Lifting support for X-ray flaw detection machine

A lifting bracket and flaw detection machine technology, applied in the field of industrial X-ray flaw detection, can solve the problems of difficult flaw detection work, single function of the bracket, and inaccurate moving distance, etc., and achieve the effects of small space occupation, flexible height adjustment, and simplified work requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

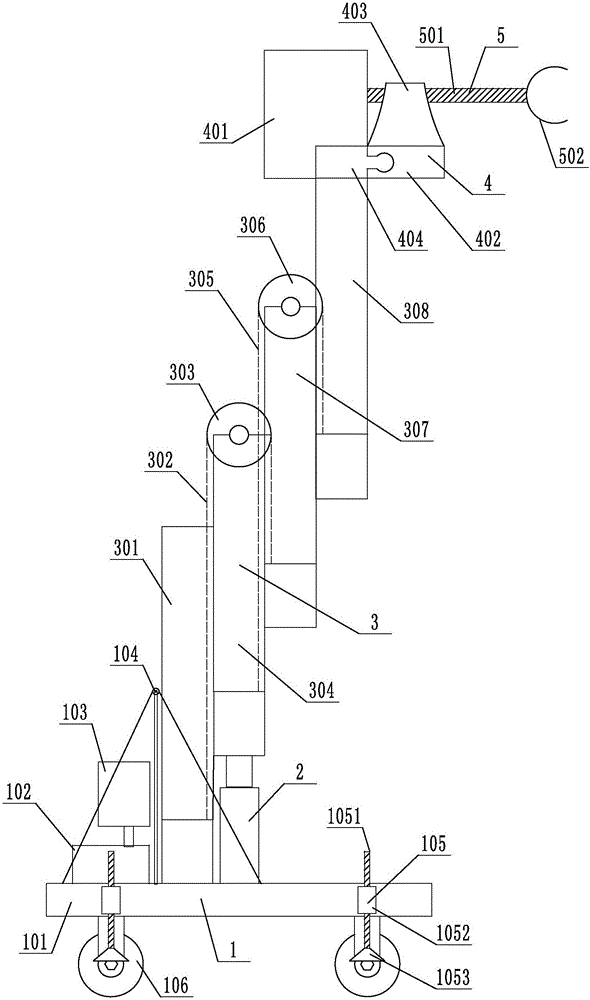

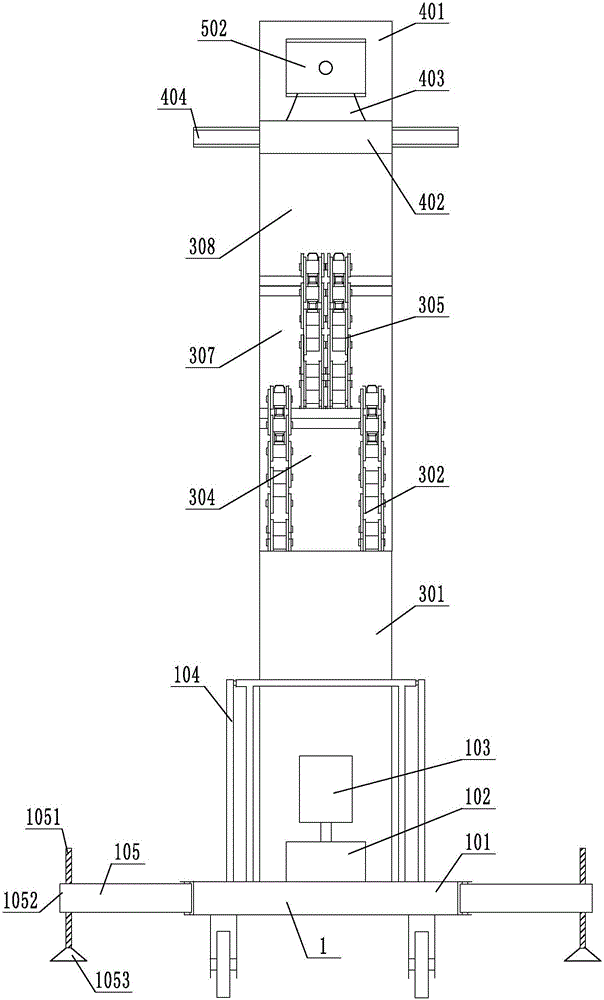

[0026] Such as Figure 1 to Figure 2 as shown,

[0027] The lifting bracket of the X-ray flaw detector includes a base 1 , a driving part 2 , a lifting component 3 , a sliding component 4 and a rotating component 5 . The base is provided with a driving part and a lifting assembly, the driving part is connected with a lifting assembly, the lifting assembly is provided with a working bucket 401, the working bucket is provided with a sliding assembly, and the sliding assembly is connected with a rotating assembly. The end of the rotating assembly is equipped with an X-ray flaw detector.

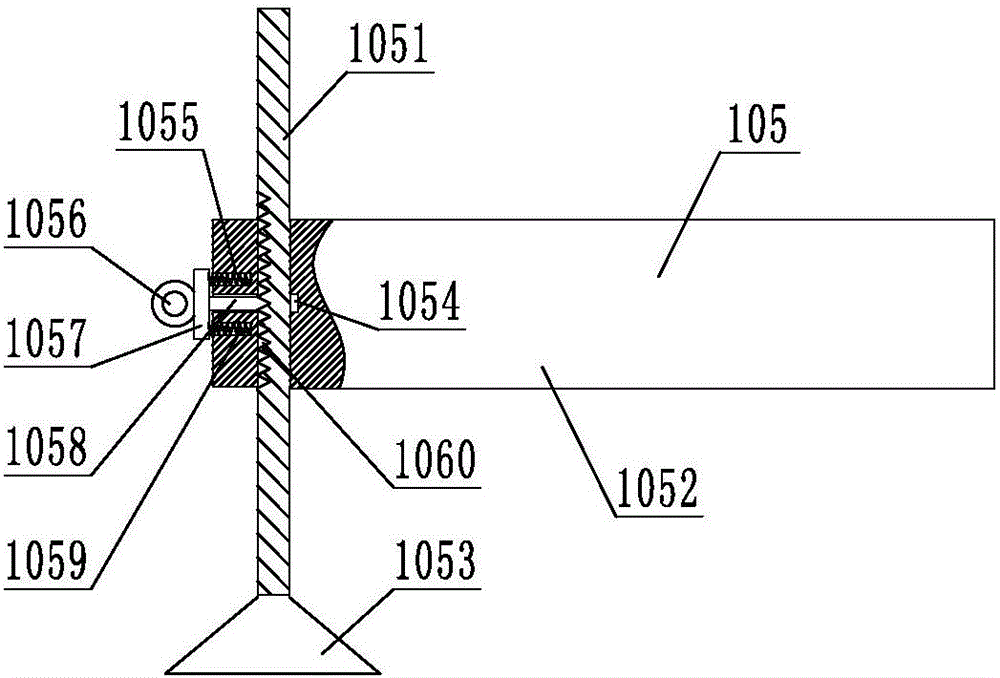

[0028] The base includes a chassis 101, the chassis is provided with a base support 104, a driving part 2 and a lifting assembly 3, a hydraulic tank 102 and a compression motor 103 are installed on the base support, the compression motor 103 is connected with the hydraulic tank 102, and the driving part 2 is hydraulic cylinder. The hydraulic tank 102 is connected with the hydraulic cylinder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com