Integrated type forklift sidesway mechanism with internally-installed di-oil cylinder

An integral and oil cylinder technology, applied in the direction of lifting devices, etc., can solve the problems of lowering the comprehensive carrying capacity of forklifts, poor vision of forklifts, and limited lateral movement distance, etc., and achieve the effect of improving the vision of forklifts, flexible operation, and little impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

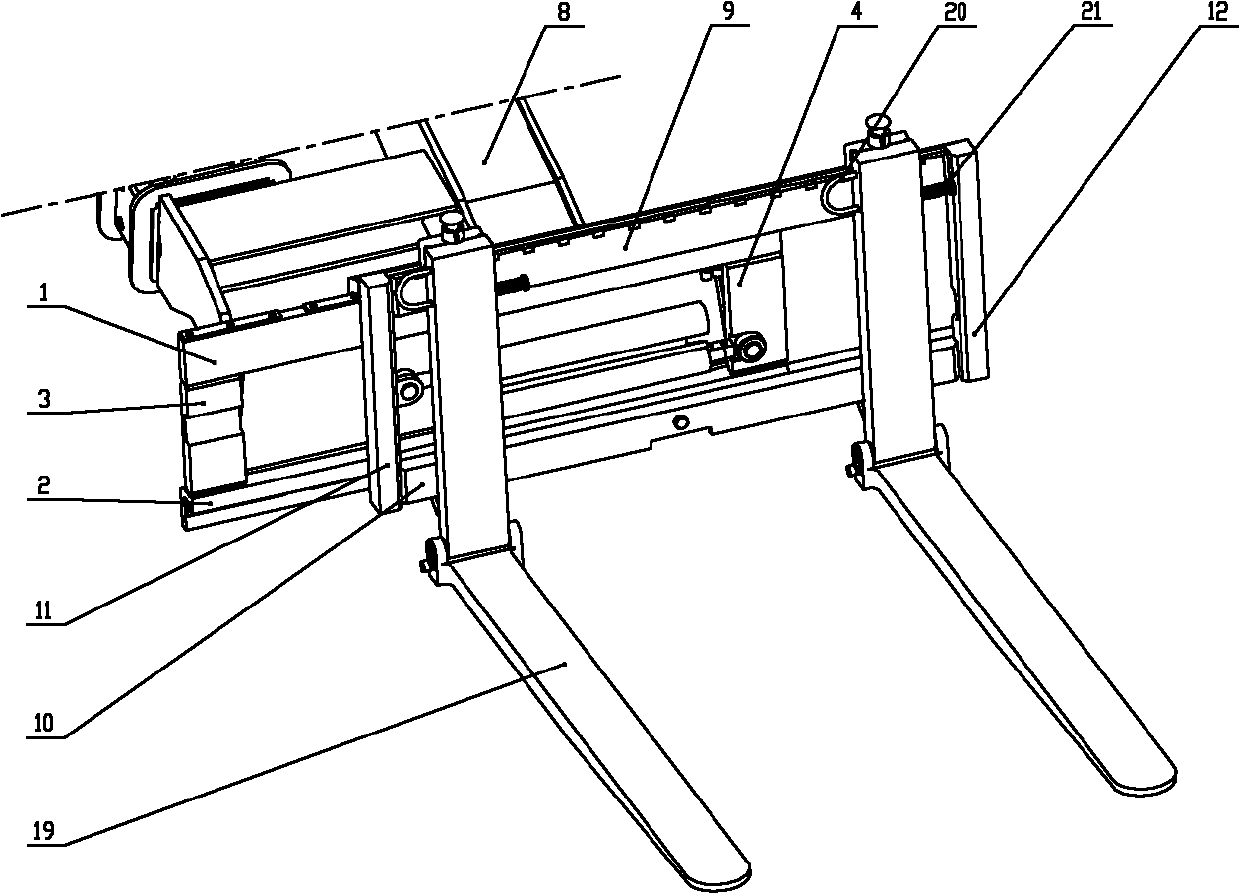

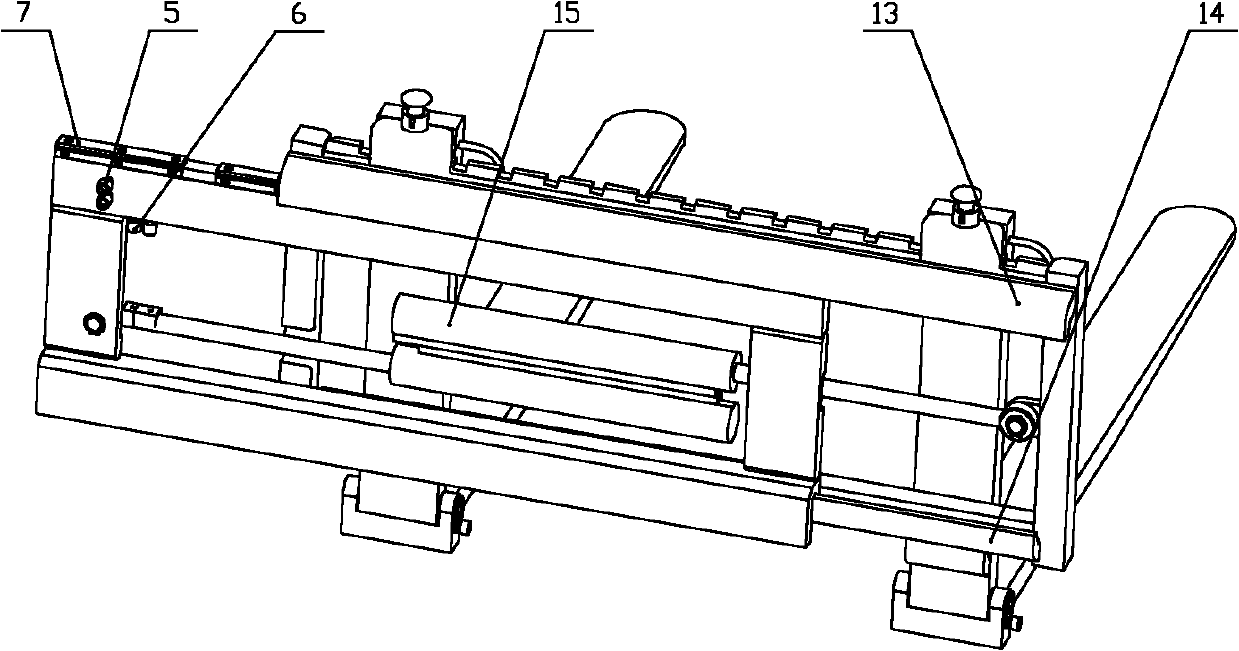

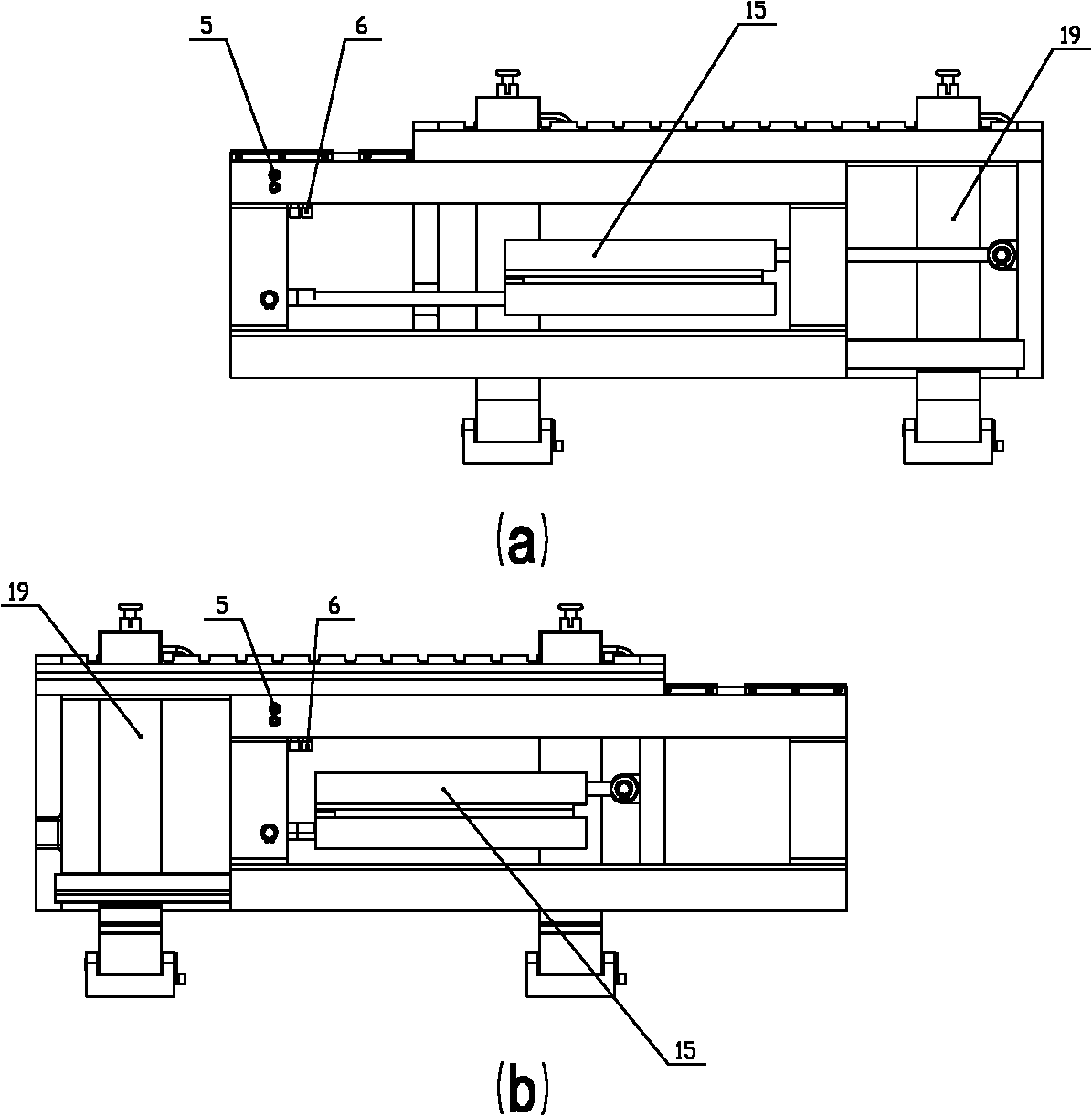

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] refer to figure 1 , 2 , 3, 4, and 5, the present invention includes a fixed carriage, a movable carriage, a duplex side-moving oil cylinder, a folding fork, and the like. The fixed carriage consists of the upper beam of the fixed carriage 1, the lower beam of the fixed carriage 2, the left support plate of the fixed carriage 3, the right support plate of the fixed carriage 4, the oil port of A area 5, the oil port of B area 6, and the self-lubricating strip 7 Composition, the fixed carriage is fixed on the working mechanism 8. The movable carriage is made up of the upper beam 9 of the movable carriage, the lower crossbeam 10 of the movable carriage, the left column of the movable carriage 11, the right column of the movable carriage 12, the upper chute 13 of the movable carriage, and the lower groove 14 of the movable carriage. The movable carriage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com