Trolley applicable to strawberry production and pickup

A trolley and strawberry technology, applied in the field of trolleys for strawberry production and picking, can solve problems such as low efficiency per unit time, inability to get rest, and reduced work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

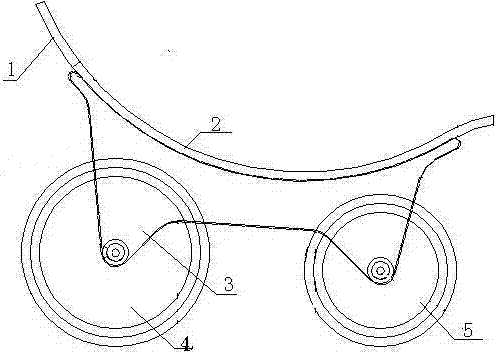

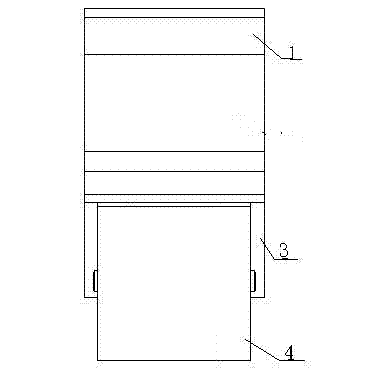

[0019] Such as figure 1 with figure 2 As shown, the trolley suitable for strawberry production and picking disclosed by the present invention includes a body 2, a wheel frame 3, a yoke 1, a front wheel 4 and a rear wheel 5, the yoke 1 is arranged at one end of the body 2, and the wheel frame 3 is set on Below the main body 2, the front wheel 4 and the rear wheel 5 are all installed on the wheel frame 3, and the wheel widths of the front wheel 4 and the rear wheel 5 are the same.

[0020] An improvement of the trolley suitable for strawberry production and picking disclosed by the present invention, the wheel surface width of the front wheel 4 and the rear wheel 5 ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com