Patents

Literature

41results about How to "Simple and clear design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

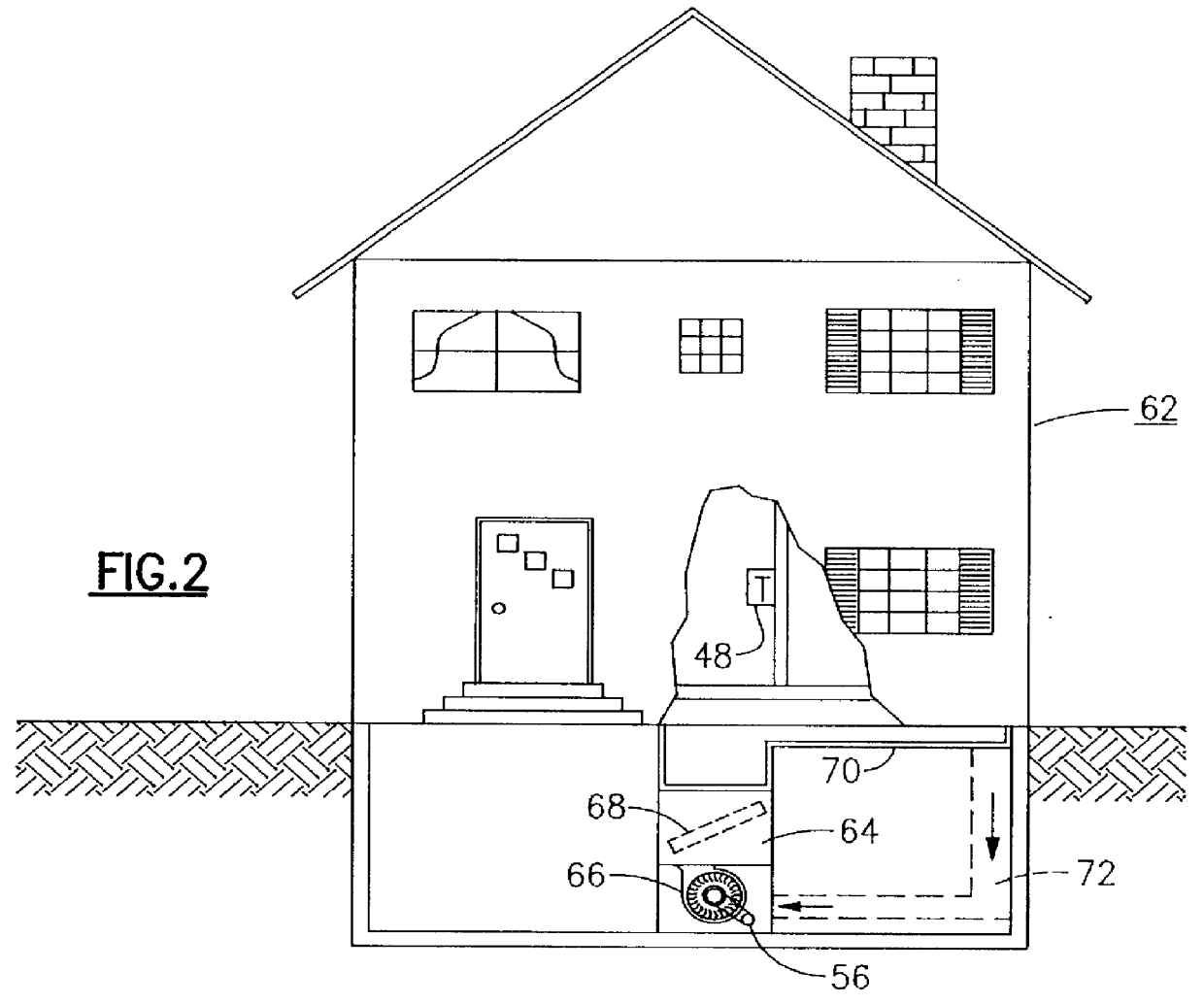

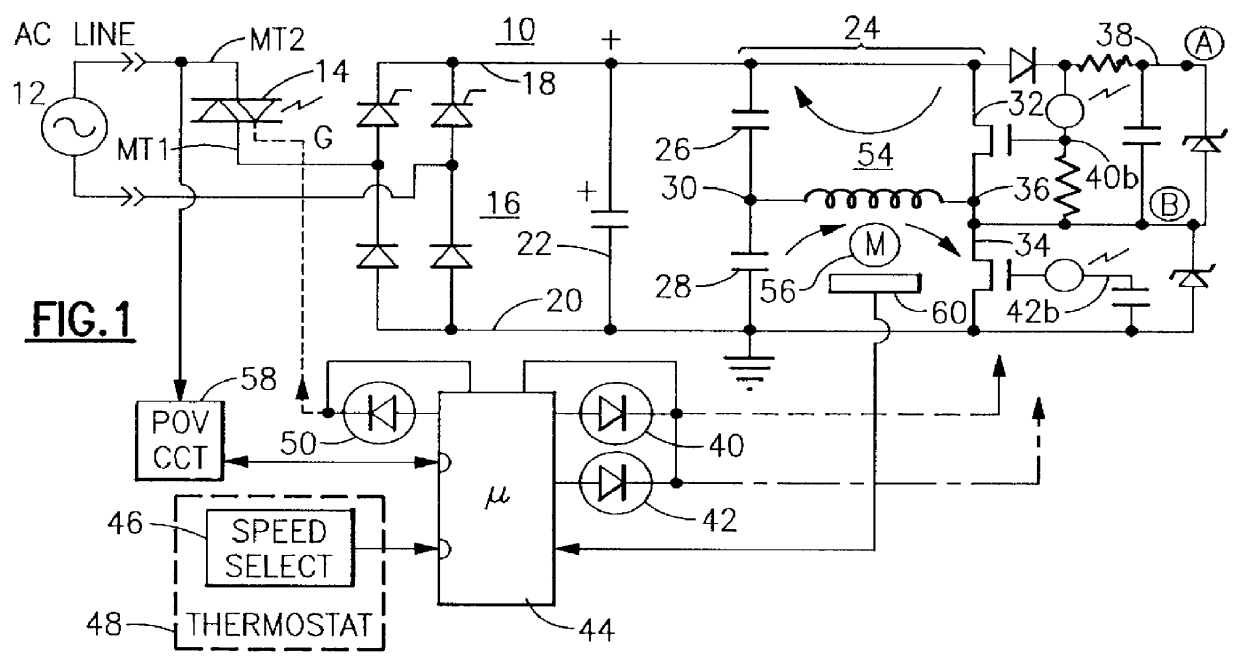

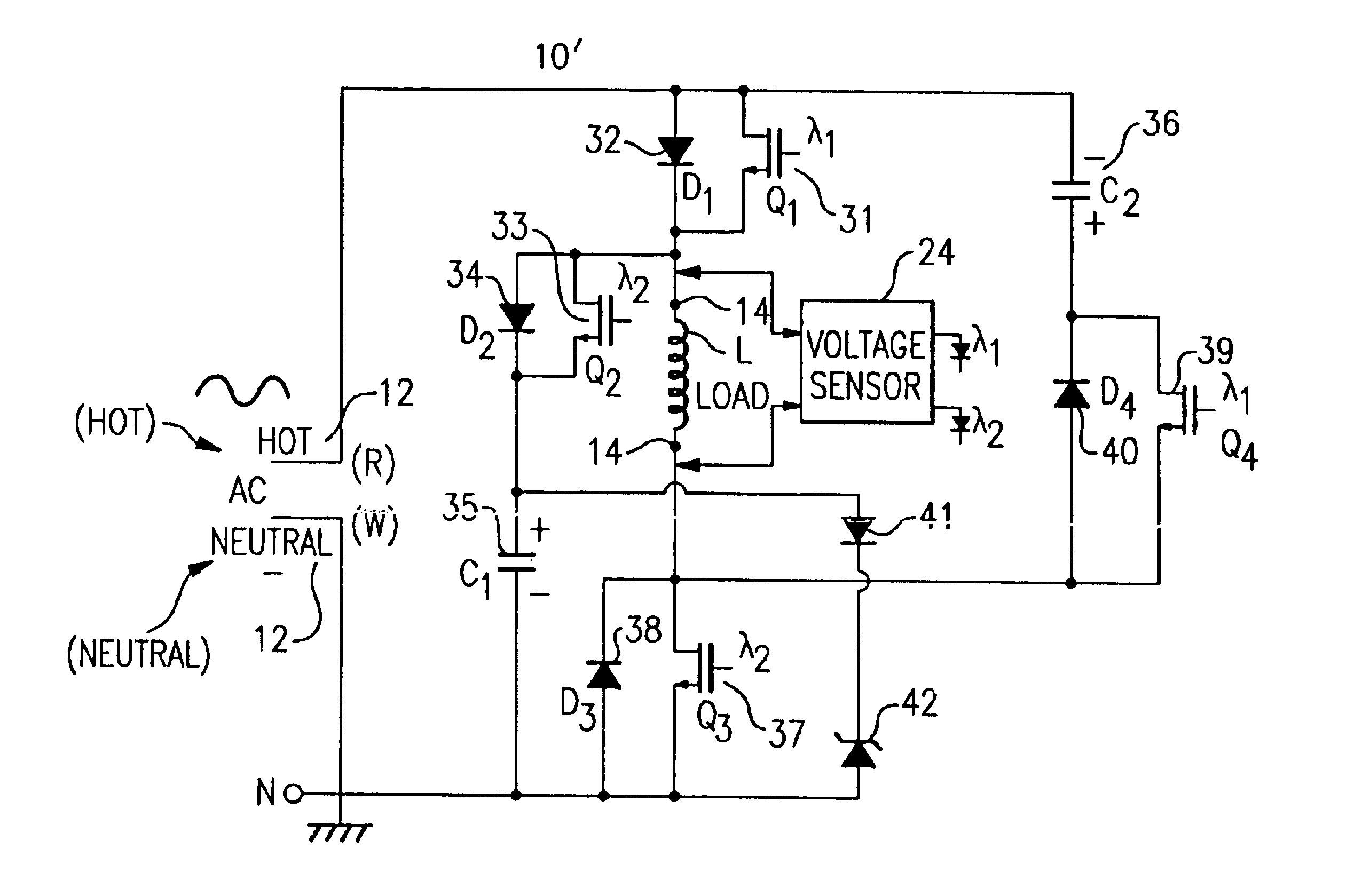

Speed control drive circuit for blower motor

InactiveUS6118239AEasy to operateEasy to controlAC motor controlDC motor speed/torque controlMotor driveControl theory

Drive circuit for a blower motor employs a microprocessor control element, a controlled rectifier to provide DC power at a controlled rail voltage, and an inverter employing a pair of switching transistors arranged as a bridge inverter or half-bridge inverter. The drive circuit operates over a range of blower speeds and varies both the frequency and amplitude of bipolar pulses that are applied to the blower motor armature.

Owner:INT CONTROLS & MEASUREMENT

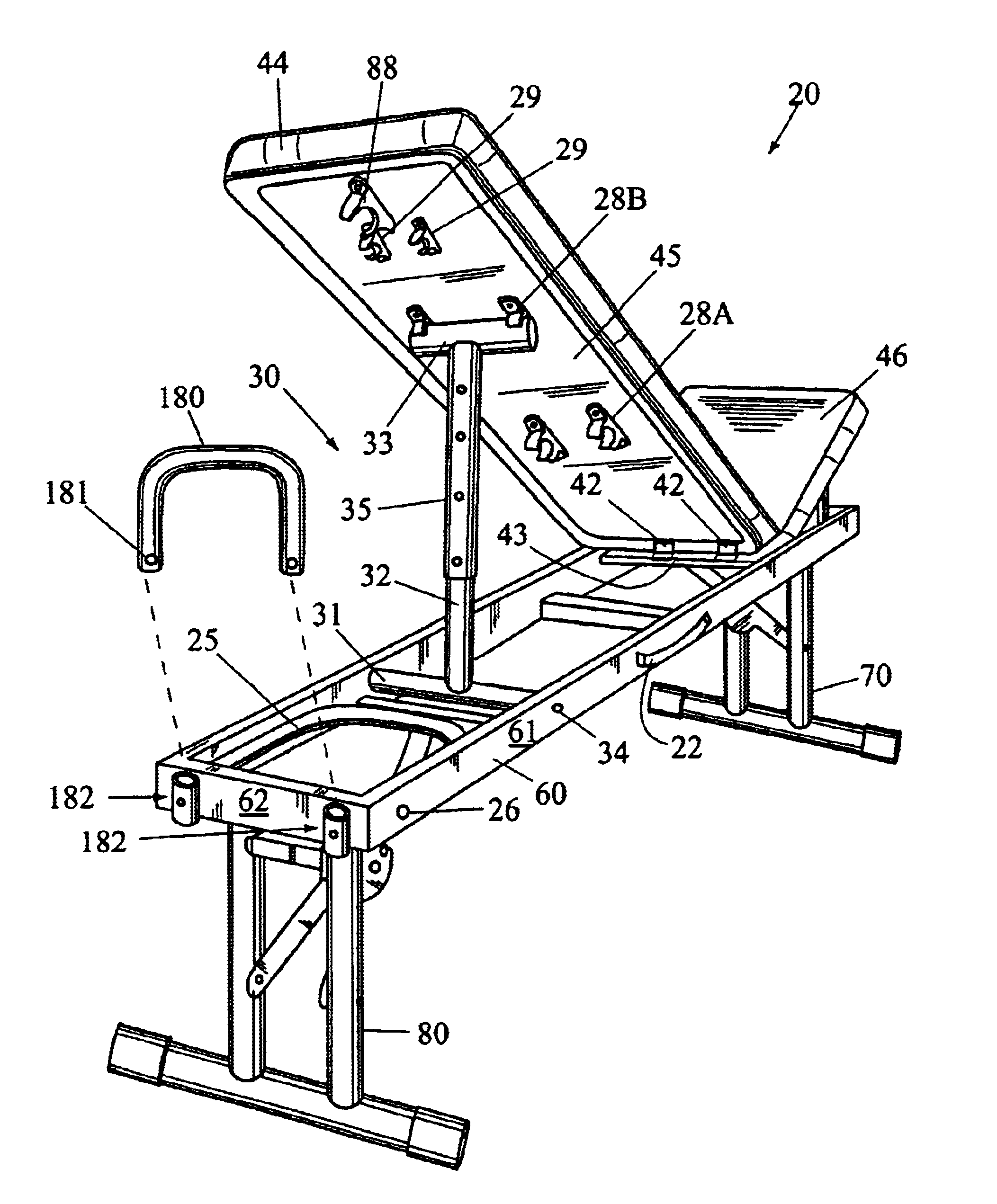

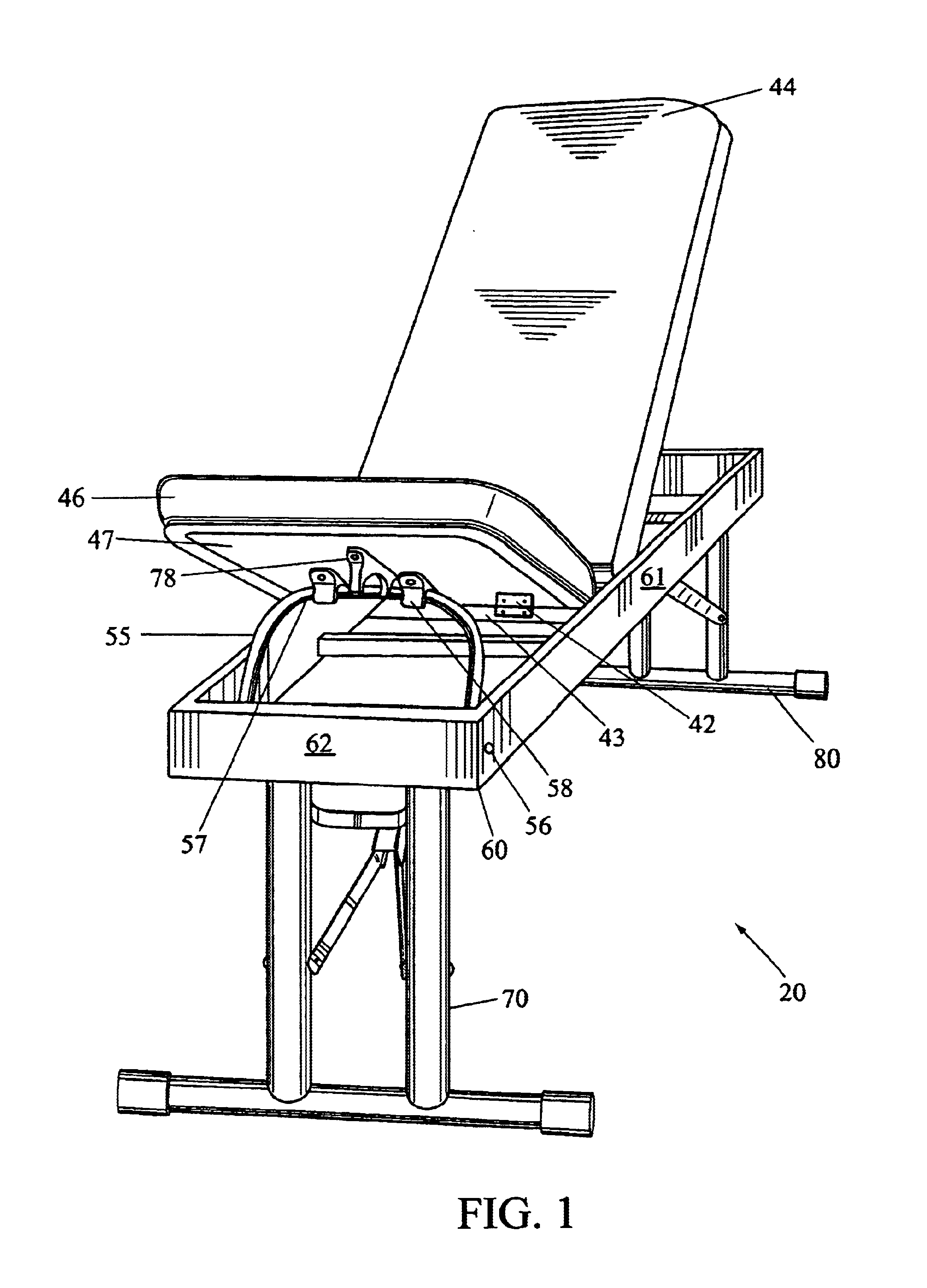

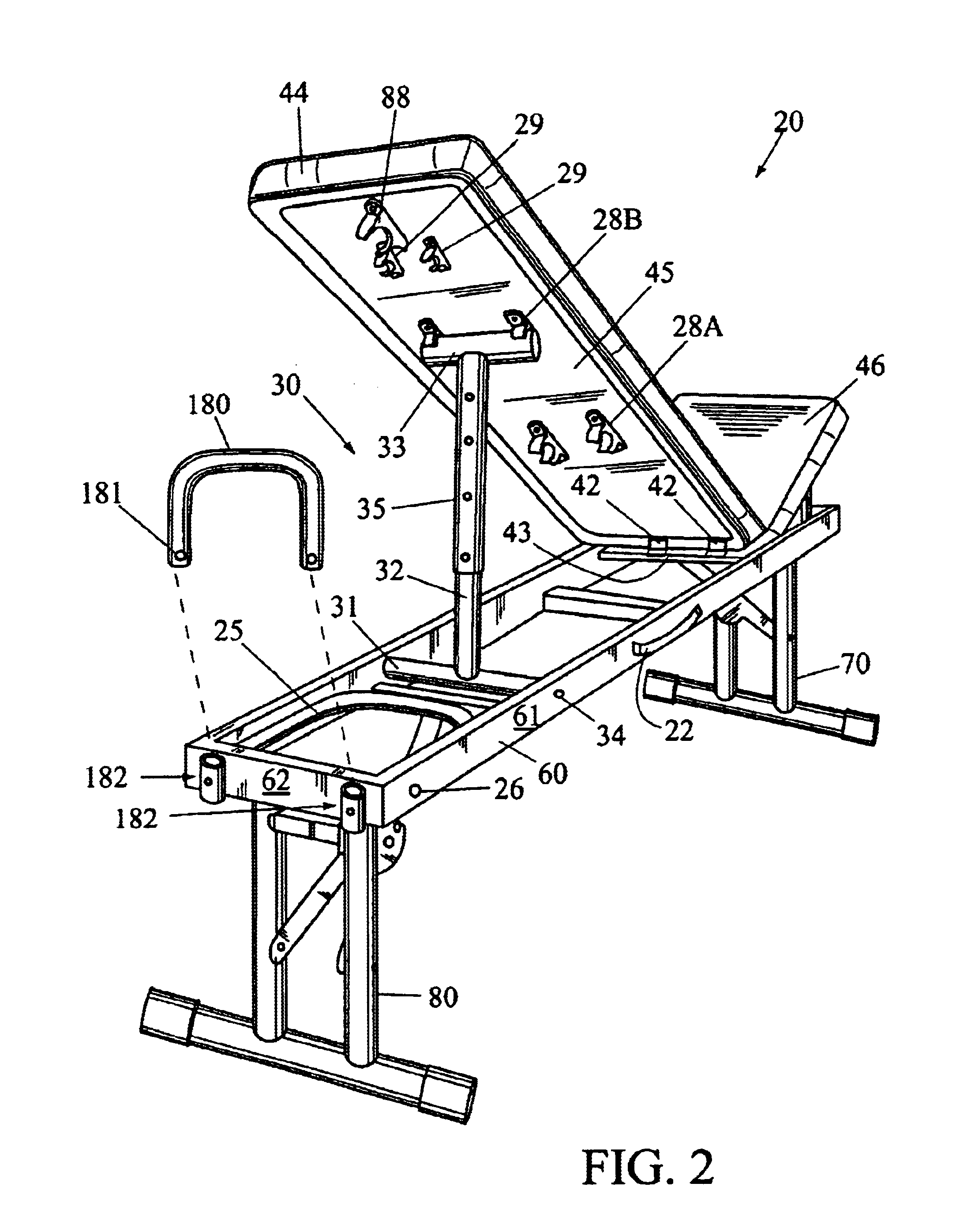

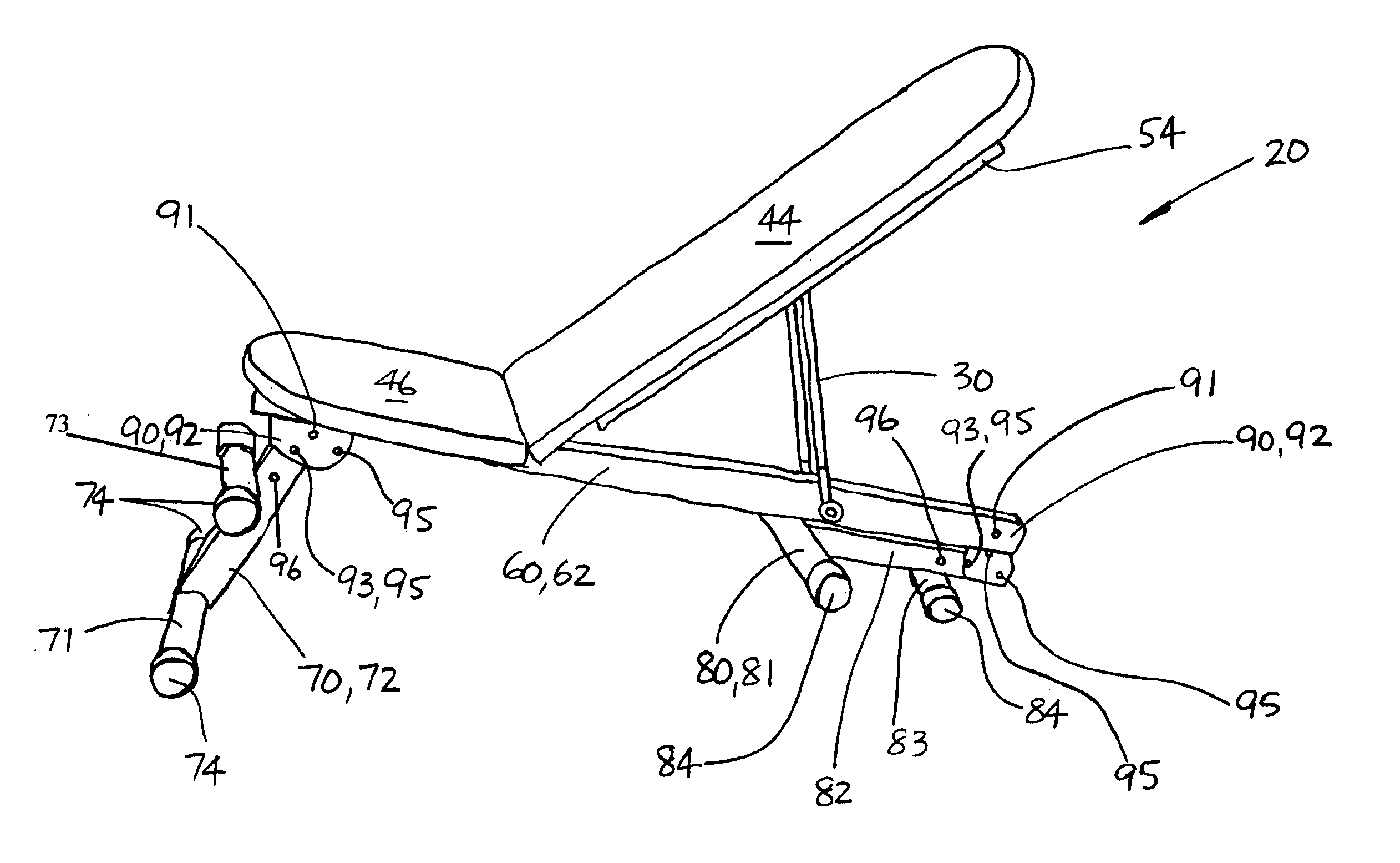

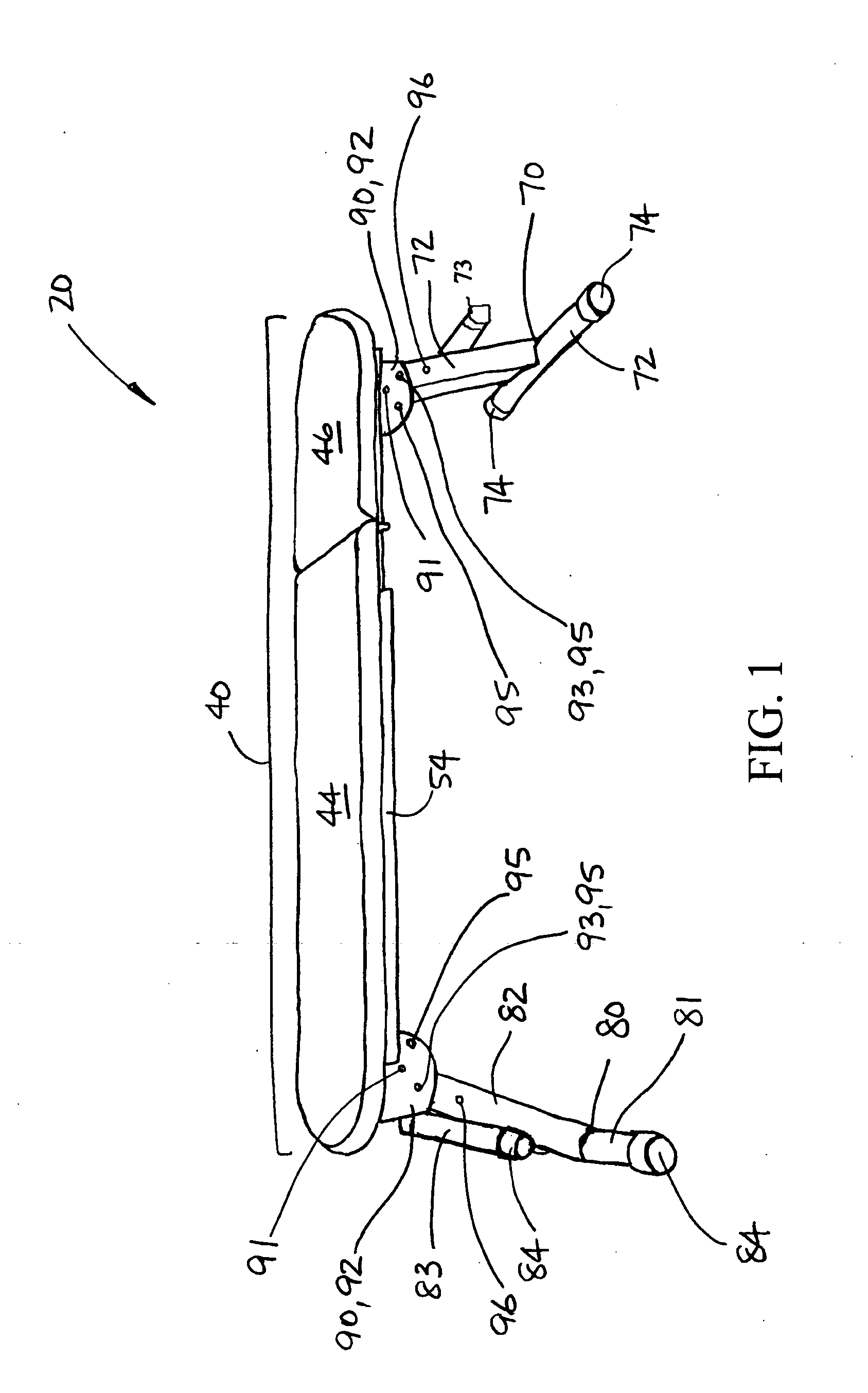

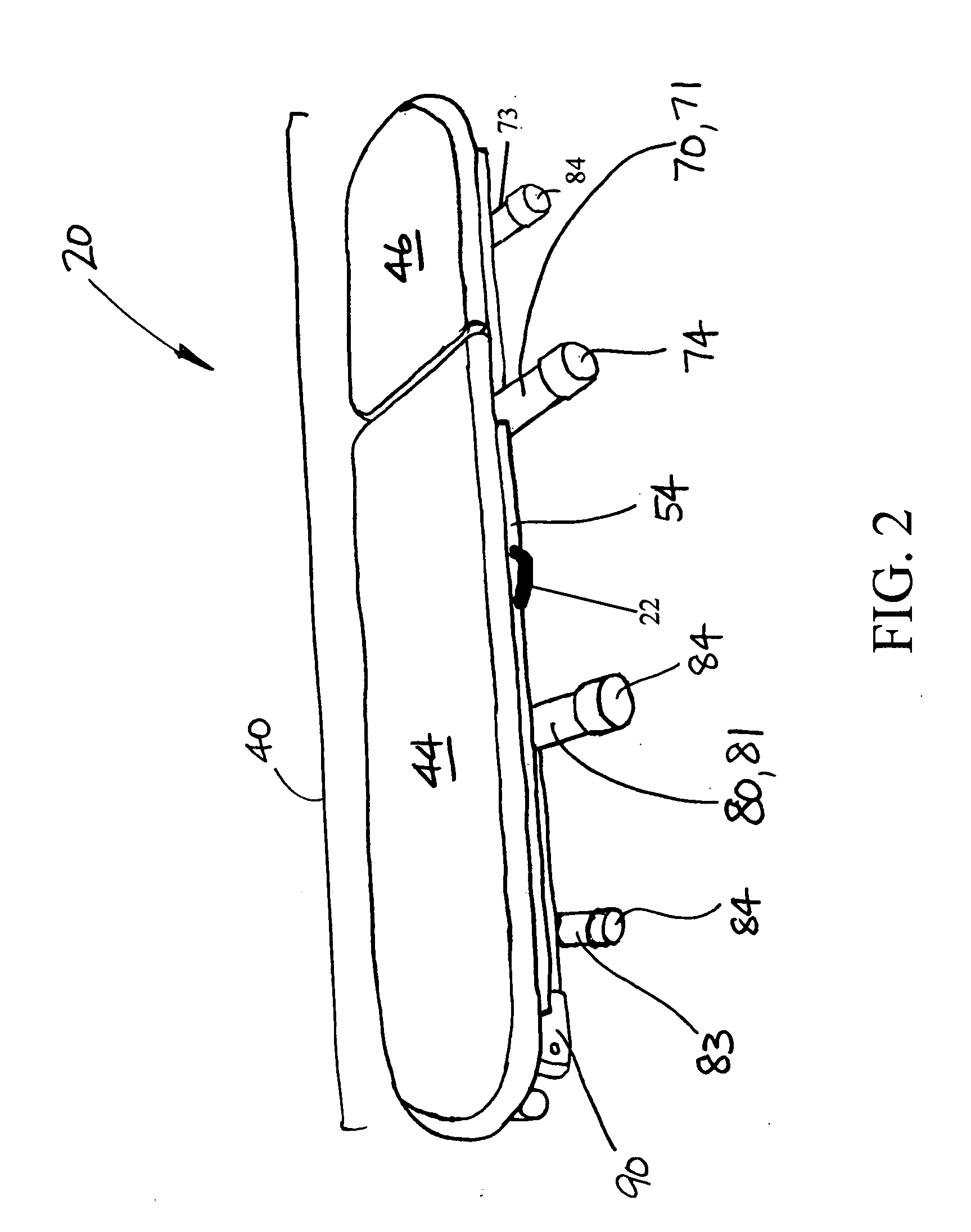

Articulated bench

InactiveUS6805409B2Reduce manufacturing costProvide durabilityOperating chairsDismountable chairsSurface mountingEngineering

An articulated bench comprising a two-section pad attached to a rectangular frame and two folding / pivoting support leg assemblies. The two padded sections are pivotally attached to the frame. Either of the two padded end sections can be pivoted upward and locked at a selectable incline. Either of a length-adjustable I-shaped brace assembly, or alternatively, a U-shaped support assembly fold out of the frame from beneath the longer of the two pivoting, padded end sections (i.e. the section for supporting the upper body) and are inserted into one of a series of catches located on the section's rear surface to hold it at a selectable incline. The shorter of the two pivoting, padded end sections (i.e. the section for supporting an individual's lower body) also pivots upward and a U-shaped support assembly folds out of the frame and is inserted in a pair of surface-mounted catches to maintain the section in an inclined position. The present invention's design is simple and straightforward, and can be economically manufactured and can quickly and easily be set up, or knocked down and carried.

