Electronic industrial wastewater near zero release water treatment process

An electronic industry wastewater, near-zero discharge technology, applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of low efficiency, complicated acid recovery steps and methods, etc. Recovery efficiency, ensuring economic rationality and effectiveness, and long-term stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

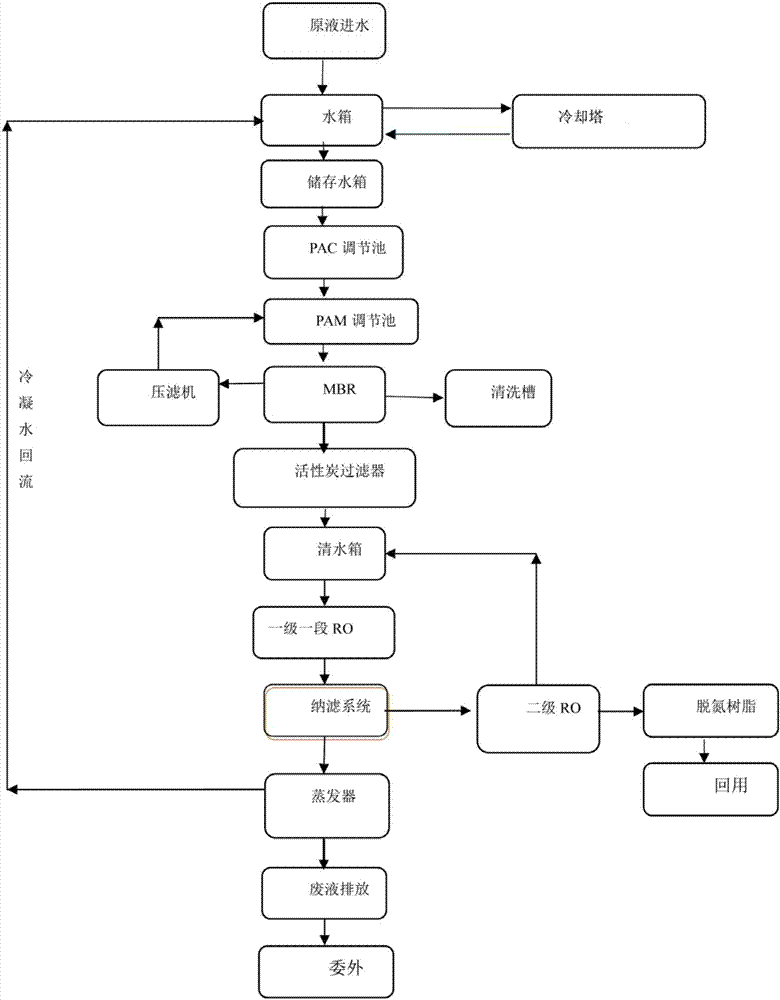

[0021] see figure 1 As shown, the present invention relates to a near-zero discharge water treatment process for electronic industrial wastewater, comprising the following steps:

[0022] Step 1: The original solution is directly put into the water tank for storage. The COD content of the original solution at this time is less than or equal to ≦3000, the TN is 153, and the pH is 10.2; COD is the chemical oxygen demand, which reflects the pollution of reducing substances in the water These substances include organic matter, nitrite, ferrous salt, sulfide, etc.; TN refers to the total amount of various forms of inorganic and organic nitrogen in water; PH is the basis for judging whether the solution is acidic, neutral or alkaline;

[0023] Step 2: Add physical and chemical drugs to the water tank once a month. The physical and chemical drugs are a mixture of hydrogen peroxide and sodium hypochlorite. The raw liquid after adding the physical and chemical drugs is processed by an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com