Patents

Literature

44results about How to "Eliminate environmental hazards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Arsenic-containing soot dearsenication method

InactiveCN104593610ASolve storage problemsEliminate environmental hazardsProcess efficiency improvementIndiumSmelting process

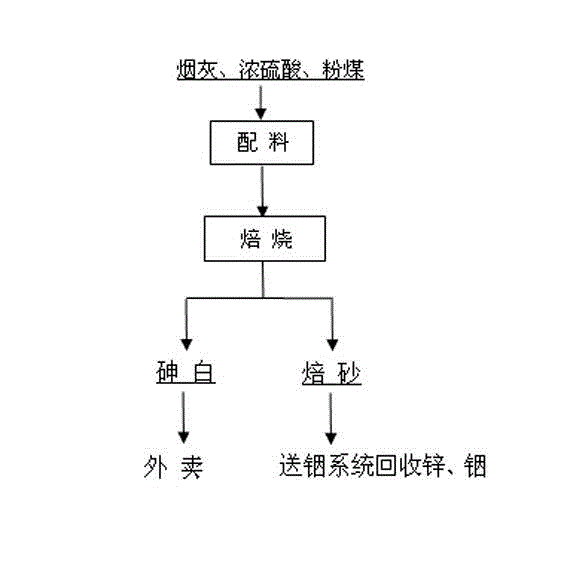

The invention discloses a dearsenication method of arsenic-containing soot in a pyrogenic smelting process of lead, copper, tin or the like. The method comprises the following steps: calculating the amounts of concentrated sulfuric acid and coal powder required by each ton of soot according to the arsenic content according to the following components in percentage by weight: 1% of As, 0.10-1.50% of concentrated sulfuric acid and 0.10-0.50% of coal powder; and evenly mixing the soot, concentrated sulfuric acid and coal powder; reduction roasting: adding the prepared raw materials into an electrothermal converter, starting a dust collection blower, heating to 300-450 DEG C, carrying out rotary roasting for 1.5-3 hours, and discharging; and leaching the dearsenicated roasted product in an indium recovery system to leach zinc and indium, and extracting to recover the indium. The reduction roasting is adopted to directly convert the arsenic into the finished product arsenic white, thereby avoiding the problem of stacking of the arsenic-containing slag and eliminating the hidden danger of environmental protection caused by stacking of the arsenic-containing slag. By adopting the sulfating roasting, the indium can be conveniently recovered, the leaching rate of the acidified soot is enhanced, and the recovery rate of indium can reach 95% above.

Owner:CHENZHOU FENGYUE ENVIRONMENTAL PROTECTION TECH

Liquid crystal screen cleaning method

InactiveCN101879509AImprove removal effectEliminate environmental hazardsCleaning using liquidsChemistryLiquid crystal

The invention discloses a liquid crystal screen cleaning method, which aims at providing a cleaning method capable of eliminating organic matters and cleaning agent residual, eliminating environment protection hidden trouble of water base cleaning, and meeting the environment protection requirement. The method comprises the following steps: placing crystal liquid screen cleaning agents in a first tank; heating the cleaning agents to 50 to 60 DEG C; soaking a basket containing a liquid crystal screen into the first tank to be matched with the ultrasonic wave or trillion sound effect for being cleaned for 3 to 5 minutes; placing electrochemical oxidation liquid in a second tank to be heated to 50 to 60 DEG C; taking out the basket containing the liquid crystal screen to be placed into the second tank to be matched with the ultrasonic wave or trillion sound effect for being cleaned; then, carrying out de-ionized water matched ultrasonic wave cleaning for three times; and next, carrying out spraying and baking. Because the electrochemical oxidation liquid is adopted to be matched with ultrasonic waves for cleaning after the cleaning by the cleaning agents, the generation of a large amount of waste water containing the cleaning agents can be avoided, the environment protection hidden trouble of the water base cleaning can be eliminated, and the environment protection requirement can be met.

Owner:HEBEI UNIV OF TECH

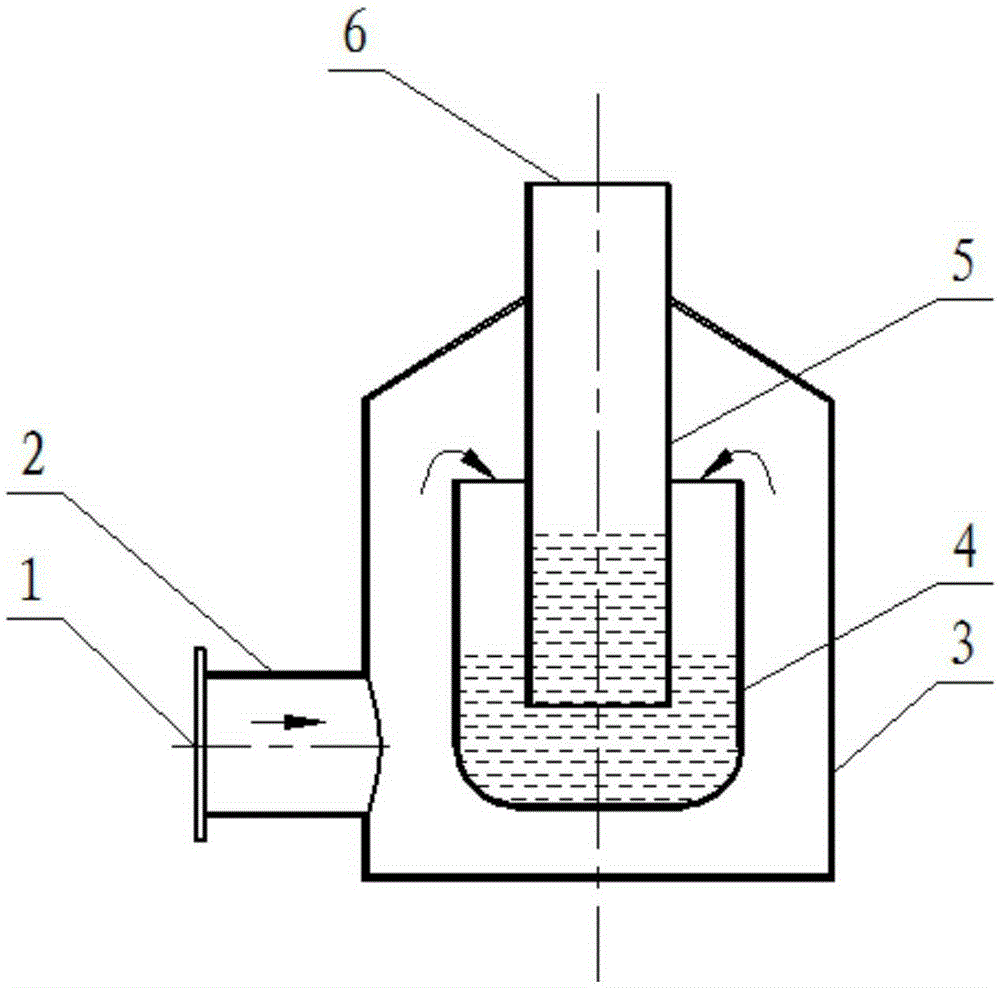

Fixed bed biomass gasification process and equipment capable of collecting tar in steps

InactiveCN102492468AEliminate environmental hazardsAlleviate the energy crisisGas purification by non-gaseous materials condensationFixed-bed gasificationTarProcess engineering

The invention provides a fixed bed biomass gasification process and equipment capable of collecting tar in steps. According to the invention, a high temperature filter collector is arranged to be connected with a gasification furnace, a plurality of tar collectors are cascaded at a gas outlet of the high temperature filter collector, gasified wind current is blown into the top or the bottom of the gasification furnace through a gasified wind inlet, high temperature mixed gas containing tar in the gasification furnace is discharged, and under the condition that temperature is maintained, the high temperature mixed gas enters into the high temperature filter collector through a first gas-guide tube for high temperature dedusting and then enters into the cascaded tar collectors through a second gas-guide tube for segmental treatment so as to obtain tar containing different components. The tar in combustion gas is collected in steps through cooling according to different distillation sections of the components in the tar, and the tar is effectively utilized according to collected different components. According to the invention, stepped collection of tar is realized, harm of tar to environment is eliminated, obtained chemical raw materials are effectively utilized, and collected components with a high calorific value can be returned to the furnace for burning; the invention has important scientific significance to alleviation of energy crisis and improvement of environment.

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD

System and method for the capture and storage of waste

ActiveUS9162914B1Improved waste confinementMinimal processingGlass furnace apparatusRadioactive decontaminationMetal-organic frameworkEngineering