Owner:PARKER JAMES

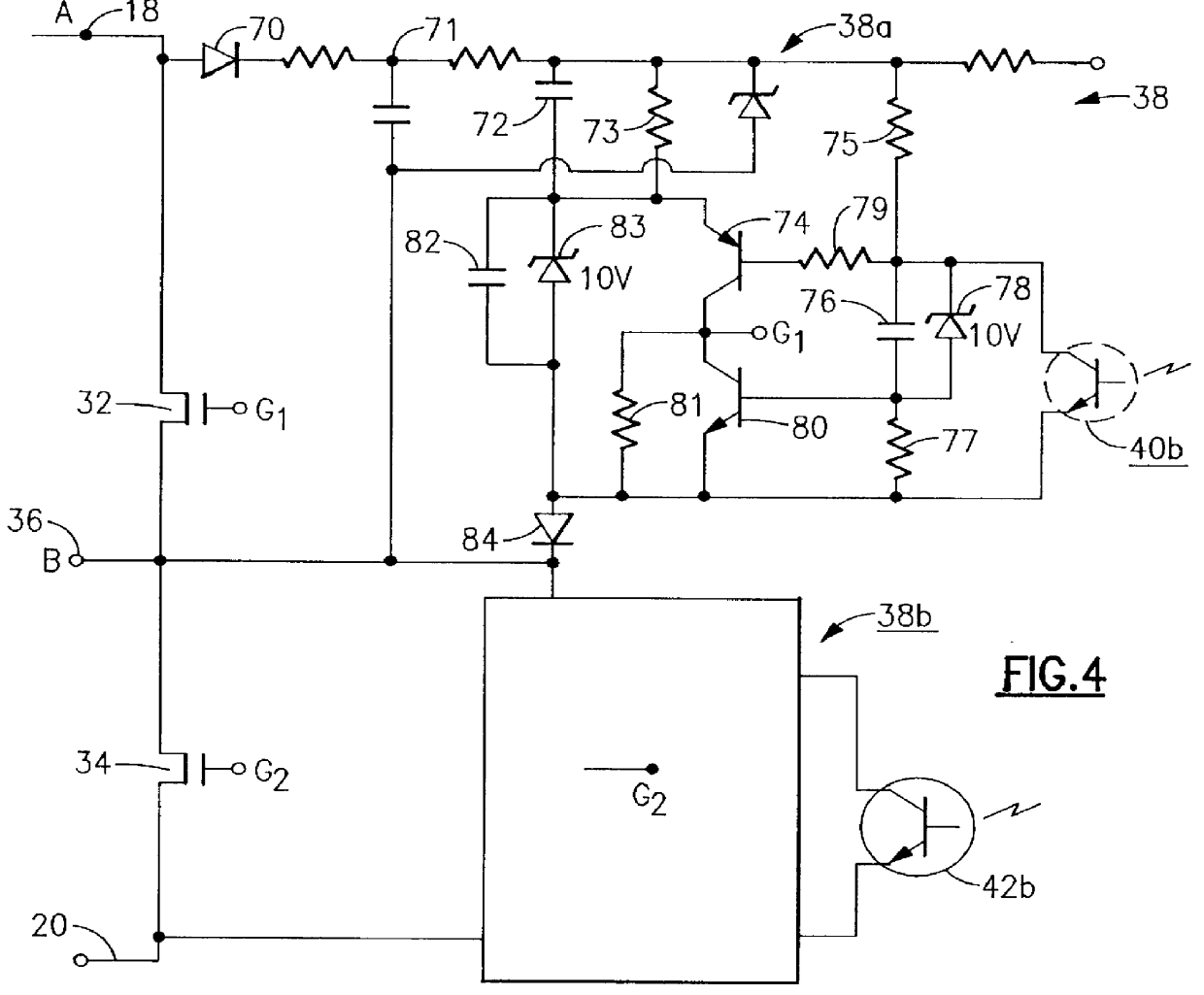

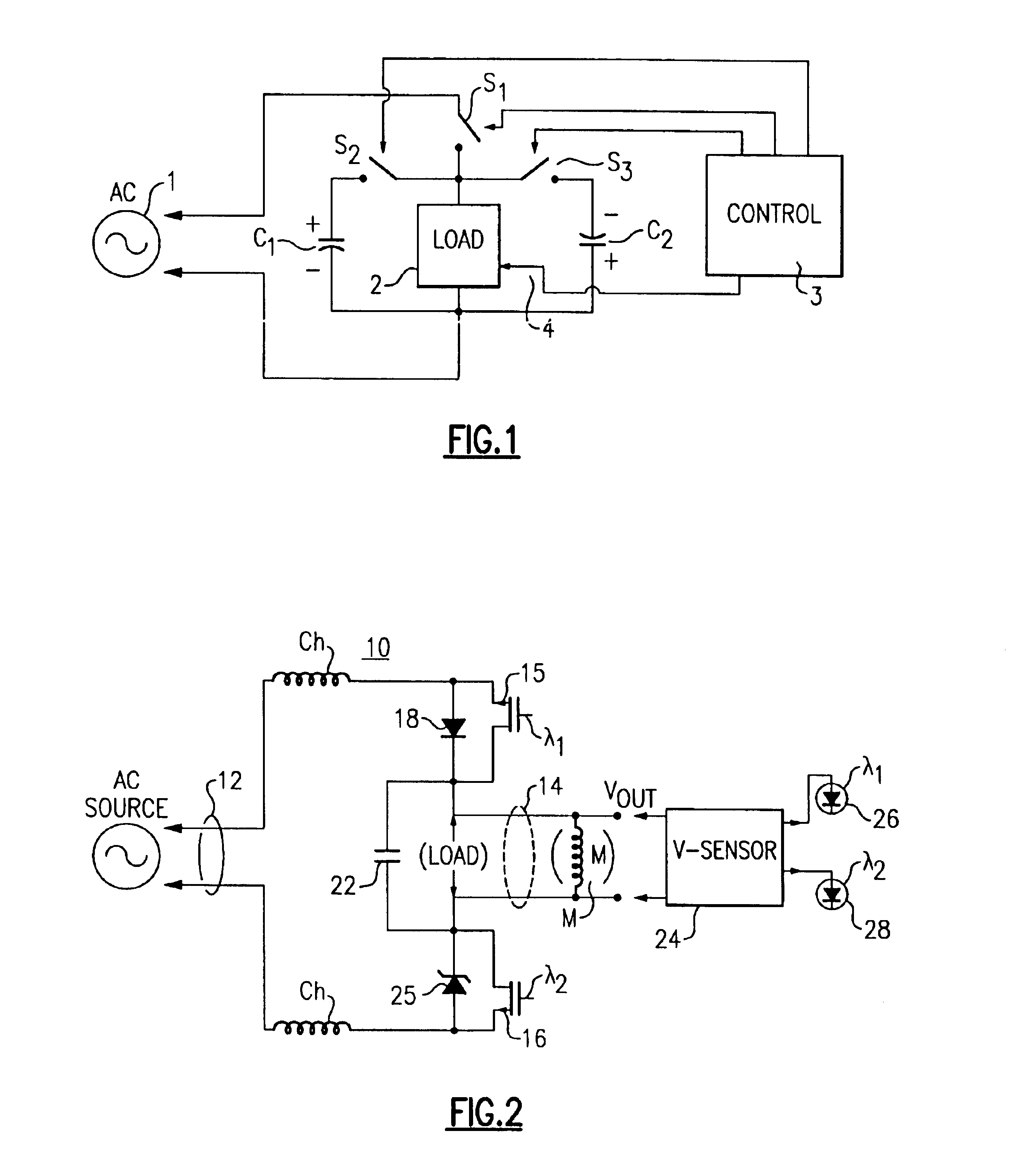

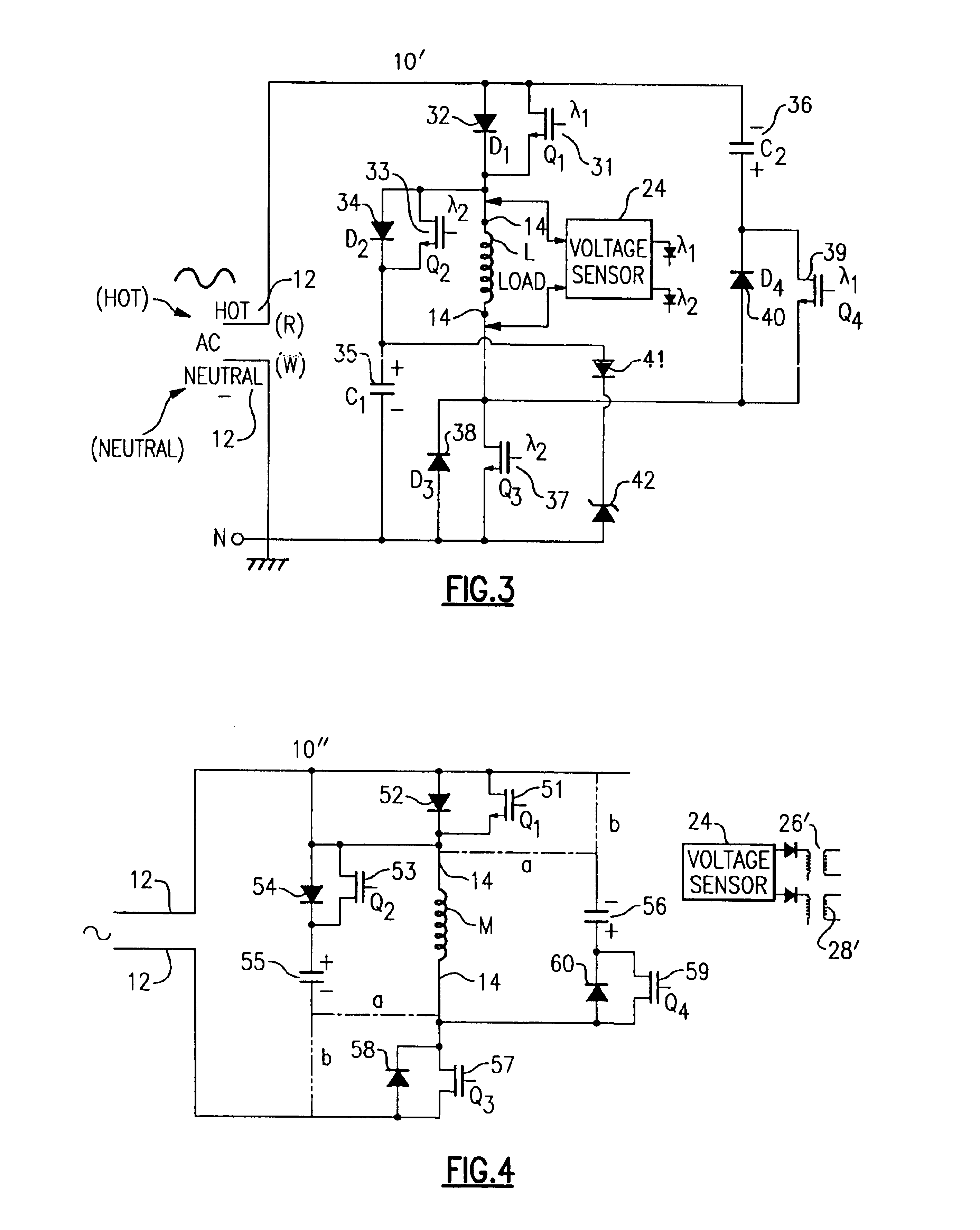

Universal energy regulating controller circuit

InactiveUS6753670B2Avoid disadvantagesSimple and clear designSingle-phase induction motor startersMotor/generator/converter stoppersMotor speedPower controller

A power controller for applying power to an induction motor or similar AC load has a variable drive circuit for staring and switching a portion of the AC input line power. In one mode, the input line power is fed straight through to the load. In another mode, the AC waveform is reshaped to improve the power factor or to boost its RMS value, e.g., for brownout protection. In a further mode the output power can be provided at a different frequency from the input line power. Vector control increases efficiency through power optimization, with sensing of load requirements. Sensing of regeneration pulses at the commencement of a half cycle can be employed for direct sensing of motor speed or load.

Owner:INT CONTROLS & MEASUREMENT

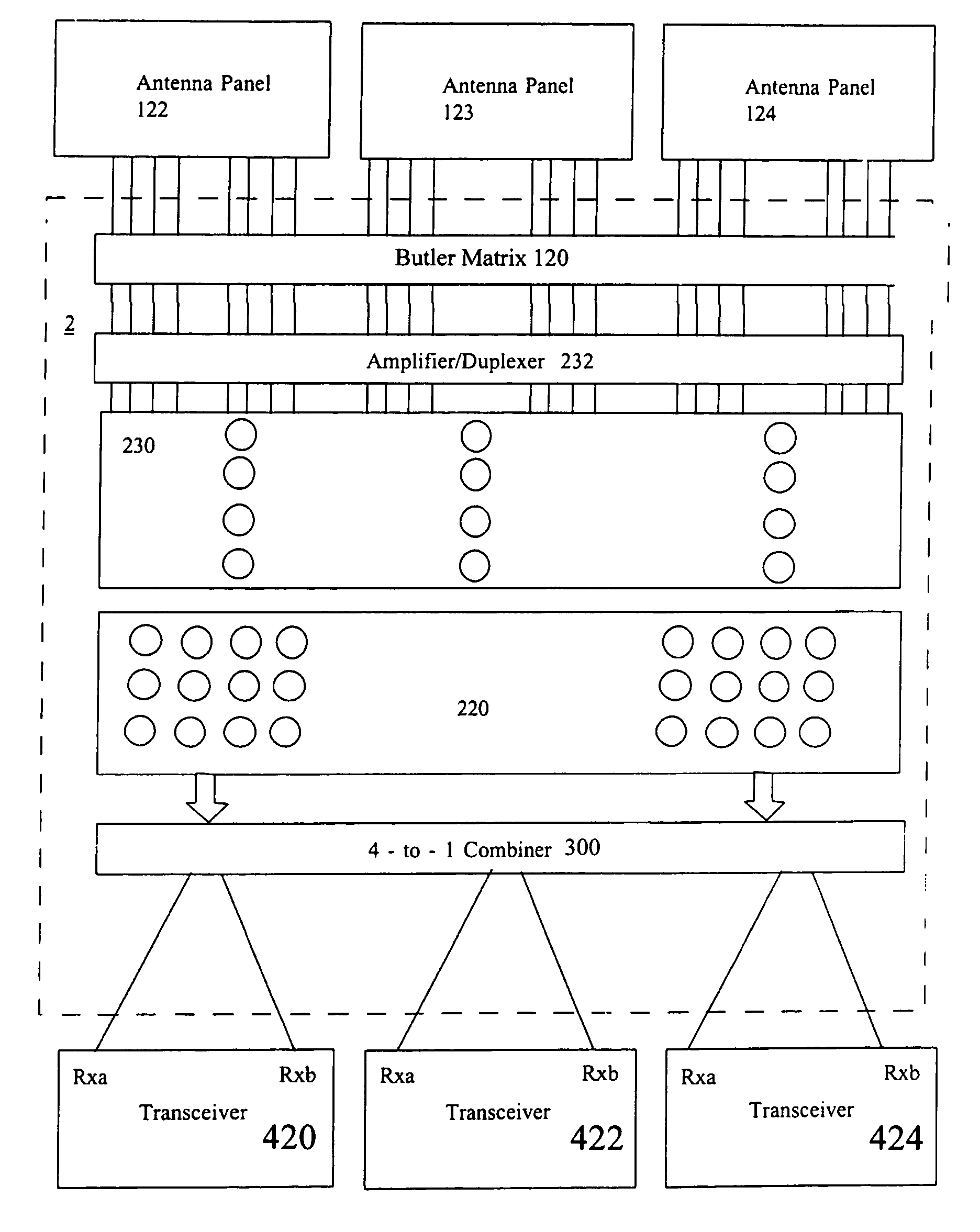

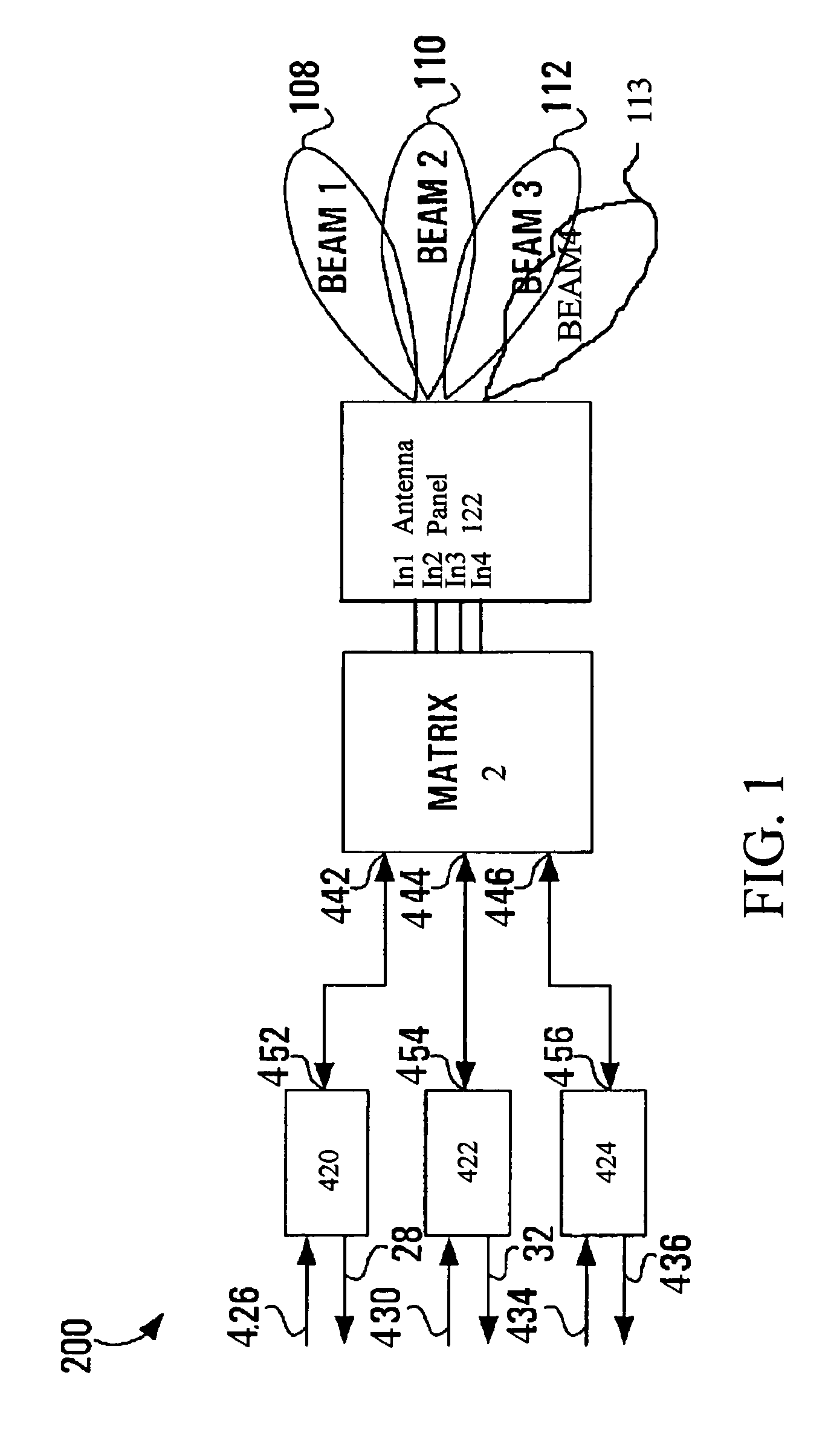

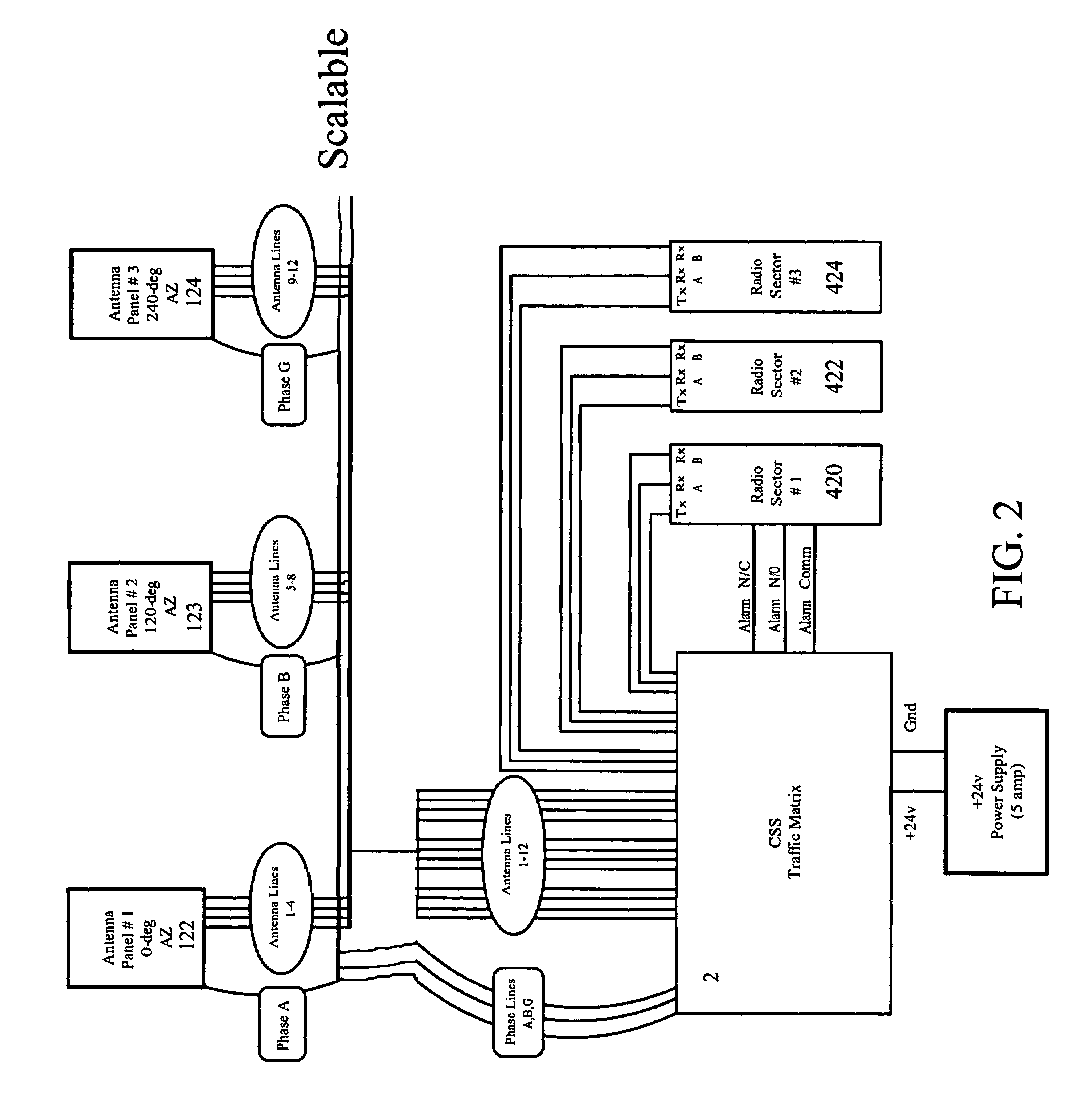

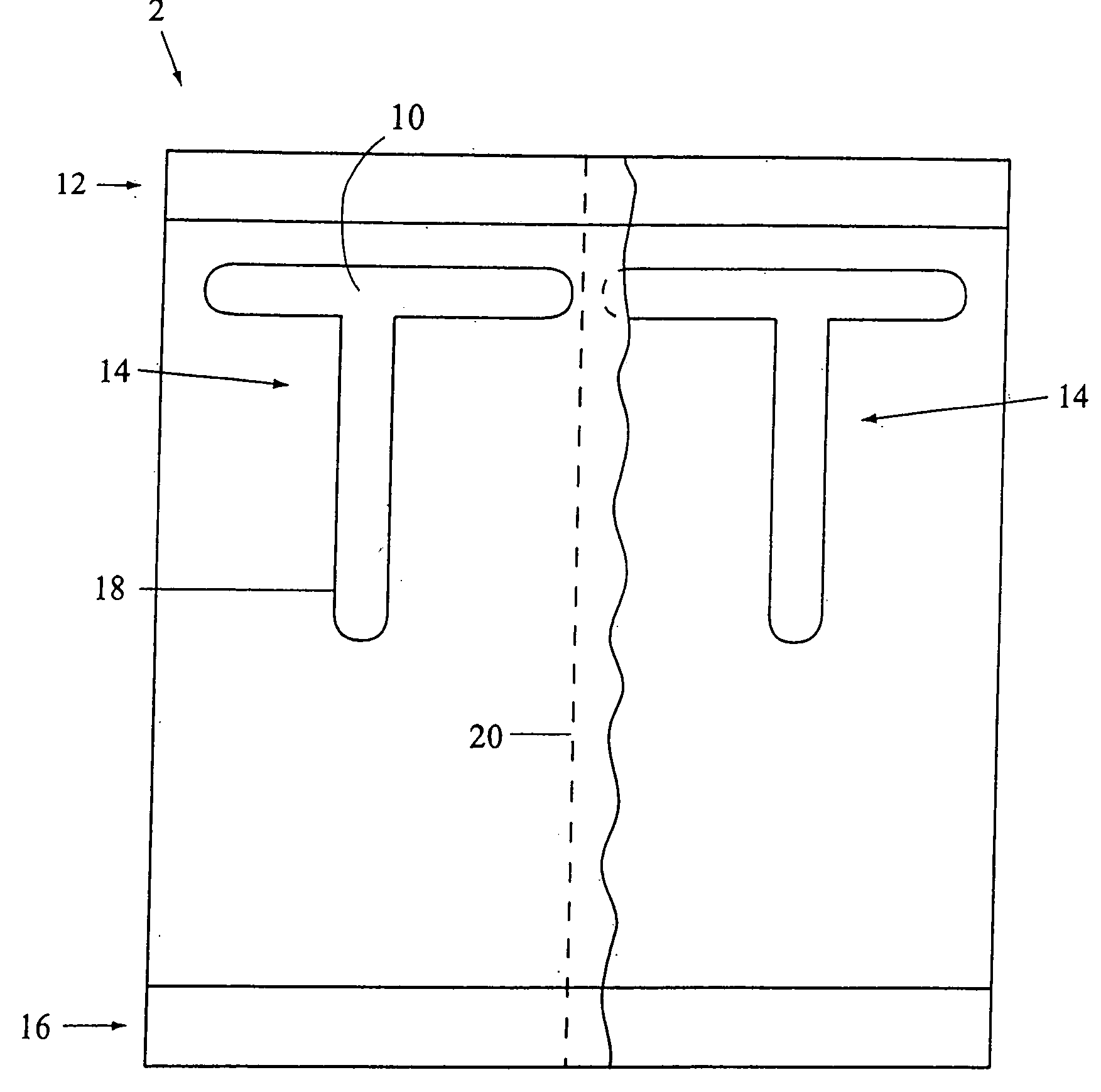

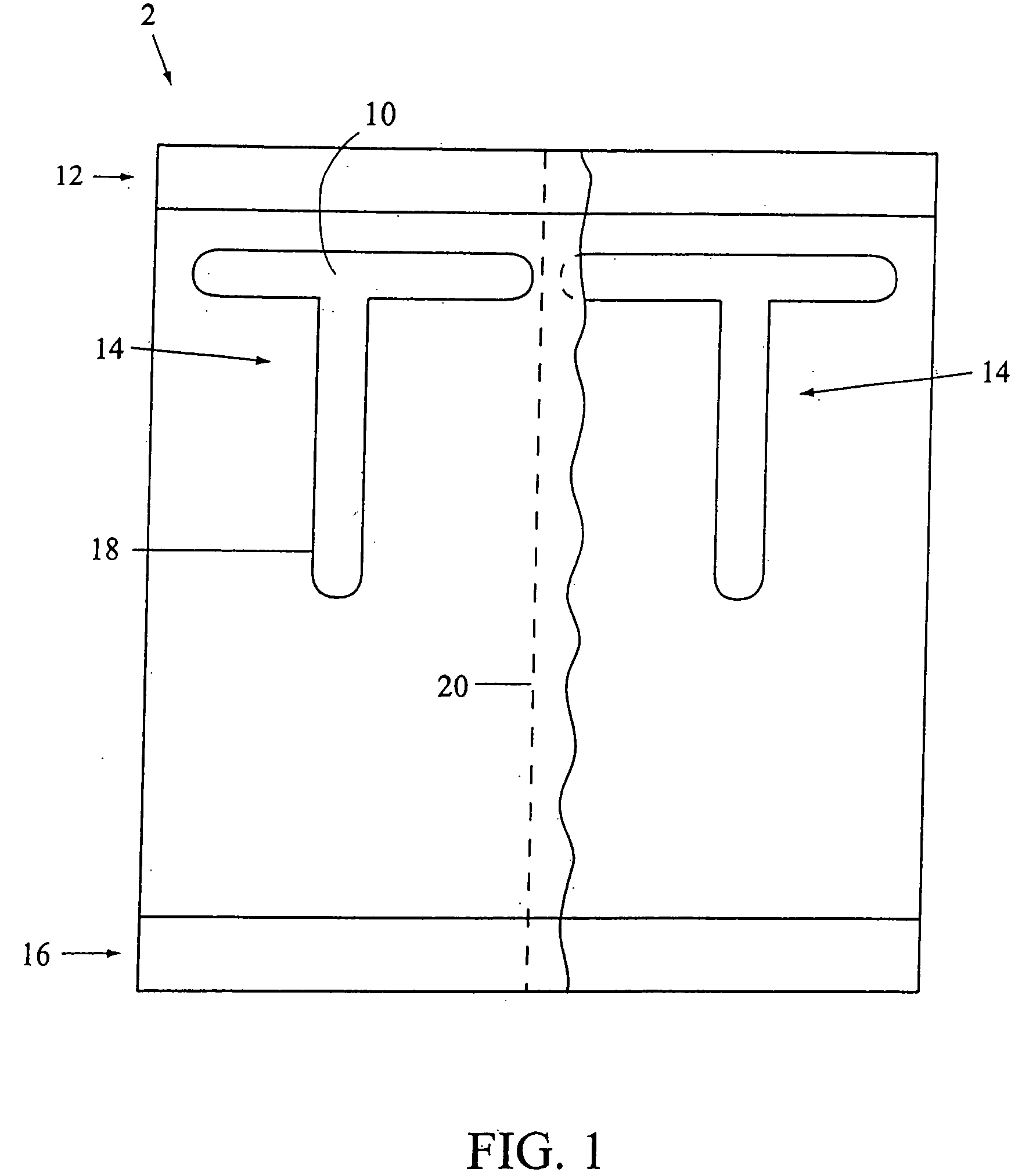

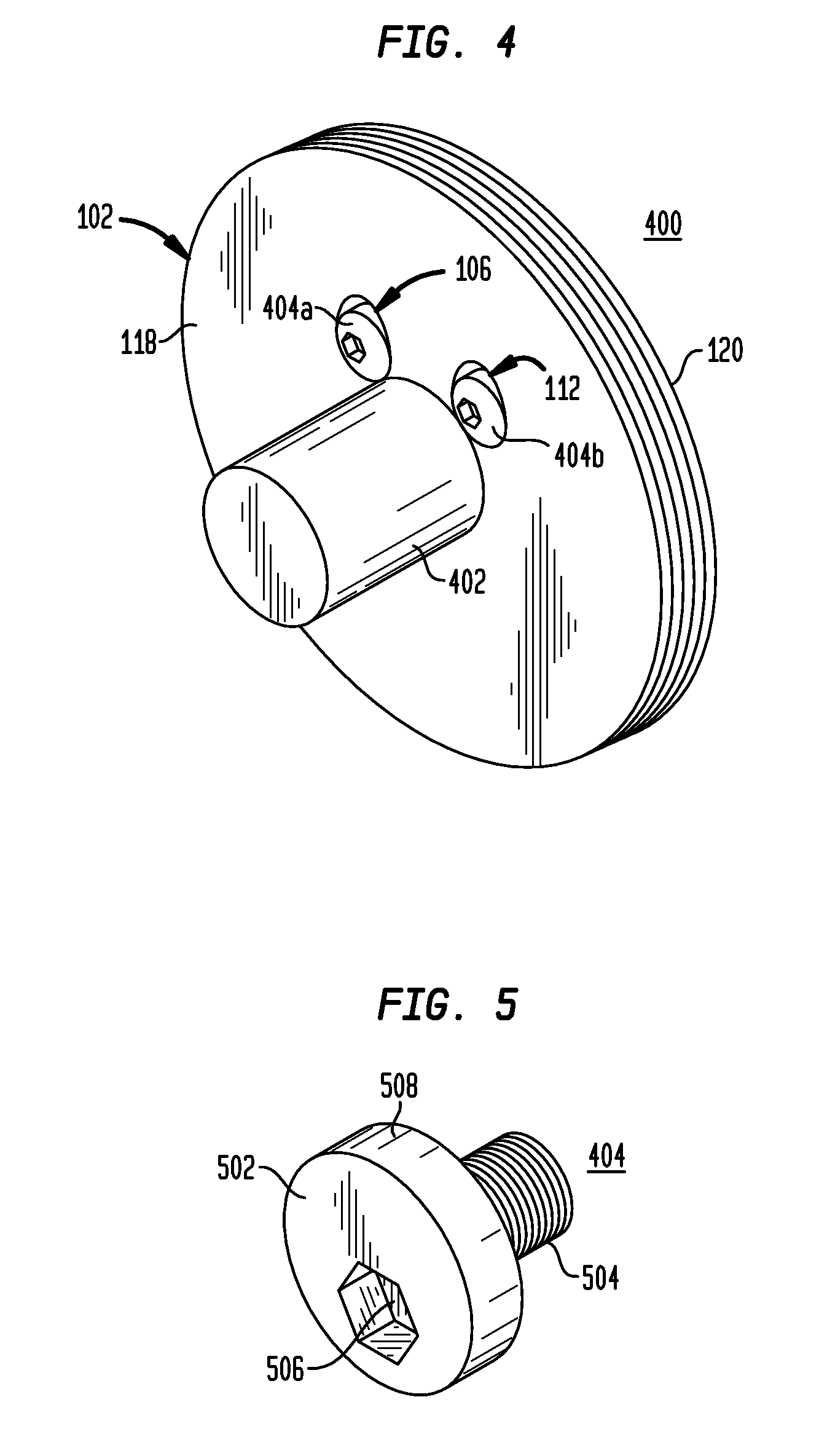

Wireless antenna traffic matrix

InactiveUS7245938B2Simple procedureNo equipment failure or downtimePolarisation/directional diversityAntenna supports/mountingsTraffic capacityPatch panel

A beam shaping antenna matrix for use in wireless cell towers that is manually-configured at a patch panel by a wireless operator based on selection of a desired beam size and point of direction. The traffic matrix allows a wireless operator to sculpt and resculpt the beams to accommodate demographic or other changes preferably without a large amount of hardware or intensive processing capability.

