Recloseable bag and method of production

a self-closing, bag technology, applied in the field of food bags, can solve the problems of requiring an expensive zipper profile applicator, no good self-closing method, and inability to fold and/or twist the end, etc., and achieves the effect of low cost, no wasted material, and high effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

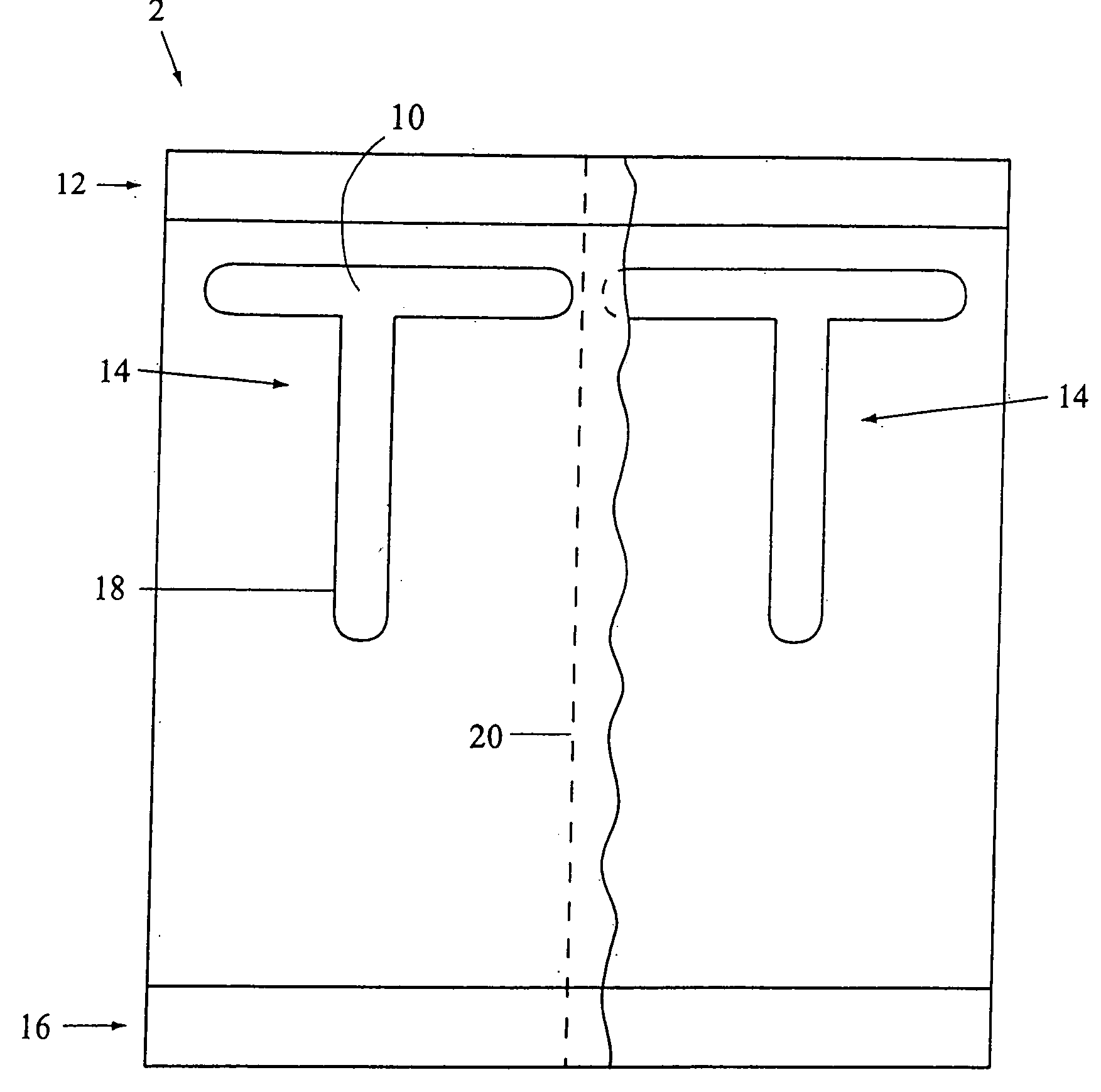

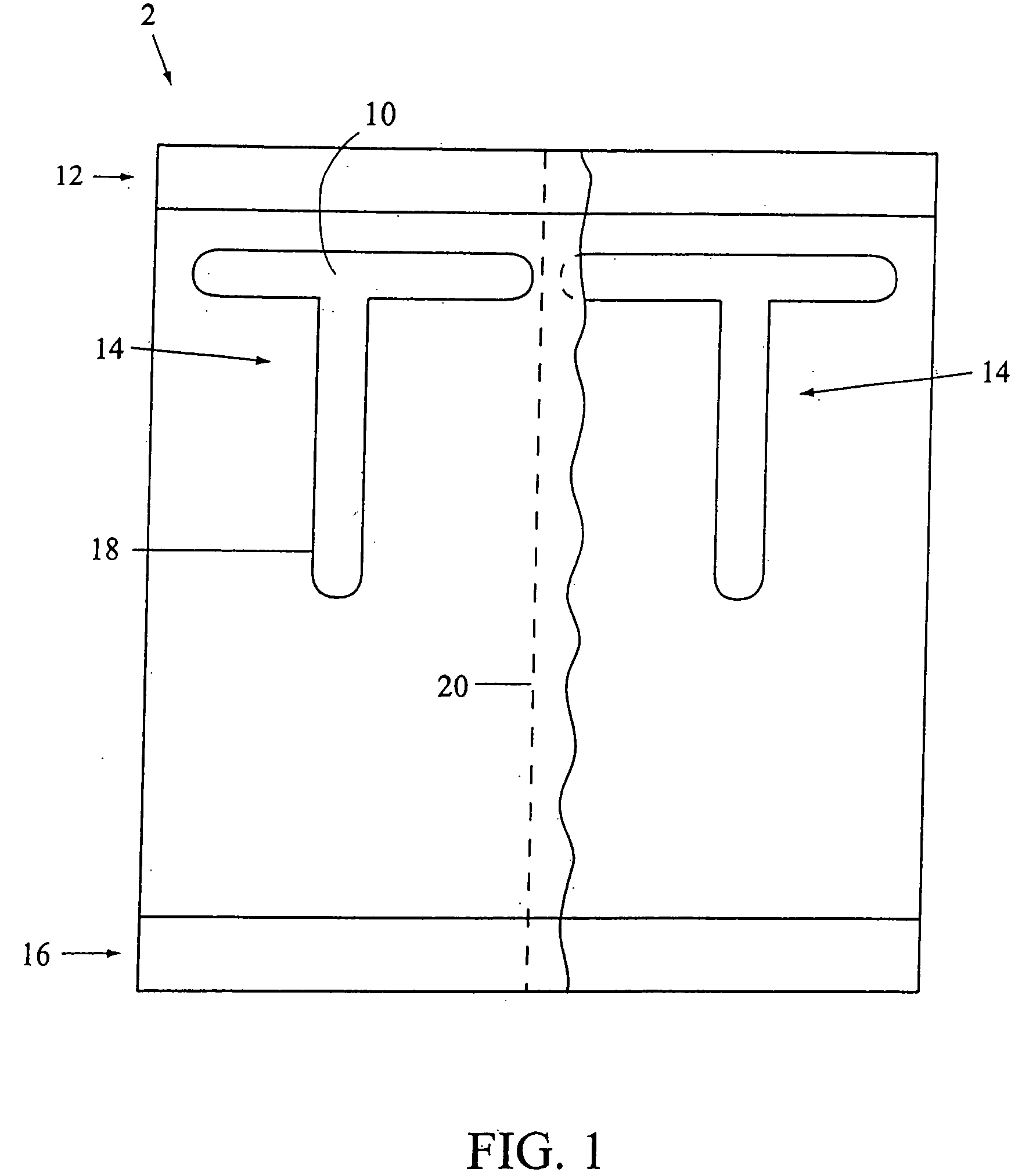

[0026]FIG. 1 is a rear perspective view of the recloseable self-sealing bag 2 for food articles according to one embodiment of the present invention. The recloseable self-sealing bag 2 is folded and formed with a top heat seam 12, bottom heat seam 16 and a center rear heat seam 20, as are conventional bags. It is produced from film stock by horizontal or vertical form, fill and seal machines in a conventional manner. Specifically, rolls of bag material are activated by a power unwind and advance down over a bagger's forming collar. They are code-dated by an ink-jet encoder-printer, and can be spot-labeled by a pressure-sensitive label applicator, depending on customer requests. Conventional form, fill and seal machines are typically equipped with a vertical sealing bar and horizontal sealing bar. The bags are pulled over the forming collar by sealing jaws, and the vertical sealing bar and horizontal sealing bar are applied to create the bottom and center rear seams 16 and 20, respec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| resilient | aaaaa | aaaaa |

| stamping force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com