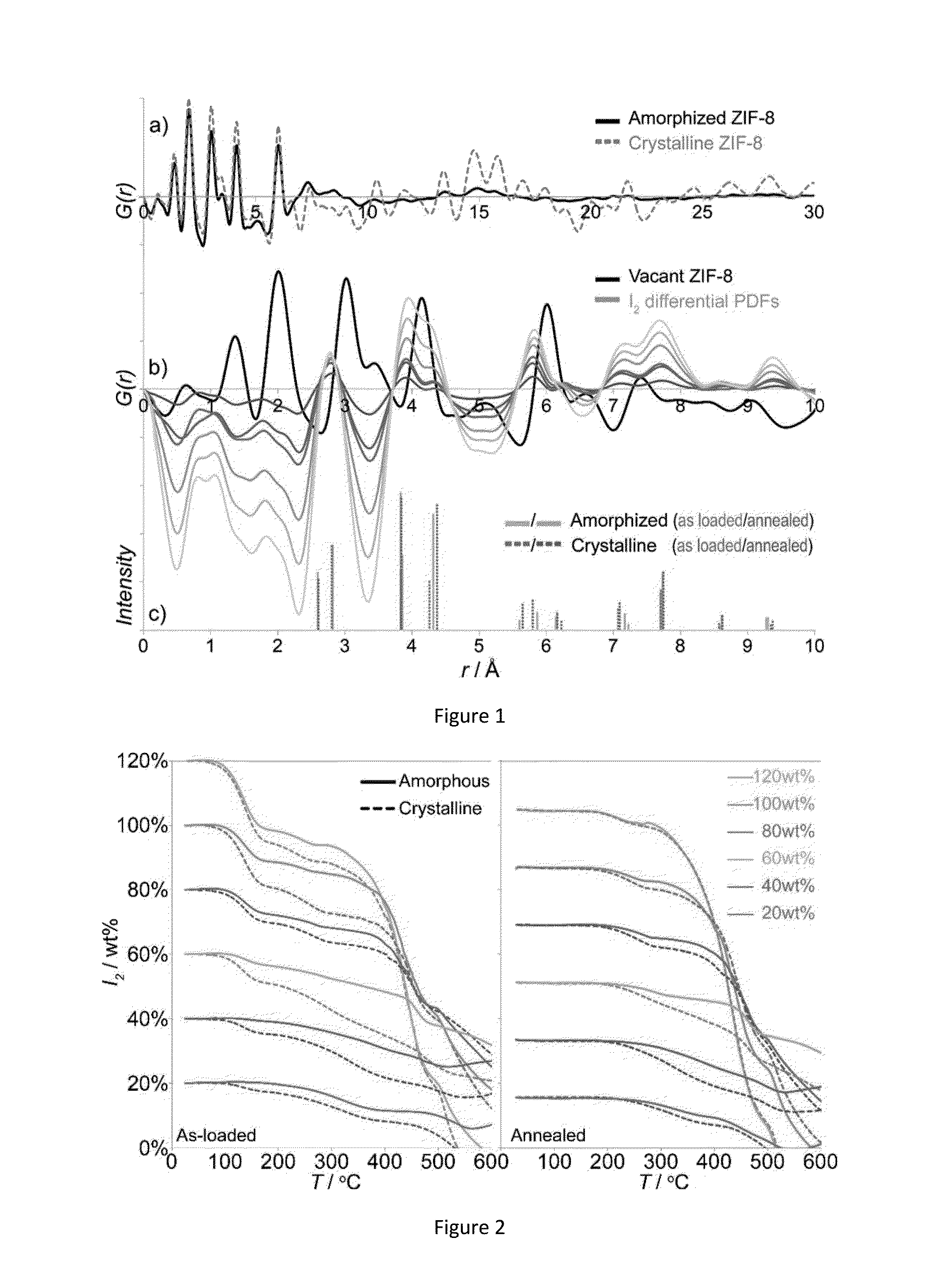

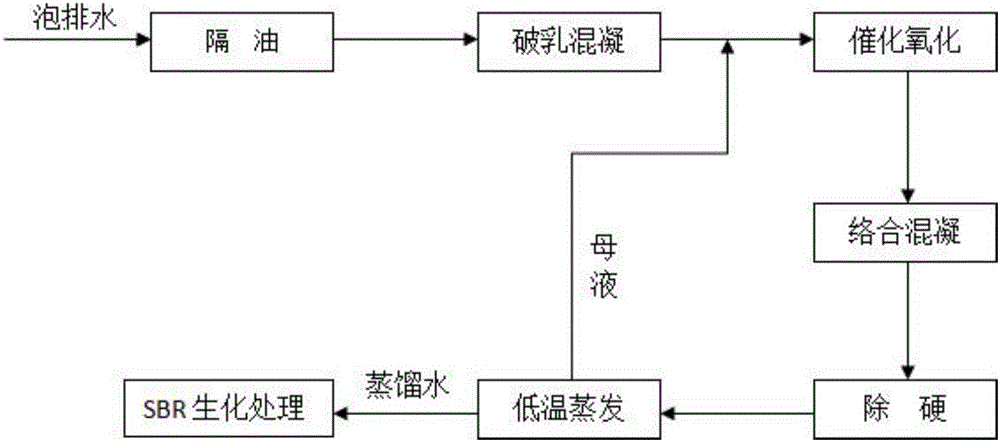

The present disclosure is directed to systems and methods that absorb waste into a metal-organic framework (MOF), and applying pressure to the MOF material's framework to crystallize or make amorphous the MOF material thereby changing the MOF's pore structure and sorption characteristics without collapsing the MOF framework.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Foam water drainage treatment process

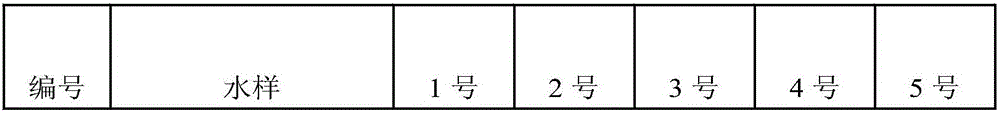

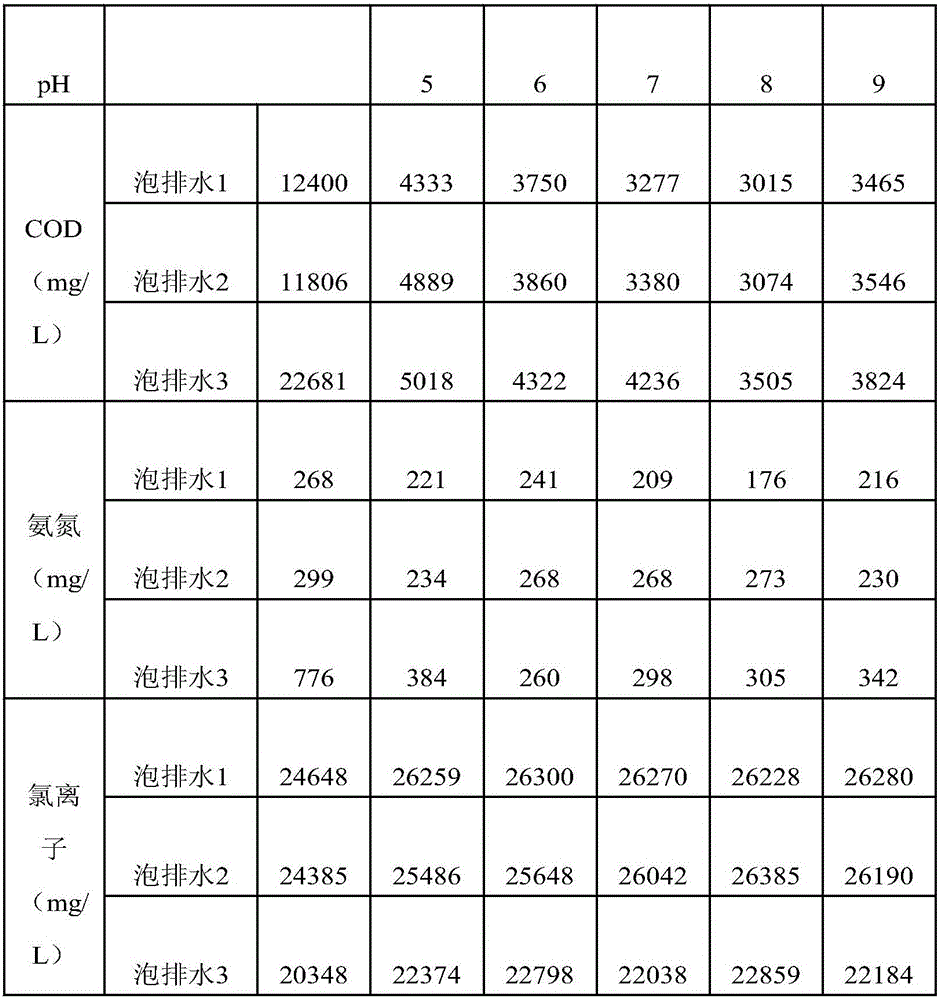

InactiveCN105967452ALow boiling pointRealize comprehensive utilizationWaste water treatment from quariesFatty/oily/floating substances removal devicesEcological environmentCatalytic oxidation

The invention provides a bubble drainage treatment process, which belongs to the technical field of mining drainage treatment, and comprises the following steps in sequence: oil separation, demulsification coagulation, catalytic oxidation, complex coagulation, hard removal, low temperature evaporation and SBR biochemical treatment. The bubble drainage treatment process provided by the present invention realizes the treatment goals of harmless, reduction and resource utilization of gas extraction wastewater in gas fields; ensures the normal production of gas fields, and does a good job in pollution prevention and energy saving and emission reduction; eliminates environmental hidden dangers, protects Ecological environment of the gas field; speed up the construction of "ecological engineering" of the gas field, promote the harmonious and scientific development of the local economy and the gas field, and achieve a win-win situation for the economy and the environment.

Owner:四川光隆环保科技有限公司

Antiskid polyurethane paint and its prepn

InactiveCN1453319ASolve self-leveling problemsShorten drying timePolyurea/polyurethane coatingsSolventTolylene Diisocyanate

The antiskid polyurethane paint is prepared with tolylene diisocyanate, polyether N210, trihydroxymethyl propane, butyl acetate, acetone, dibutyltin dilaurate, benzoyl chloride, antioxidant, 1,2-propylene glycol and water absorbent, and through dewatering butyl acetate, acetone and polyether N210 in reactor at 90-100 deg.c; adding trihydroxymethyl propane into the reactor before heating and stirring to dewater; adding benzoyl chloride, antioxidant and tolylene diisocyanate, heating and adding dibutyltin dilauratel; reflux evaporating solvent butyl acetate or acetone; packing the prepolymer into paint tank; and mixing prepolymer, xylene or butyl acetate or acetone, 1,2-propylene glycol and water absorbent in certain proportion to obtain the paint. The paint has simple preparation process,strong adhesive force, high wear resistance, high weather resistance and other advantages.

Owner:INST OF AQUATIC LIFE ACAD SINICA

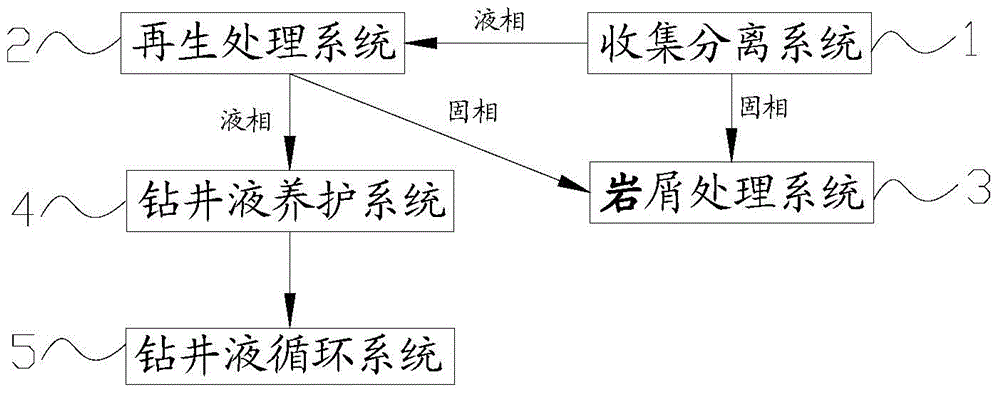

Waste drilling fluid processing device

InactiveCN103556967AAchieve recyclingRealize comprehensive utilizationFlushingWell drillingResource utilization

The invention discloses a waste drilling fluid processing device which comprises a collection and separation system, a waste drilling fluid regeneration processing system, a rock debris (solid waste) processing system and a drilling fluid maintenance system, wherein the collection and separation system collects a waste drilling fluid from a solid control circulation device of a drilling platform during drilling and separates the liquid into solid-phase and liquid-phase components; a liquid phase of the collection and separation system is conveyed to the regeneration processing system through a first transmission system, and the processed liquid phase is conveyed to the drilling fluid maintenance system, so that on-site recycling is realized; a solid phase of the collection and separation system is conveyed to the rock debris processing system through a second transmission system and then is processed, and resource utilization is realized. Recycling of liquid-phase and solid-phase wastes caused by well drilling can be realized, so that the resource utilization rate is increased, the production cost is saved, well-site zero release is realized, and the environmental protection problem of a well site is solved fundamentally.

