Large-scale ultrahigh lift height floating crane

A lifting height and ultra-high technology, applied to cranes and other directions, can solve the problems of low installation efficiency and constraints on the development of marine engineering, and achieve high installation efficiency, save installation costs, and super-high effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

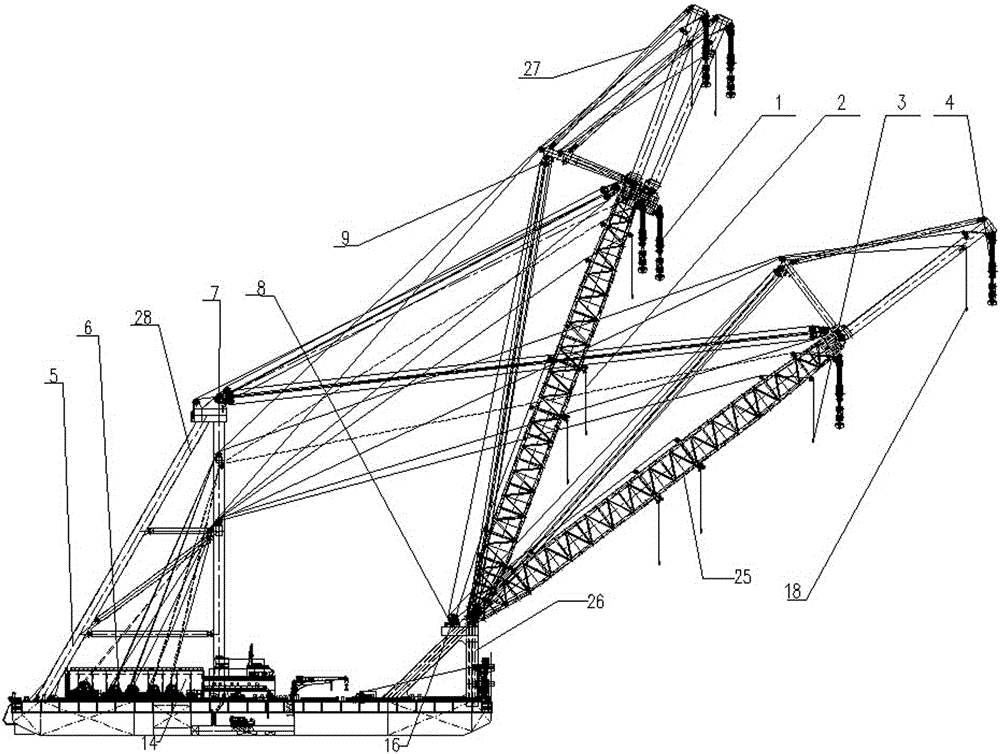

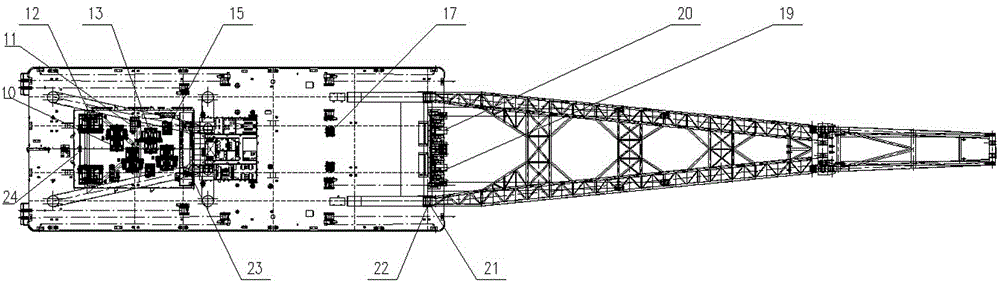

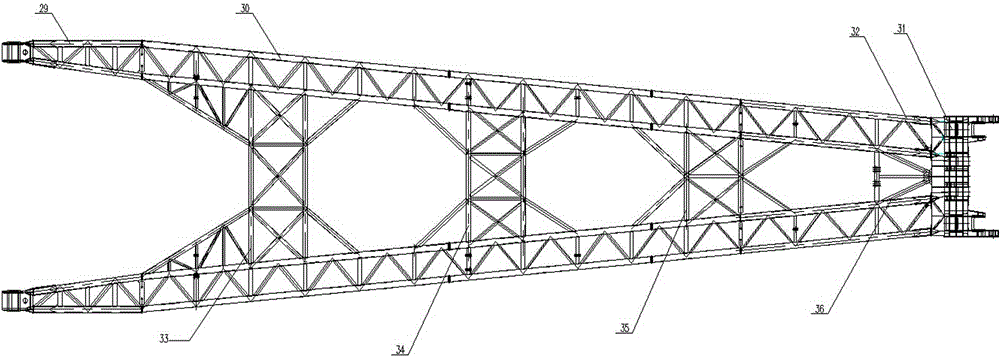

[0019] Such as Figure 1-5 As shown, a large-scale ultra-high lifting height floating crane, the floating crane includes a floating crane boom 25, a small boom 27, a boom bracket 26, and a herringbone frame 28, and the boom bracket, the boom and the small boom Connected in sequence, the jib is equipped with the main hook pulley system 1, the anchor pulley system 2 and the main hook rigging hook pulley system 3, and the jib root is equipped with the jib head adjustment mechanism 8, the anchor mechanism 16 and the auxiliary winch mechanism 17. Auxiliary hook pulley system is provided on the small boom frame 4. Auxiliary hook rigging hook pulley system 18. Boom head adjustment pulley system connecting the boom frame and small boom frame. There are 1500T hook box 19 and 750T hook box 20 under the frame support, a limit system 21 and a lubrication system 22 are provided at the connection between the boom and the boom bracket, and a metal structure 5 and a luffing pulley system 7 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com