Semiconductor laser heat sink

A laser and semiconductor technology, applied in semiconductor lasers, lasers, laser components, etc., can solve the problems of short life, large difference in thermal expansion coefficient, low yield, etc., achieve high-efficiency thermal conductivity, improve stability, and avoid deterioration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

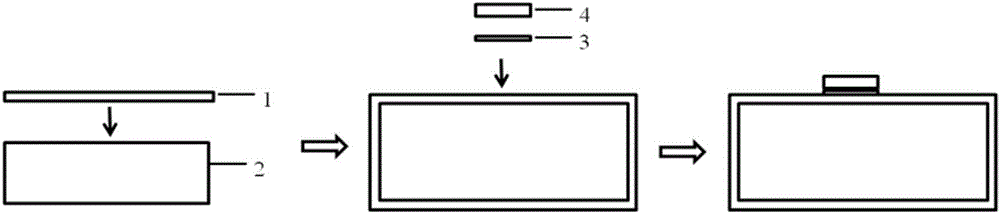

[0011] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

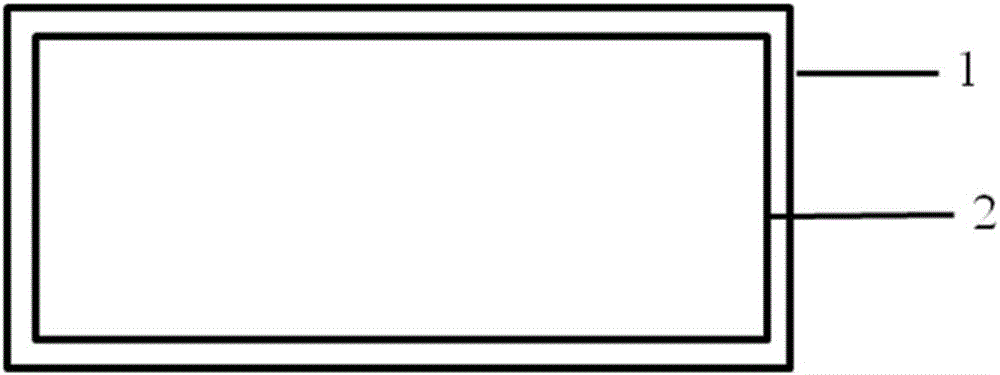

[0012] A semiconductor laser heat sink proposed by the present invention, the semiconductor laser heat sink includes a graphene film layer and a copper heat sink, the graphene film layer is prepared by using methane or acetylene as a carbon source by a CVD method, the graphene film Layer preparation Copper heat sink is coated on the surface of copper heat sink, which is used to quickly transmit the heat generated by the semiconductor laser chip to the copper heat sink, and isolate the copper heat sink from the air to avoid oxidation. The copper heat sink is machined The copper heat sink is used to dissipate the heat transmitted by the graphene to the air or other media. Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] like figure 1 Shown is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com