Owner:CSS ANTENNA

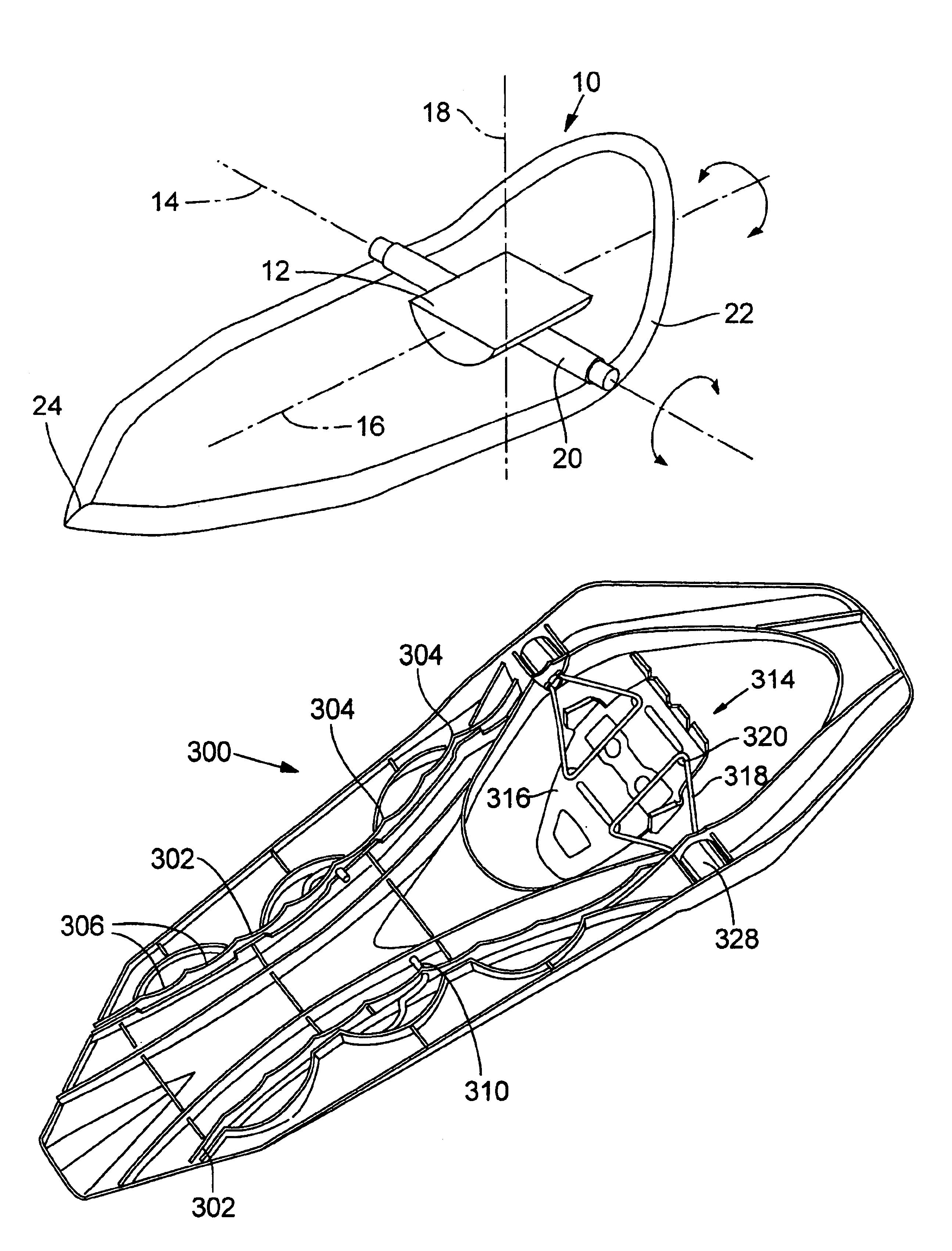

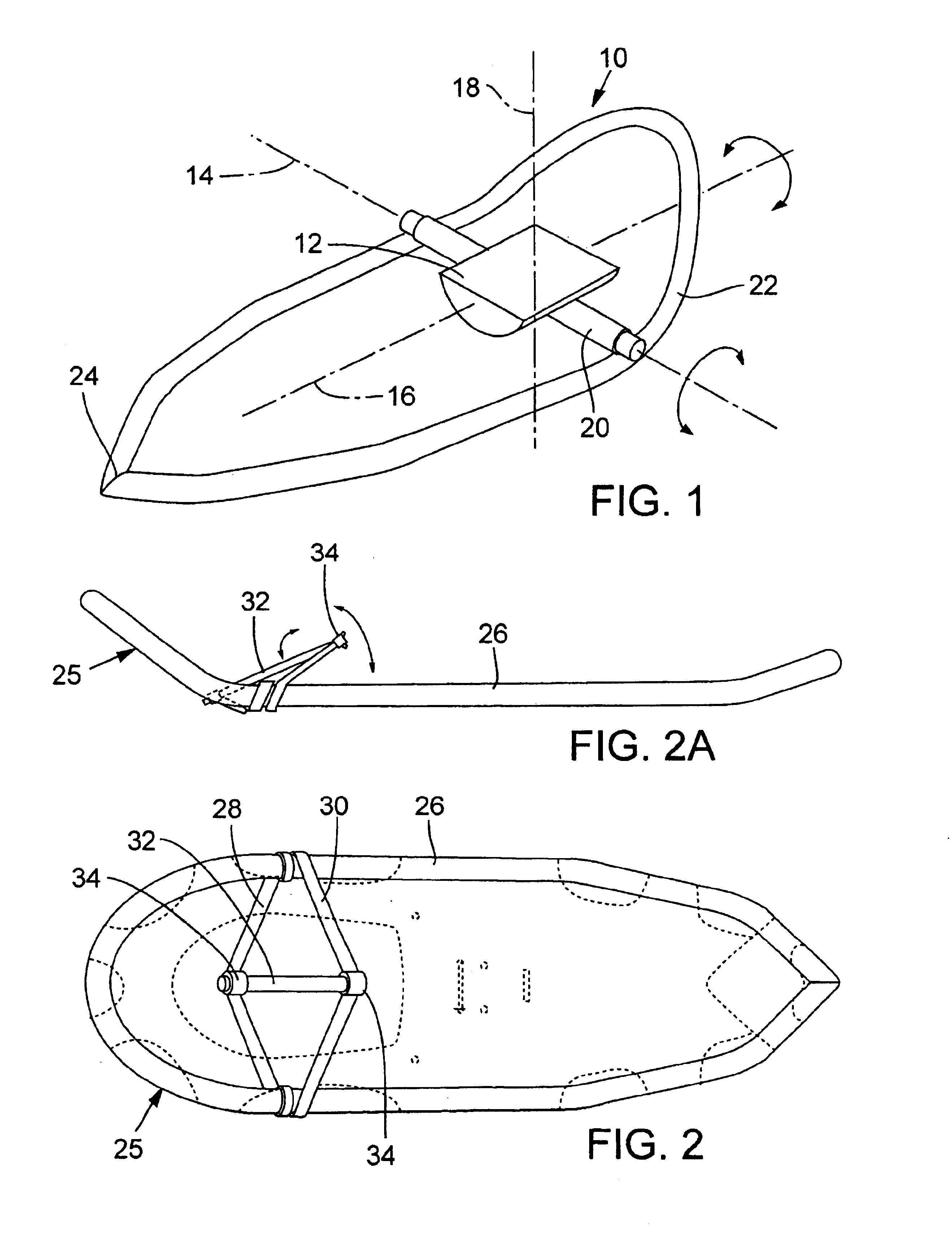

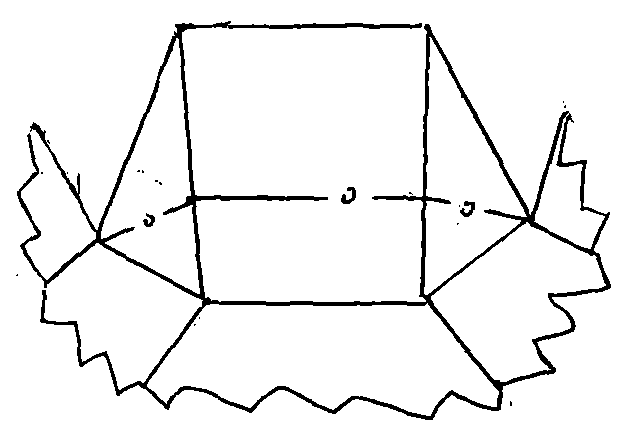

Snowshoe with two degrees of rotational freedom

InactiveUS6898874B2Simple and clear designPrevent rotationFasteningsSnow shoesTerrainRotational freedom

A snowshoe has a pivoted mounting on its boot harness, for rotation about a pitch axis for a first degree of freedom in movement of the user's boot relative to the snowshoe; and provision for a second degree of freedom of motion along a roll axis, allowing the user's boot to tip from side to side, particularly for uneven or sidehill terrain. In both axes the boot preferably is spring-biased toward a neutral position. At the same time, freedom of movement is restricted and essentially prevented between the boot and snowshoe relative to a third axis, the yaw or vertical axis. Several different structural arrangements are disclosed in several types of snowshoes, for achieving the second degree of freedom.

Owner:K 2 CORP

Buffer arrangement

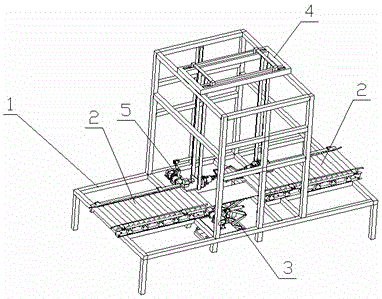

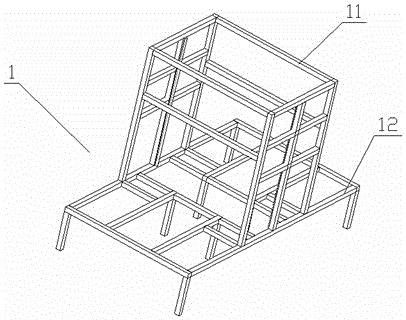

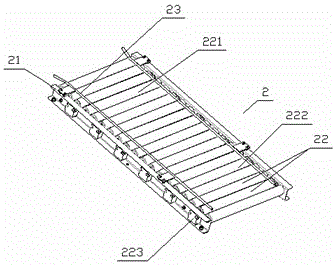

InactiveUS20080184552A1Increase storage capacitySimple and clear designConveyorsMetal working apparatusEngineeringMechanical engineering

Owner:LANG TECHN

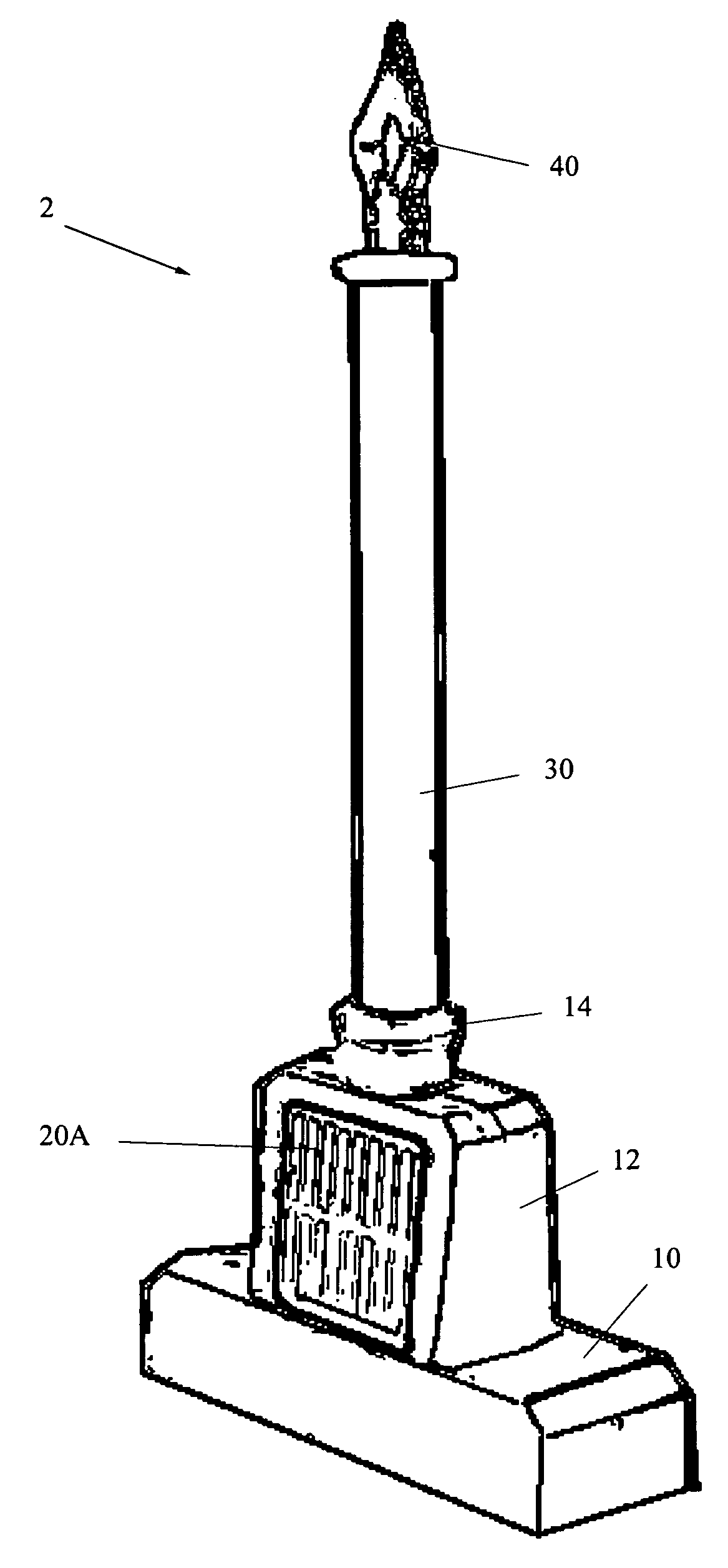

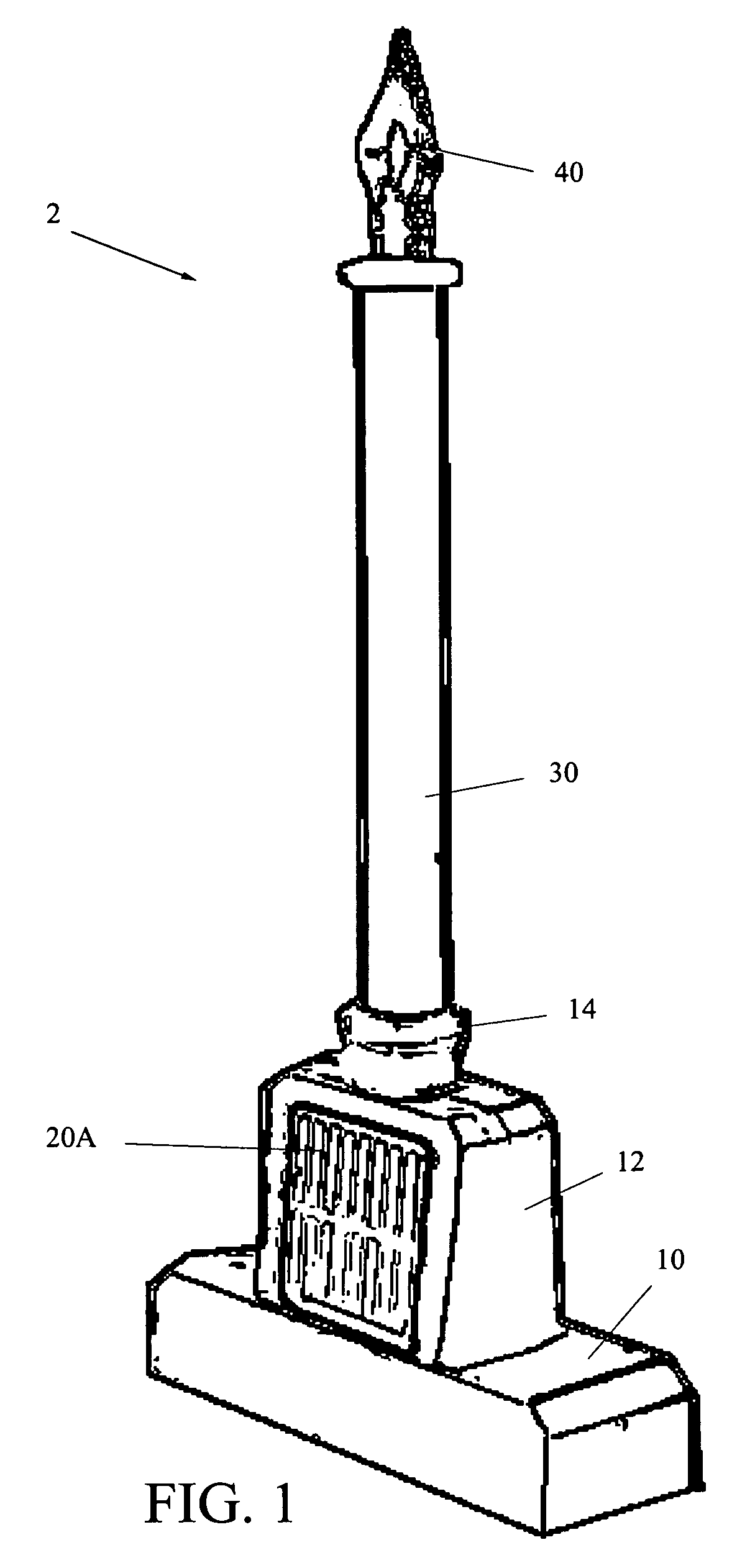

High-efficiency solar-charging LED window candle

InactiveUS7360918B2Efficient chargingReduced current demandCandle holdersWith electric batteriesElectrical batteryRechargeable cell

Owner:TROMBETTA VINCE +1

Articulated bench

InactiveUS20050197238A1Wide rangeImprove overall utilizationStiltsMuscle exercising devicesHand heldEngineering

An articulated bench comprising a two-section pad and two folding / pivoting support leg assemblies attached to a frame. A length-adjustable (telescoping) dual tubular brace assembly folds out of the frame from beneath the pivoting padded section (i.e. the section for supporting the upper body) and is inserted into one of a series of catches located on the section's rear surface to hold it at a selectable incline. Improved pivoting support leg assemblies include primary foot cross-bars, and secondary foot crossbars each fixedly attached to a leg to either provide lateral floor-support when the support legs are locked in the inwardly stowed position, or alternatively serve as a hand holds or foot rests when the legs are deployed for performing exercises, thereby allowing a broader range of positions and much greater utility. Since either support leg assembly can be folded inward and locked such that the end of the frame may be inclined downward and supported on the secondary foot crossbar, the number of angular positions for the padded sections is effectively tripled.