Owner:北京华油兴业能源技术有限公司

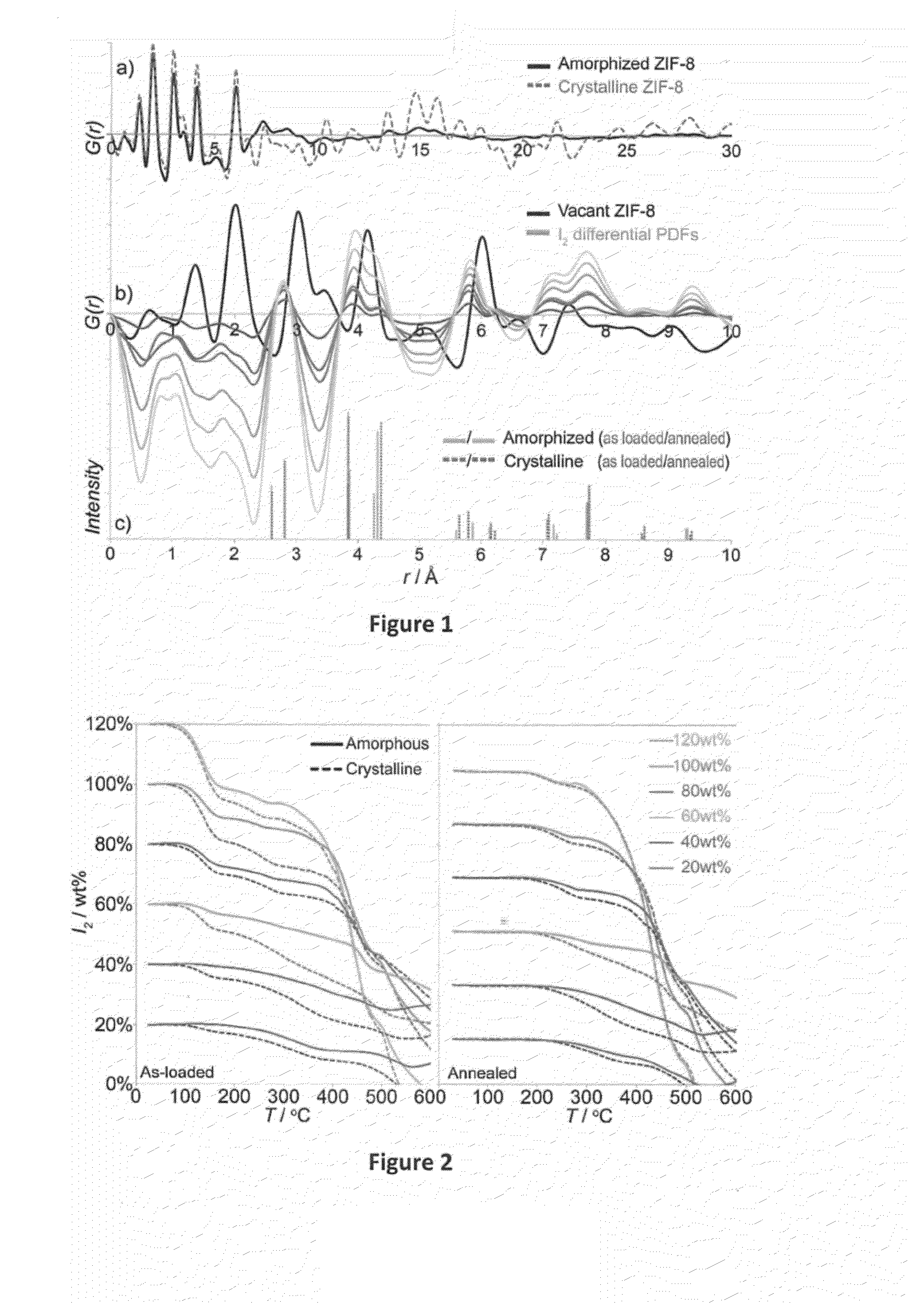

System and method for the capture and storage of waste

ActiveUS20160012927A1Eliminate environmental hazardsIncrease wasteRadioactive decontaminationMetal-organic frameworkEngineering

Systems and methods for capturing waste are disclosed. The systems and methods provide for a high level of confinement and long term stability. The systems and methods include adsorbing waste into a metal-organic framework (MOF), and applying pressure to the MOF material's framework to crystallize or make amorphous the MOF material thereby changing the MOF's pore structure and sorption characteristics without collapsing the MOF framework.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

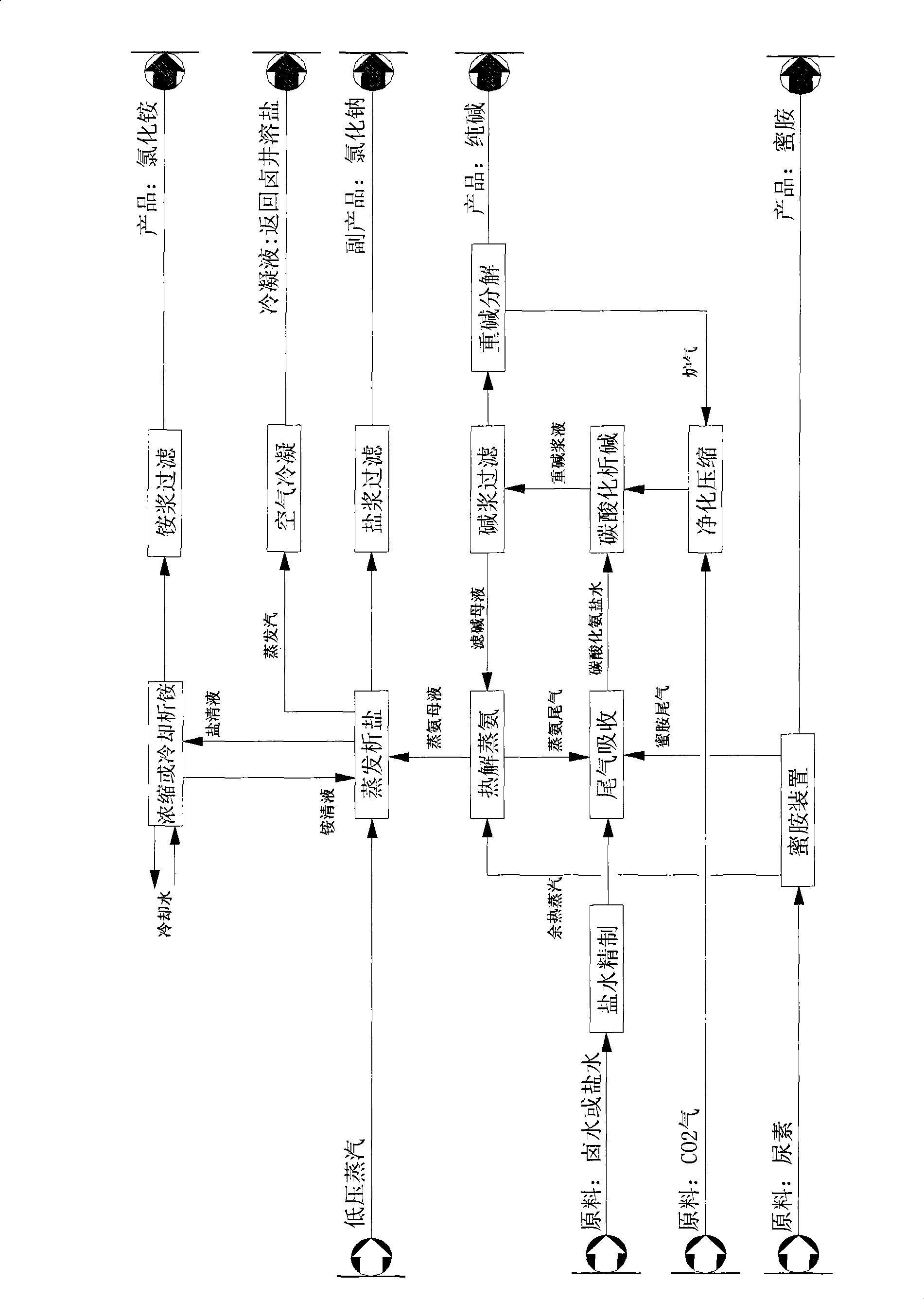

Process for jointly producing cyanuramide, sodium carbonate and ammonium chloride by using carbamide

ActiveCN101519383AEfficient use ofSave energyOrganic chemistryAmmonium halidesSodium bicarbonateChloride sodium

The invention relates to a process for jointly producing cyanuramide, sodium carbonate and ammonium chloride by using carbamide, which comprises the steps of producing the cyanuramide, refining bittern or brine and absorbing tail gas, acidulating sodium bicarbonate to separate base out, separating the sodium carbonate, decomposing, rectifying and denitrifying the mother liquor of the sodium bicarbonate, steaming and concentrating deamination liquor to separate sodium chloride, and separating ammonium chloride from the clear solution of salt. The total utilization of the carbamide can be up to 100 percent, the tail gas and considerable afterheat and steam generated in the cyanuramide production process can be fully utilized and the energy is saved.

