Pallet fork mechanism with quick change function

A technology of forks and functions, applied in the field of material handling equipment, can solve problems such as mobility impact and safety impact, and achieve the effect of meeting safety requirements and meeting the needs of safe handling of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

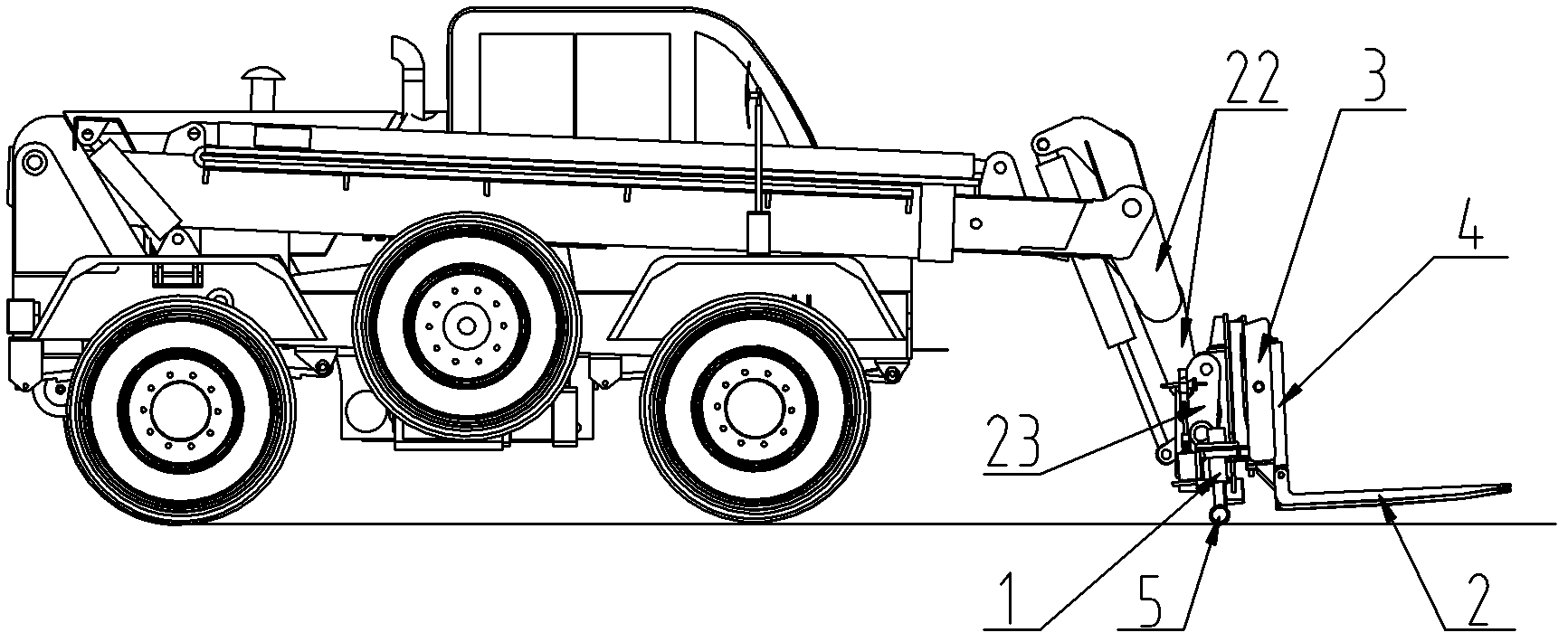

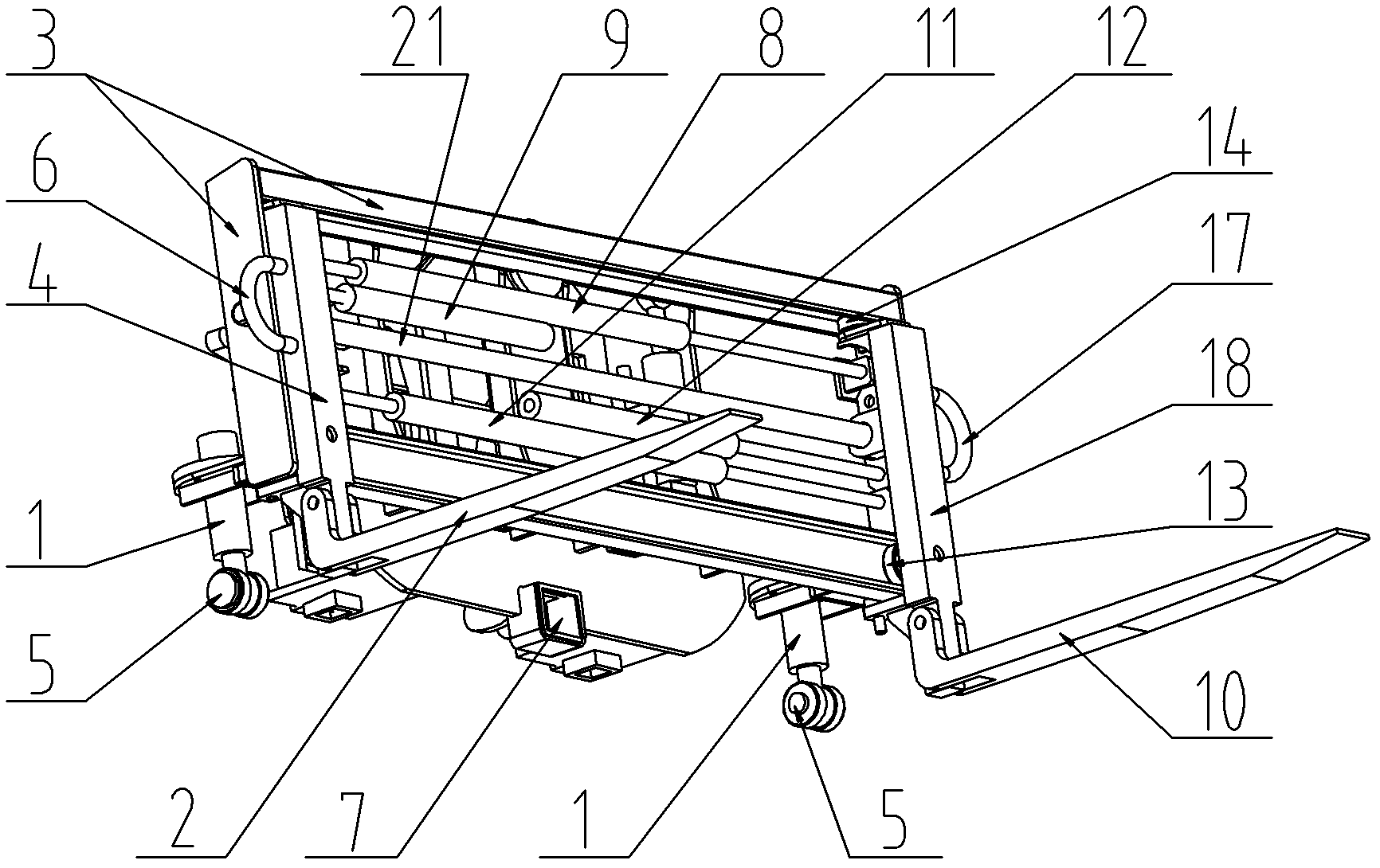

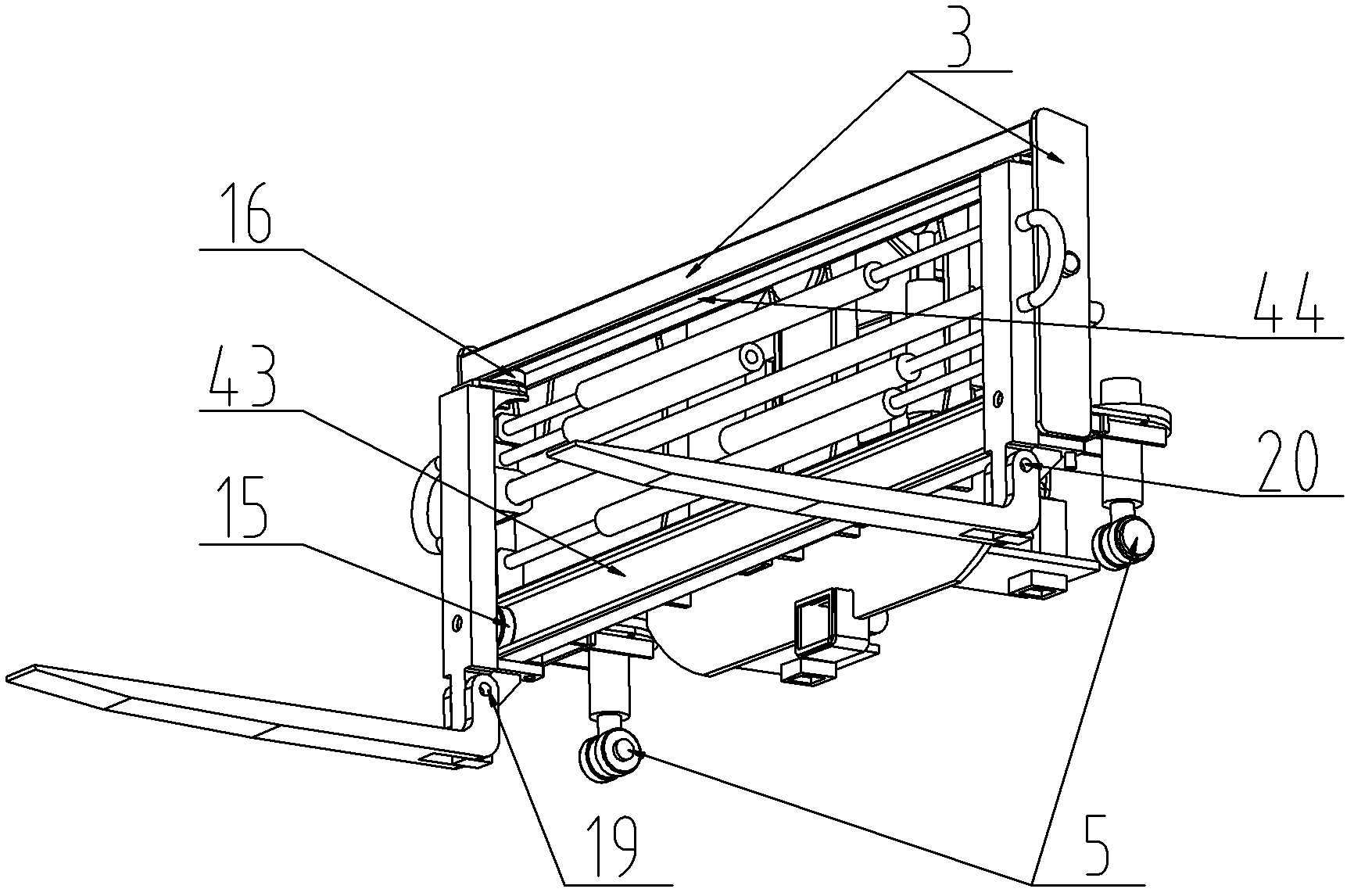

[0024] refer to figure 1 , 2 , 7, 8, and 9, the present invention includes a fork mechanism with a quick change function, consisting of a fork frame 3, a left fork back plate 4, a left fork 2, a right fork 10, a baffle mechanism 23, Hanging plate mechanism 26, two supporting oil cylinders 1 and two supporting oil cylinder rollers 5 are composed; baffle plate mechanism 23 is connected with folding arm mechanism 22, and folding arm mechanism 22 belongs to a part of high-speed telescopic arm forklift truck working device, and baffle plate mechanism 23 It can rotate around the folding arm mechanism 22; the baffle mechanism 23 is provided with two quick-change handles 29 and two limit blocks 31, and the two quick-change handles 29 can pull the two limit blocks 31 through the pin shaft 30; the hanging plate Mechanism 26 is provided with camera installation hole 7 and two position-limiting holes 32, and baffle plate mechanism 23 is inserted in two position-limiting holes 32 of plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com