Owner:PARKER JAMES

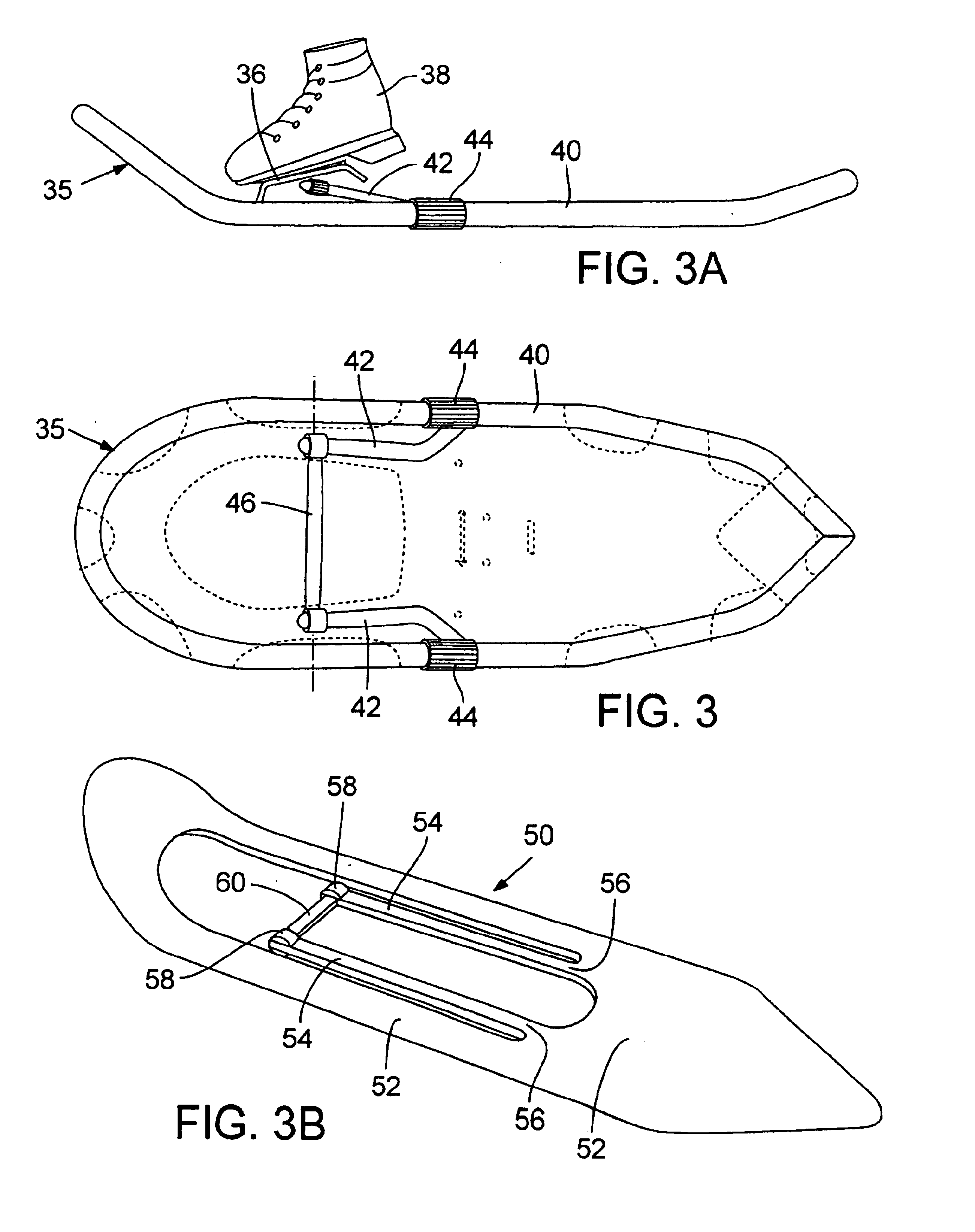

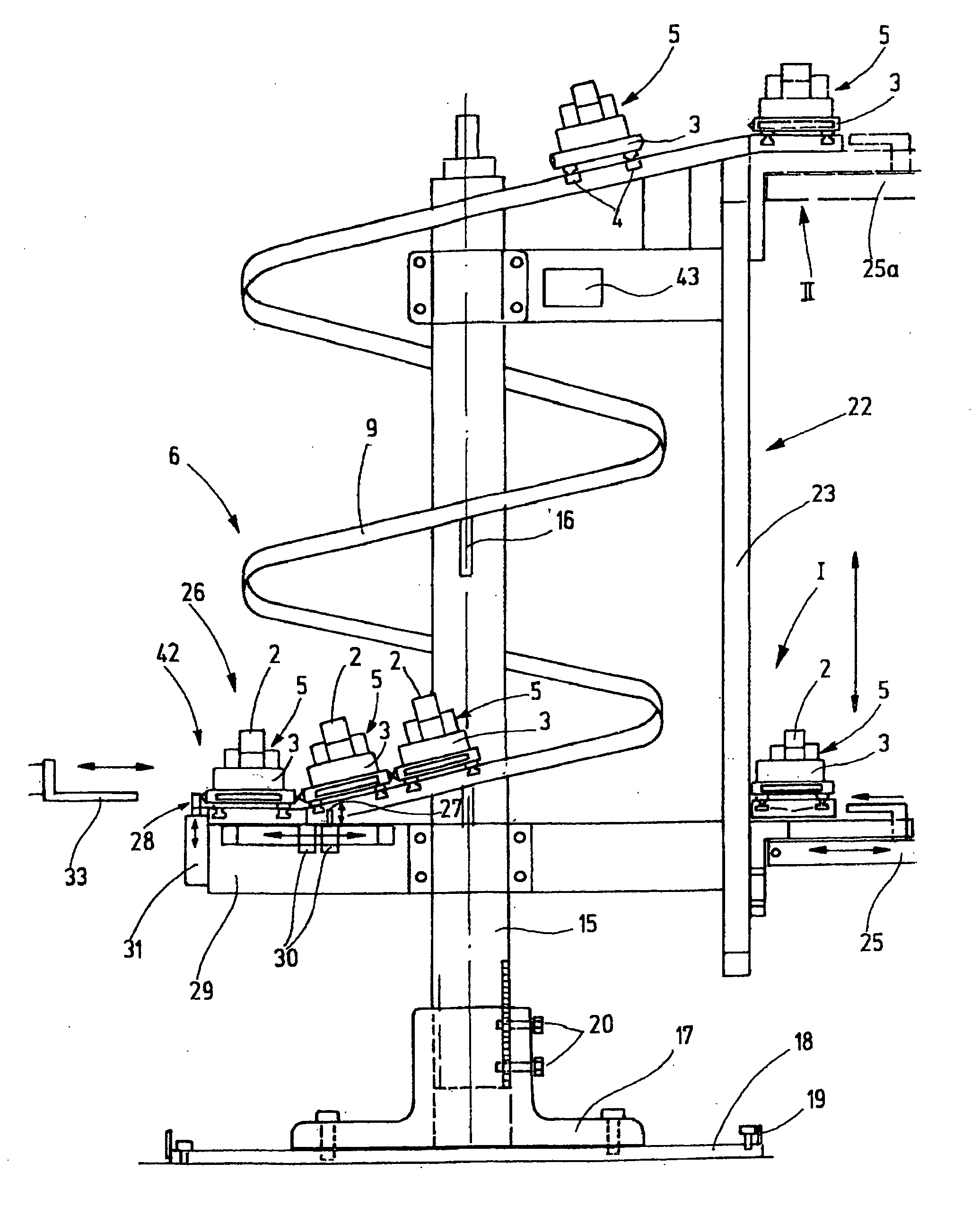

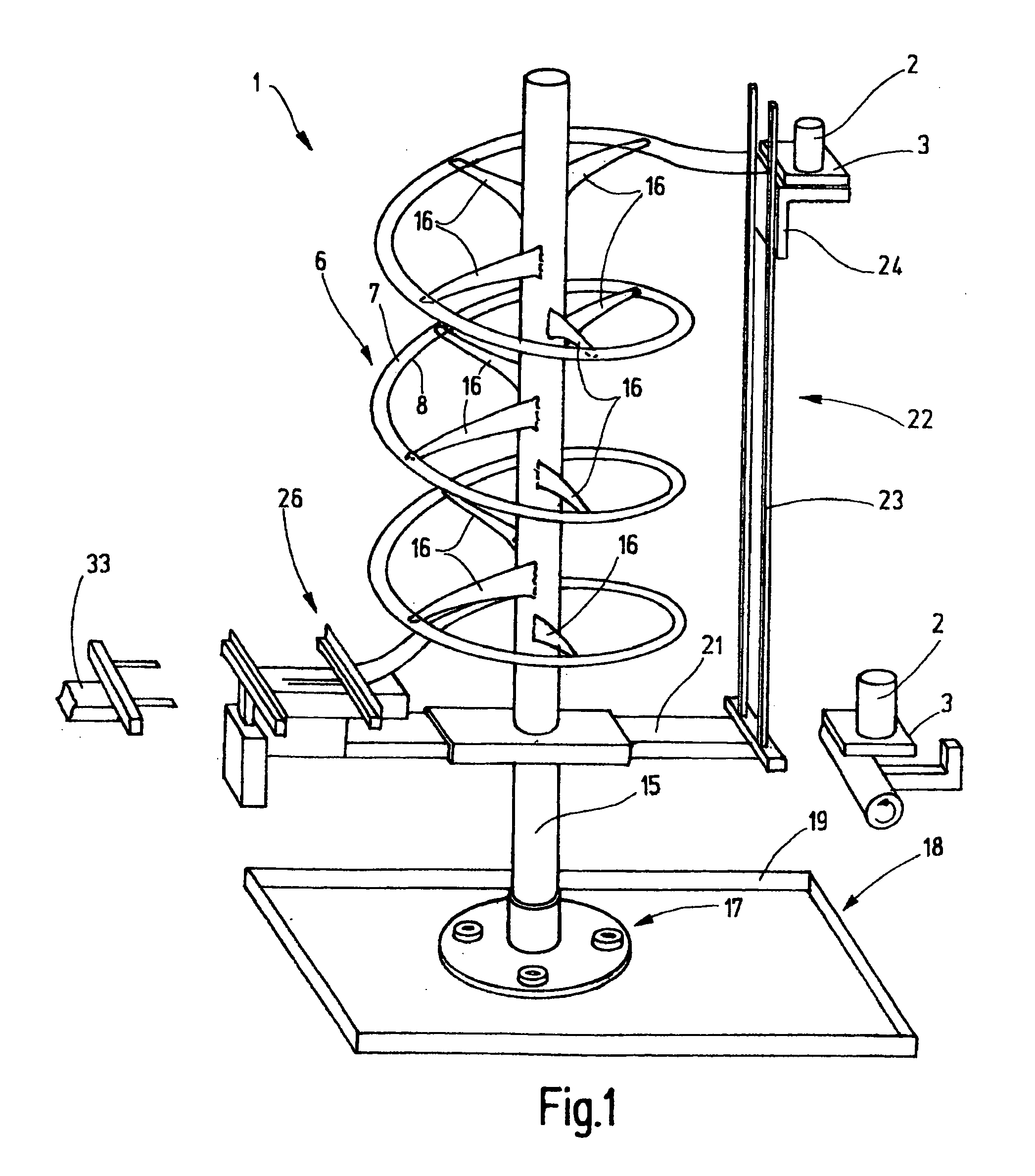

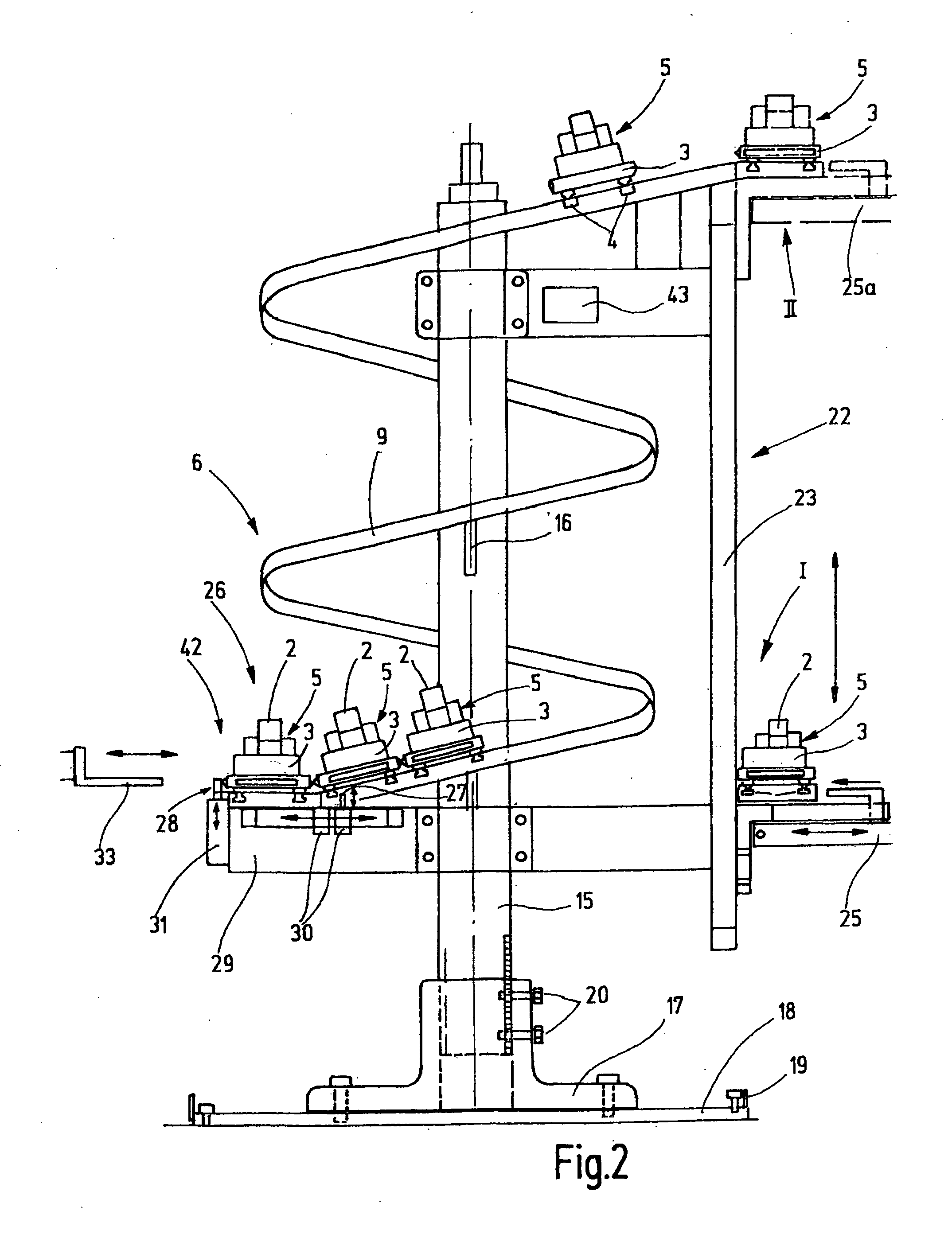

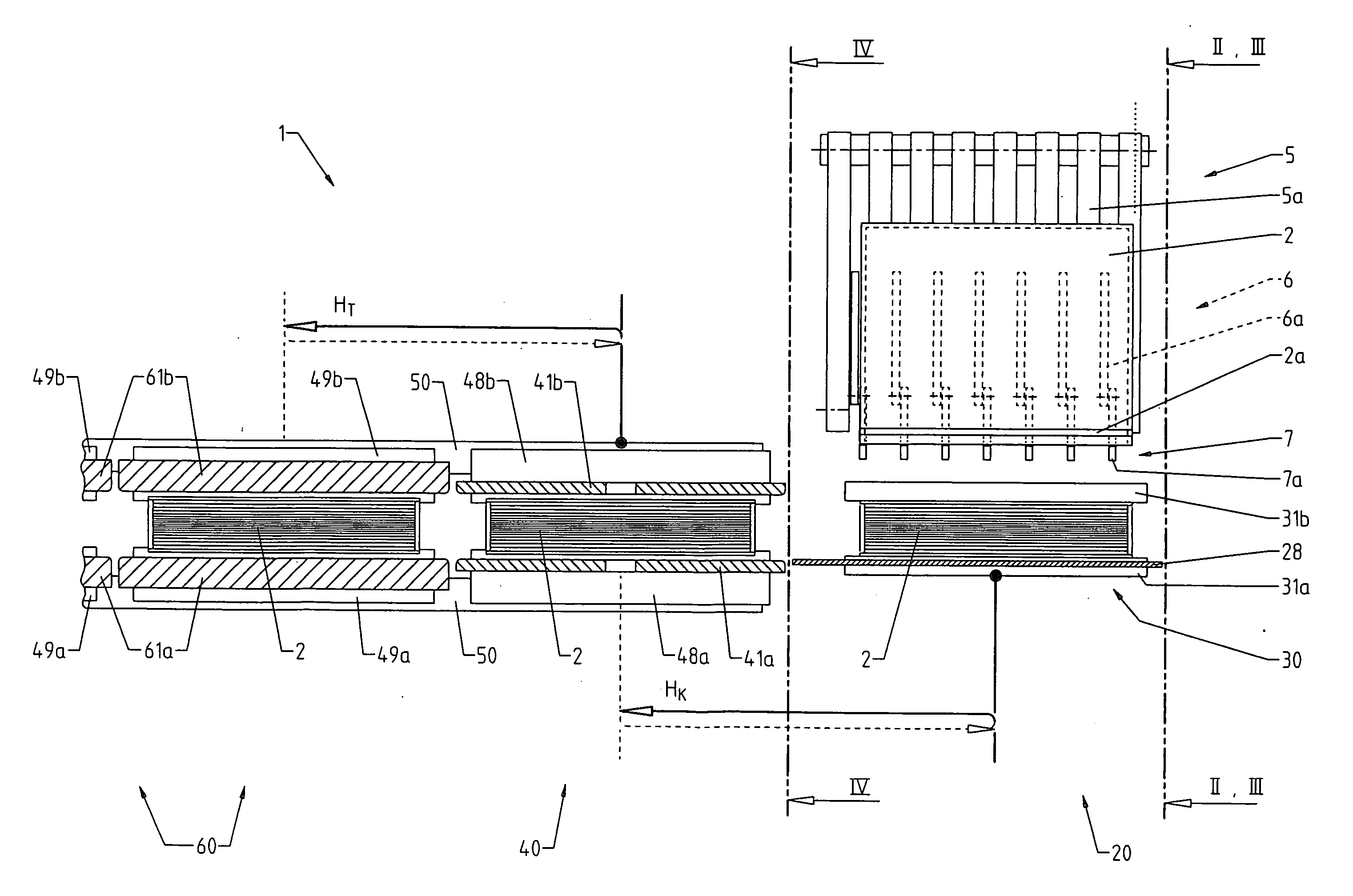

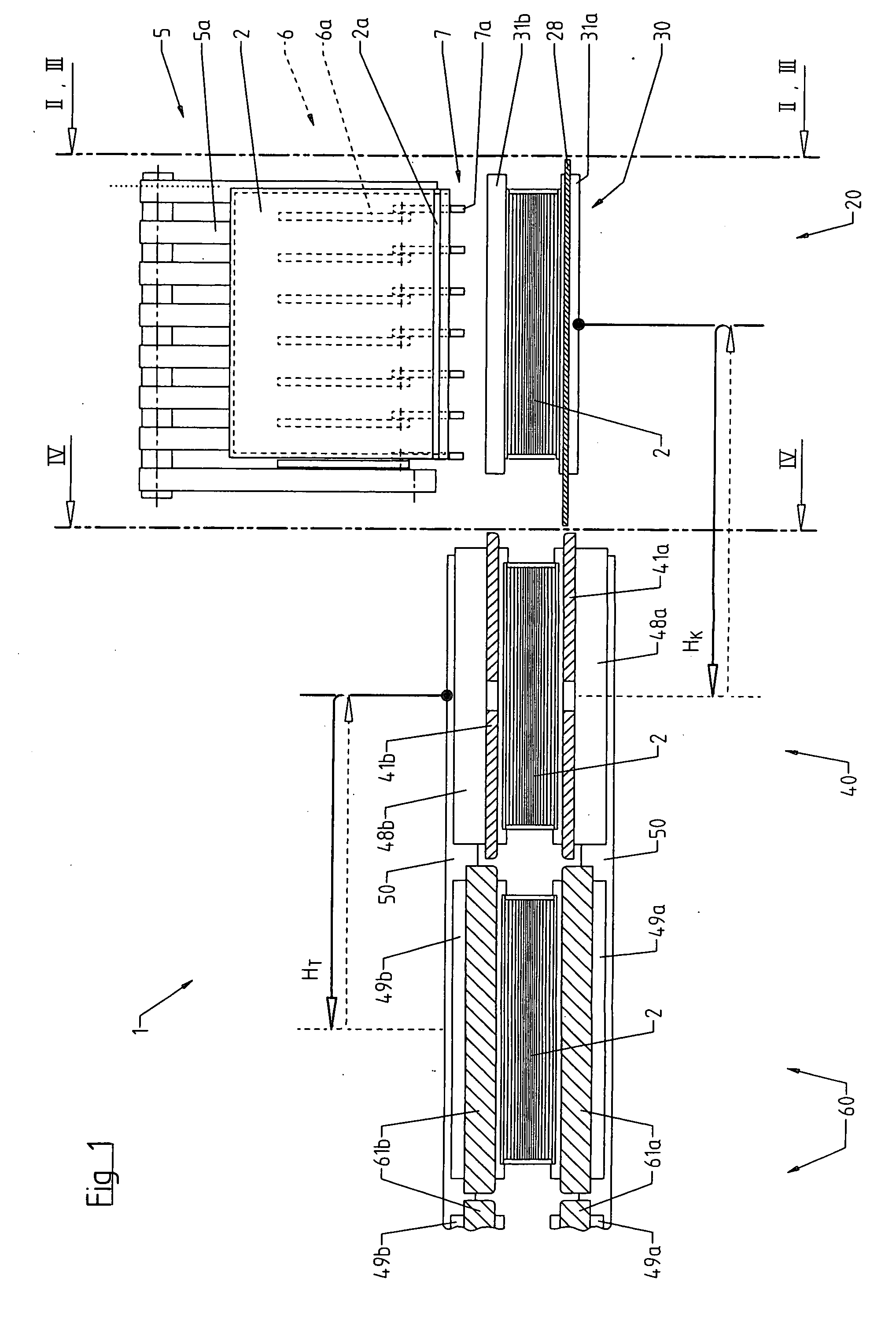

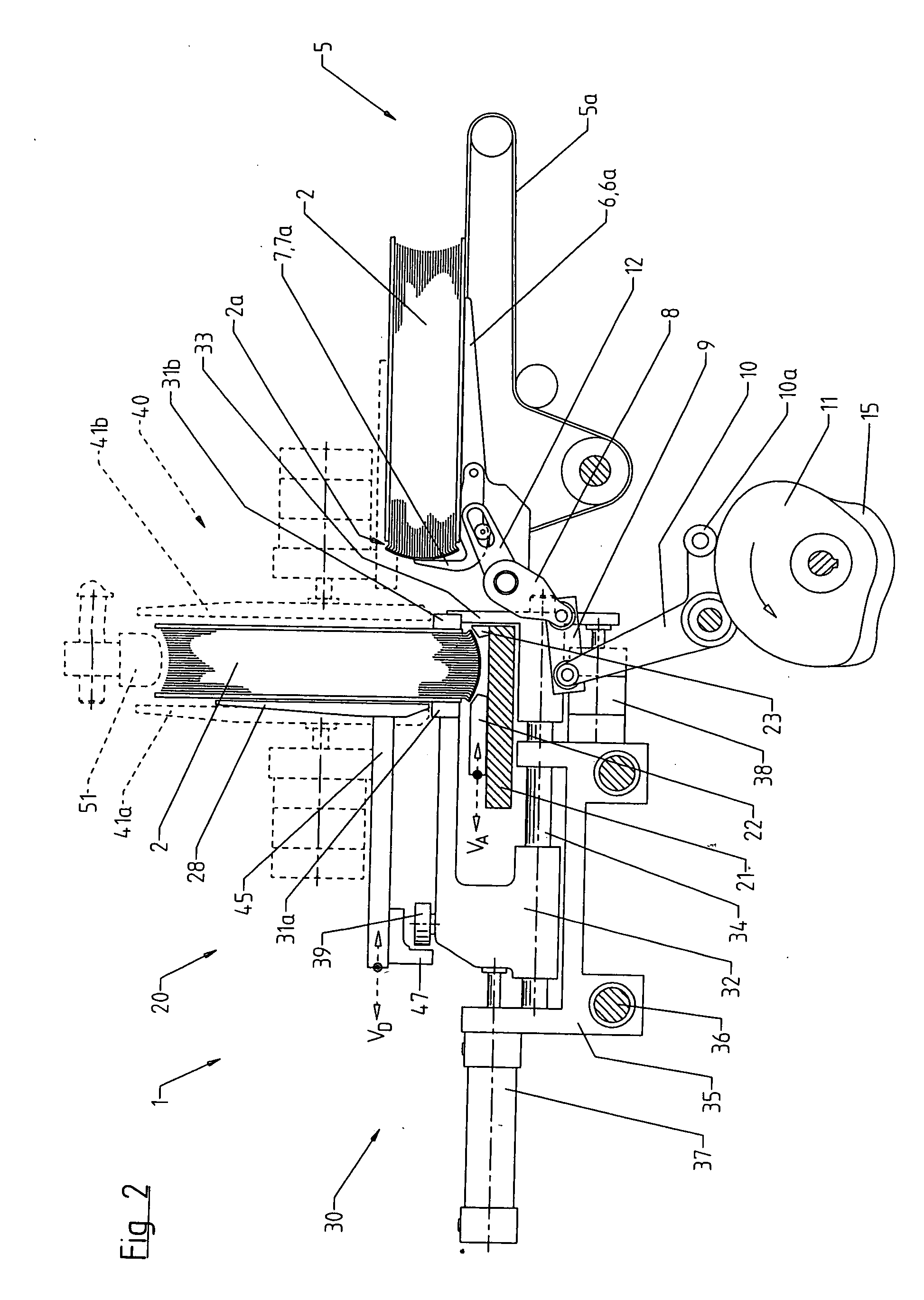

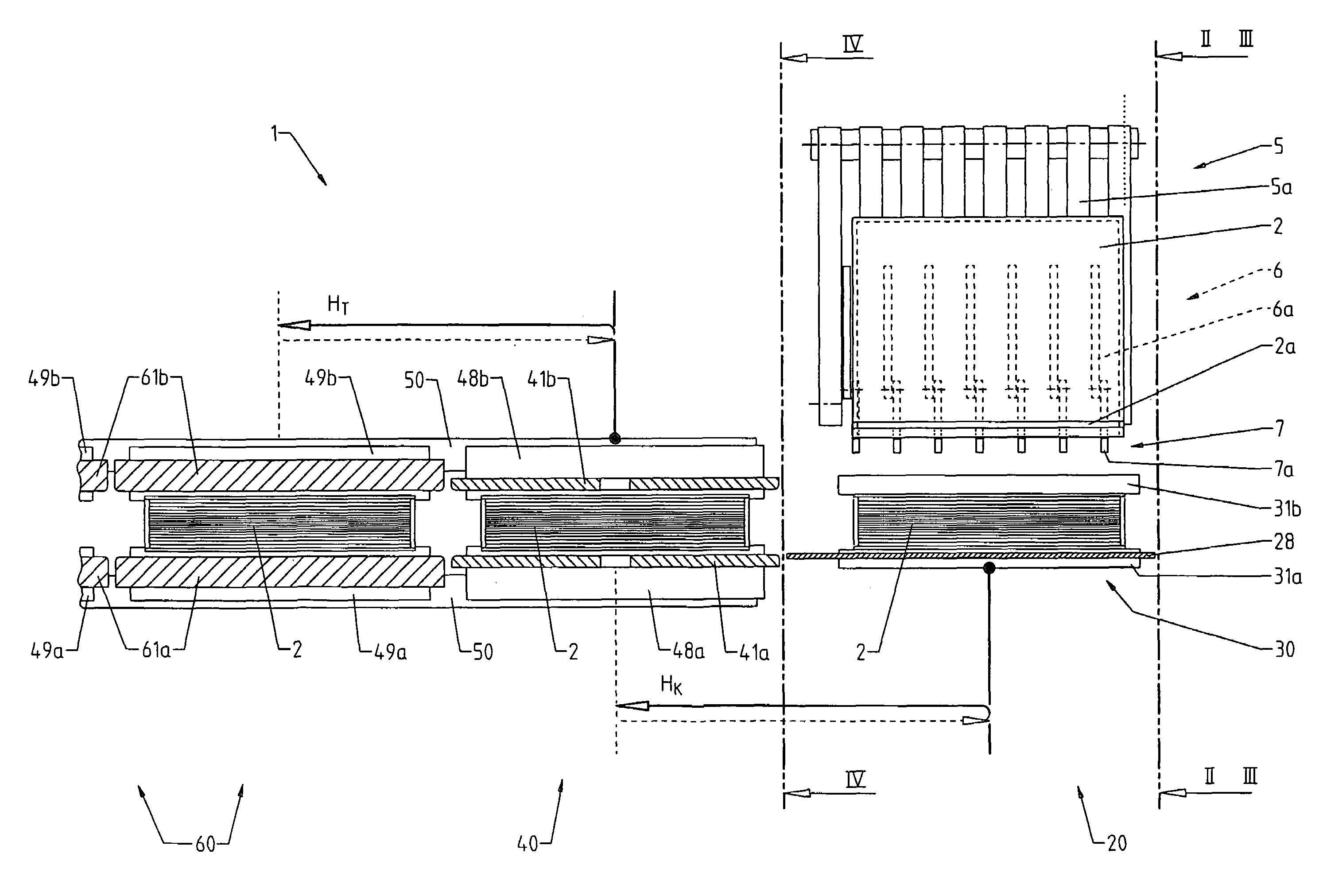

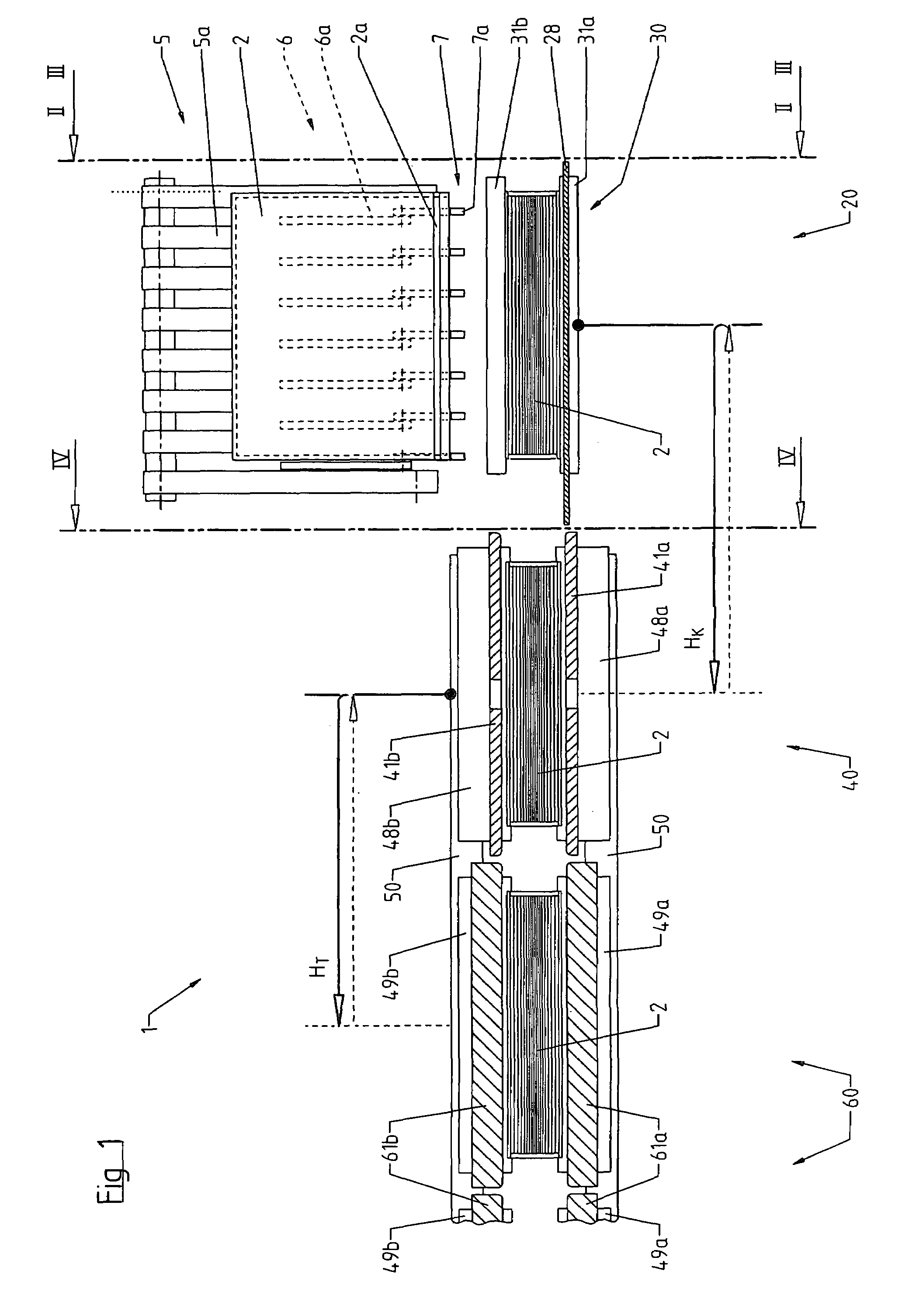

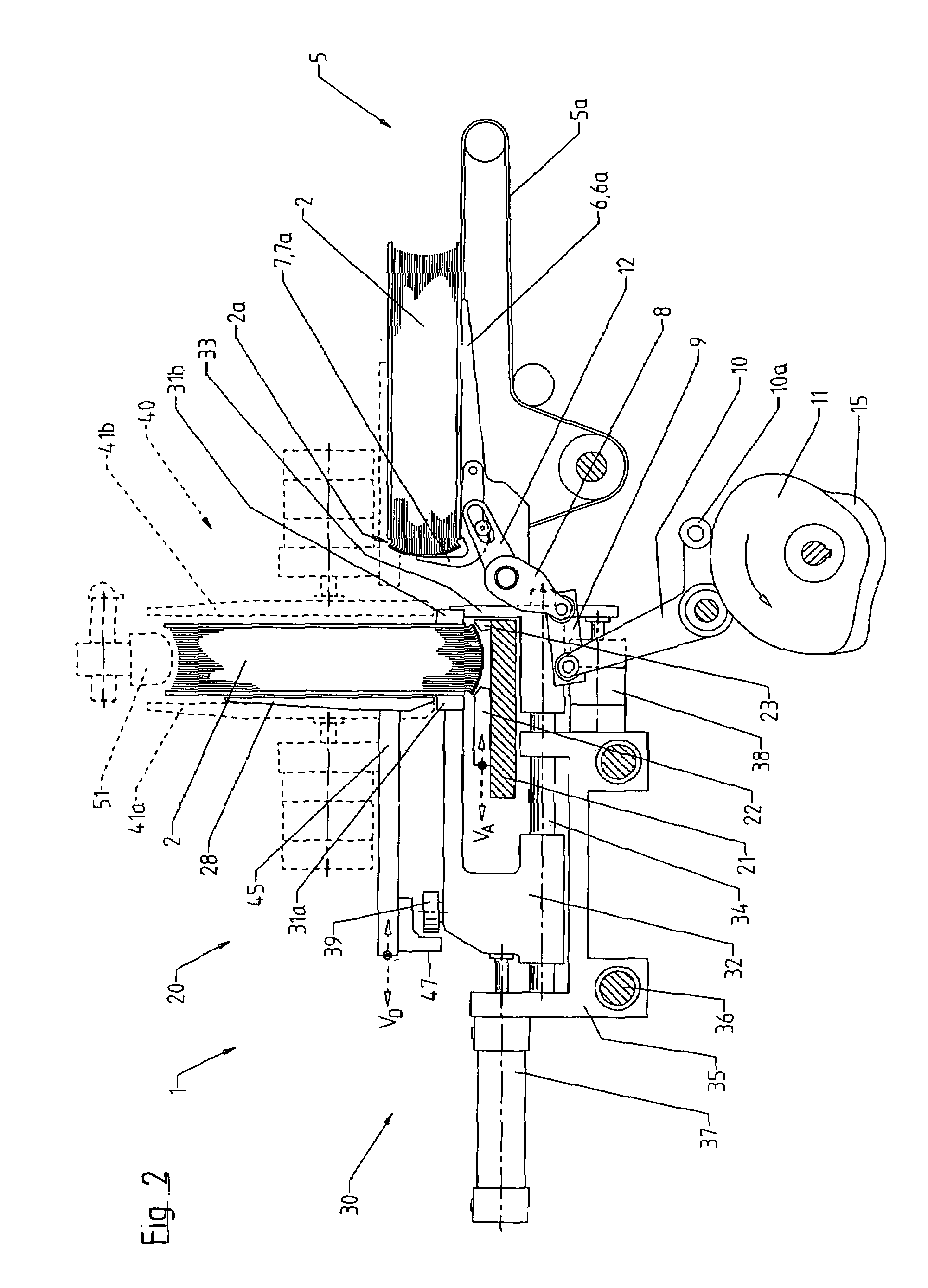

Binding-in and pressing machine

InactiveUS20060140742A1Simple and cost-efficient designQuality improvementBookbinding casesCasing-inLateral regionEngineering

A binding-in and pressing machine (1) with a plurality of pressing stations (60) and heated joint forming rails situated on a reciprocating carriage (50). An alignment station (20) is provided for aligning the book case joints (2a) at the height of the joint forming rails (49a, b), including a height-adjustable alignment table (21) with rails (22, 23) for supporting the book (2) on the outer edges of its spine and guide elements (28, 6) for centering the book on the alignment table. A separate pre-forming station (40) is also provided that comprises the forming rail (51), clamping plates (41a, b), and joint rails (48a, b) that engage into the book case joints (2a) and counteract a downward movement of at least the book case joints (2a). The books (2) aligned in the alignment station (20) are transferred into the pre-forming station (40) while being clamped in lateral regions near the joints. The effective times available for realizing a functionally safe alignment and a permanent pre-forming of the books are extended due to the assignment of the alignment and pre-forming functions to two separate stations.

Owner:KOLBUS

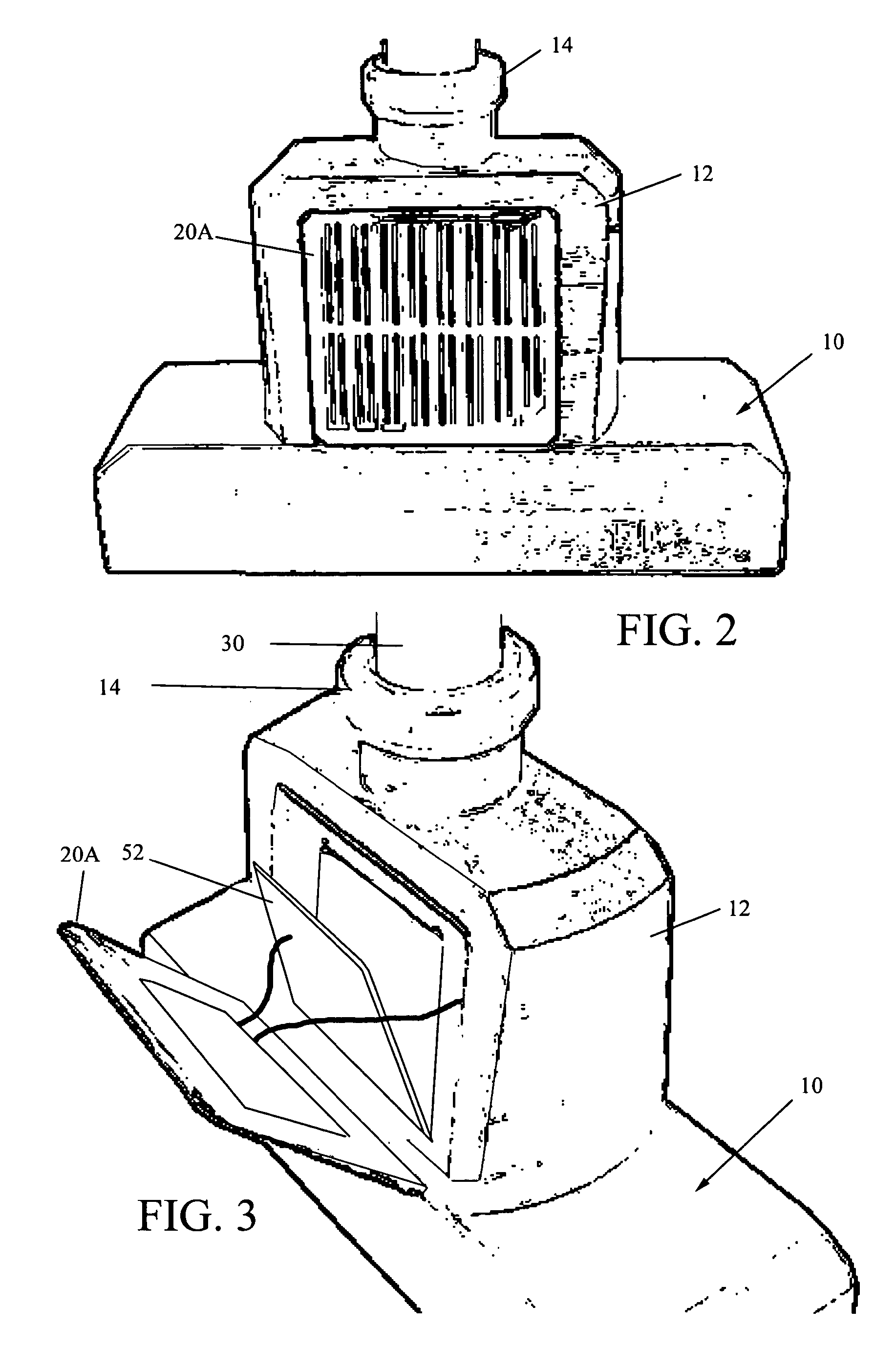

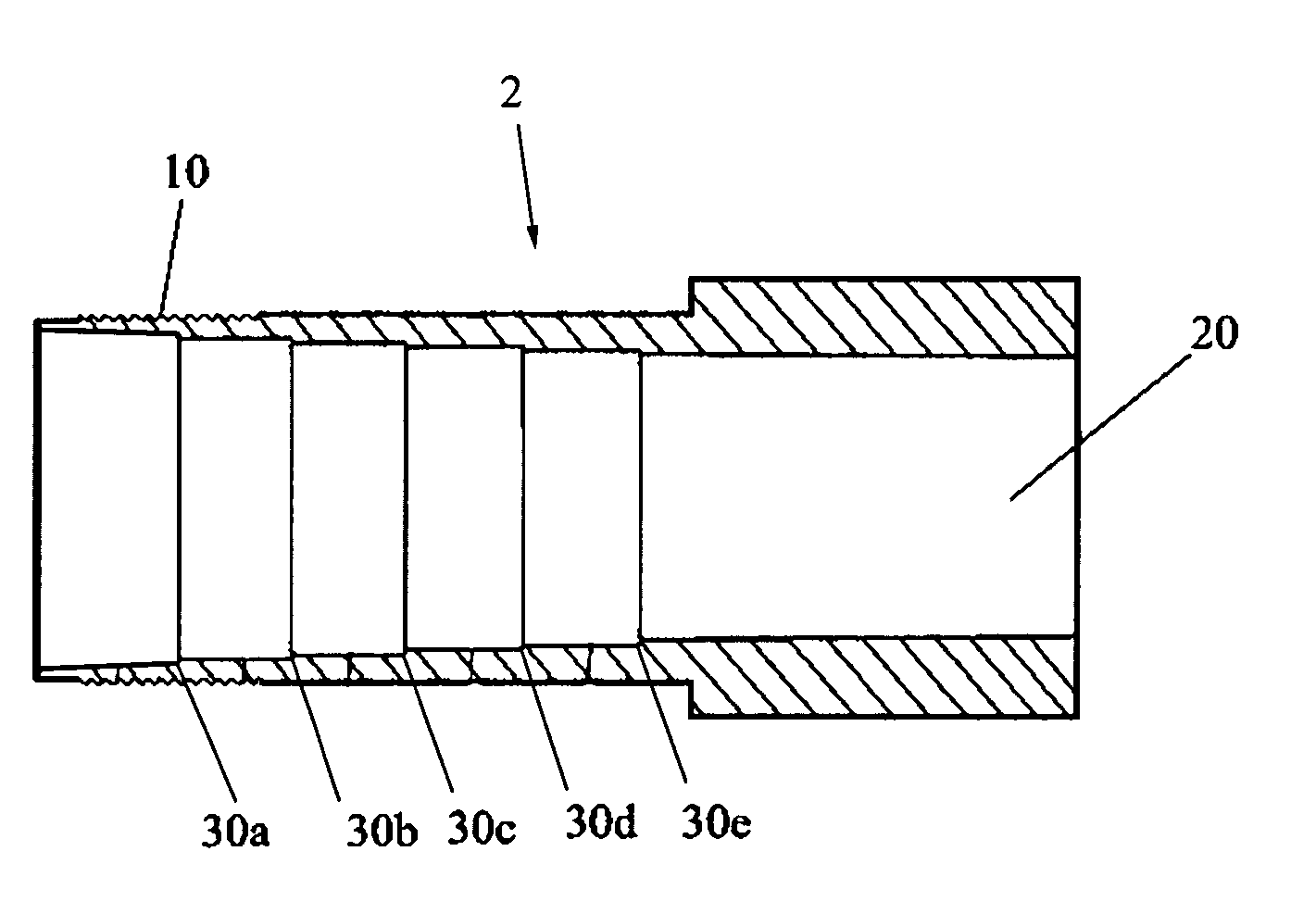

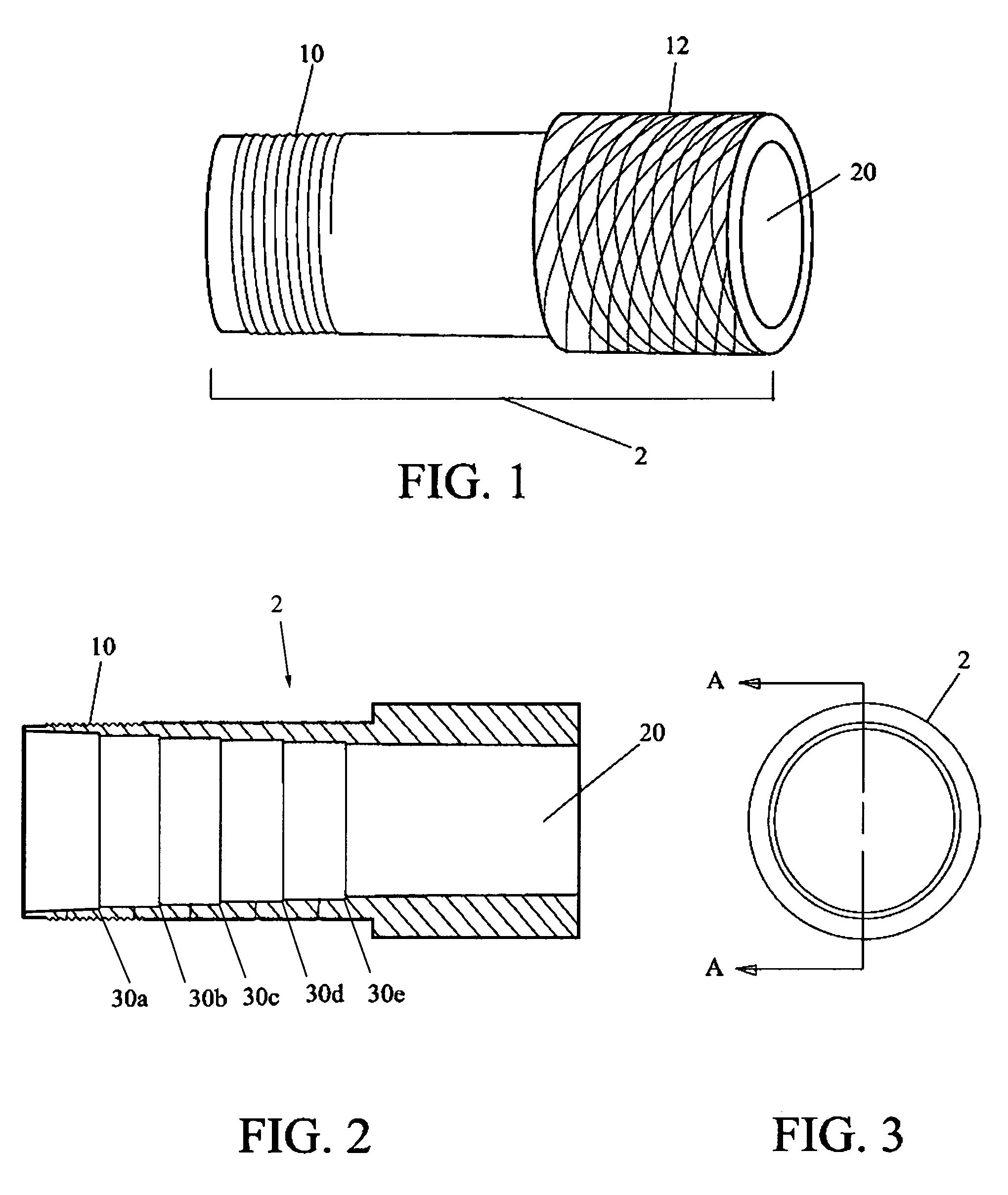

Shotgun choke with integral wad-stopping feature

Disclosed herein is a shotgun choke with integral wad-stopping feature for use with an existing shotgun. The choke generally comprises a hollow cylinder having (an) a coupling for securing it to the muzzle end such as an external series of screw threads proximate one end for screw-insertion to the muzzle end of an existing shotgun, and an internal channel defined by an overall taper running from the inserted end to the output end to constrict shotgun pellets passing there through. The wad-stopping feature is accomplished with a series of raised internal projections or steps (raised from the internal walls of the channel), the projections being spaced throughout the tapered channel to retard and separate a traveling wad from the shot when passing there through.

Owner:BOYER FR

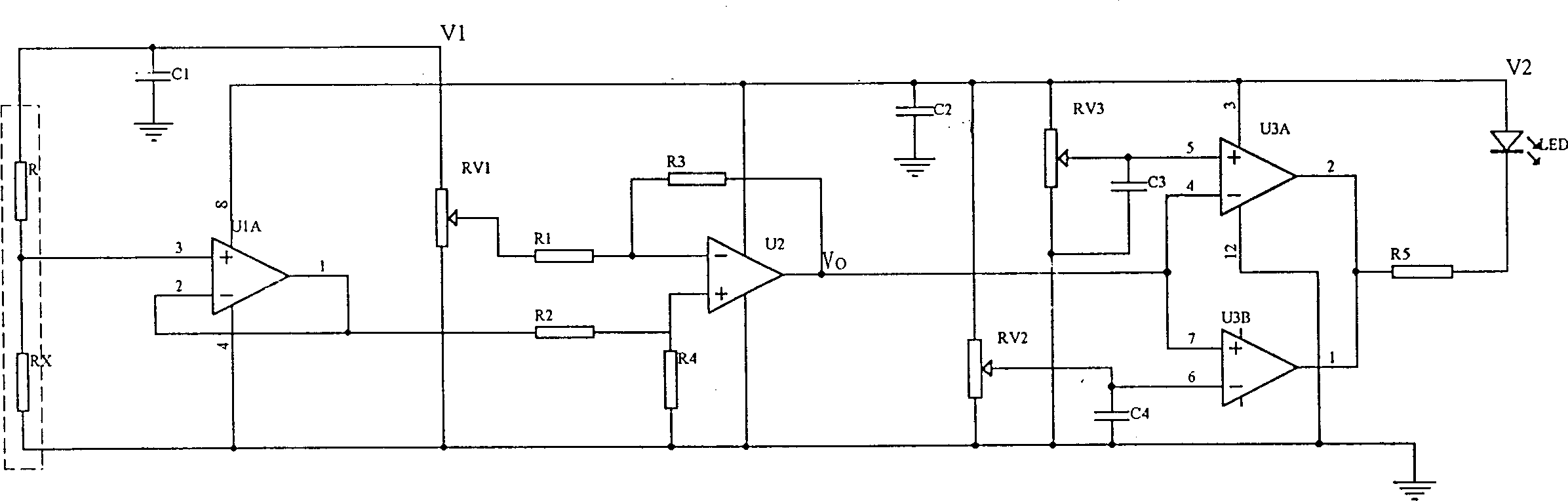

Circuit for testing negative temperature coefficient thermistor

InactiveCN1445555AEasy to integrateSimple and clear designResistance/reactance/impedenceElectrical resistance and conductanceNegative temperature

A circuit for testing the thermosensitive resistor having negative temp. coefficient is composed of a constant-voltage source, a bridge consisting of standard NTC resistor, R, NTC resistor Rx to be tested and potentiometer RV1, voltage follower V1A connected to the said R, Rx and Rv1 all of which are further grounded, differential amplifier U2 connected to U1A, operating amplifier (U3A and U3B), and dual-limiting voltage detecting circuit. Its advantages are high precision, stability and integrated level, and low cost.