Owner:BEIJING EDGEIN TECH +1

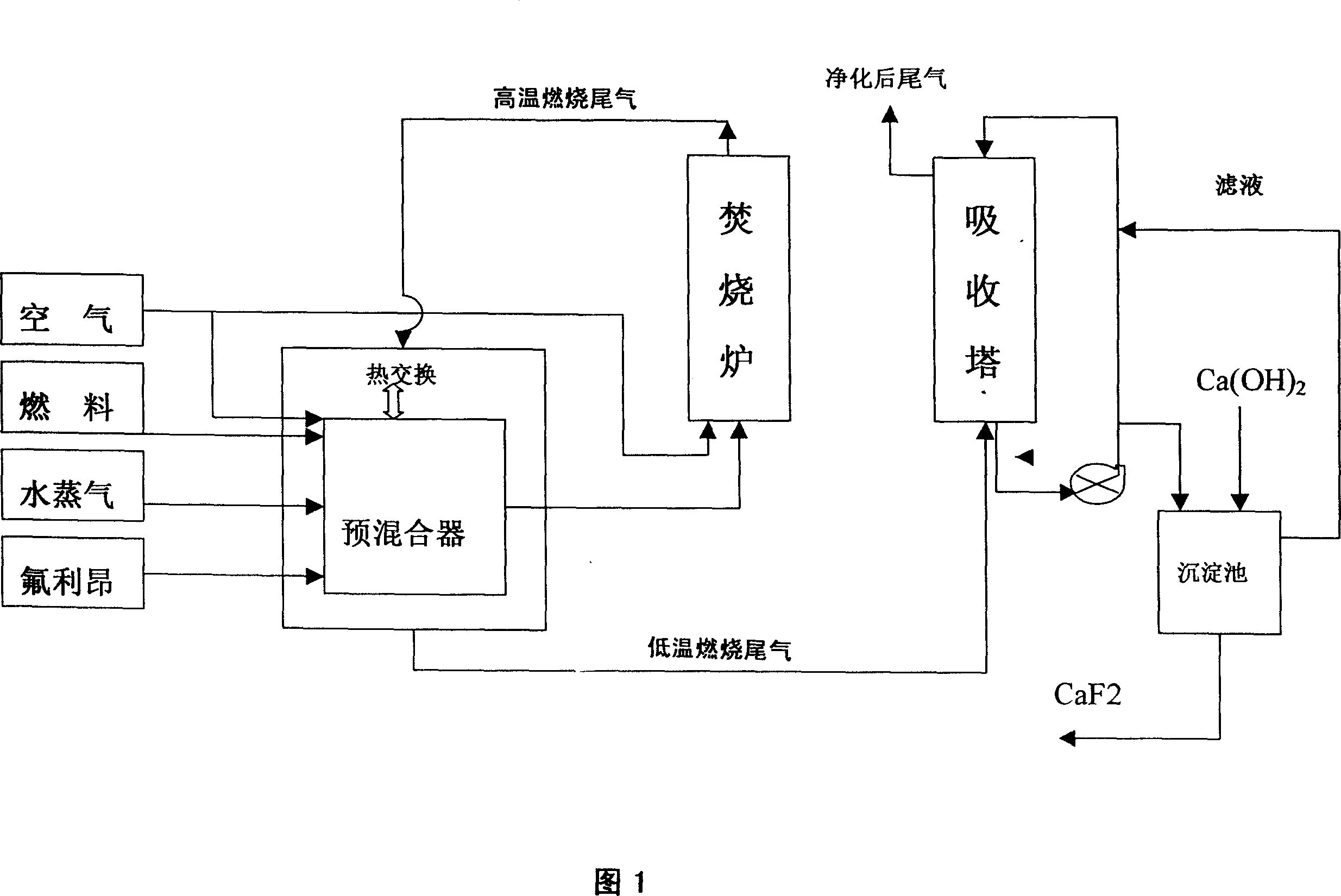

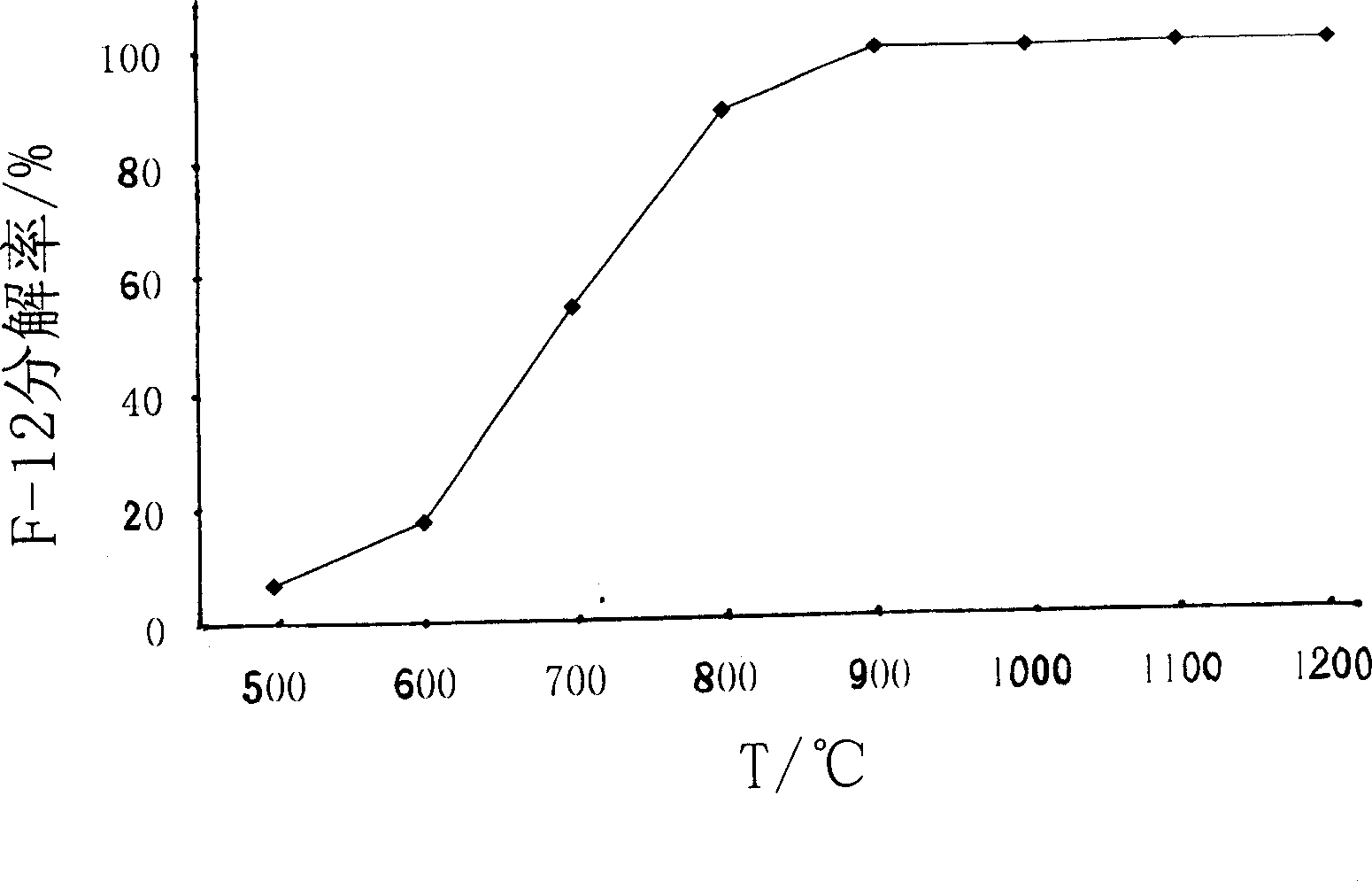

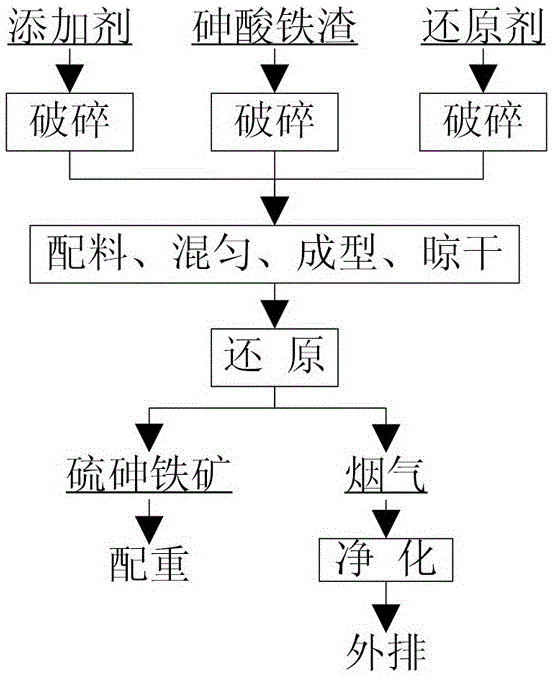

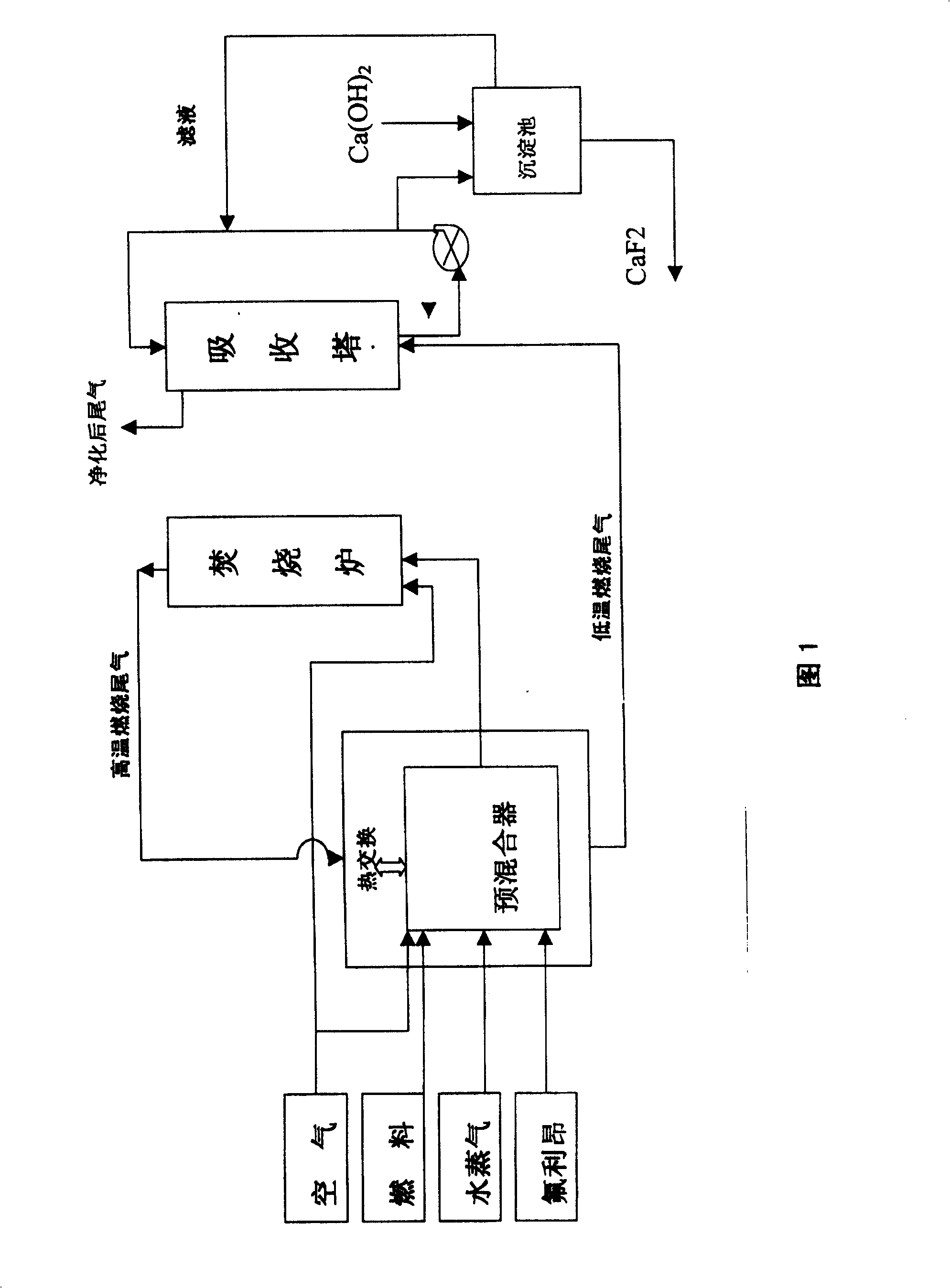

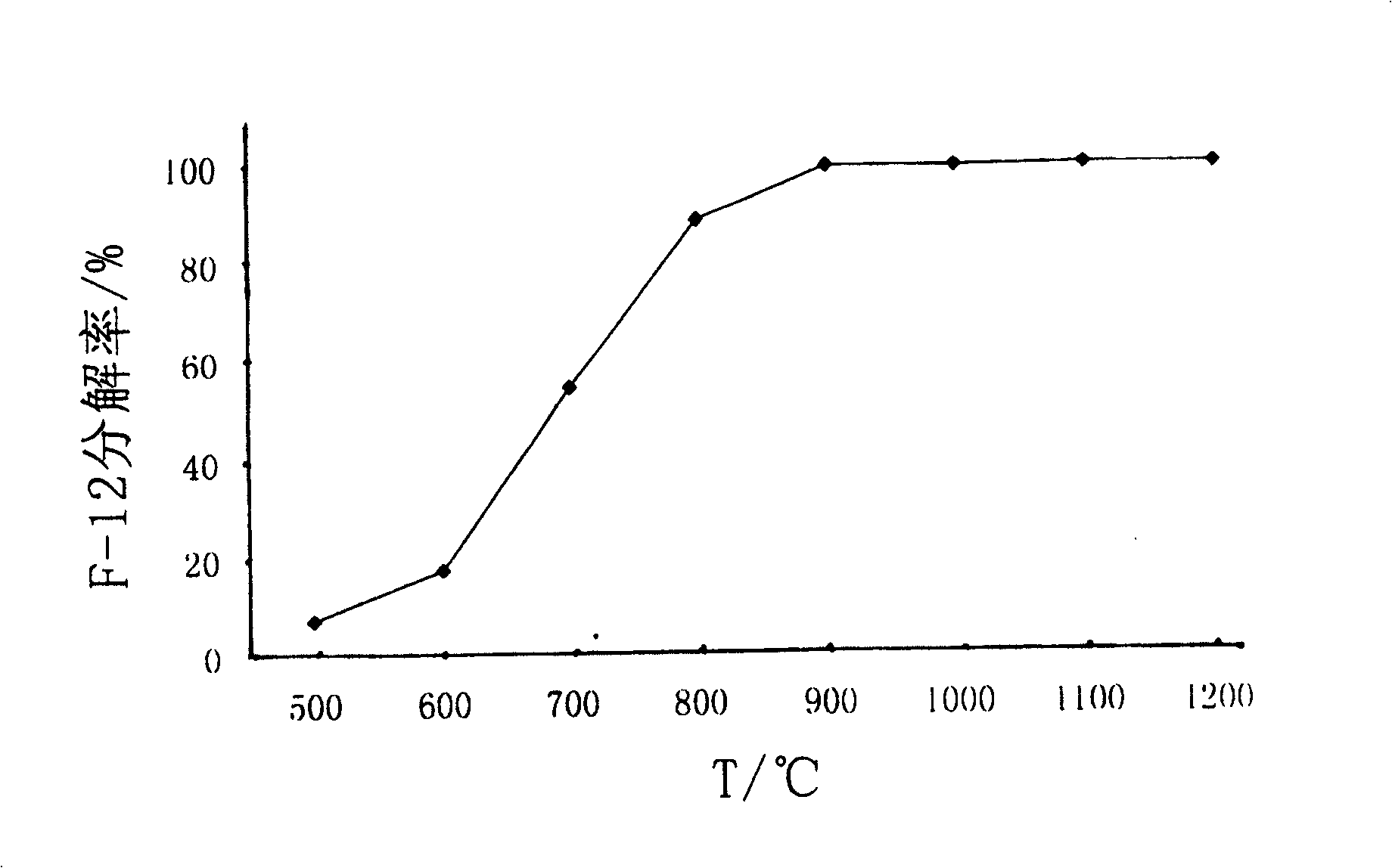

Freon treated by premixed combustion and method for producing said resource

InactiveCN1924439AIncrease flame propagation speed and combustion temperatureImprove combustion intensityIncinerator apparatusExhaust gasProcess engineering

This invention relates to one method to pre-mix fuel for chlorofluoromethane and its materials, which comprises the following steps: mixing the reactor chlorofluoromethane, water, fuel and air for heating up to improve reaction molecule energy and to improve fuel heating speed; mixture gas pre-heating makes burst furnace temperature lift helpful for back reactions; using fuel tail fuel gas and air to improve flare transmission speed and temperature to add burst intensity and to improve device heat efficiency.

Owner:KUNMING UNIV OF SCI & TECH

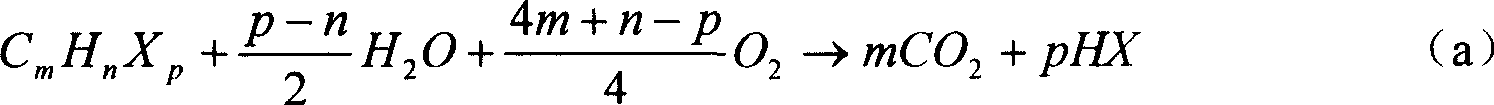

Stable arsenic acid iron slag solidifying method

The invention discloses a stable arsenic acid iron slag solidifying method. The stable arsenic acid iron slag solidifying method comprises the steps that arsenic acid iron slag, an additive and a reducing agent are mixed evenly, geierite is obtained through forming and reduction, and stable solidifying treatment is completed. The method can be used for directly producing geierite, dissolution of arsenic in waste slag can be effectively prevented, bounce does not occur with time, the geierite obtained after stable solidifying is high in strength, large in specific gravity and good in hydrolytic resistance, can be used for balance weight, the environmental environment caused by arsenic-containing slag stockpiling is eliminated, and stable solidifying of arsenic slag is achieved.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

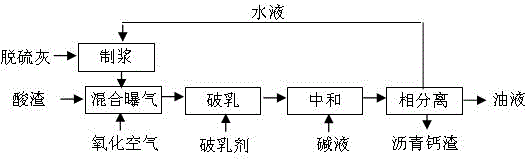

Combined treatment method for acid sludge and desulfurization ash

InactiveCN104415963ARealize harmless disposalSimple processSolid waste disposalActivated sludgeEconomic benefits

