Light bidirectional fork for stacker

A stacker, light technology, applied in the direction of lifting devices, etc., can solve the problems of inconvenient installation and adjustment, difficult processing and manufacturing, unreasonable mechanism, etc., and achieve the effect of small space occupation, convenient installation and adjustment, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

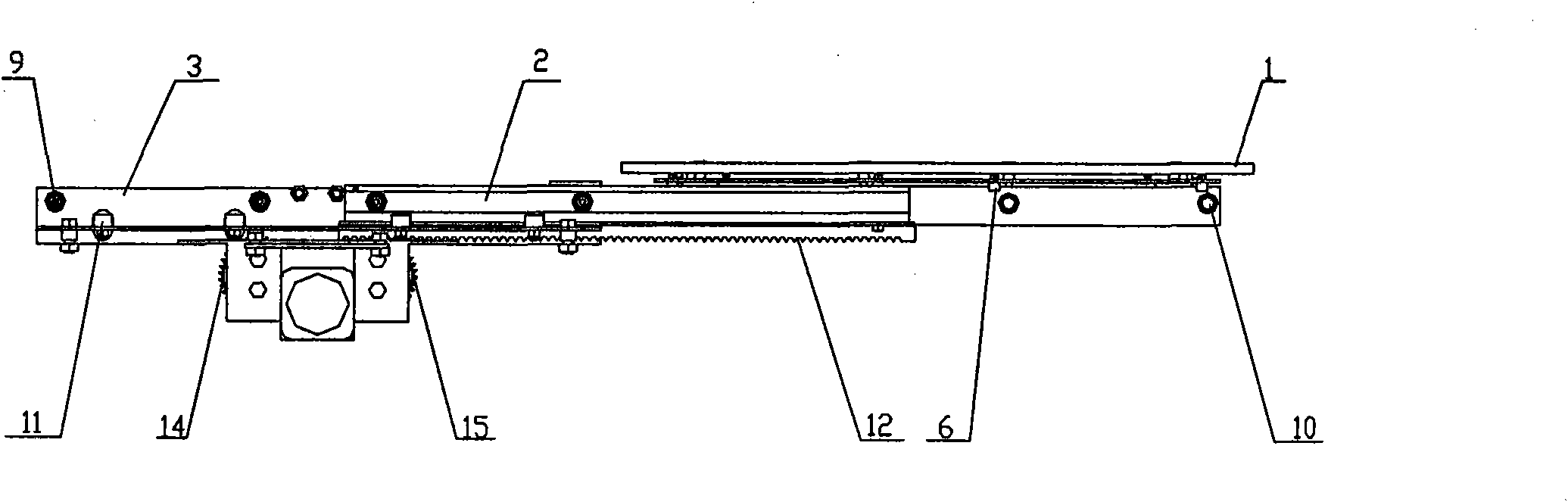

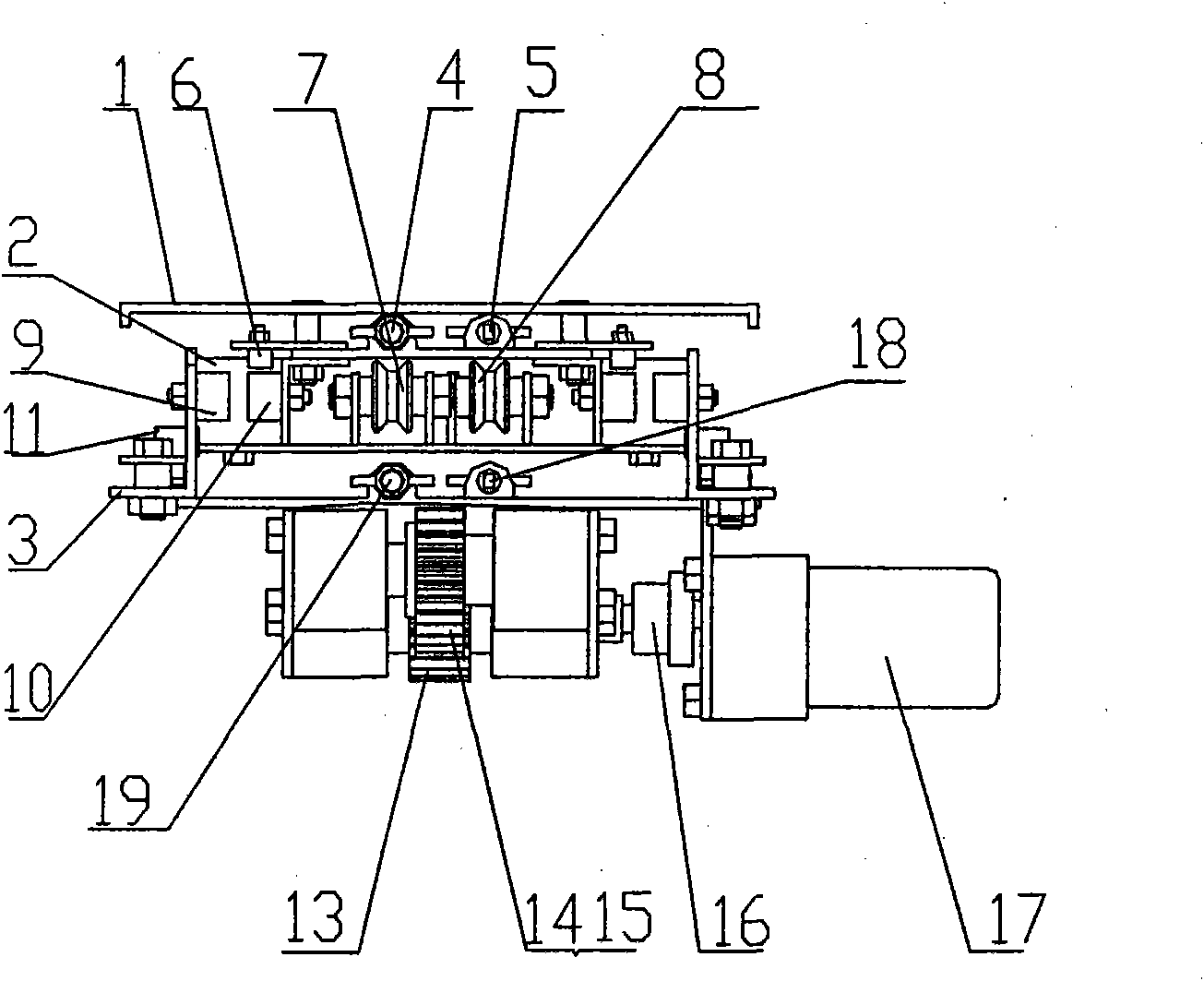

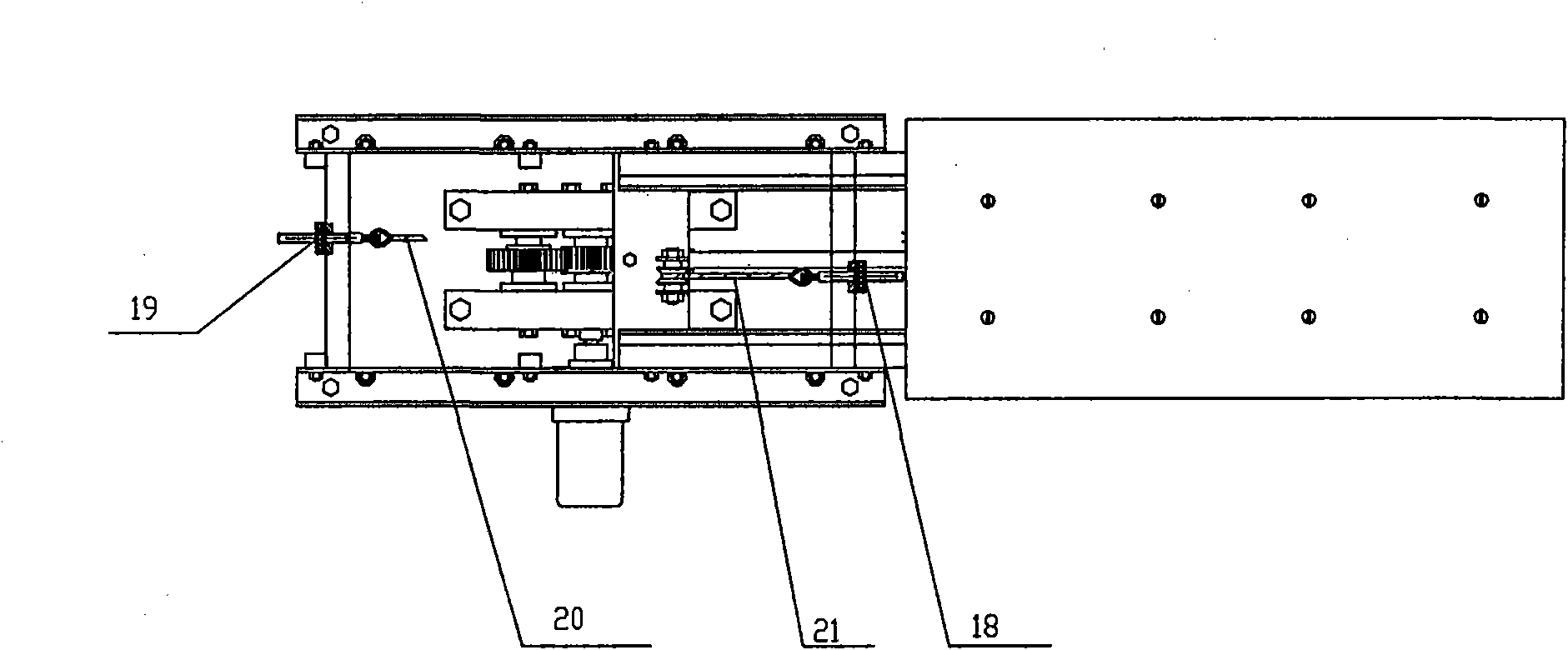

[0009] Such as figure 1 , figure 2 and image 3 Shown, the light-duty two-way goods fork of stacker among the present embodiment, it is by upper fork 1, middle difference 2, lower fork 3, wire rope adjuster (4,5,18,19), roller (7,8), Guide bolt bearings (6,9,10,11,), transmission rack 12, gears (13,14,15), shaft coupling 16, motor 17, steel wire rope (20,21). Among them, the steel wire rope adjusters 4, 5 are arranged on the lateral sides of the upper fork 1 and are staggered; the steel wire rope adjusters 18, 19 are arranged on the lateral sides of the lower fork 3 and are staggered; Side, guide bolt bearings, 9, 11 are arranged on the lateral sides of the lower fork 3, rollers 7, 8 are arranged on the lateral sides of the middle fork 2 and are staggered, the rack 12 is meshed in the middle of the middle fork cross section, and the gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com