Owner:HUIZHOU BLUEWAY ELECTRONICS

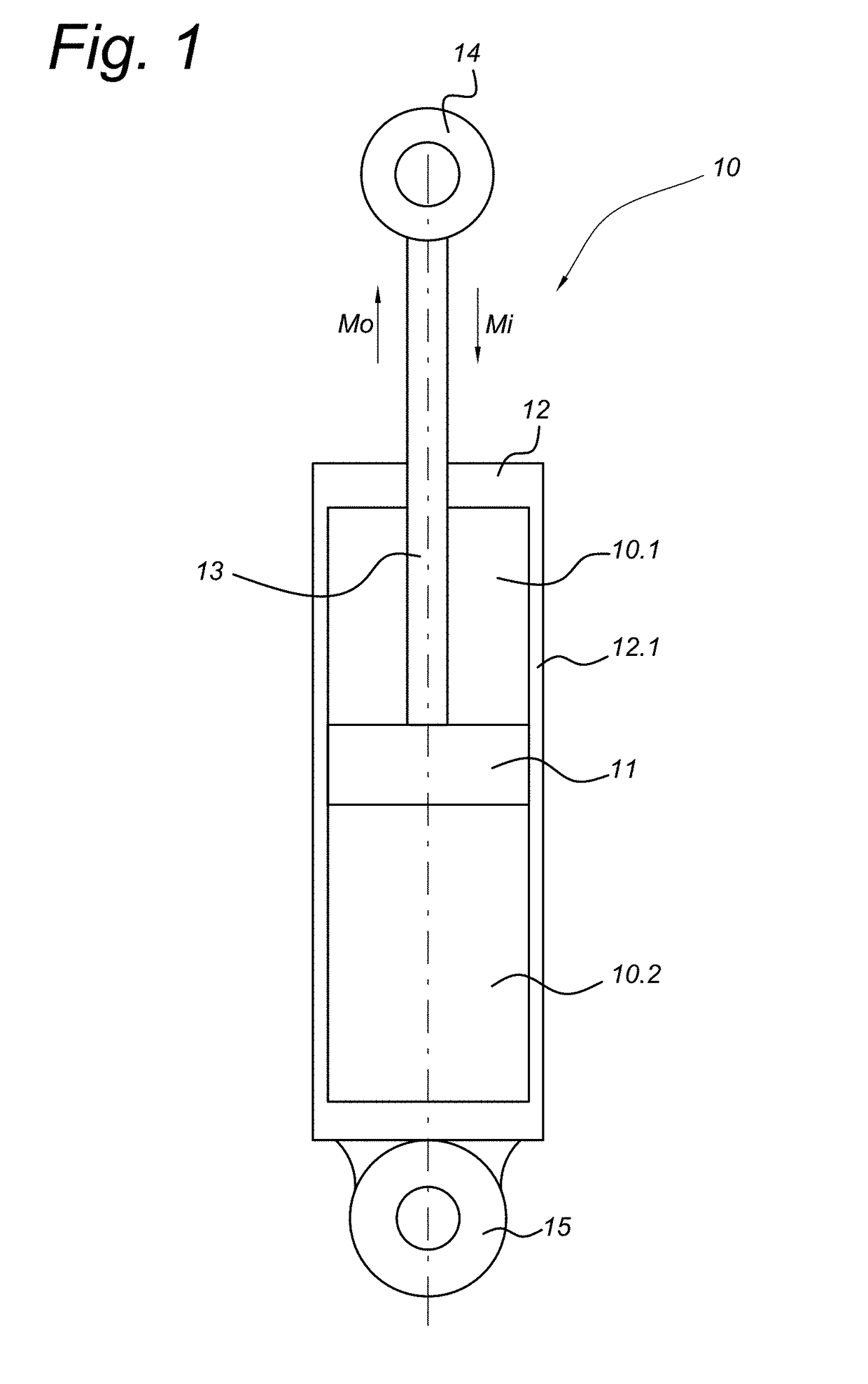

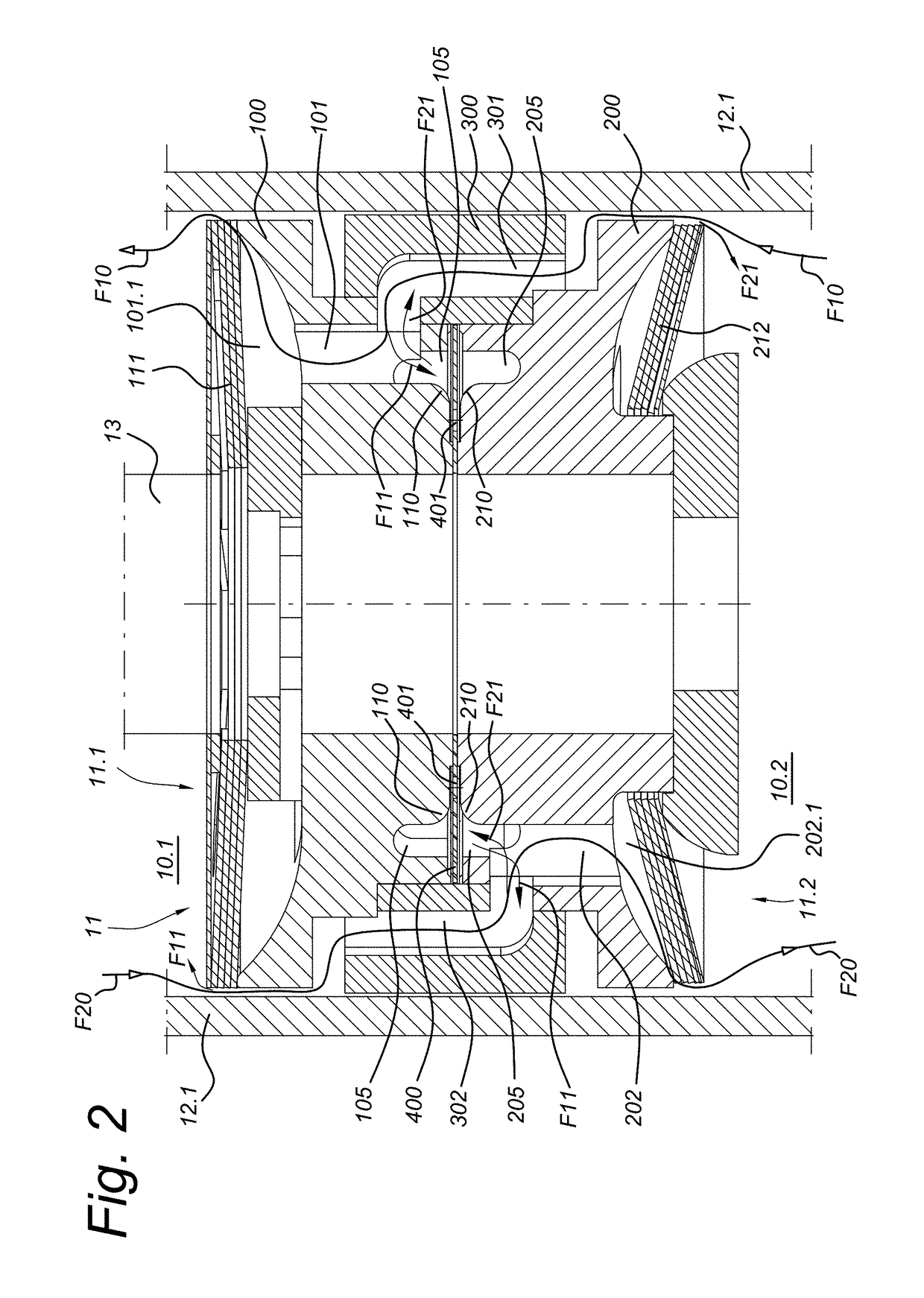

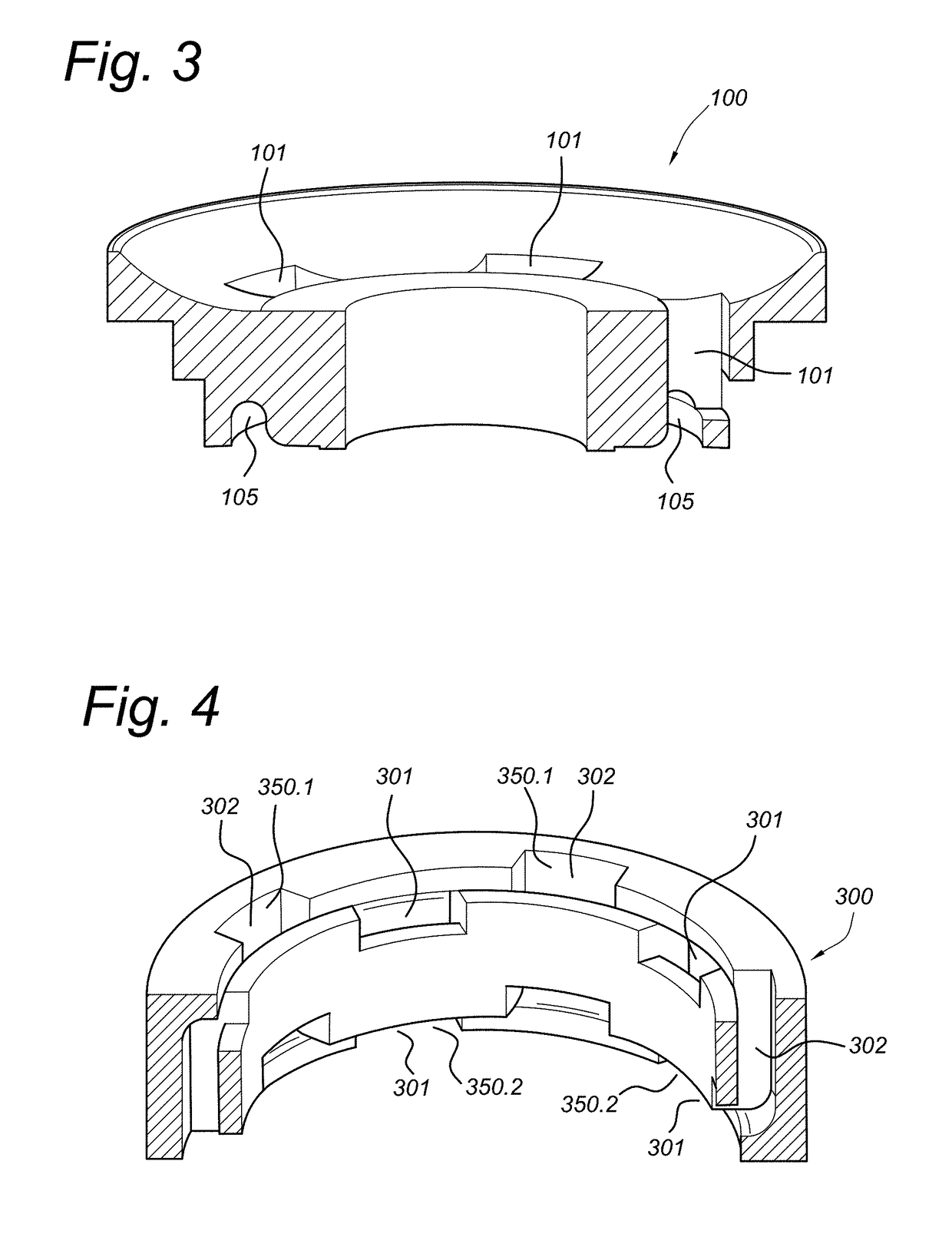

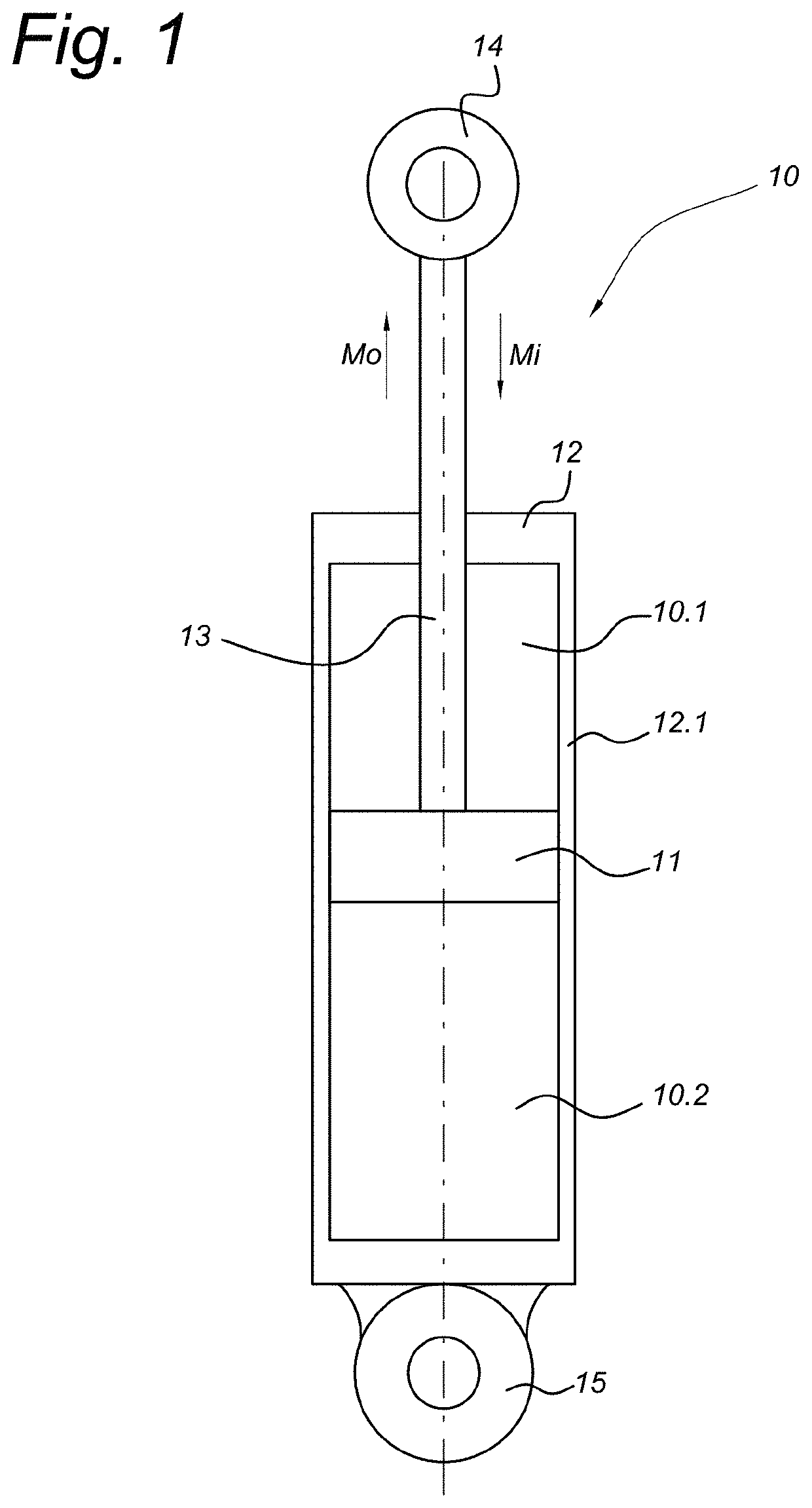

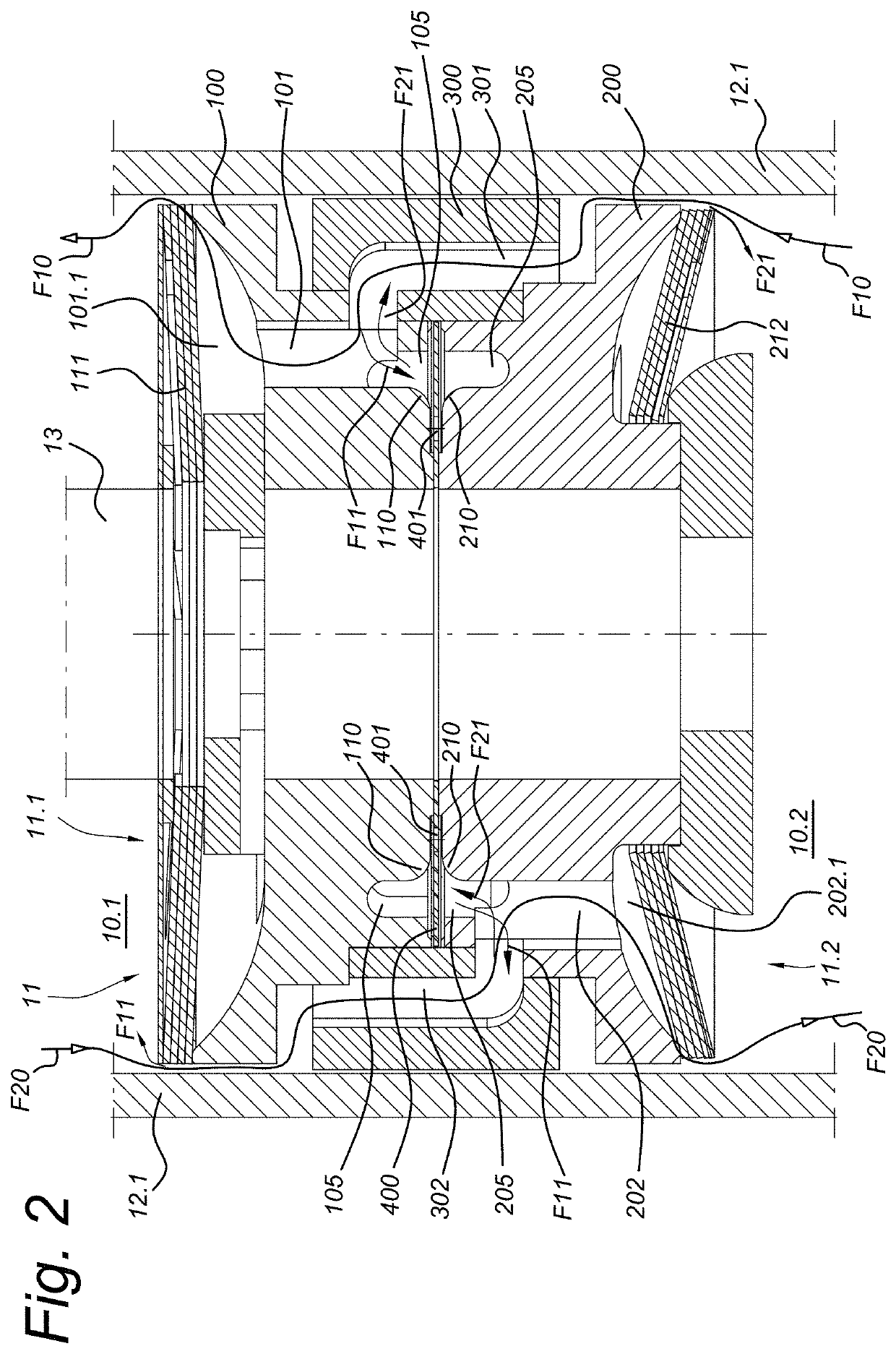

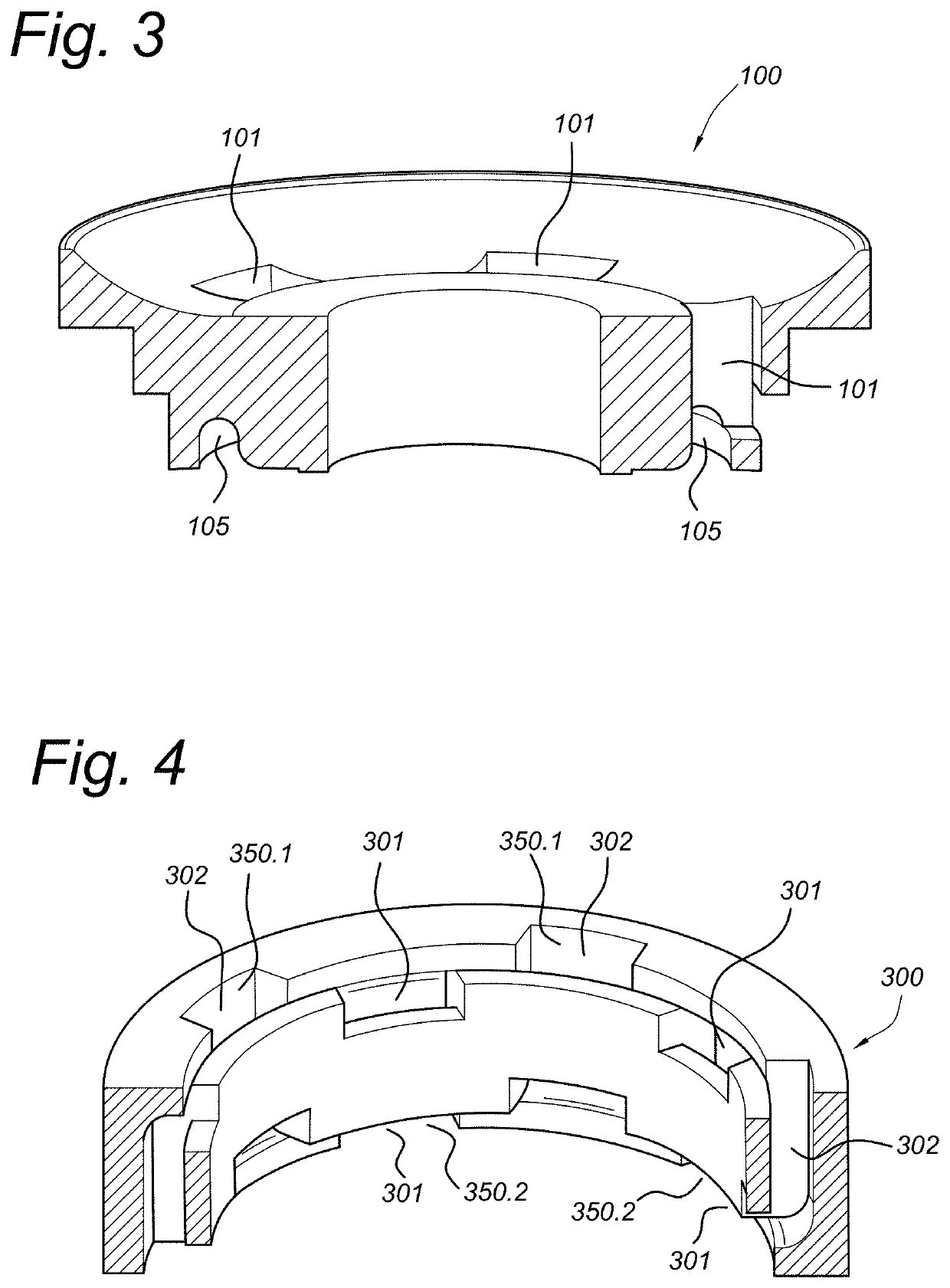

Shock absorber with comfort valve

ActiveUS20180355945A1Simple and clear designCost of implementationSpringsLiquid based dampersRest positionMain channel

A shock absorber includes a cylinder; a piston dividing the cylinder into first and second chambers, the piston being movable within the cylinder in inward and outward directions; a first main channel and a first main non-return valve allowing a first main fluid flow from the second to the first cylinder chamber; a second main channel and a second main non-return valve allowing a second main fluid flow from the first to the second cylinder chamber; a comfort channel allowing an auxiliary fluid flow between the first and second cylinder chambers; and a comfort valve providing an open connection for the auxiliary fluid flow through the comfort channel in a rest position of the comfort valve and closing off the auxiliary fluid flow at increasing pressure difference across the comfort valve at either inward or outward movement to influence an auxiliary fluid flow between first and second piston sides.

Owner:KONI BV

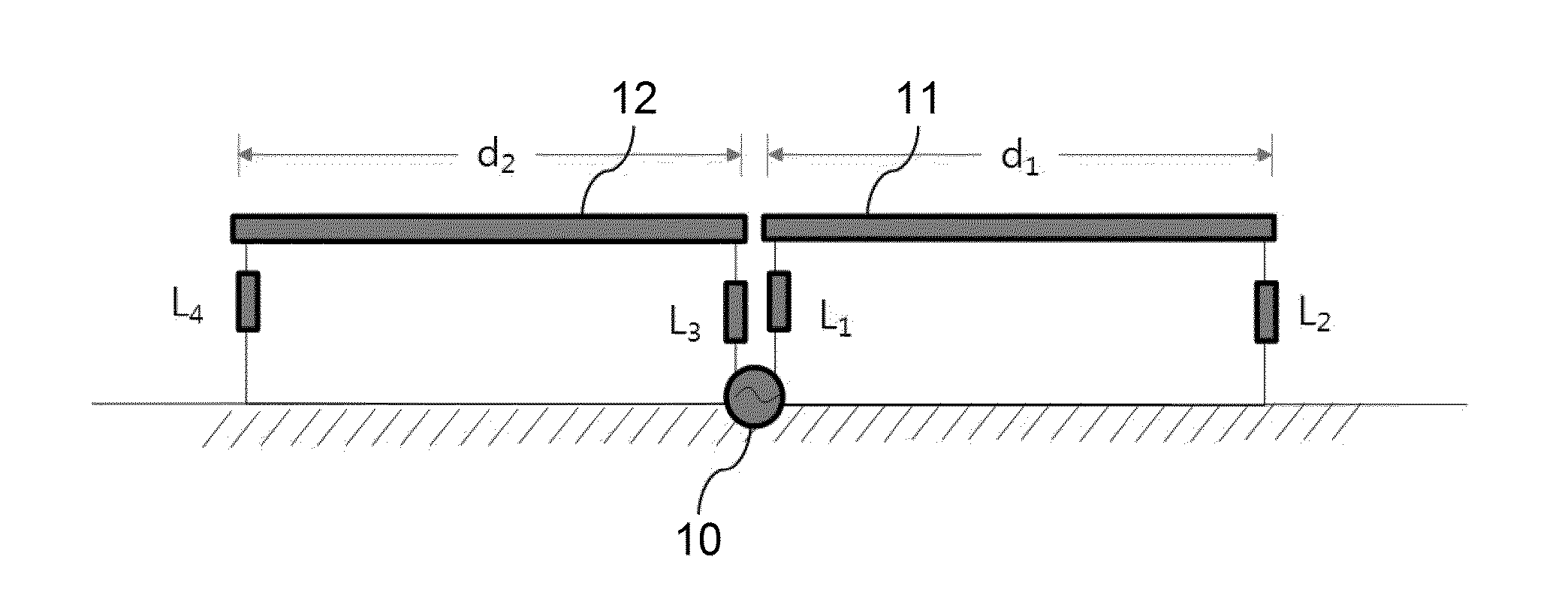

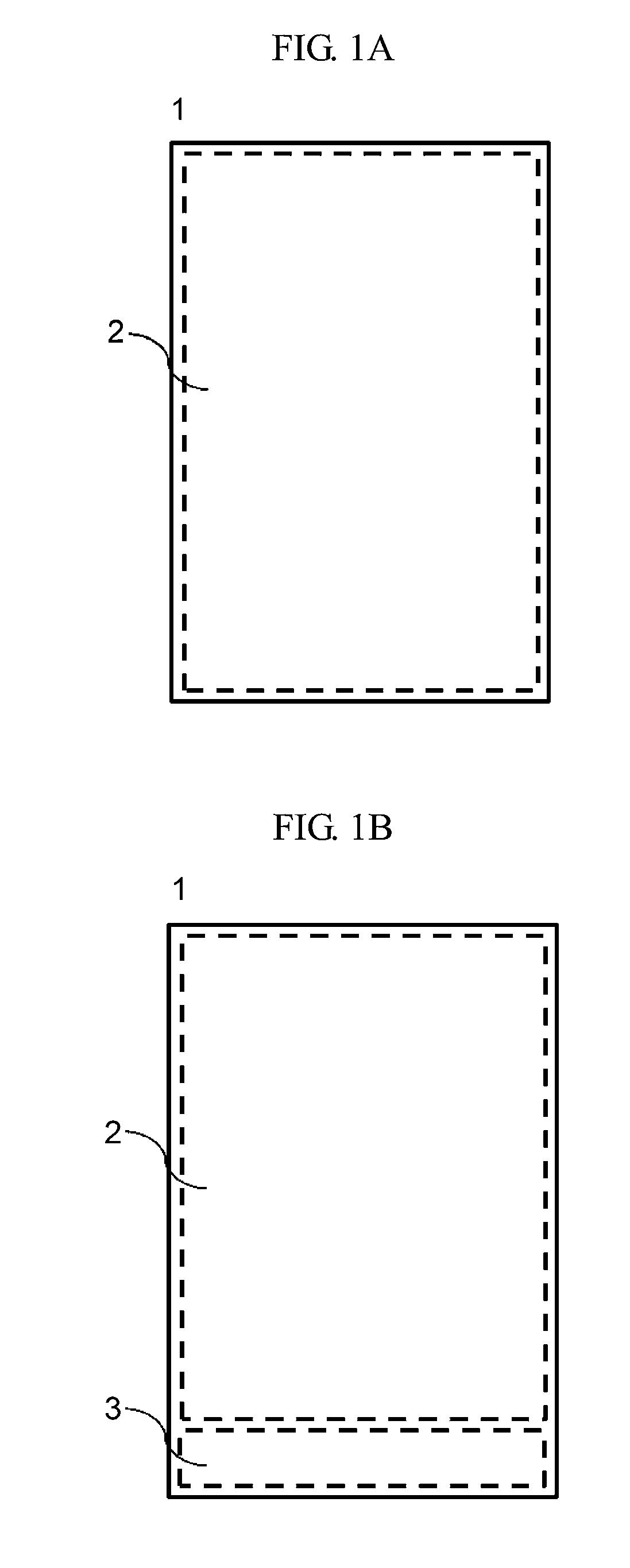

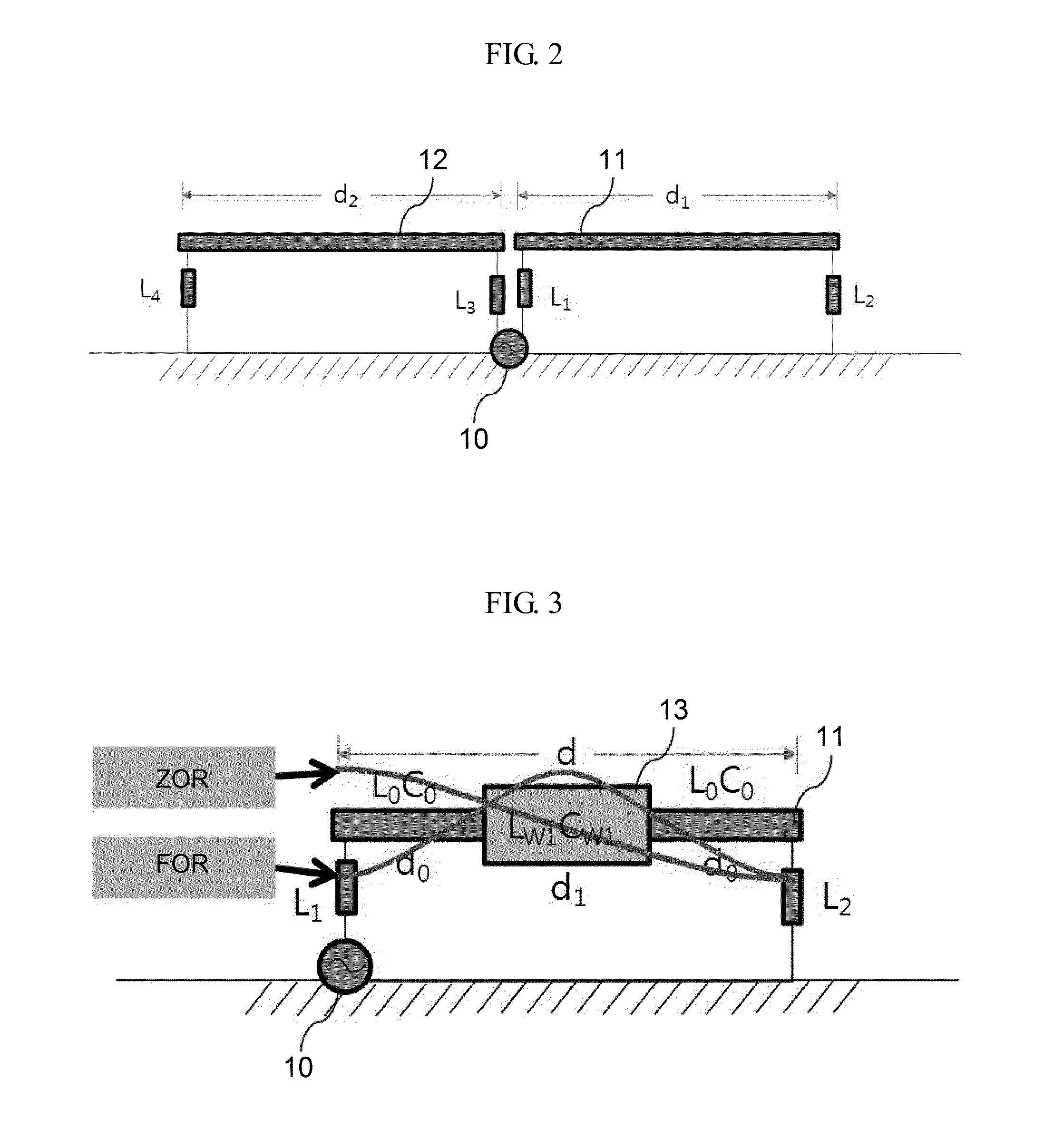

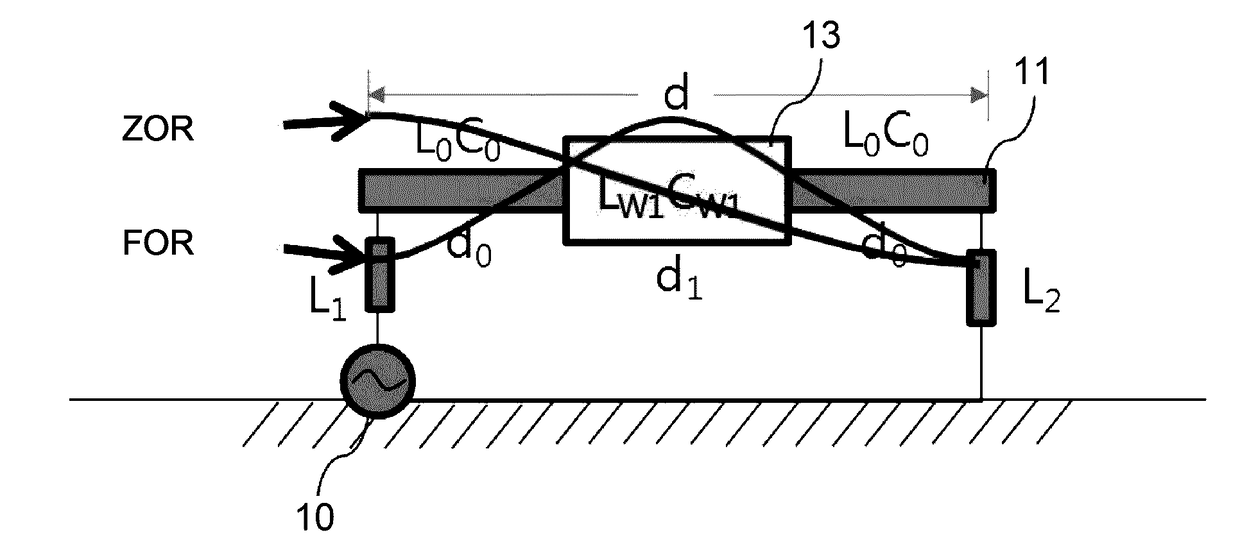

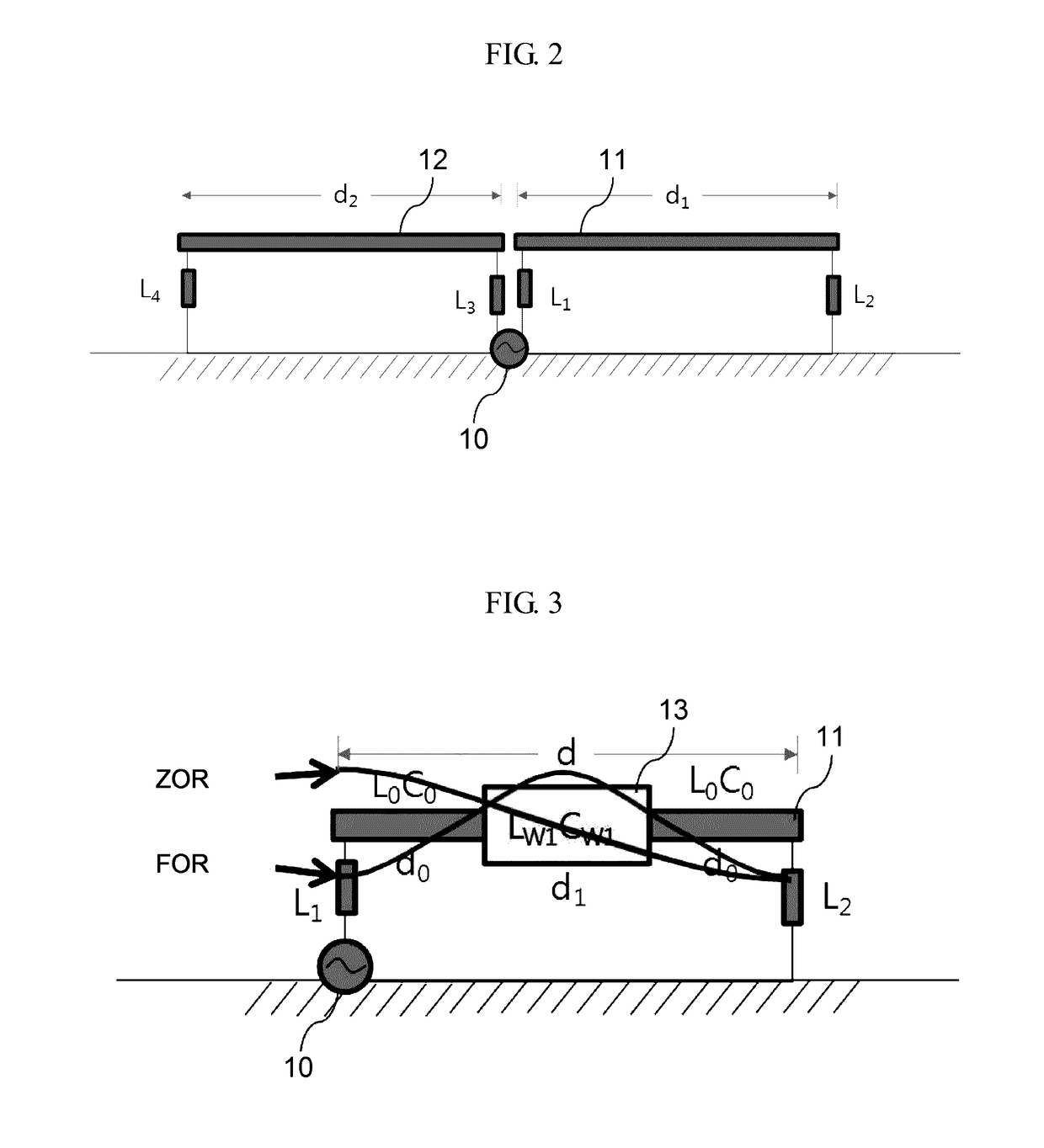

Antenna and communication device comprising same

ActiveUS20150123855A1Simple and clear designImprove performanceSimultaneous aerial operationsAntenna supports/mountingsLine widthImpedance matching

Disclosed are an antenna and a communication device including the same. The antenna includes a feeder, a first loop antenna that has an end connected to the feeder and the other end connected to a ground, and a second loop antenna that has an end connected to the feeder and the other end connected to the ground, and has an electrical length different from that of the first loop antenna, wherein an impedance matching line having a discontinuously different line width is formed in a partial area of the first loop antenna.