The invention relates to the field of comprehensive utilization of industrial wastes and particularly relates to a combined treatment method of waste acid sludge in the lubricating oil recycling industry and desulfurization ash in the dry-process / semidry process flue gas desulfurization industry. The combined treatment method of the acid sludge and the desulfurization ash comprises the following steps: after pulping the desulfurization ash, mixing and aerating with the acid sludge, and performing phase separation by virtue of emulsion-breaking and neutralizing effects, wherein an oil phase is utilized as fuels, a water phase is returned to a desulfurization ash pulping system for recycling, and a solid phase is utilized as a building material. The combined treatment method disclosed by the invention is simple in process, environmentally friendly, and capable of realizing innocent treatment of harmful wastes and developing a new way for recycling the harmful wastes, and has good economic benefits and environmental benefits.

Owner:BAOSHAN IRON & STEEL CO LTD +1

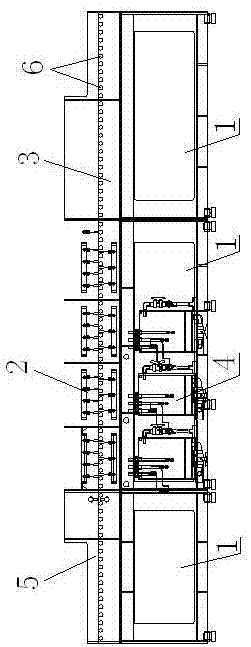

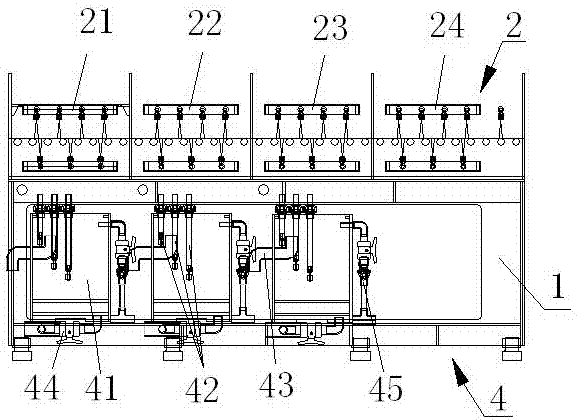

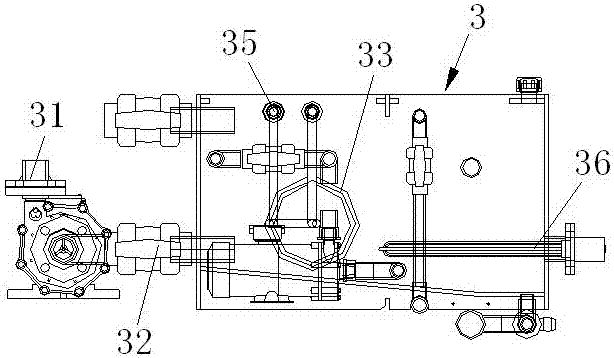

Liquid crystal cleaning and production equipment

InactiveCN106955882AGood removal effectAvoid it happening againFlexible article cleaningCleaning using gasesProduction lineSurface layer

The invention discloses liquid crystal cleaning and production equipment which comprises a plurality of base supports and a conveying belt. The base supports are sequentially arranged on a production line. The top end plane of the first base support is provided with a feeding device, the top end plane of a second base support is provided with a cleaning device, three cleaning liquid circulating systems are installed in the second base support and assembled together with the cleaning device, and the top end plane of the last base support is provided with a water tank. According to the cleaning device, organic matter and cleaning agent residue on the surface layer of liquid crystals are removed through electrochemical oxidation liquid at first, the removal effect on organic matter is enhanced, more importantly, a large amount of waste water containing the cleaning agent can be prevented from being produced, environmental protection requirements can be met, finally pure water is filtered through a self circulation system and then sprayed by a cleaning spray head to the surface layer of the liquid crystals, the liquid crystals are completely and thoroughly cleaned, and no impurity or cleaning agent is left on the surface layer.

Owner:苏州亚信华电子科技有限公司

Method for producing carbon disulfide

A process for preparing CS2 features that the semi-coke or coke powder which is the solid dregs after dry distillation of crude coal or the refuse of coking plant is used as its raw material.

