Ultralong multifunctional movable conveyer

A mobile conveying, multi-functional technology, applied in conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of limited conveyor height, inability to stack sand and gravel, limited lifting height, etc., to reduce self-weight and use costs, The effect of improving equipment utilization and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

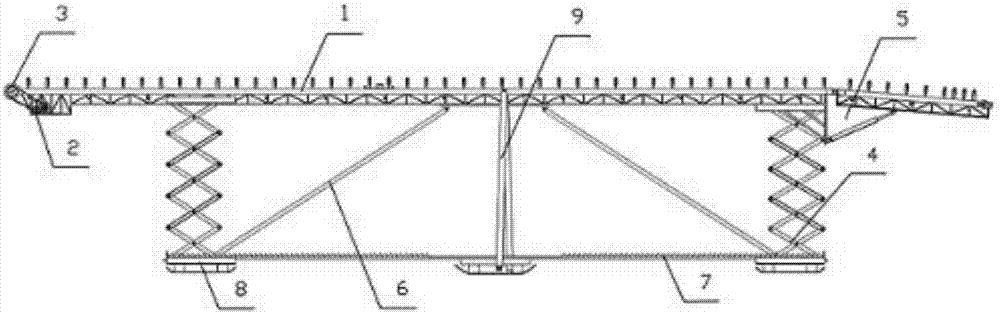

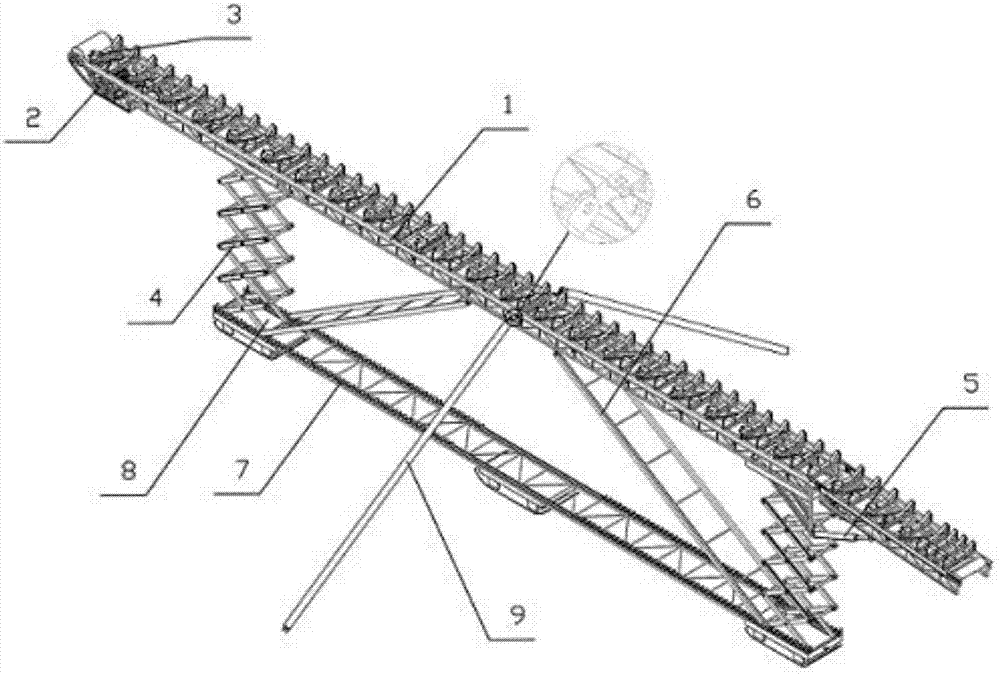

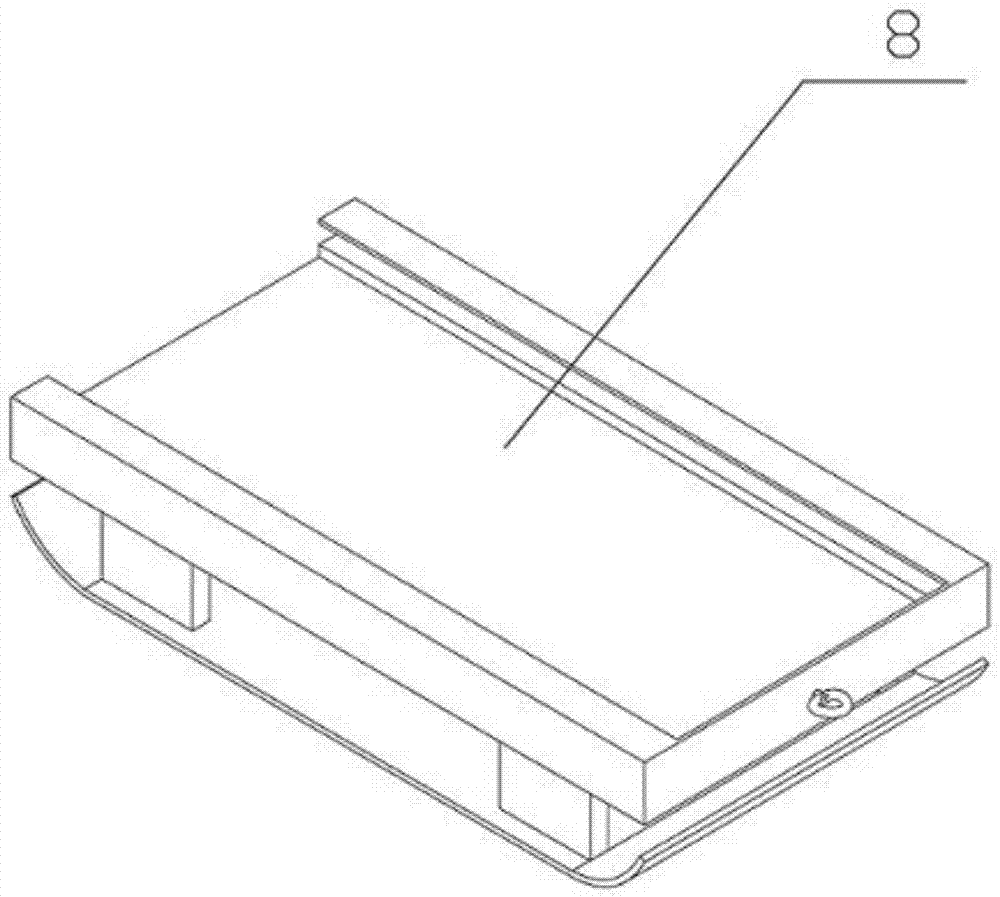

[0019] as attached figure 1 and figure 2 As shown, the present invention discloses an ultra-long multifunctional mobile conveyor, which includes a conveying arm frame 1, a power system 2, and a driving roller 3, and is characterized in that it also includes a lifting mechanism 4, a luffing mechanism 5, a support rod 6, and a groove Bar 7, slide plate 8, stabilizer bar 9; the conveying boom 1 is hinged by two booms of different lengths, the main girders on both sides of the conveying boom 1 are I-shaped steel, the upper and lower surfaces are truss structures, and the upper surface is horizontal. The rod is equipped with idler rollers; the lifting mechanism 4 is a multi-layer scissors structure, which is driven by a hydraulic cylinder. The other side is a mobile connection, moving back and forth along the main beam; the conveyor inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com