Owner:KESPION CO LTD

Recloseable bag and method of production

InactiveUS20050238262A1Economically manufacturedNo wasted materialEnvelopes/bags making machineryBag making operationsEngineeringEuhedral and anhedral

Disclosed herein is a recloseable bag having a front and rear faces. The reclosing feature is accomplished with one or more bendable shape-retaining spines formed and bonded to a face of the bag. The spines are formed of resilient plastic having a shape-retaining strand such as wire embedded centrally therein, or from a shape-memory polymer. A variety of spine-shapes are disclosed including straight, T-shaped and curved spines. An installation machine is also disclosed for formation of and heat- or adhesive-application of the spines to the recloseable self-sealing bag material either prior to or during the filling and sealing process. The present invention=s design is simple and straightforward, highly effective, and can be economically manufactured.

Owner:JENKINS GORDON

Bin packing equipment for solar cells

Owner:浙江巨力宝纺织科技有限公司

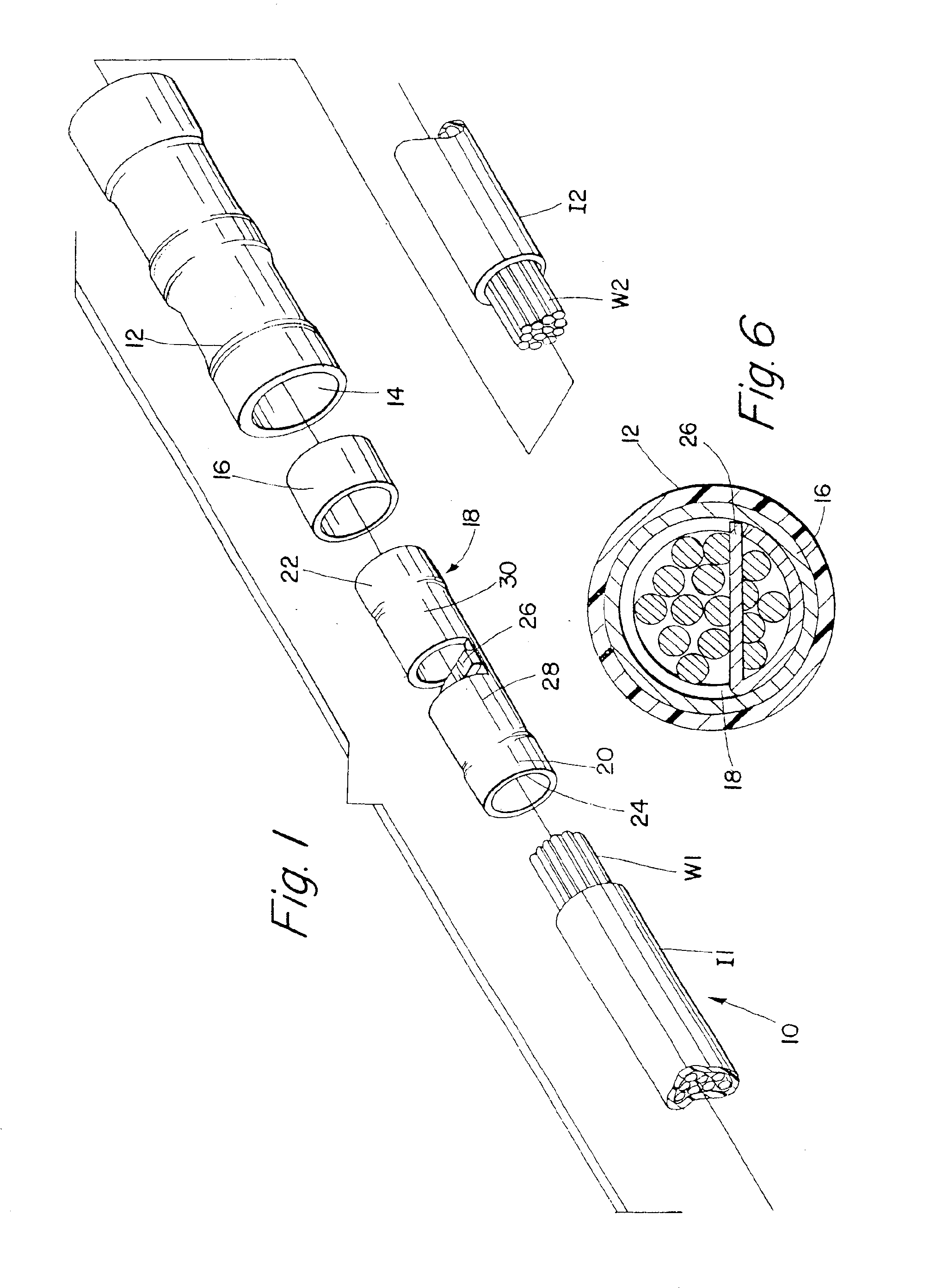

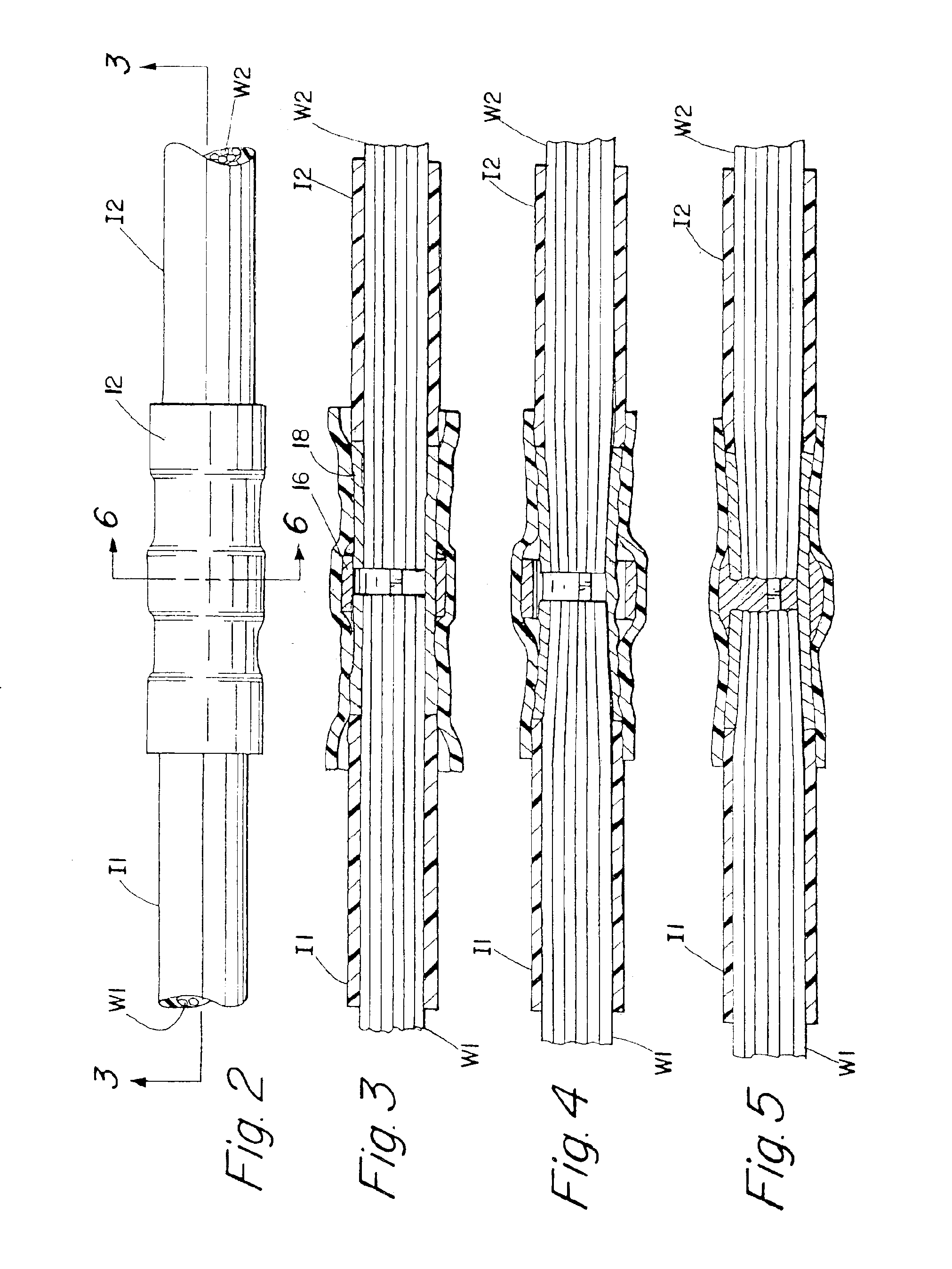

Wire connector

InactiveUS6838621B2Simple and clear designReduce manufacturing costFinal product manufactureDustproof/splashproof/drip-proof/waterproof/flameproof connectionProtective barrierPolyolefin

A wire connector for electrically connecting a pair of wires, allows crimping the wires in place and thereafter allows for soldering of the wires. A hollow sleeve, made from heat shrinkable polyolefin with a heat activated adhesive layer, is translucent and tinted and has a tubular-shaped solder member disposed therein. A body member, made from tin plated annealed copper, is disposed within the solder member. The body member has a channel having and a pair of spaced apart hoods the hoods providing a medial opening for visual inspection of the connected wires. A stop member is disposed within the channel. A first wire member is inserted into the channel until it abuts the stop member, while a second wire member, each wire member being either solid or stranded, is inserted into the opposite end of the channel until it abuts the stop member. The first hood and the second hood are each crimped thereby crimping their respective wires. Thereafter, the hollow sleeve is heated causing the solder member to melt and solder the two wires to the body member, while the hollow sleeve heat shrinks and recovers to the wire insulation providing a protective insulator with the adhesive providing a protective barrier.

Owner:ENDACOTT JOHN E

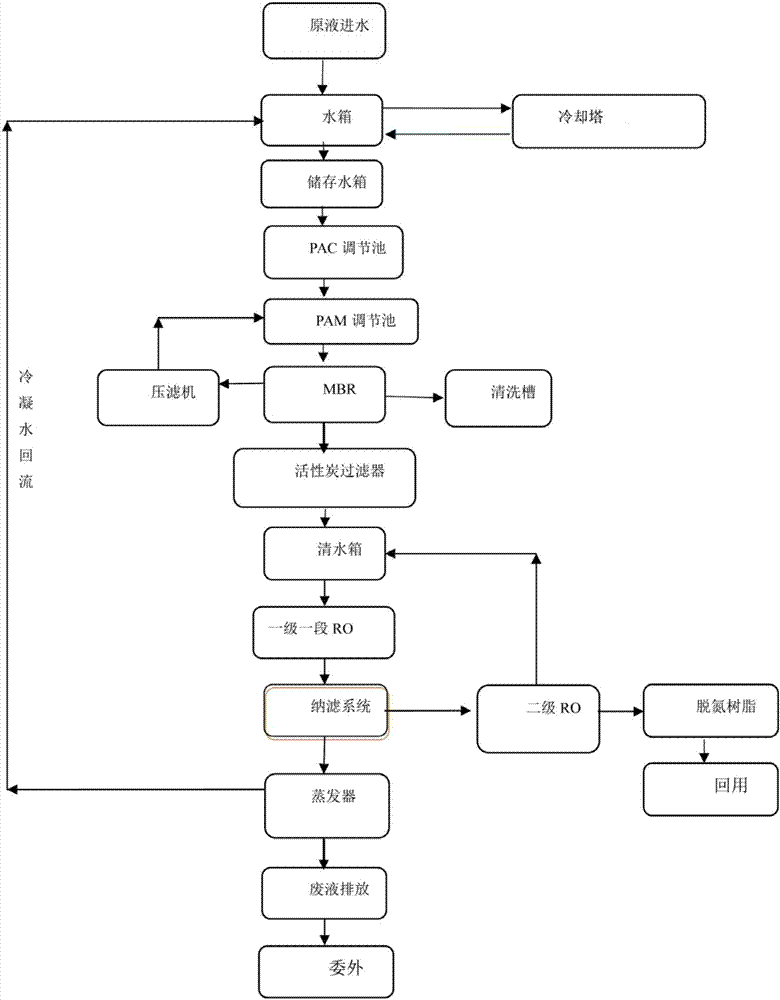

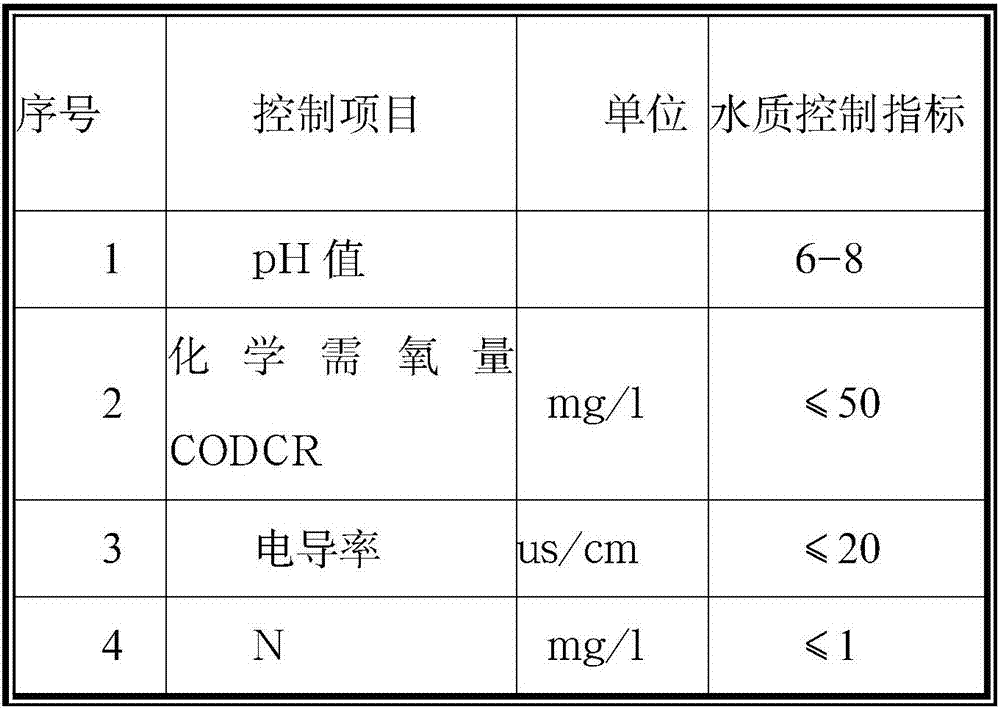

Electronic industrial wastewater near zero release water treatment process

PendingCN107089762AFast separationSimple stepsWater treatment compoundsWater contaminantsWater useWastewater

The invention relates to an electronic industrial wastewater near zero release water treatment process. A basic solution directly enters a water tank to be stored, and a physical and chemical agents is added into the water tank once every month; the basic solution treated in the second step is conveyed into a storage water tank through a pipeline, and the basic solution sequentially enters a PAC adjusting pond and a PAM adjusting pond through a lifting pump; the basic solution treated in the third step enters an MBR through a pipeline, and clear liquid obtained after membrane separation through the MBR enters a filter; filtrate enters a clear water tank through a pipeline, the filtrate is sequentially conveyed into a primary one-segment RO and a nanofiltration system to be filtered by the clear water tank through a pipeline, concentrated liquid separated by the nanofiltration system is recycled to the clear water tank through a pipeline, clear liquid separated by the nanofiltration system enters a secondary RO to be separated through a pipeline, and clear liquid separated through the secondary RO enters denitrification resin to be reused. Effluent reaches or is superior to corresponding water use indexes, and a treatment facility can run stably and reliably for a long time. By the adoption of the reasonable and effective treatment process technology, the economical efficiency, reasonability and effectiveness of overall construction investment are guaranteed, and meanwhile the running and using cost is reduced to the greatest extent.

Owner:广东雅迪环保设备有限公司

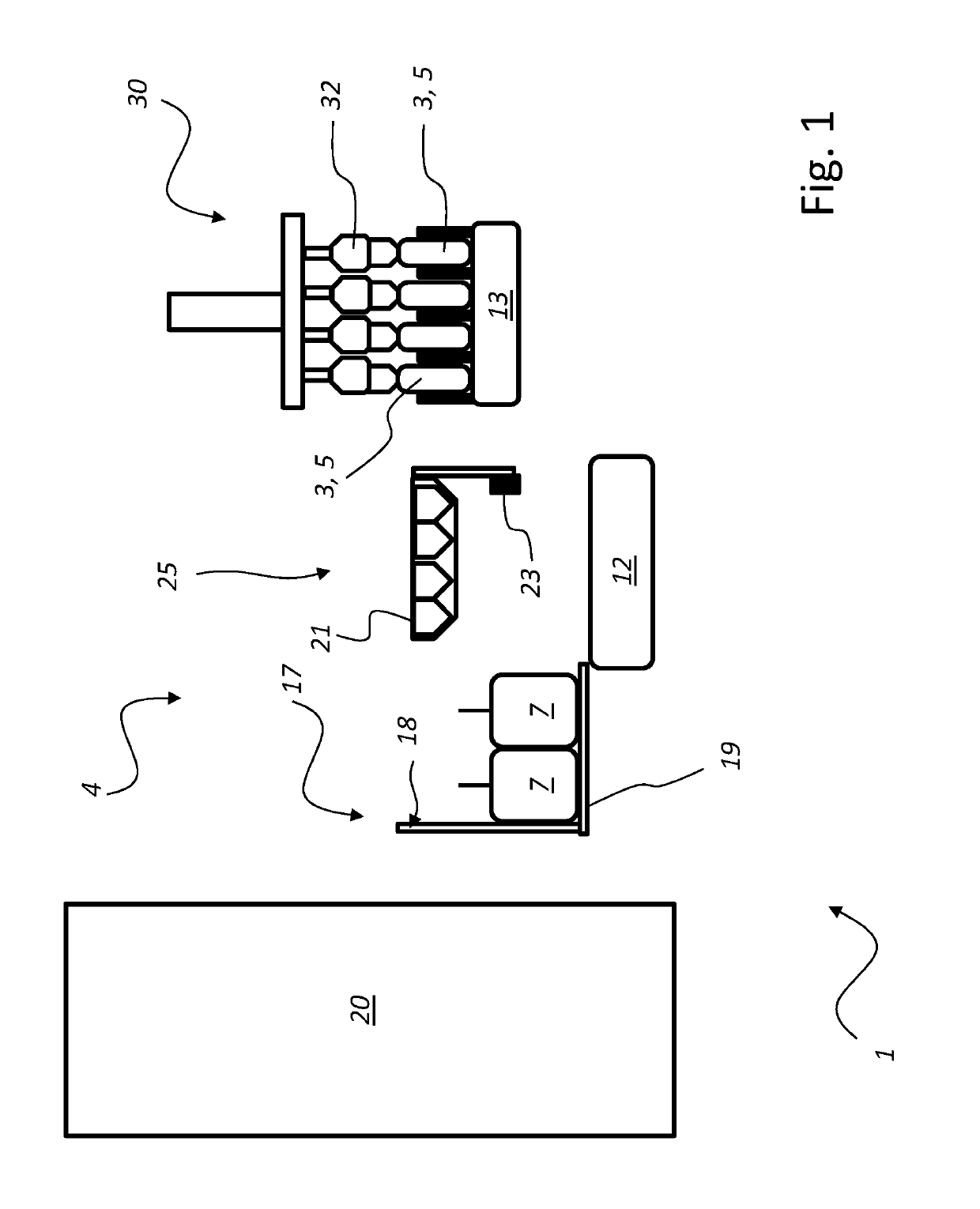

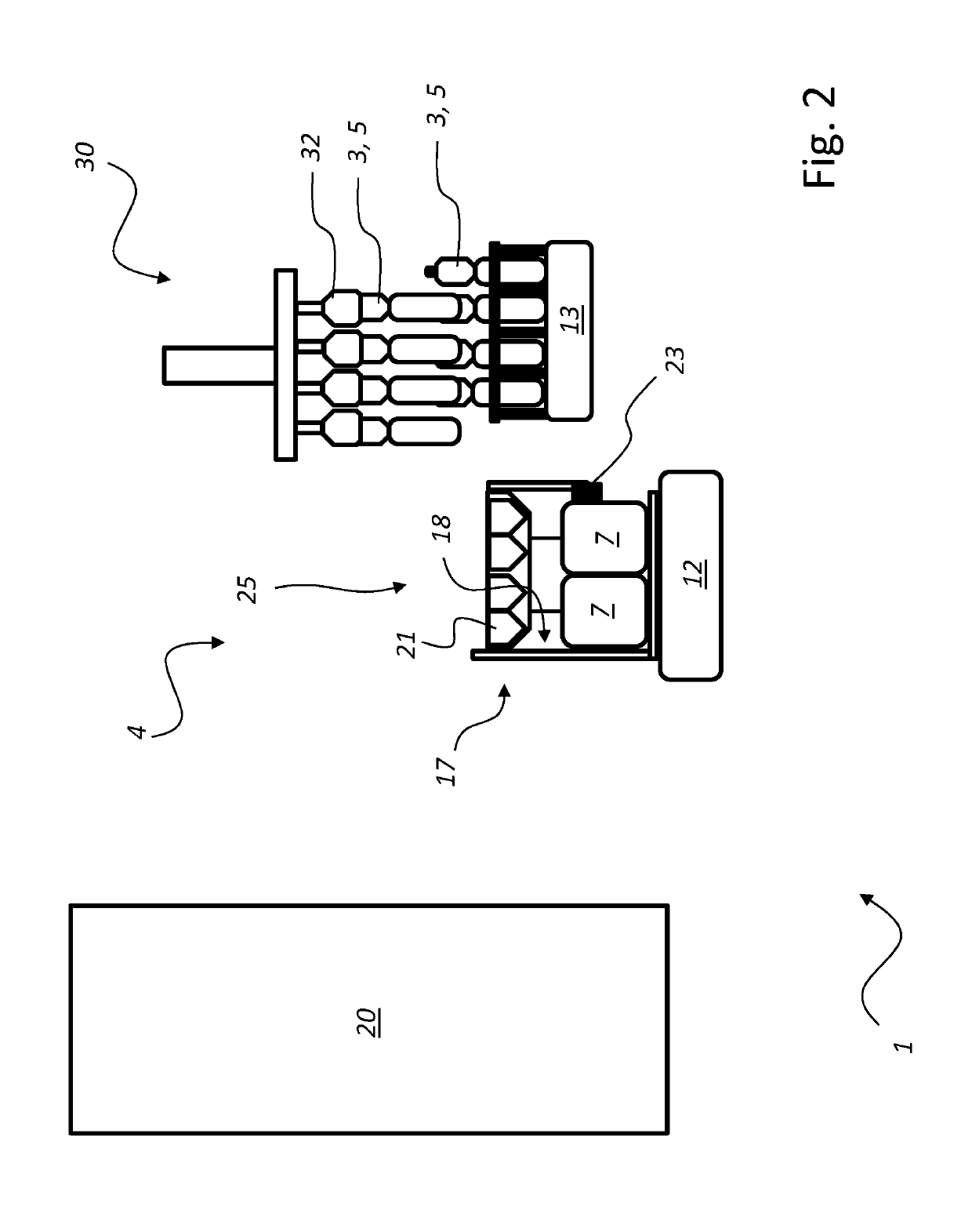

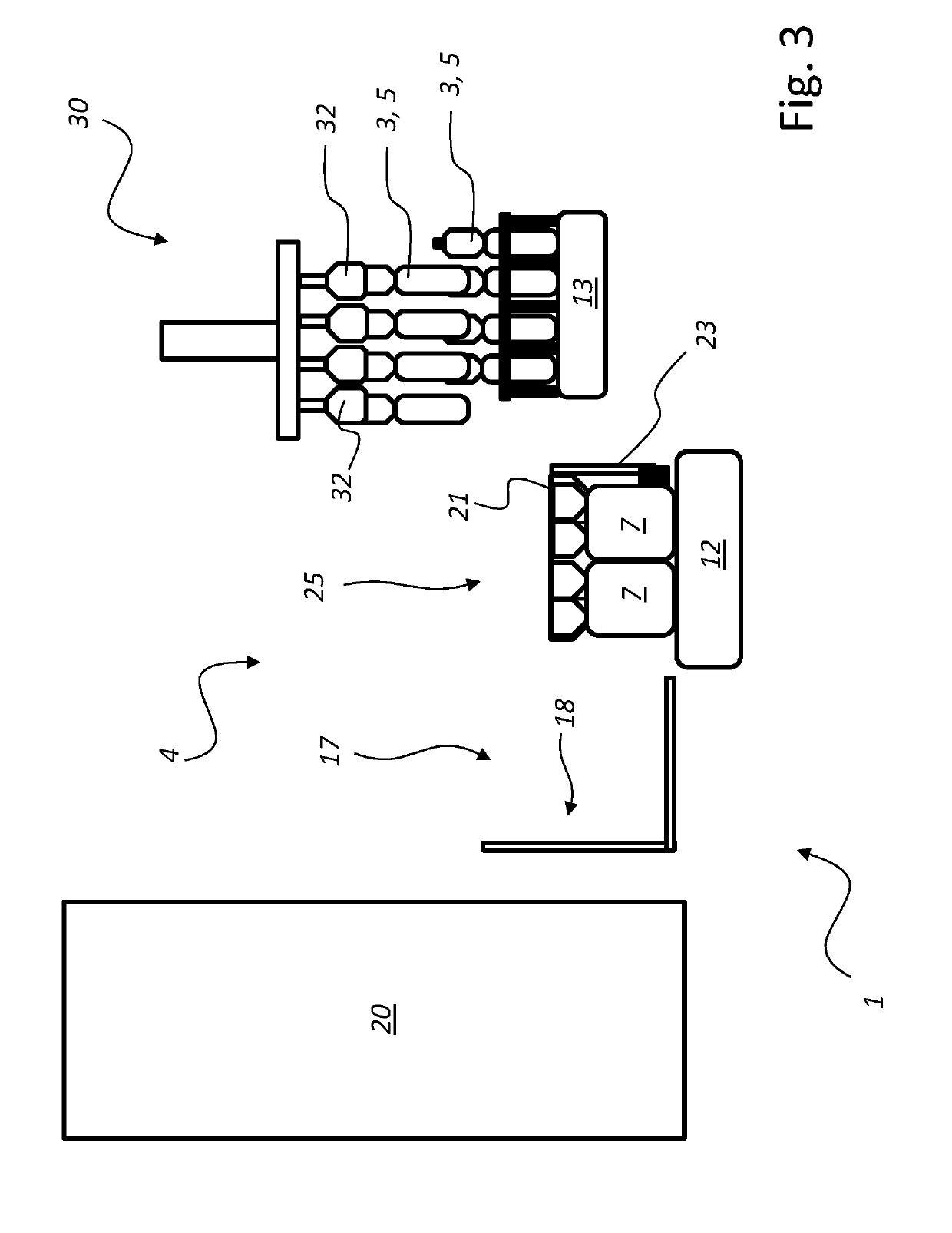

Packaging device for articles and method for inserting articles into prepared outer packaging

InactiveUS20190185190A1Simple and clear designEasy to set upConveyorsPackaging bottlesManipulatorCardboard box

A packaging device (1) for articles, such as beverage containers and the like, is disclosed. The packaging device (1) comprises a transport device (12), at least one transfer device (4), which can receive a packaging means already unfolded into a cardboard box and / or outer packaging (7) and transfer it to the transport device (12), and at least one manipulator (30) designed for inserting articles into packaging means already unfolded into a cardboard box and / or outer packaging (7). It is provided that the at least one transfer device (4) can align packaging means already unfolded into a cardboard box and / or outer packaging (7) and thereby orientate them, which orientation is adapted to the respective insertion of articles (3) via the at least one manipulator (30).

Owner:KRONES AG

Binding-in and pressing machine

InactiveUS7658585B2Simple and cost-efficient designQuality improvementBookbinding casesCasing-inLateral regionEngineering

A binding-in and pressing machine (1) with a plurality of pressing stations (60) and heated joint forming rails situated on a reciprocating carriage (50). An alignment station (20) is provided for aligning the book case joints (2a) at the height of the joint forming rails (49a, b), including a height-adjustable alignment table (21) with rails (22, 23) for supporting the book (2) on the outer edges of its spine and guide elements (28, 6) for centering the book on the alignment table. A separate pre-forming station (40) is also provided that comprises the forming rail (51), clamping plates (41a, b), and joint rails (48a, b) that engage into the book case joints (2a) and counteract a downward movement of at least the book case joints (2a). The books (2) aligned in the alignment station (20) are transferred into the pre-forming station (40) while being clamped in lateral regions near the joints. The effective times available for realizing a functionally safe alignment and a permanent pre-forming of the books are extended due to the assignment of the alignment and pre-forming functions to two separate stations.

Owner:KOLBUS

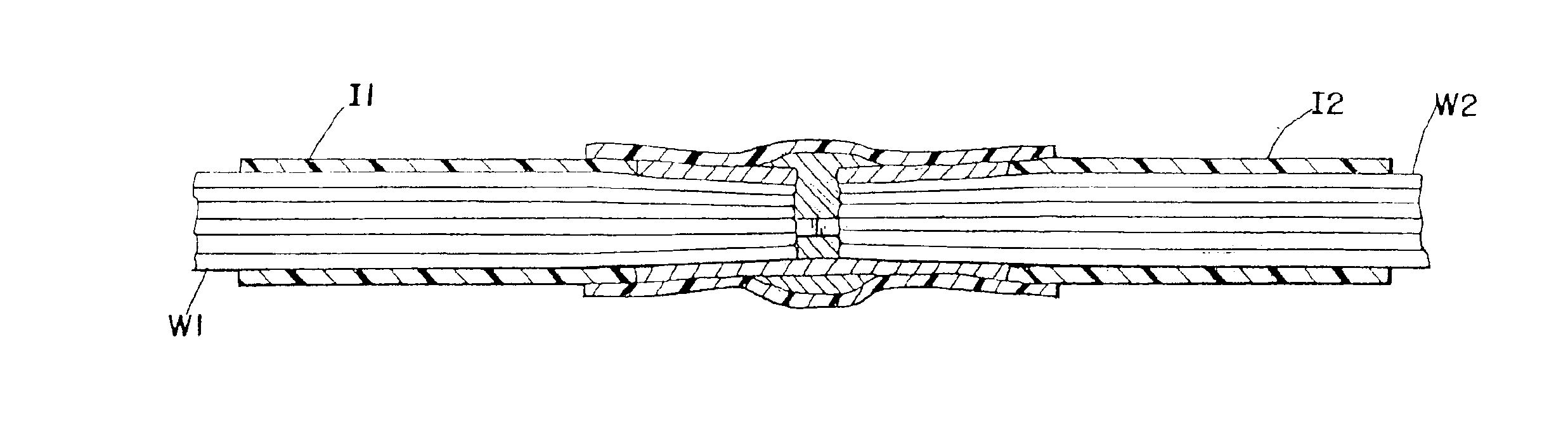

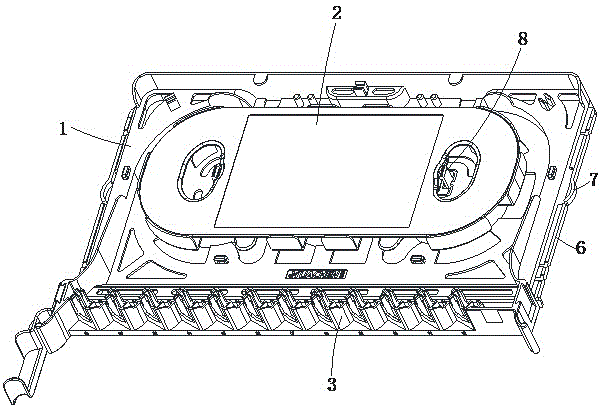

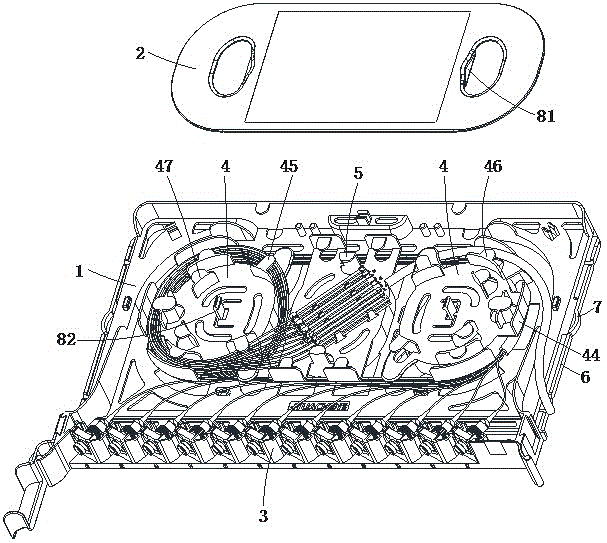

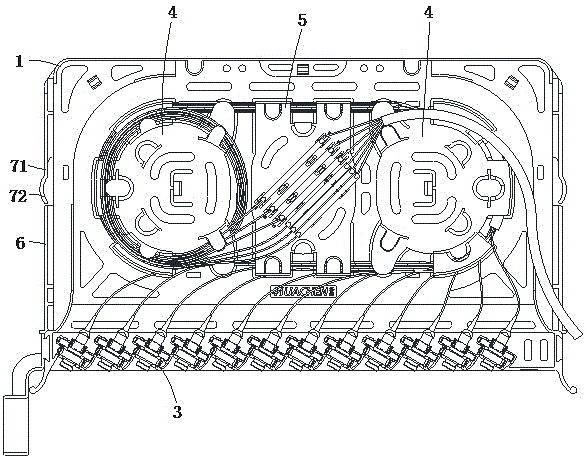

Integrated fiber fusion module

InactiveCN103728695BEasy to operate on siteSimple and clear designCoupling light guidesFiberEngineering

The invention relates to an integrated optical fiber melting module which comprises a melting base and a platform cover which are buckled mutually, wherein two fiber winding zones for winding fibers are arranged on the melting base, a welding zone for welding the optical fibers is arranged between the two fiber winding zones, and gaps are reserved among the welding zone and the two fiber winding zones. Upper fiber storing rails and lower fiber storing rails are arranged in the fiber winding zones and partitioned through a plurality of fiber blocking plates. An external optical fiber enters into a welding platform positioned in the middle directly through the upper fiber storing rails and is welded with a distribution tail fiber on the welding platform. The distribution tail fiber passes through coiled paths of the upper fiber storing rails and the lower fiber storing rails and an adapter clamping seat to be connected with users. Different from the conventional design that an optical fiber distribution plate and a welding plate are split, the integrated optical fiber melting module integrates the optical fiber distribution plate and the welding plate, coiled paths of the external optical fiber and the distribution tail fiber are independent to each other and are not overlapped, and therefore, convenience is brought to uses to perform on-site operation.