Owner:SHANGHAI BAIJIN CHEM GROUP

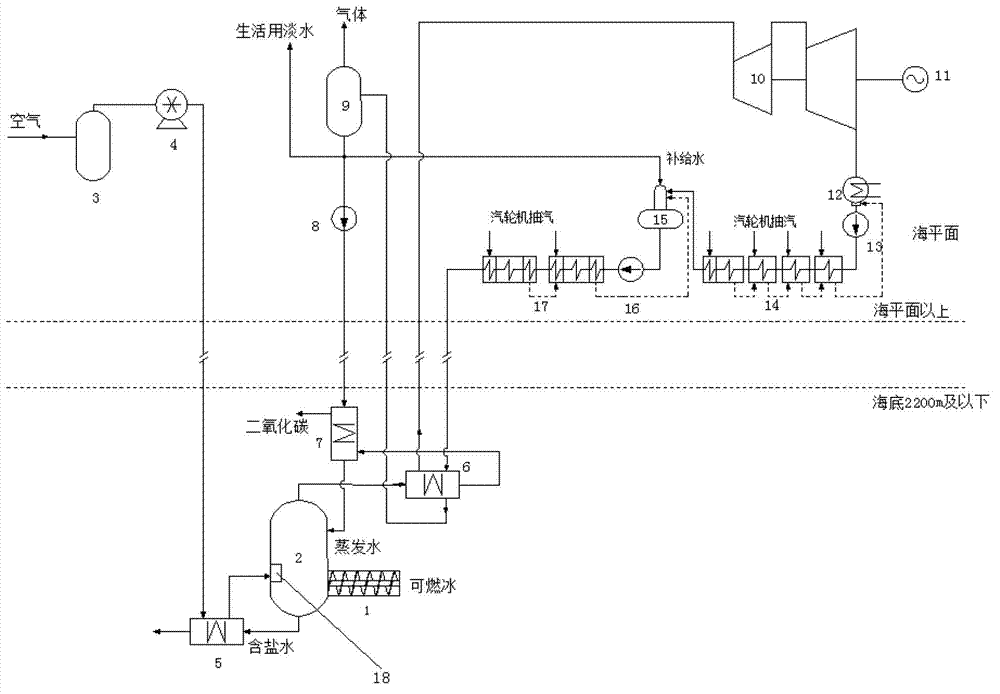

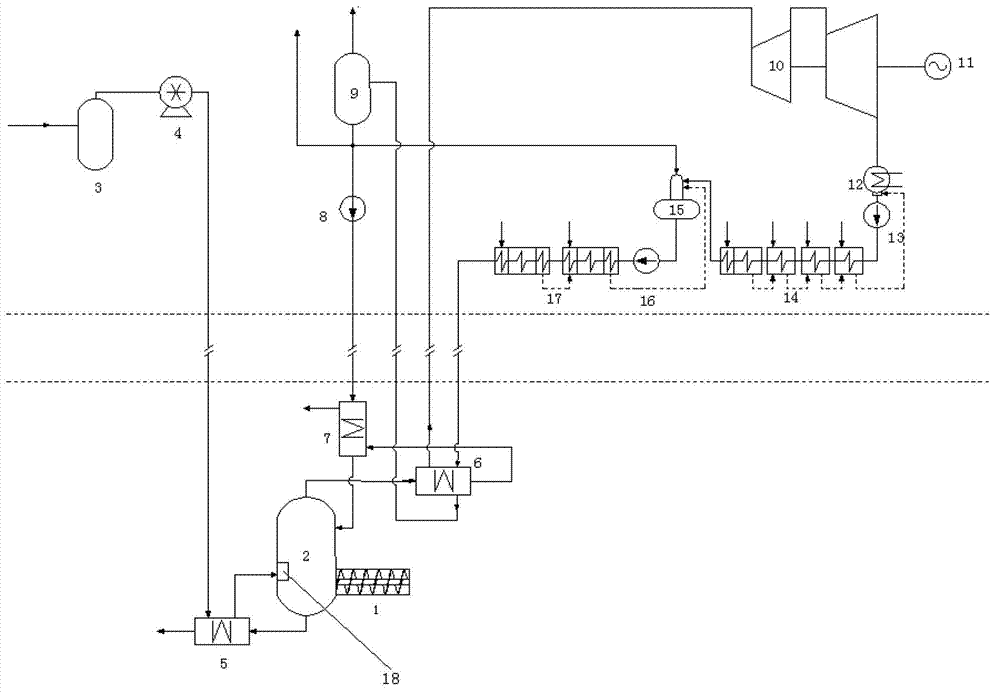

Method and device for exploiting deep sea combustible ice

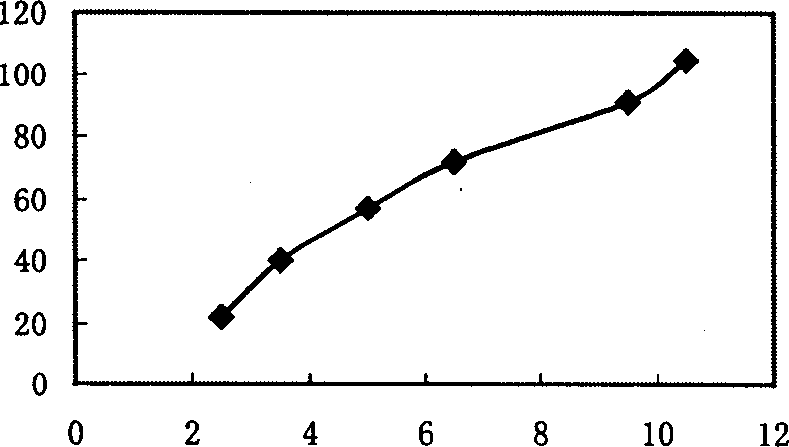

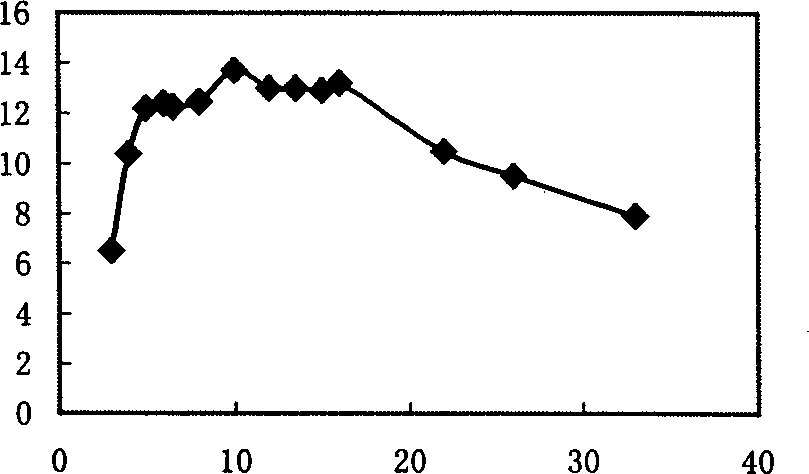

InactiveCN102787830AEliminate environmental hazardsImprove energy utilizationFluid removalChemistryElectricity

The invention relates to a method and a device for exploiting deep sea combustible ice. The method comprises the following steps of: transporting the combustible ice to a supercritical water oxidation reactor in seabed, wherein the supercritical water oxidation reactor is filled with water medium; sending preheating oxygen to the supercritical water oxidation reactor from an external pump, wherein the pressure of the oxygen is equal to or a little more than the pressure in the supercritical water oxidation reactor; igniting in the supercritical water oxidation reactor; and performing an oxidation reaction on the combustible ice, wherein the heat generated through reaction is sent to seal level through heating water vapor by a deep sea steam heater so as to drive a steam turbine to generate electricity, the concretes and non-condensing materials from the deep sea steam heater are separated, and a part of the separated water returns to the supercritical water oxidation reactor to be used as evaporable water. By the invention, the combustible ice can be oxidized under a deep sea supercritical water state; and oxidation exothermic is used for generating electricity, so that the combustible ice can be prevented from volatilizing in the process of transporting to the sea level, and environmental risk is eliminated.

Owner:SHANDONG UNIV

Method for recovering vanadium and sodium from sodium vanadate solution

InactiveCN110358935AAvoid it happening againLow concentration of vanadiumVanadium oxidesProcess efficiency improvementSodium bicarbonateHydrometallurgy

The invention belongs to the technical field of vanadium hydrometallurgy, and particularly relates to a method for recovering vanadium and sodium from a sodium vanadate solution. The method comprisesthe following steps: (1) adding ammonium salt into the sodium vanadate solution, and carrying out solid-liquid separation after reaction to obtain solid and liquid; and (2) calcining the solid to obtain vanadium pentoxide; decomposing ammonium salt in the liquid to obtain a deamination solution, introducing CO2 to adjust pH to 7.8-8.5, and carrying out solid-liquid separation to obtain sodium bicarbonate. The method can improve recovery rate of vanadium, and simultaneously recover sodium salt; and generation of solid waste sodium sulfate can be avoided.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

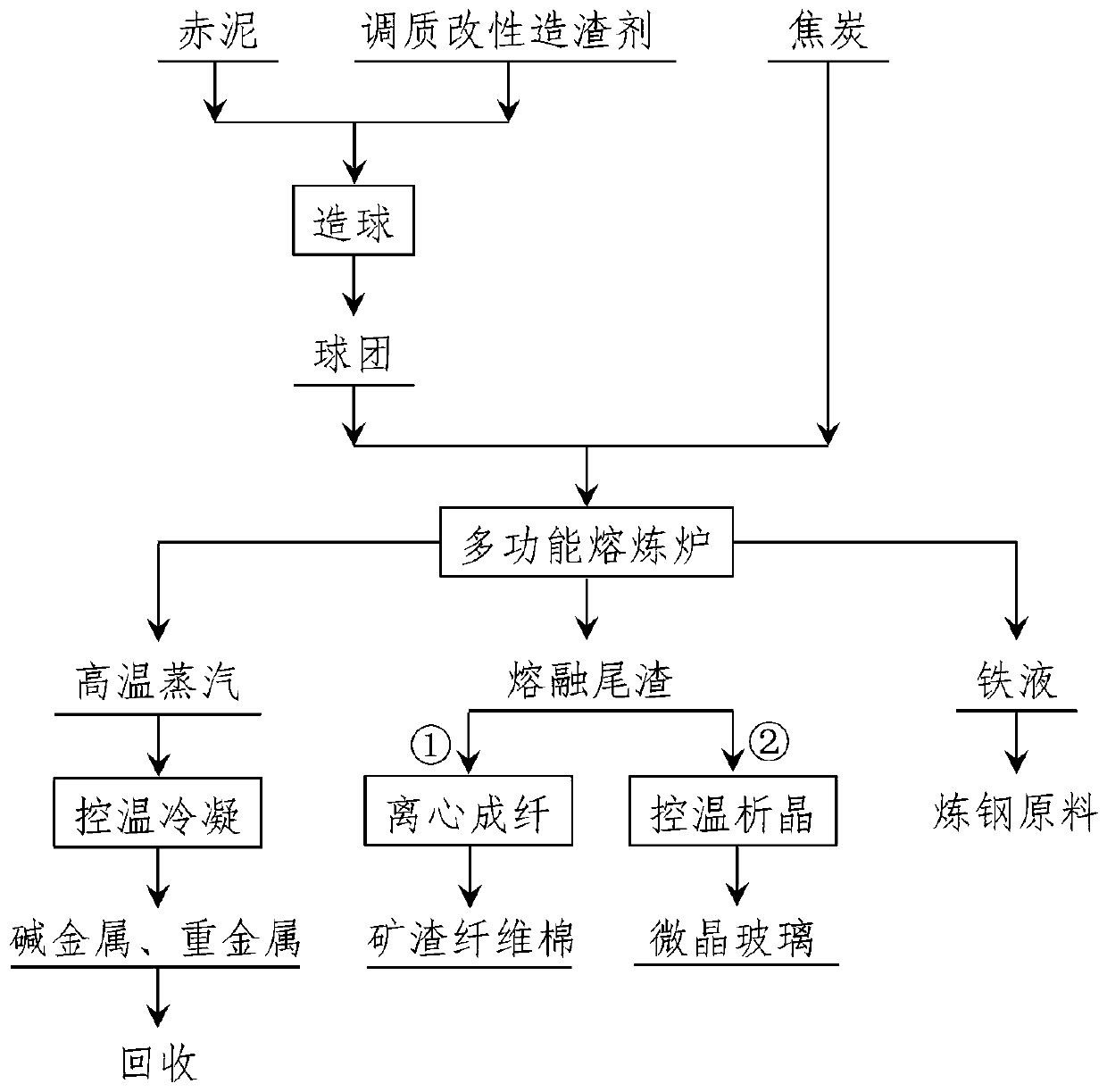

Process for red mud multi-component separation and tailings hardening and tempering utilization

InactiveCN110669935AEliminate environmental hazardsGood economic benefitsProcess efficiency improvementChemistryEnvironmental geology

The invention relates to the field of comprehensive utilization of solid waste resources, and discloses a process for red mud multi-component separation and tailings hardening and tempering utilization. The process comprises the following steps of mixing the red mud and a tempering modified slagging agent according to a certain proportion; rolling and molding the mixed material and performing drying treatment so as to obtain dried pellets; putting the dried pellets and coke into a multifunctional smelting furnace for reduction, separating alkali metal, heavy metal and the like through gas phase, and separating iron liquid through liquid phase; and preparing mineral wool and rock wool from residual high-temperature molten slag in a furnace through a centrifugal or blowing method, or preparing microcrystalline glass through a template crystallization method. According to the process for recycling the red mud, the multi-component separation and full-component utilization of the solid waste red mud are realized, the current situation that the red mud is insufficient in utilization which leads to environment pollution can be solved, thus meeting the national waste recycling environmental protection policy; and meanwhile, the high value-added alkali metal and heavy metal components, iron liquid and mineral wool / rock wool / microcrystalline glass can be obtained after treatment, and accordingly significant environmental benefits and economic benefits are obtained.

