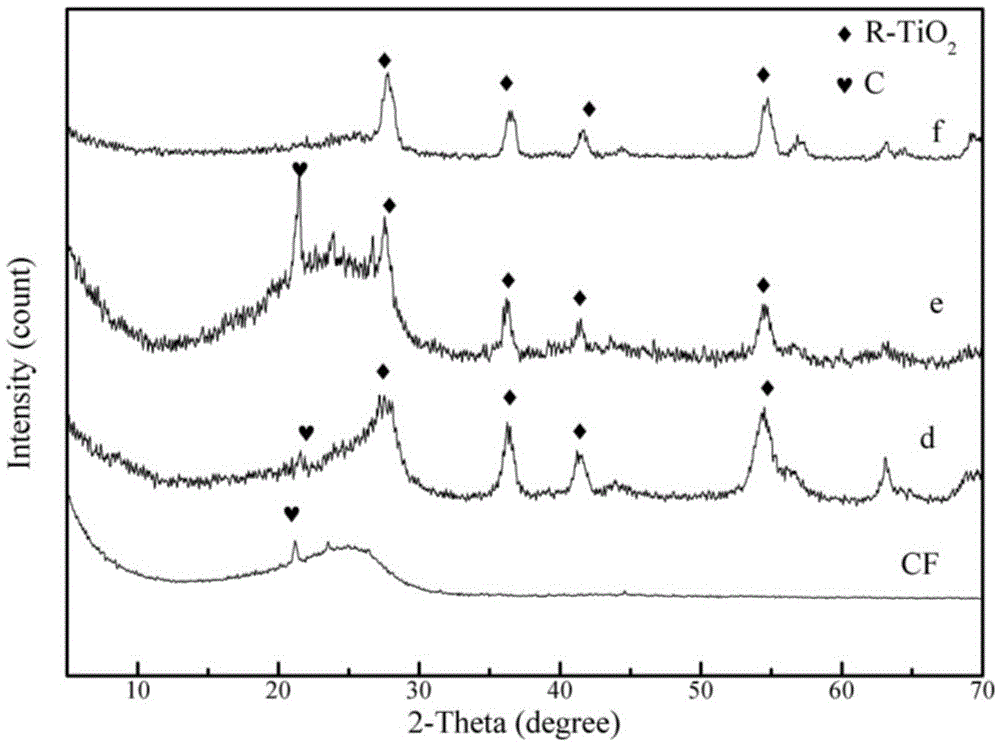

[0029] A preparation method of titanium dioxide modified carbon fiber reinforced resin-based composite material, comprising the following steps:

[0030] Step 1: In terms of parts by mass, take 20-30 parts of deionized water, add concentrated hydrochloric acid (concentration: 12mol / L) dropwise to it to pH=-0.4-3 to obtain an acidic solution, and then add 1-3 parts of titanium Tetrabutyl nitrate is added to the acidic solution to obtain mixed solution A, and 0.05 to 0.2 parts of carbon fibers pretreated by concentrated nitric acid are added to mixed solution A to obtain mixed solution B. The method for pretreating carbon fibers with concentrated nitric acid is: Concentrated nitric acid (concentration: 16mol / L) was condensed and refluxed for 6 hours under the condition of 80°C oil bath (silicone oil);

[0031] Step 2: Transfer the mixed solution B into the lining of the hydrothermal kettle and install the hydrothermal kettle in a homogeneous hydrothermal instrument, and perform ...

Embodiment 1

[0035] Step 1: In terms of parts by mass, take 30 parts of deionized water, add concentrated hydrochloric acid to it to pH=1 to obtain an acidic solution, then add 1 part of tetrabutyl titanate to the acidic solution to obtain a mixed solution A, and add 0.1 parts of The carbon fiber pretreated by concentrated nitric acid is added to the mixed solution A to obtain the mixed solution B, wherein the method of pretreating the carbon fiber with concentrated nitric acid is as follows: the carbon fiber is condensed and refluxed with concentrated nitric acid for 6 hours under the condition of an oil bath (silicone oil) at 80°C;

[0036] Step 2: Transfer the mixed solution B into the lining of the hydrothermal kettle and install the hydrothermal kettle in a homogeneous hydrothermal instrument, and perform a homogeneous hydrothermal reaction at a temperature of 110°C for 5 hours. After the reaction is completed, naturally cool to room temperature, and the obtained Carbon fibers are wash...

Embodiment 2

[0039] Step 1: In terms of parts by mass, take 25 parts of deionized water, add concentrated hydrochloric acid to it to pH = 2 to obtain an acidic solution, then add 2 parts of tetrabutyl titanate to the acidic solution to obtain a mixed solution A, and add 0.1 parts of The carbon fiber pretreated by concentrated nitric acid is added to the mixed solution A to obtain the mixed solution B, wherein the method of pretreating the carbon fiber with concentrated nitric acid is as follows: the carbon fiber is condensed and refluxed with concentrated nitric acid for 6 hours under the condition of an oil bath (silicone oil) at 80°C;

[0040] Step 2: Transfer the mixed solution B into the lining of the hydrothermal kettle and install the hydrothermal kettle in a homogeneous hydrothermal instrument, and perform a homogeneous hydrothermal reaction at a temperature of 150 °C for 6 hours. After the reaction is completed, naturally cool to room temperature, and the obtained Carbon fibers are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com