Owner:SHENZHEN HUACHEN COMM TECH

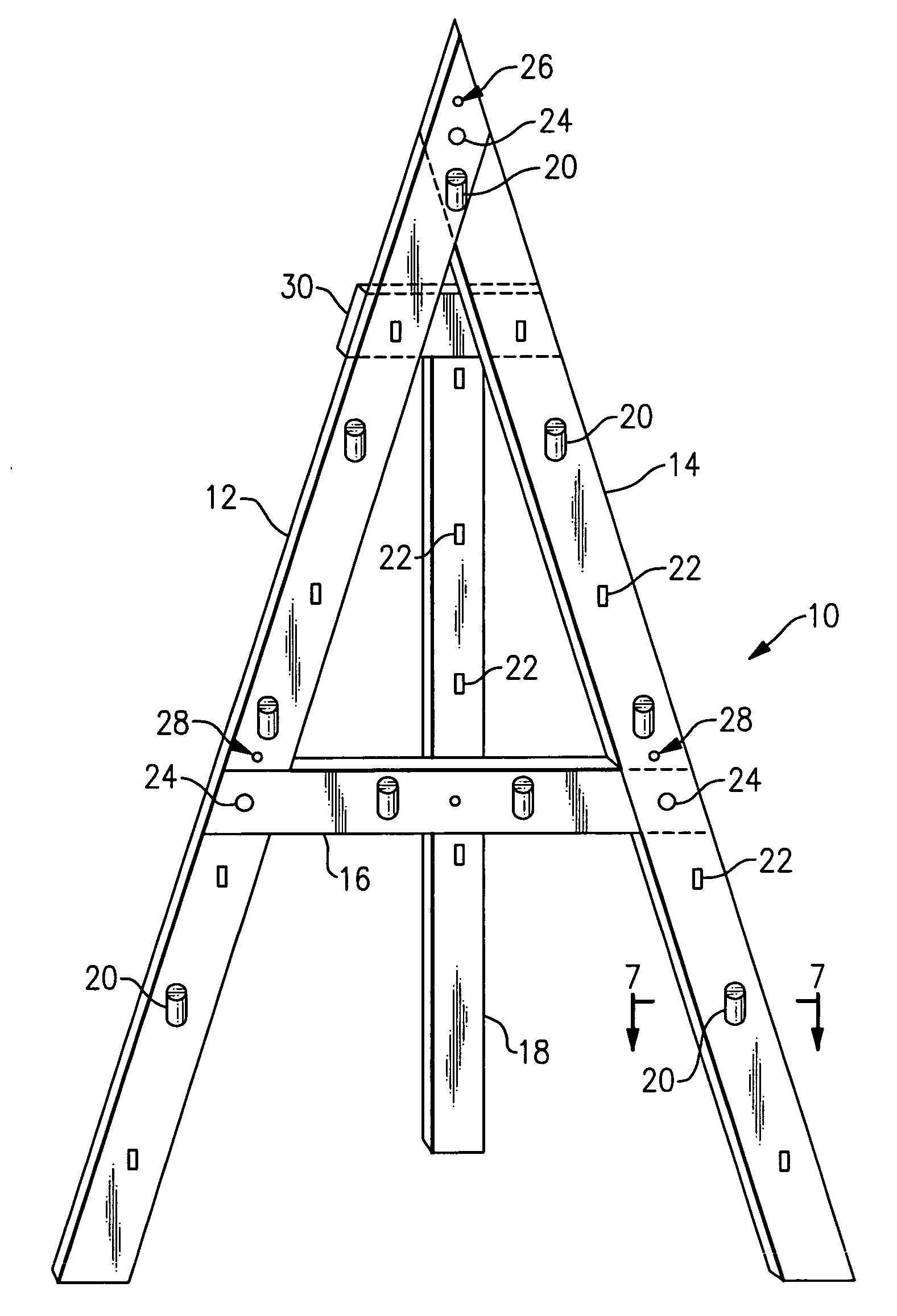

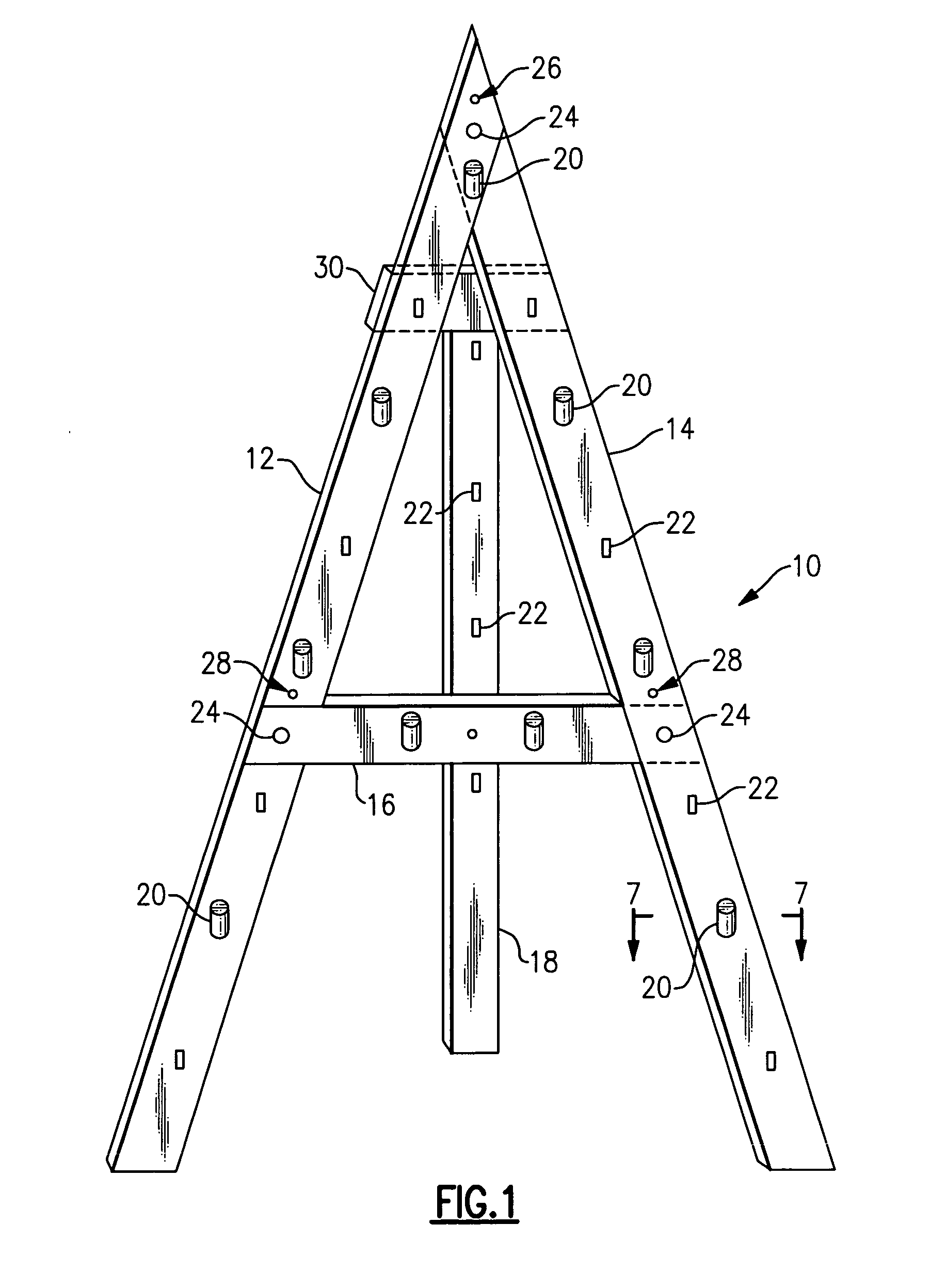

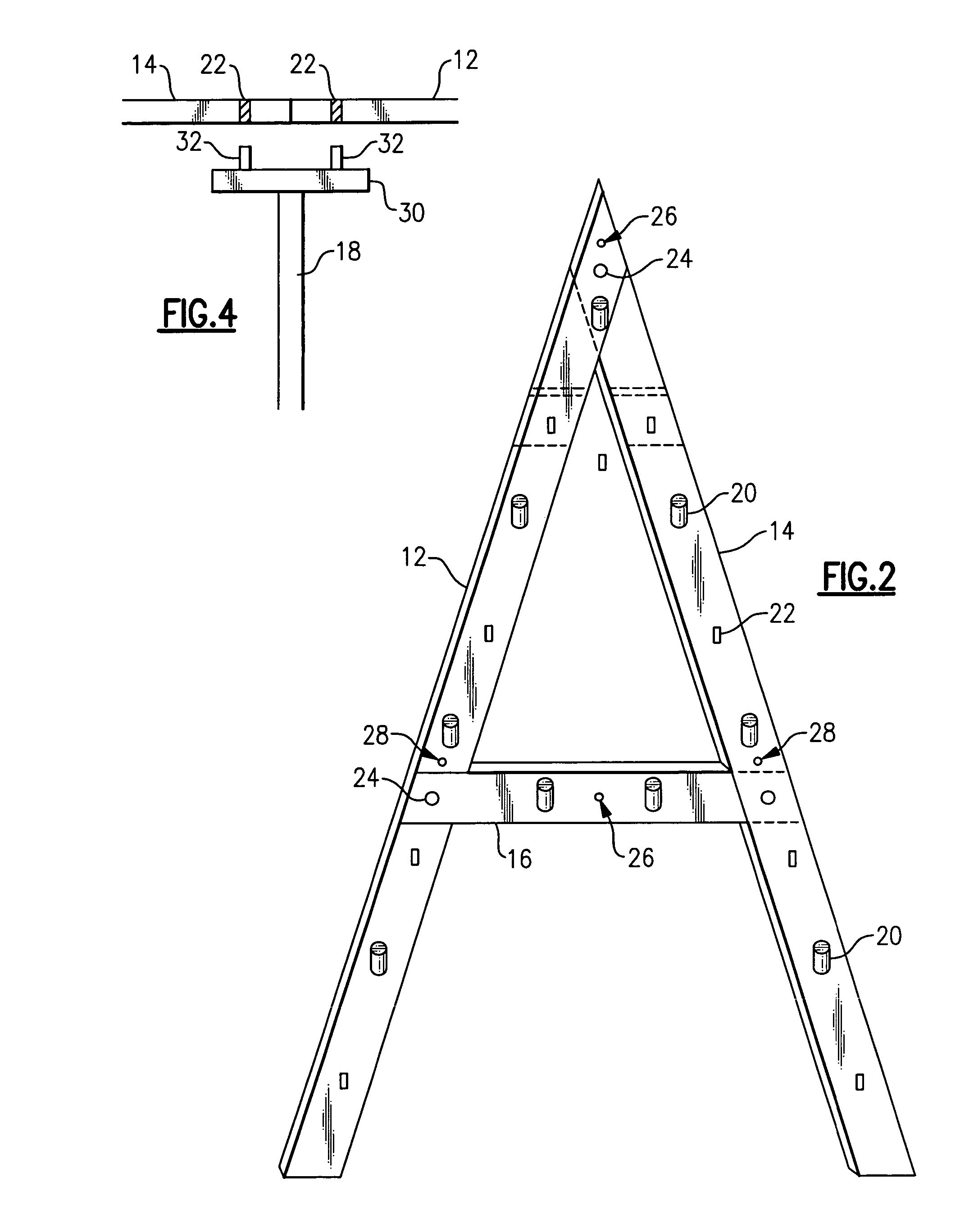

Equipment dryer

InactiveUS20060266716A1Easy to installEasy to transportLocks for portable objectsDrying chambers/containersEngineeringMechanical engineering

An equipment drying rack for athletic gear has the form of an A-frame with left and right legs that meet at an apex, and a cross arm. These are joined with removable snap-in pins, so the rack can be quickly assembled and taken down, and stuffed compactly into a bag for travel. The rack can be wall mounted or a back leg can be installed for free-standing floor use. Hanging pegs can be removably plugged into sockets on the side legs, cross arm, and back leg.

Owner:PERRY ALAN J

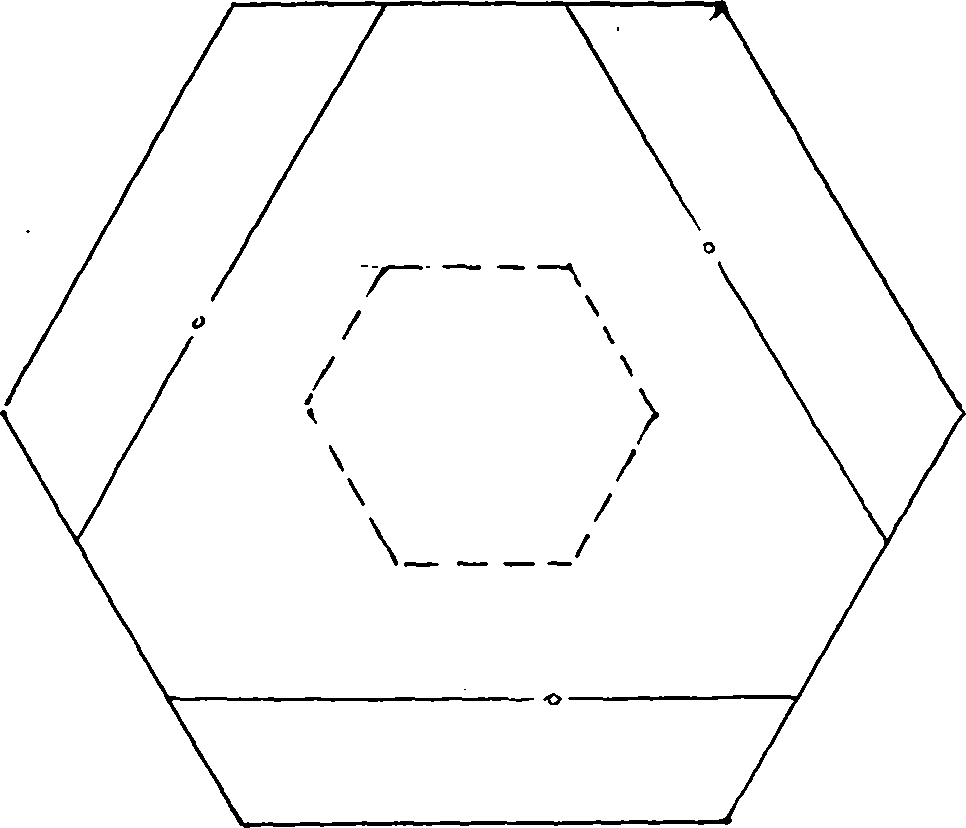

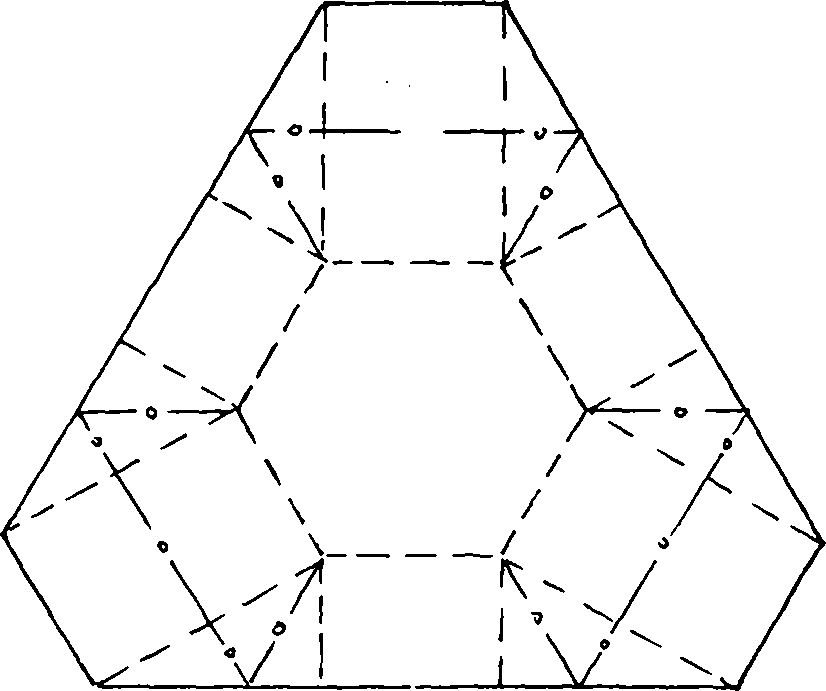

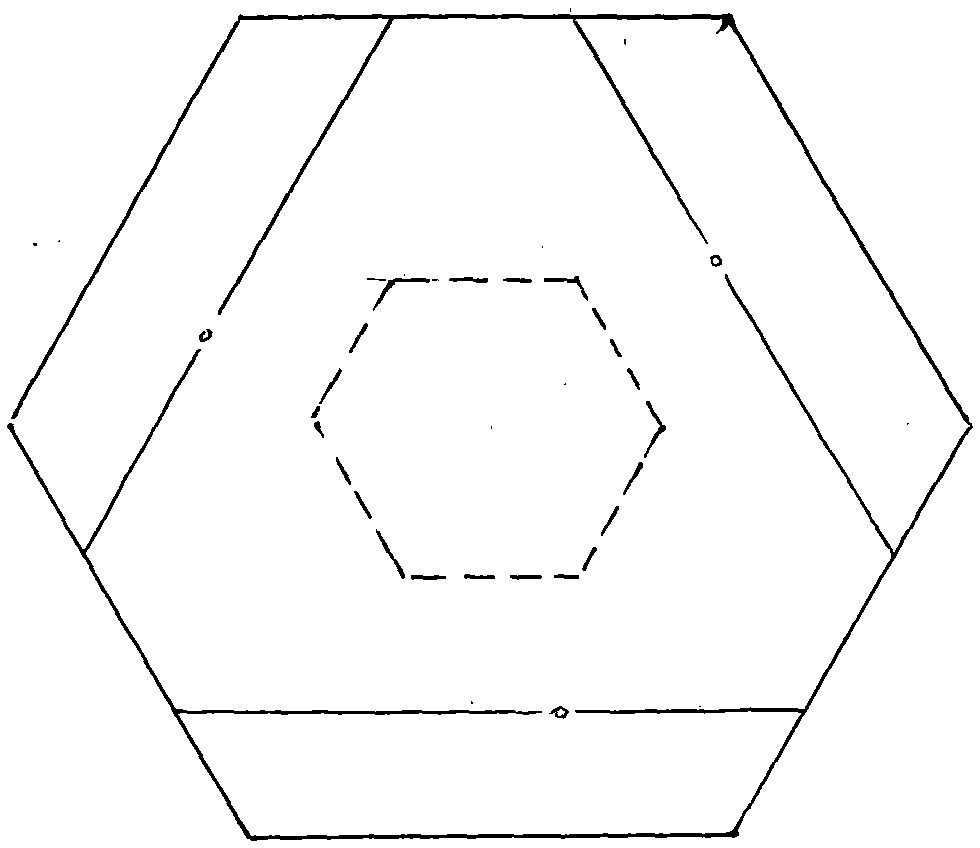

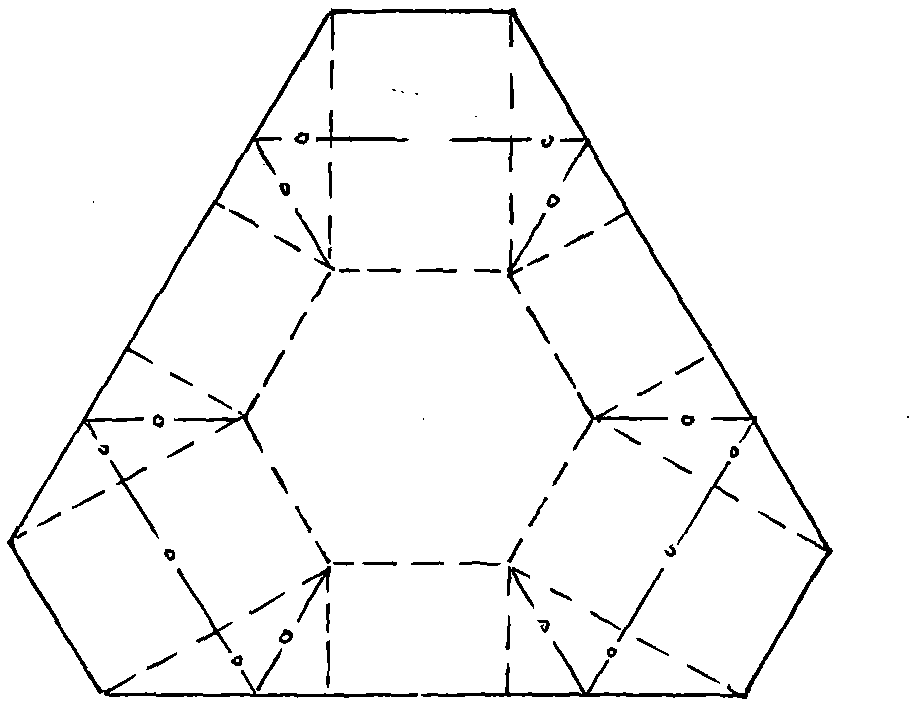

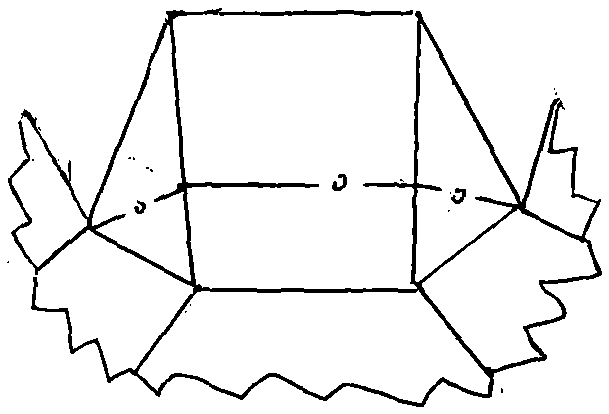

Regular hexagonal paper box

ActiveCN104176349ASimple and clear designFold lines are clear and regularRigid containersIsosceles trapezoidPulp and paper industry

A regular hexagonal paper box relates to a paper vessel manufacturing method. The method includes taking a piece of regular hexagonal paper and making a box bottom regular hexagon in the middle of the paper; making three parallel line negative fold lines parallel to the paper sides of the regular hexagon to form a first isosceles trapezoid between the closest parallel paper sides; folding the first isosceles trapezoid to enable the regular hexagonal paper to be changed to an irregular hexagon; making a long positive fold line, a short positive fold line, an angular bisector negative fold line and a long side intersection point connection line negative fold line; conducting folding according to the short positive fold line, the long positive fold line and the angular bisector negative fold line to form the preliminary shape of the regular hexagonal paper box, wherein the portion higher than the box sides is a second isosceles trapezoid; folding the second isosceles trapezoid towards the box outside to form the regular hexagonal paper box. The regular hexagonal paper box made by the regular hexagon paper is visual and easy to understand and simple and clear in design. The folding lines are clear and regular. The box body is sturdy and attractive in modeling.

Owner:南通市金马包装材料有限公司

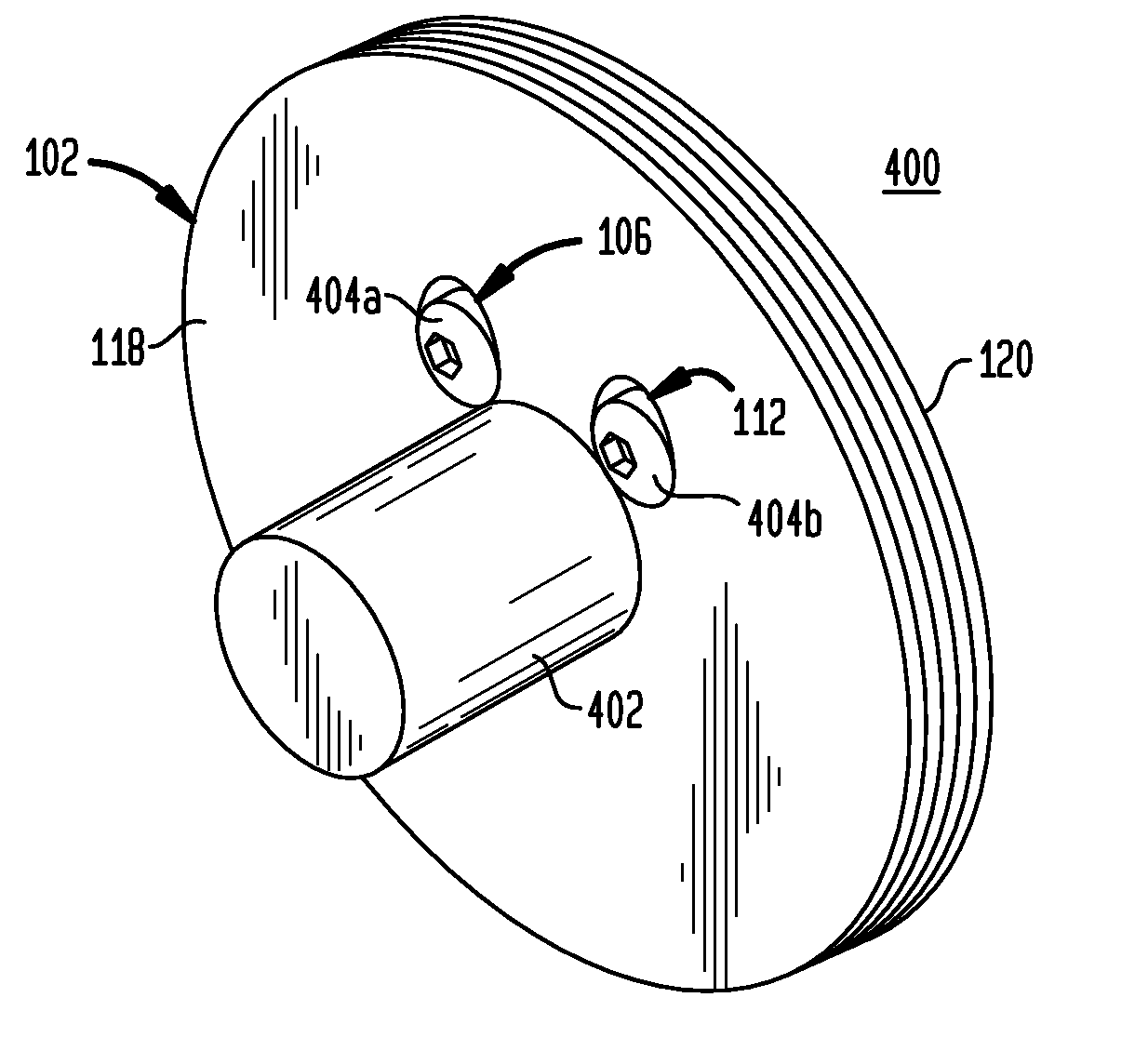

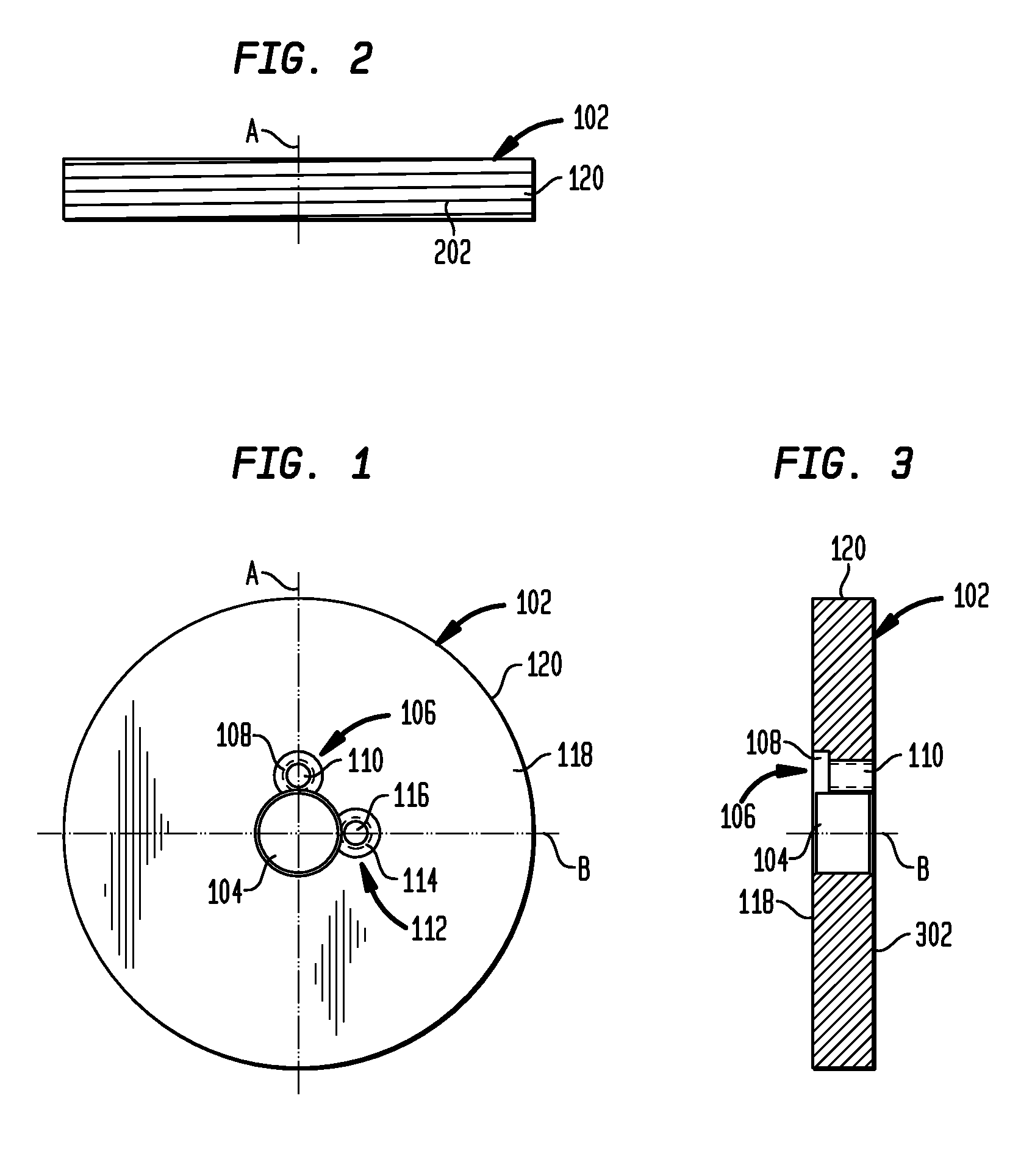

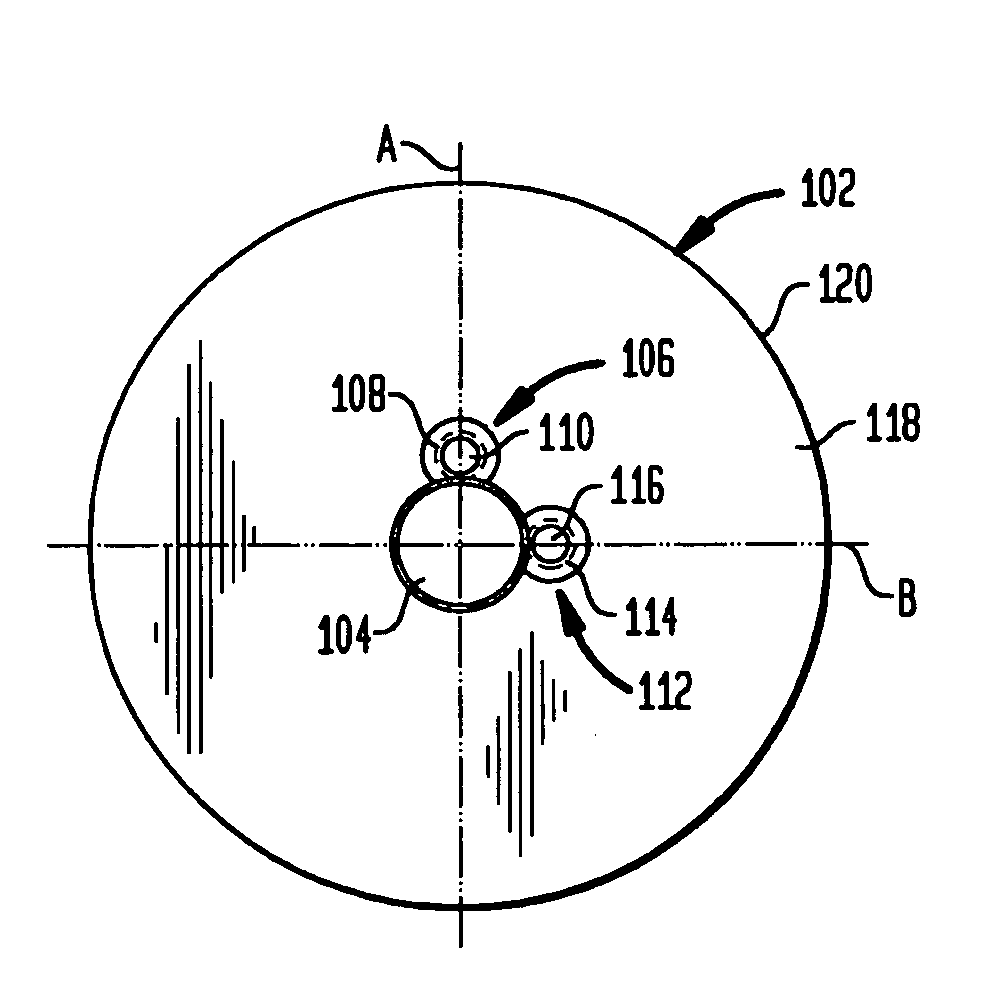

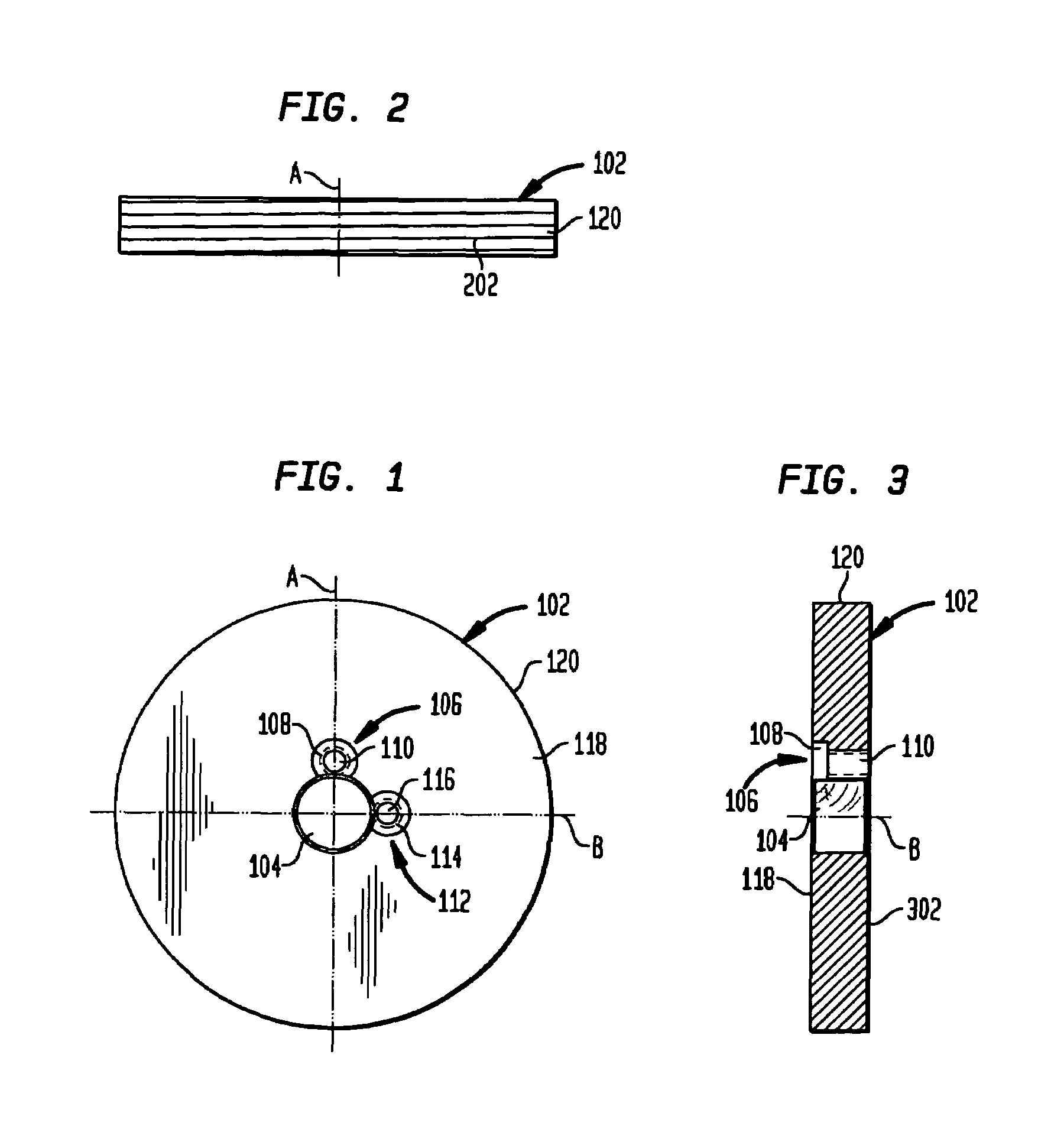

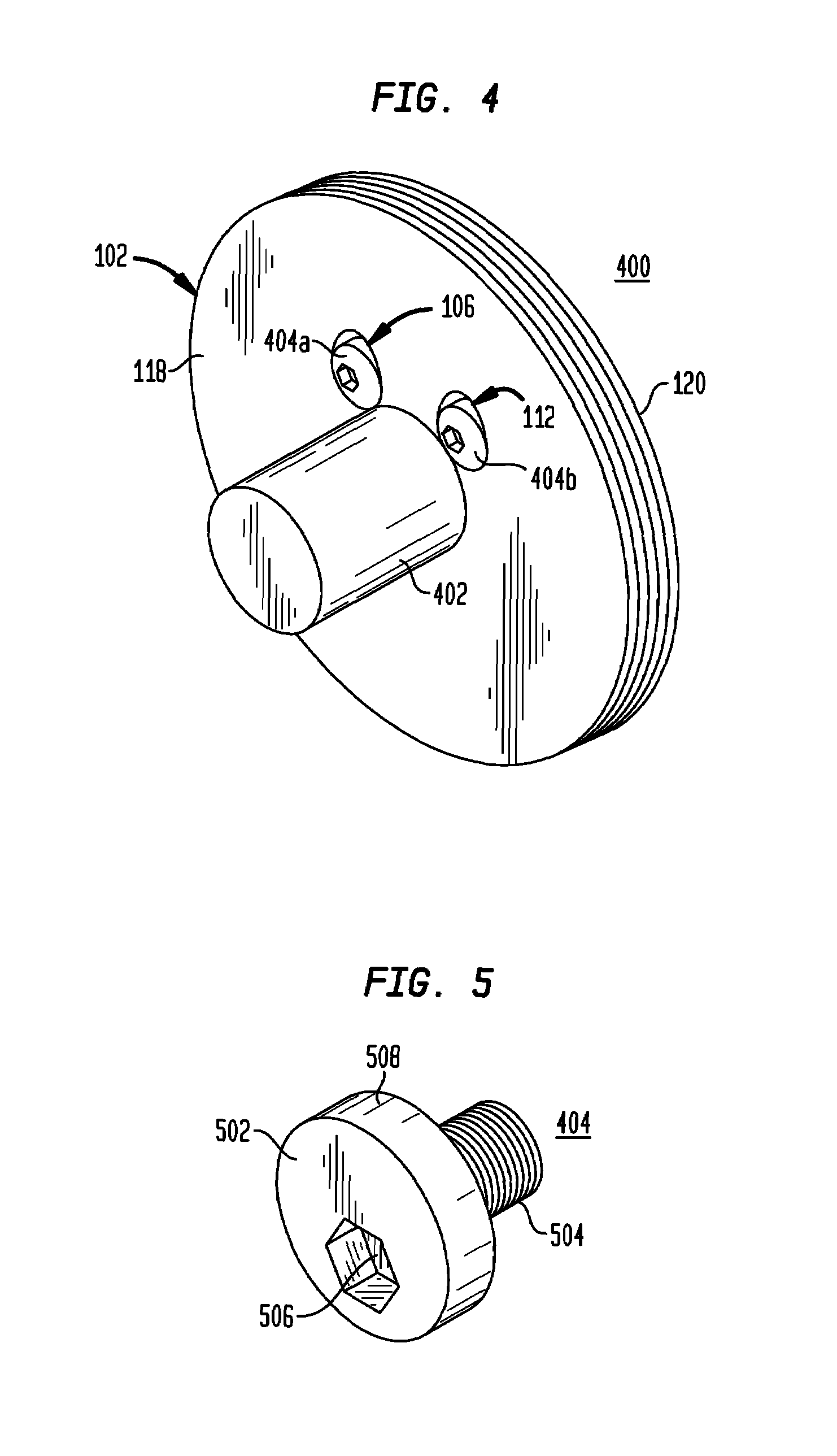

System and Method for Securing a Rotor to a Motor Drive Shaft Using Cam Fasteners