Owner:PEKING UNIV

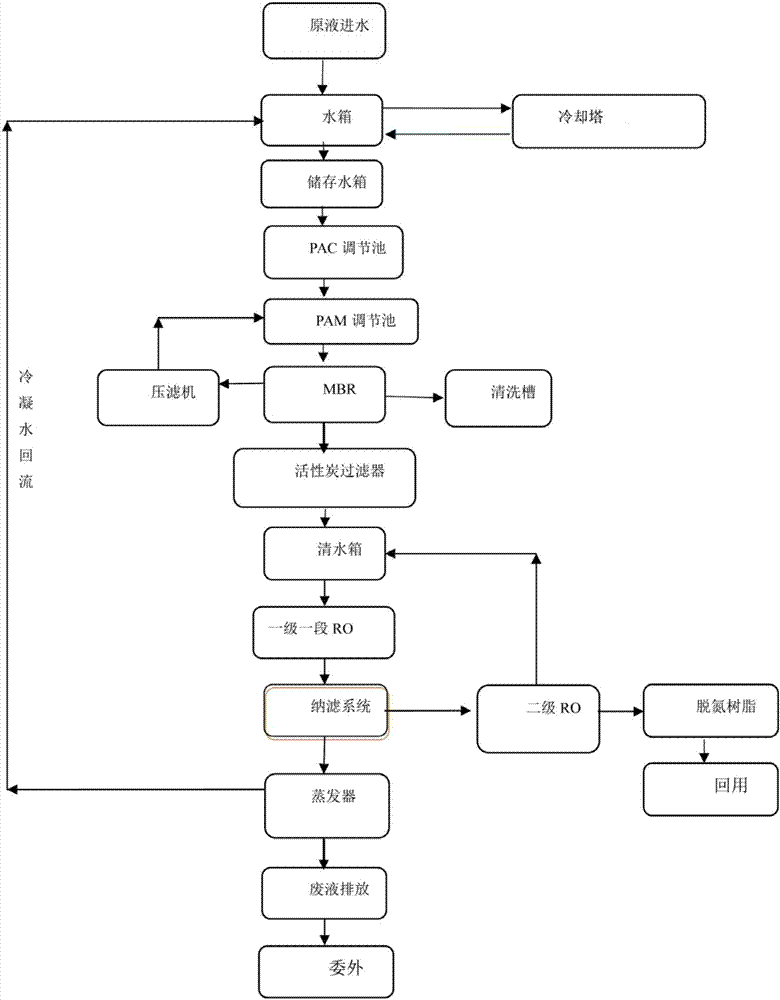

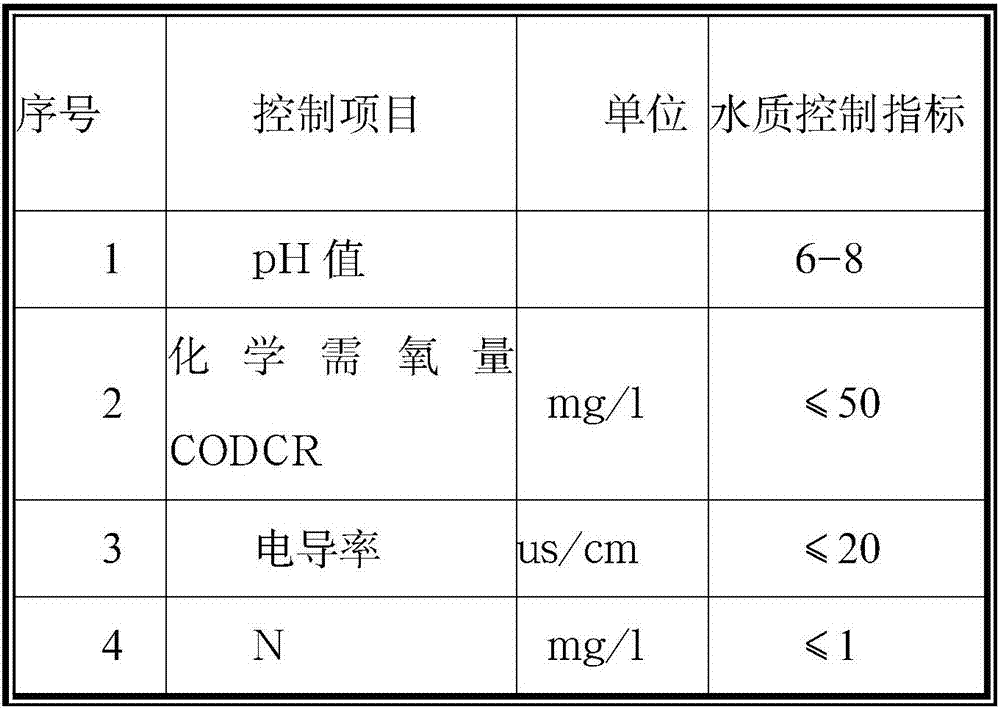

Electronic industrial wastewater near zero release water treatment process

PendingCN107089762AFast separationSimple stepsWater treatment compoundsWater contaminantsWater useWastewater

The invention relates to an electronic industrial wastewater near zero release water treatment process. A basic solution directly enters a water tank to be stored, and a physical and chemical agents is added into the water tank once every month; the basic solution treated in the second step is conveyed into a storage water tank through a pipeline, and the basic solution sequentially enters a PAC adjusting pond and a PAM adjusting pond through a lifting pump; the basic solution treated in the third step enters an MBR through a pipeline, and clear liquid obtained after membrane separation through the MBR enters a filter; filtrate enters a clear water tank through a pipeline, the filtrate is sequentially conveyed into a primary one-segment RO and a nanofiltration system to be filtered by the clear water tank through a pipeline, concentrated liquid separated by the nanofiltration system is recycled to the clear water tank through a pipeline, clear liquid separated by the nanofiltration system enters a secondary RO to be separated through a pipeline, and clear liquid separated through the secondary RO enters denitrification resin to be reused. Effluent reaches or is superior to corresponding water use indexes, and a treatment facility can run stably and reliably for a long time. By the adoption of the reasonable and effective treatment process technology, the economical efficiency, reasonability and effectiveness of overall construction investment are guaranteed, and meanwhile the running and using cost is reduced to the greatest extent.

Owner:广东雅迪环保设备有限公司

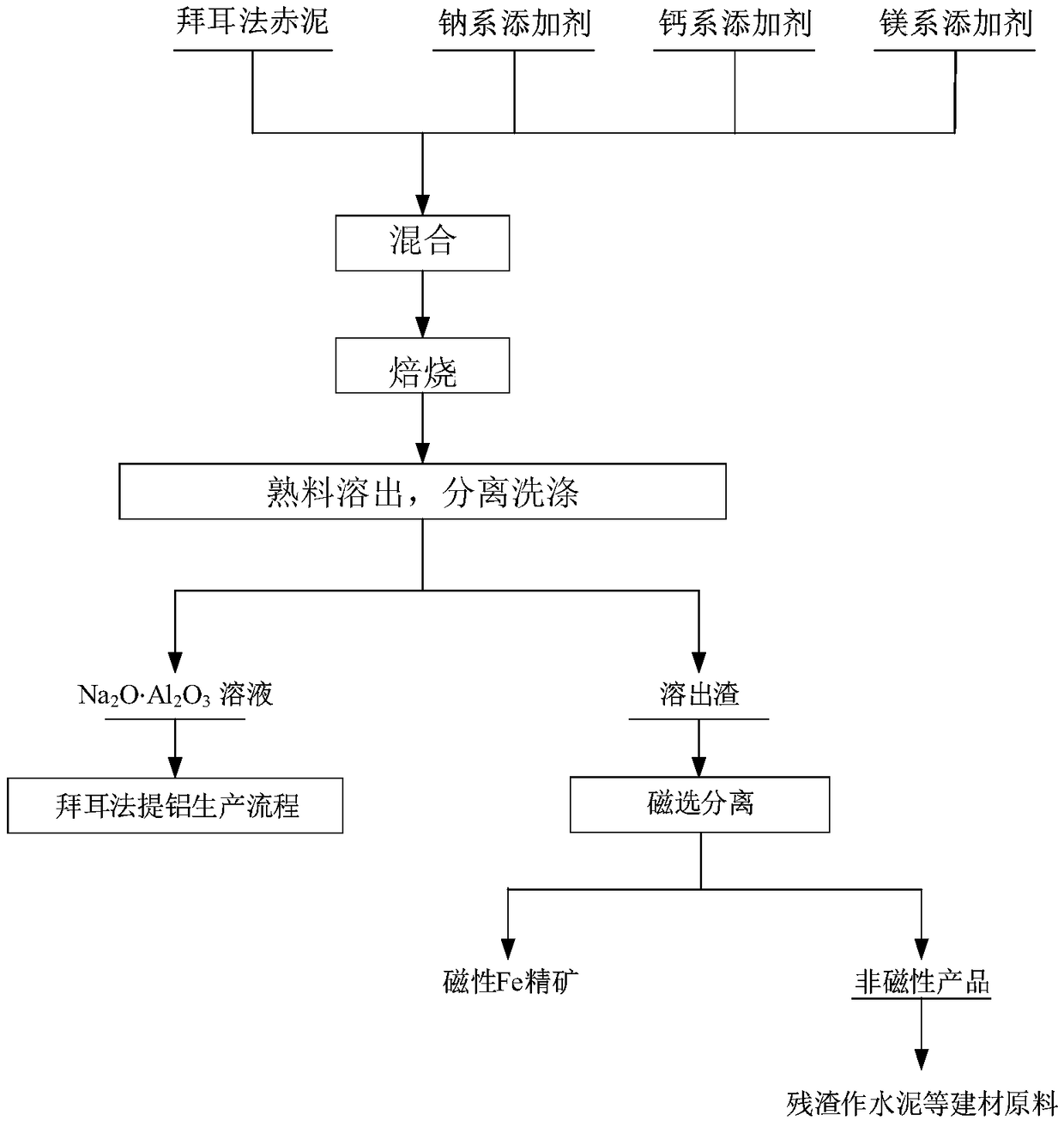

Method for comprehensively recycling sodium, aluminum and iron from red mud

ActiveCN108950212ASimple control conditionsEliminate environmental hazardsProcess efficiency improvementAluminiumMagnesium

The invention discloses a method for comprehensively recycling sodium, aluminum and iron from red mud. The red mud is mixed with an additive to obtain a raw material, the mixed raw material is subjected to calcination to obtain clinker, the clinker is added to an alkaline adjustment liquid for leaching, slid-liquid separation is performed, and leachate containing aluminum and sodium and magnetic leaching residues are obtained; the additive is a mixed additive composed of a calcium-series additive, a magnesium-series additive and a sodium-series additive. According to the technical scheme, no reducing agent needs to be added, hematite or hematite is converted as magnesioferrite with high magnetism through the magnesium-series additive and enters the leaching residues, and then an iron ore concentrate product is obtained through magnetic separating. In the technical scheme, the atmosphere control process and generation of a great quantity of polluting atmosphere in the current iron recycling process are avoided. In the method, the aluminum recycling rate is 85%, the sodium recycling rate is 92% or above, the sodium content in final residues is lowered to 1% or below, the iron grade of the iron ore concentrate is 50-55%, and the recycling rate is about 70%.

