Internal combustion engine exhaust temperature control device capable of achieving sectional pressure and temperature adjustment

A technology of pressure temperature and exhaust temperature, which is applied in the direction of exhaust device, electric control of exhaust treatment device, diagnostic device of exhaust treatment device, etc. Exhaust gas temperature requirements are more stringent and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

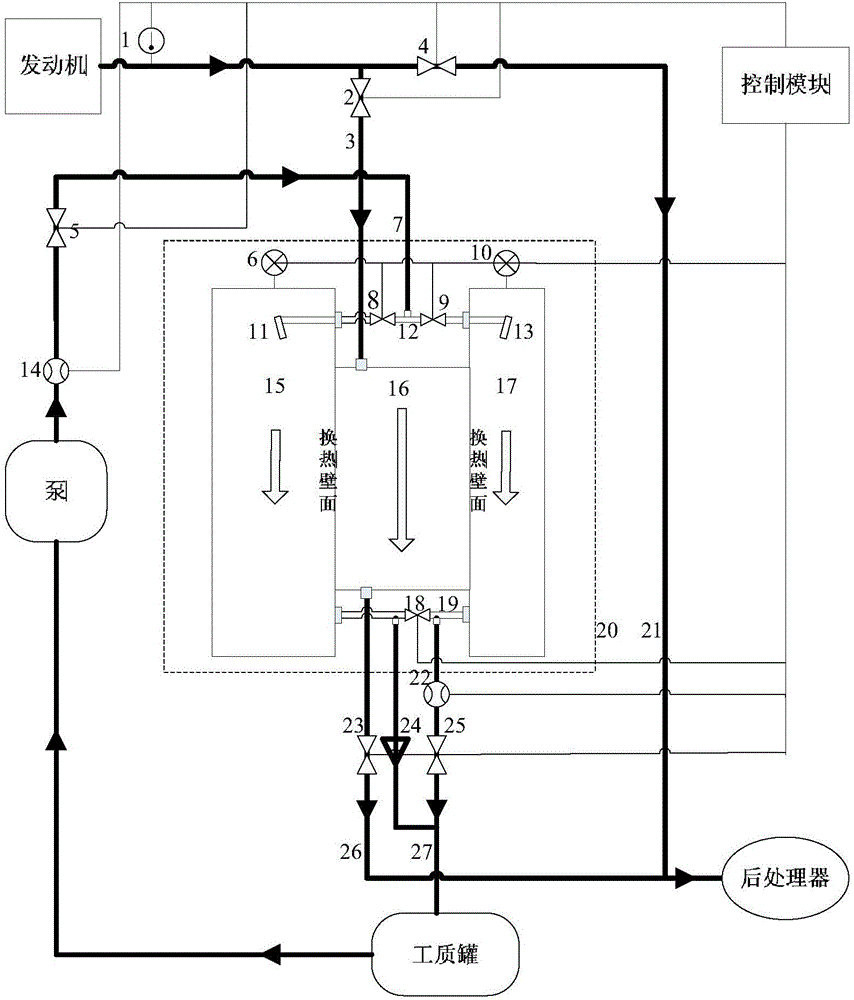

[0018] The following is attached figure 1 The technical scheme of the present invention is described in detail:

[0019] The present invention consists of an exhaust gas temperature sensor 1, an exhaust gas inlet pipe electromagnetic valve 2, an exhaust gas inlet pipe 3, an exhaust gas straight-through pipe electromagnetic valve 4, a working fluid inlet solenoid valve I5, a temperature and pressure sensor I6, a working fluid inlet pipe 7, and a working fluid inlet solenoid valve Ⅱ8, pressure division valve Ⅰ9, temperature and pressure sensor Ⅱ10, nozzle Ⅰ11, communication pipe Ⅰ12, nozzle Ⅱ13, working fluid inflow meter 14, state constant box 15, exhaust gas channel 16, state adjustment box 17, pressure division valve Ⅱ18, communication pipe Ⅱ19, temperature and pressure regulator 20, exhaust gas straight-through pipe 21, working fluid outlet flowmeter 22, exhaust gas outlet solenoid valve 23, safety valve 24, working fluid outlet solenoid valve 25, exhaust gas outlet pipe 26,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com