ActiveUS20090133242A1Narrow profileReduce manufacturing costMagnetic circuit rotating partsRod connectionsMotor driveEngineering

A rotor assembly for mounting a rotor to a motor shaft having a rotor with a centrally positioned central bore, the diameter of which is slightly larger than a diameter of the motor shaft, a first stepped bore intersecting the central bore and being aligned along a first axis of the rotor, and a second stepped bore also intersecting the central bore and being aligned along a second axis of the rotor. A first cam fastener is disposed within the first stepped bore, and a second cam fastener is disposed within the second stepped bore. Upon rotating the first and second cam fasteners, they engage the motor shaft thereby securely clamping the rotor to the motor shaft.

Owner:NIDEC MOTOR CORP

Antenna and communication device comprising same

ActiveUS9660343B2Simple and clear designImprove performanceSimultaneous aerial operationsAntenna supports/mountingsImpedance matchingCommunication device

Disclosed are an antenna and a communication device including the same. The antenna includes a feeder, a first loop antenna that has an end connected to the feeder and the other end connected to a ground, and a second loop antenna that has an end connected to the feeder and the other end connected to the ground, and has an electrical length different from that of the first loop antenna, wherein an impedance matching line having a discontinuously different line width is formed in a partial area of the first loop antenna.

Owner:KESPION CO LTD

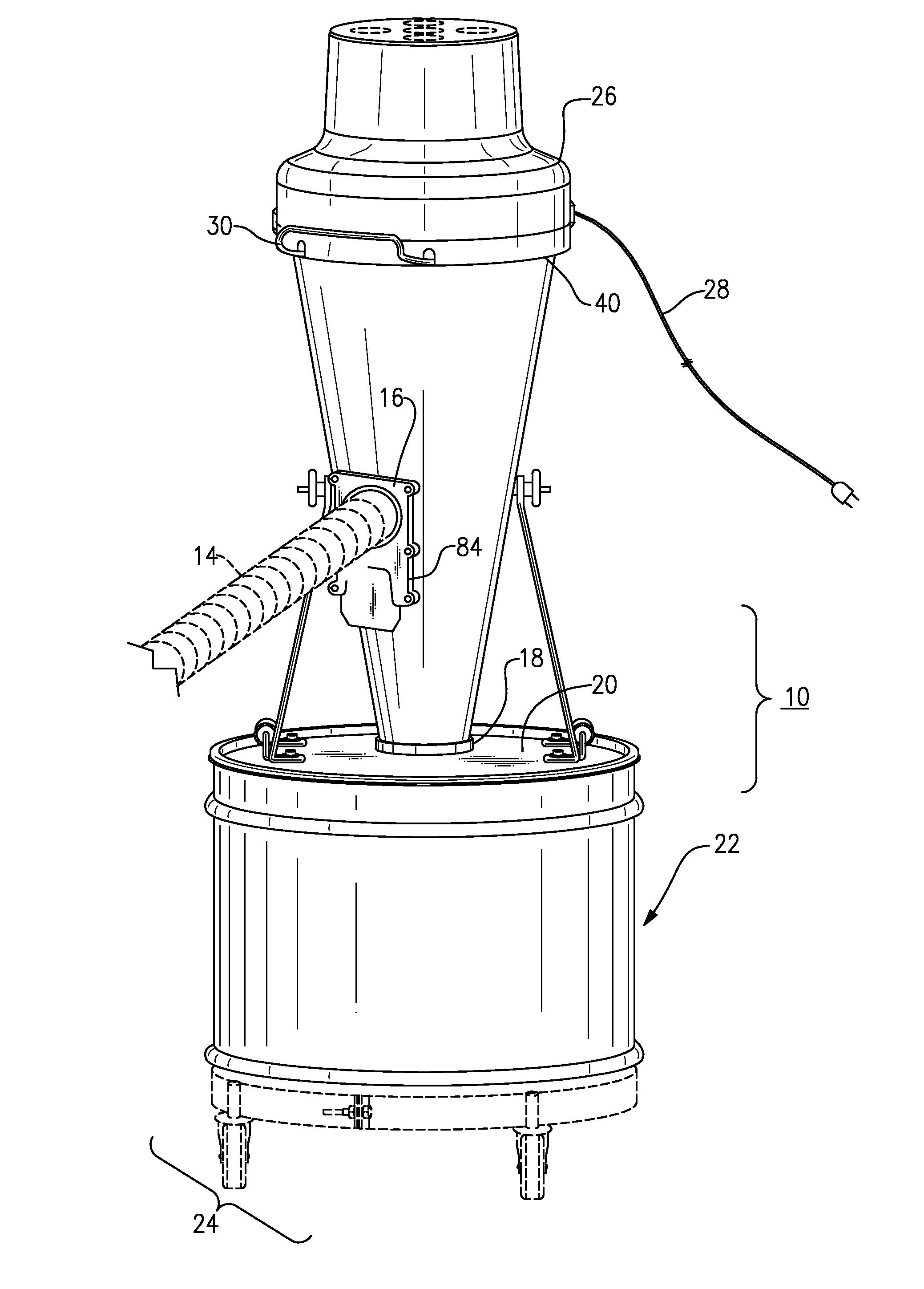

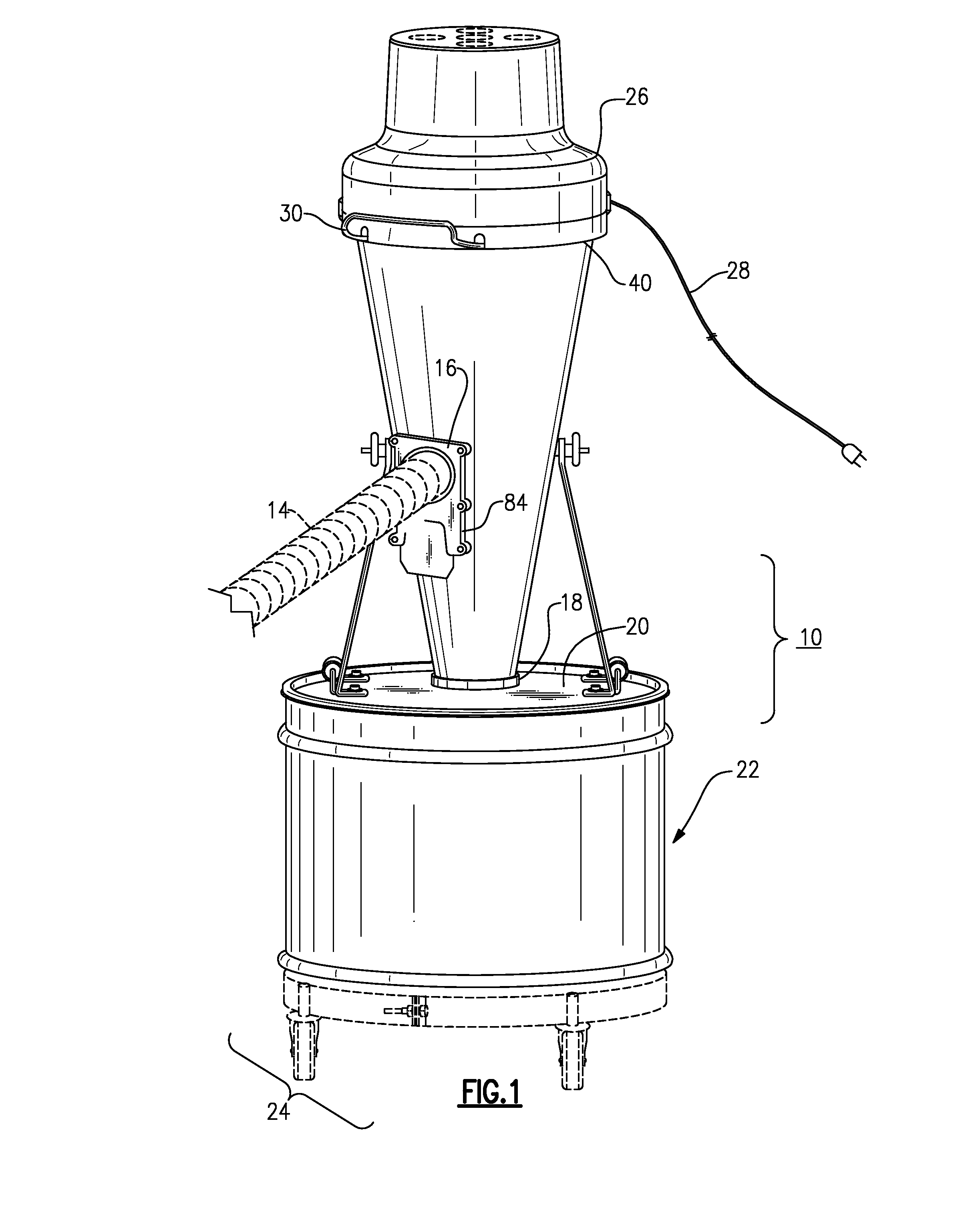

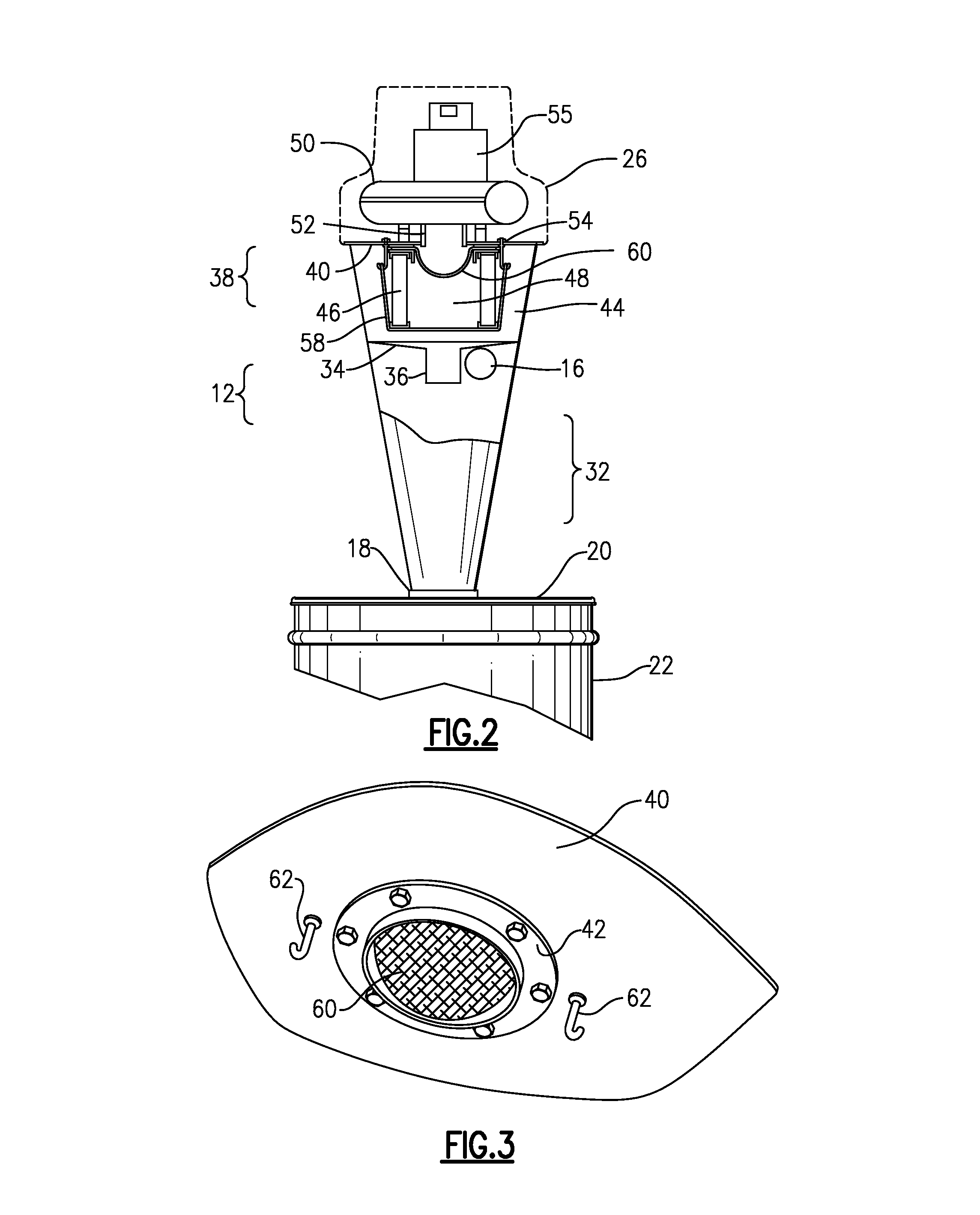

Deflagration suppression screen for portable cyclonic dust collector/vacuum cleaner

ActiveUS20160166124A9Efficient but simplified designSimple and clear designCleaning filter meansSuction filtersDeflagrationHollow core

A cyclonic portable vacuum cleaner / dust collector has a cyclonic chamber and a filter chamber. The filter chamber contains a filter cartridge with a hollow core positioned over the discharge opening of a motor plate that closes the filter chamber. A vacuum blower is mounted on the motor plate, with an intake tube at the discharge opening of the motor plate. An anti-deflagration screen mounted upon the discharge opening of the cover plate of the filter chamber. The anti-deflagration screen is in the form of a metal mesh creating a multiplicity of small passages to permit exhaust air flow from the filter chamber but blocking any flame front. The screen may be hemispherically domed.

Owner:ONEIDA AIR SYST

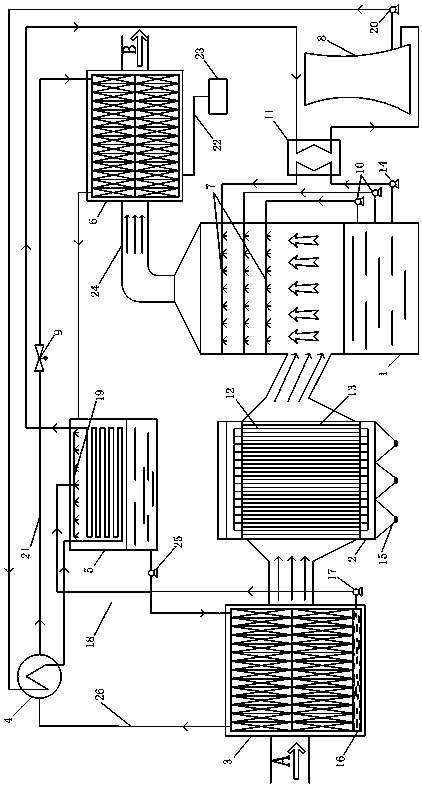

Deep condensation demisting system using flue gas waste heat

InactiveCN109925839AAchieve the effect of defogging and whiteningRealize waste heat recovery and utilizationElectrostatic separationDispersed particle separationWater vaporEvaporation

The invention discloses a deep condensation demisting system using flue gas waste heat. The deep condensation demisting system using flue gas waste heat comprises a generation chamber, a desulfurization tower, and an evaporating chamber which are connected successively, and also comprises a condenser and an absorbent; a waste heat refrigeration cycle system is composed of the condenser and the absorbent between the generation chamber and the evaporating chamber; a generation heat exchanger is arranged in the generation chamber, flue gas is driven to pass through the generation heat exchanger,the chamber of the generation chamber is charged with a refrigerant-absorbent solution; an evaporation heat exchanger is arranged in the evaporating chamber, and supersaturated water vapor in flue gasis eliminated and flue gas temperature is reduced in the evaporation heat exchanger. According to the deep condensation demisting system, industrial low quality waste heat is adopted to prepare a cold source, the adaptability is high, the stability is high, influence by the seasons is low, the prepared cold energy can be used for deep condensation of desulphurization wet flue gas, chimney demisting white plume eliminating effects are achieved, and the deep condensation demisting system can be widely used in power station boiler and industrial boiler chimney moisture smoke plume treatment.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

System and method for securing a rotor to a motor drive shaft using cam fasteners

ActiveUS7485997B1Low manufacturing costSimple and straightforward designMagnetic circuit rotating partsMagnetic circuit stationary partsMotor shaftFastener

A rotor assembly for mounting a rotor to a motor shaft having a rotor with a centrally positioned central bore, the diameter of which is slightly larger than a diameter of the motor shaft, a first stepped bore intersecting the central bore and being aligned along a first axis of the rotor, and a second stepped bore also intersecting the central bore and being aligned along a second axis of the rotor. A first cam fastener is disposed within the first stepped bore, and a second cam fastener is disposed within the second stepped bore. Upon rotating the first and second cam fasteners, they engage the motor shaft thereby securely clamping the rotor to the motor shaft.

Owner:NIDEC MOTOR CORP

regular hexagonal carton

ActiveCN104176349BSimple and clear designFold lines are clear and regularRigid containersIsosceles trapezoidCarton

A regular hexagonal paper box relates to a method for making a paper vessel. Take regular hexagonal paper, and make a regular hexagon at the bottom of the box in the middle of the paper; make three parallel lines that are parallel to the regular hexagonal paper sides and reverse the folding lines, and form the first isosceles trapezoid between the nearest parallel paper side; fold the second One isosceles trapezoid, regular hexagonal paper changes into non-equilateral hexagonal; make long positive fold line, short straight fold line, angle bisector reverse fold line, long side intersection connecting line reverse fold line; according to short positive fold line, long positive fold line and The corner bisector is folded against the folding line to form the preliminary shape of a regular hexagonal carton, and the extra part higher than the side of the box is the second isosceles trapezoid; the second isosceles trapezoid is folded to the outside of the box to form a regular hexagon Paper box: regular hexagonal paper box is made of regular hexagonal paper, which is intuitive and easy to understand; the design is simple and clear, and the folding lines are clear and regular; the box body is strong and beautiful in shape.

Owner:南通市金马包装材料有限公司

Shock absorber with comfort valve

ActiveUS10760639B2Simple and clear designCost of implementationSpringsLiquid based dampersEngineeringPressure difference

A shock absorber includes a cylinder; a piston dividing the cylinder into first and second chambers, the piston being movable within the cylinder in inward and outward directions; a first main channel and a first main non-return valve allowing a first main fluid flow from the second to the first cylinder chamber; a second main channel and a second main non-return valve allowing a second main fluid flow from the first to the second cylinder chamber; a comfort channel allowing an auxiliary fluid flow between the first and second cylinder chambers; and a comfort valve providing an open connection for the auxiliary fluid flow through the comfort channel in a rest position of the comfort valve and closing off the auxiliary fluid flow at increasing pressure difference across the comfort valve at either inward or outward movement to influence an auxiliary fluid flow between first and second piston sides.

Owner:KONI BV

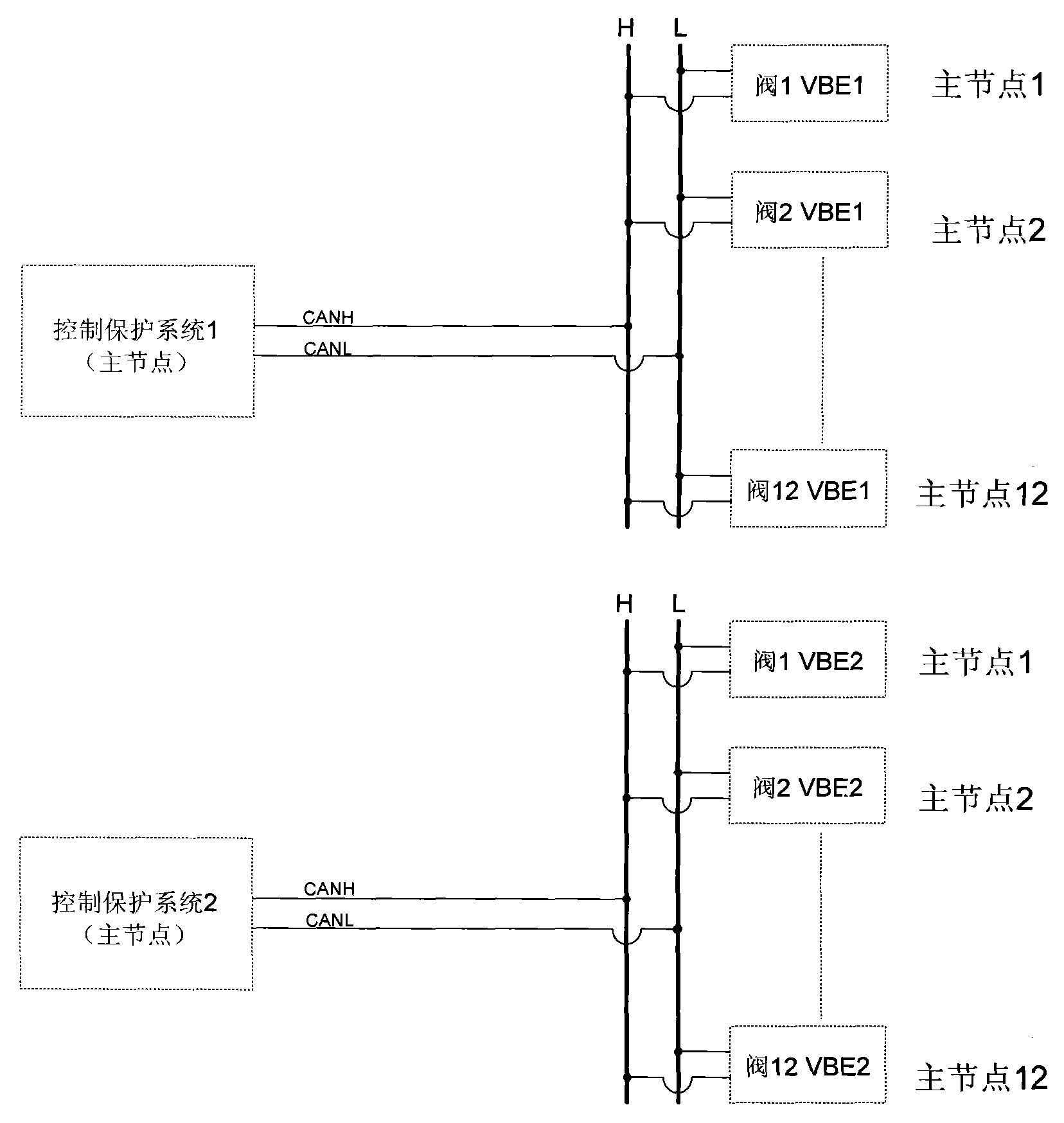

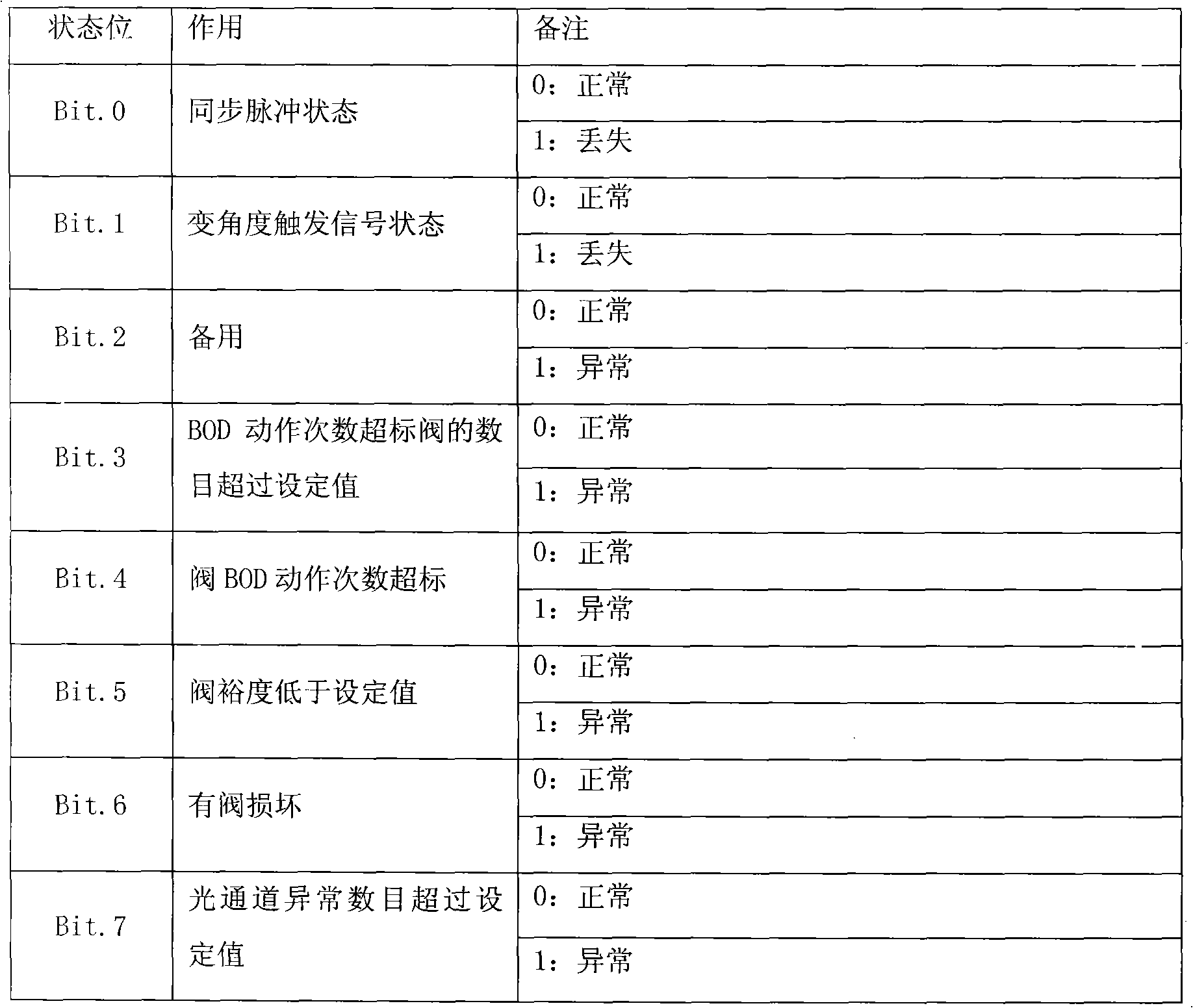

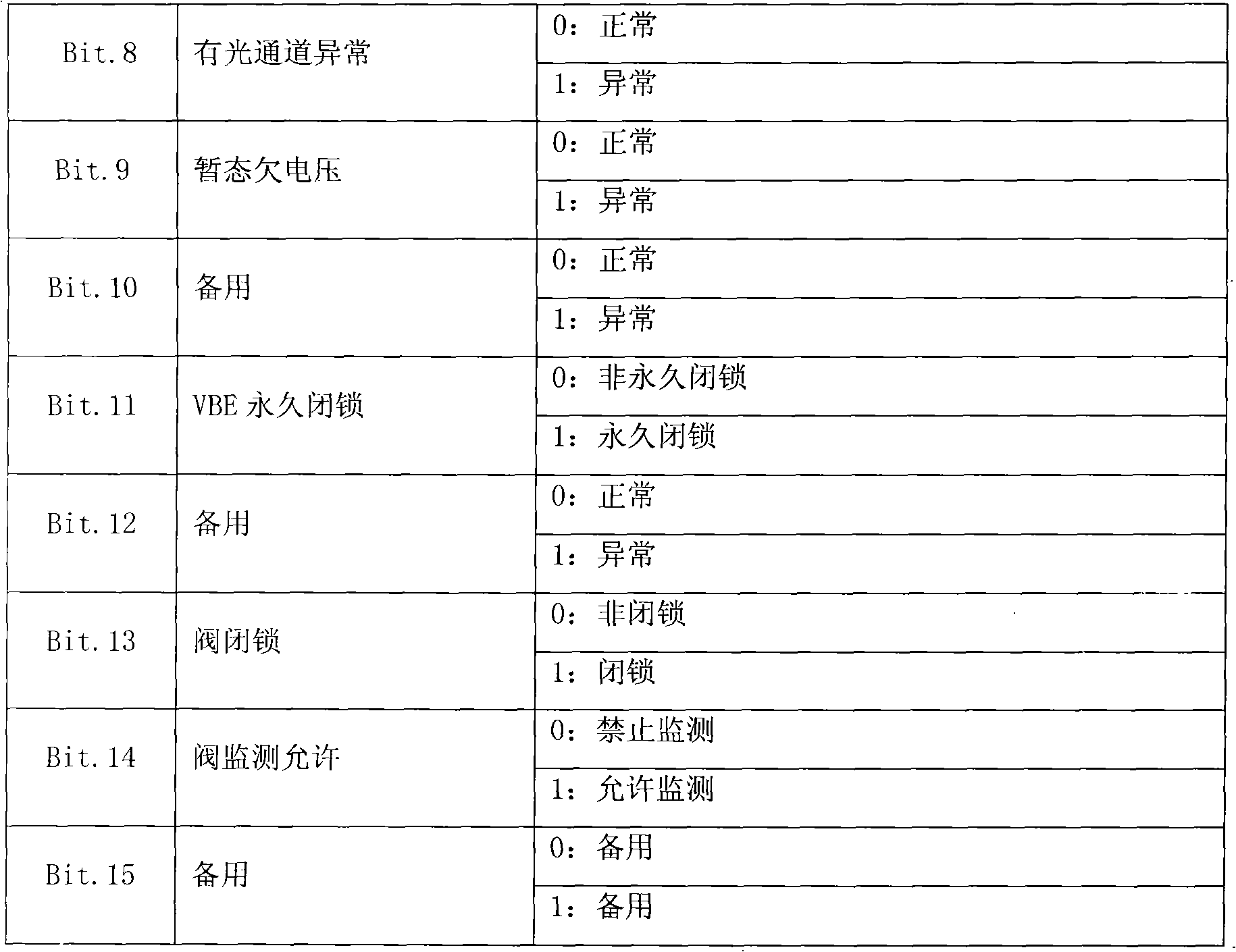

Method for designing communication protocol of high-voltage and direct-current (HVDC) thyristor valve base electronic equipment

ActiveCN101986512BSimple and clear designImprove operational reliabilityError preventionCircuit arrangementsArea networkDesign communication

The invention provides a novel method for designing a communication protocol of high-voltage and direct-current (HVDC) thyristor valve base electric equipment. Based on the controller area network (CAN) protocol, the communication protocol between a pole control system and the valve base electric equipment is set according to different working conditions of a thyristor valve, and information exchange between the valve base electric equipment and the pole control system can be completed by adopting a serial coding mode. The design is simple, clear, reliable and stable, and contains all the basic working conditions of thyristor valve operation. Byadopting the communication protocol, besides the basic communication requirement between the pole control system and the valve base electric equipment can be met, the strong interference resistance of a CAN bus can be introduced to a thyristor valve secondary control system to greatly improve the operation reliability of the system. A multi-master CAN networking communication mode is adopted between the valve base electric equipment and a control protective system, and valve base electronics (VBE) can monitor status changes at any time occurring in the thyristor valve and report the detection information to the control protective system. The networking mode ensures real time performance of monitoring the valve by the VBE.

Owner:CHINA ELECTRIC POWER RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com