Width-adjustable shuttle vehicle

A technology for adjusting shuttles and shuttles, which is applied in the field of adjustable-width shuttles, which can solve the problems of reduced compatibility, non-adjustable spacing, and singleness, and achieve the effect of improving versatility and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

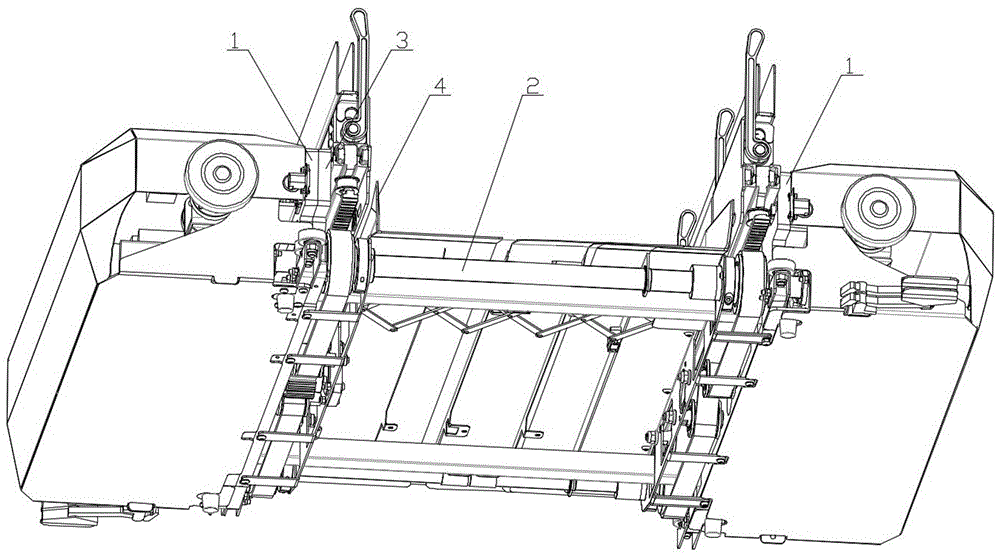

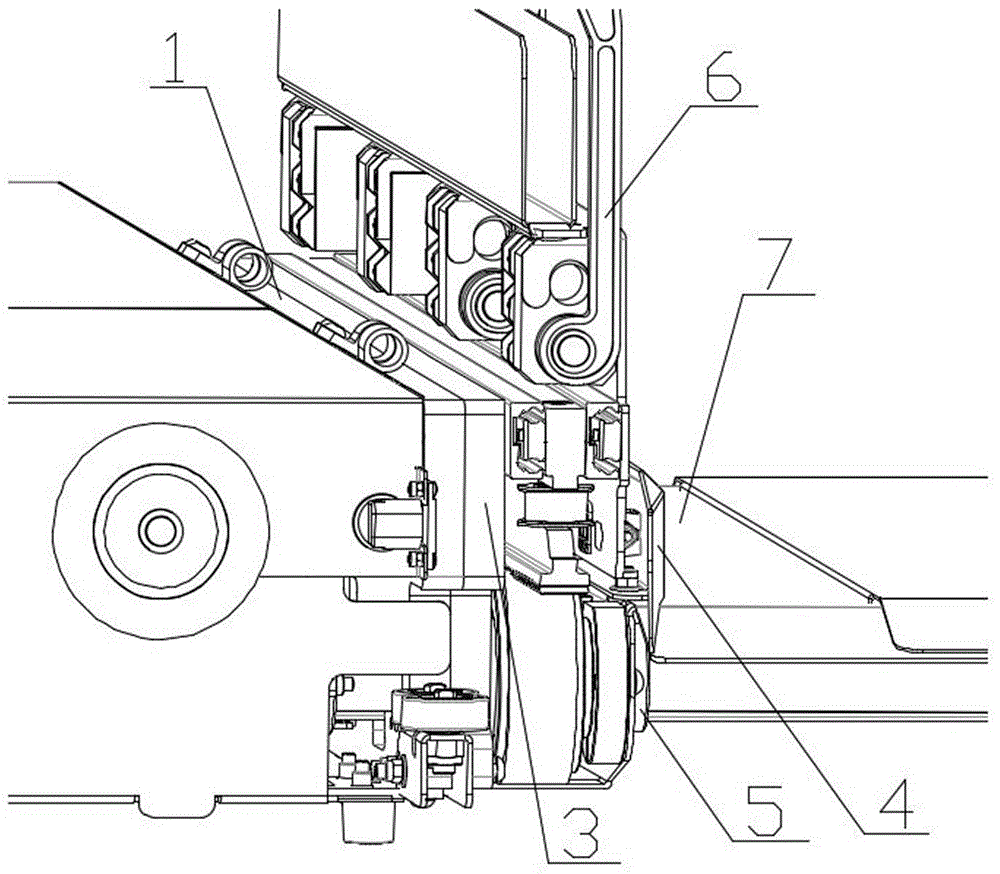

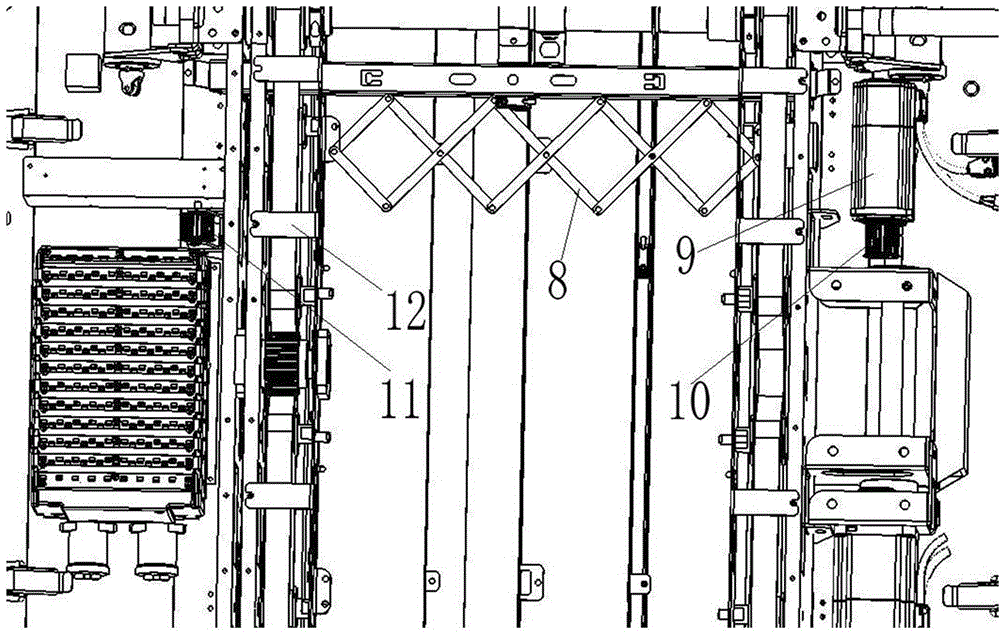

[0024] Attached below figure 1 to attach Figure 5 The present invention will be further described.

[0025] A shuttle vehicle with adjustable width, comprising: two outer fork plates 1, which are respectively located on the left and right sides and parallel to each other; two parallel connecting rods 2, whose two ends are respectively connected with the outer fork plates 1 on the same side , two outer fork plates 1 and two connecting rods 2 form a shuttle car body with a rectangular structure; the traveling mechanism is installed on the shuttle car body and is used to drive the shuttle car body to move laterally; the movable outer fork plate 3, It is slidably installed on two connecting rods 2 through sliding bearings 5; two fork assemblies 6 parallel to each other, one is installed on the movable outer fork plate 3, and the other is installed on the outer fork plate 1 on the other side; And the movable outer fork plate drive mechanism, which drives the movable outer fork p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com