Owner:CENT SOUTH UNIV

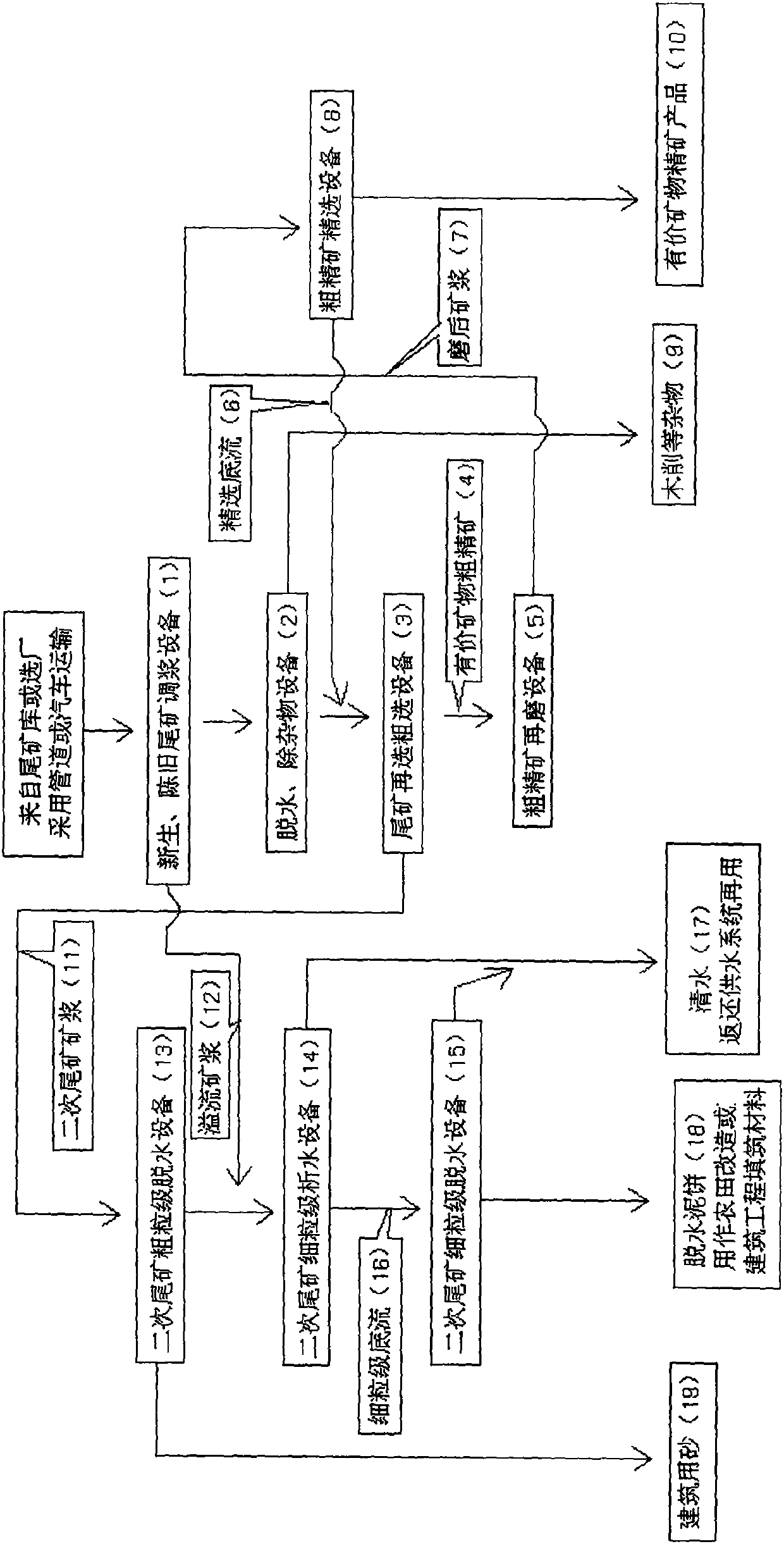

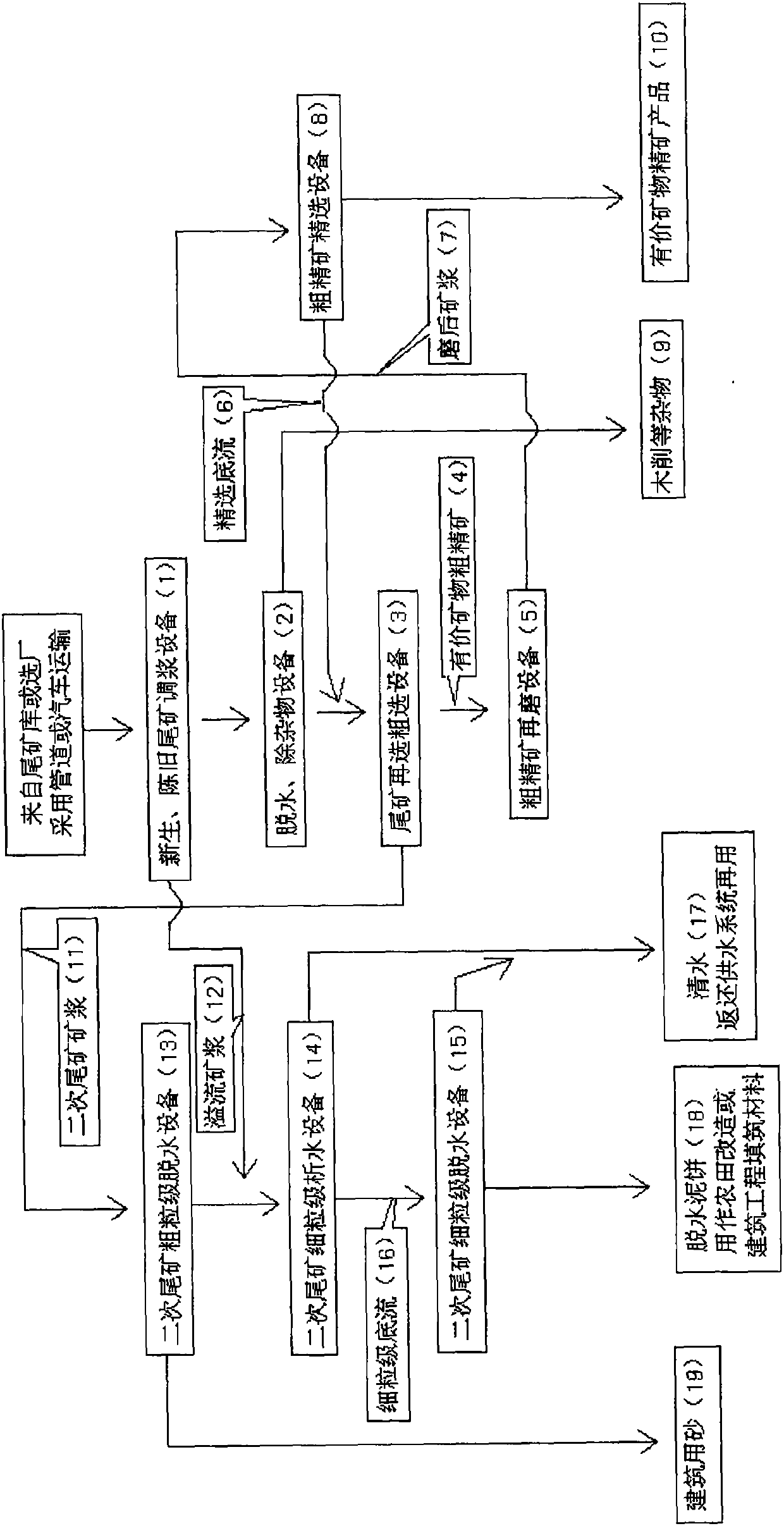

Method for comprehensive treatment of non-ferrous metal tailings

InactiveCN107774439AEliminate potential safety hazardsEliminate environmental hazardsSolid waste disposalTransportation and packagingFilling materialsBuilding material

The invention discloses a method for comprehensive treatment of non-ferrous metal tailings. The method includes a step (1) of tailing size mixing and impurity removal, a step (2) of tailing recleaningroughing, a step (3) of rough concentrate regrinding, a step (4) of rough concentrate selection for yielding concentrate products, a step (5) of secondary tailing coarse fraction dehydration, a step(6) of secondary tailing fine fraction dehydration and cake making and a step (7) of dehydration and cake making. Two processes are involved: (1) non-metallic old tailings and new tailings are subjected to recleaning (flotation and reselection and the like), residual target minerals and other valuable mineral concentrate products in the tailings are selected and yielded, and the comprehensive utilization rate of resources is improved; (2) comprehensive treatment on secondary tailings is performed, the coarse fraction tailings are converted into building materials or used as agricultural land reconstruction and construction engineering filling materials, fine fraction dehydration is performed to yield mud cakes used as agricultural land reconstruction or construction engineering filling materials, to fundamentally eliminate the environmental hazards of mine tailings and the occupation of land resources.

Owner:乔静梅

High-efficiency cleaning method of TFT-LCD screen

InactiveCN107185902AEfficient removalGood removal effectFlexible article cleaningCleaning using liquidsChemistryIon

The invention discloses a high-efficiency cleaning method of a TFT-LCD screen. The high-efficiency cleaning method comprises the steps: (1) pouring a LCD screen cleaning solution into a first groove, heating the cleaning solution to 50-60 DEG C, immersing the LCD screen into the first groove, and cleaning the LCD screen for 3-5 min by matching ultrasonic wave or mega-sonic effect; pouring an electrochemical oxidation solution into a second groove, heating the electrochemical oxidation solution to 50-60 DEG C, taking out the LCD screen from the first groove, putting the LCD screen into the second groove, and cleaning the LCD screen for 3-5 min by matching the ultrasonic wave; (2) pouring deionized water into a third groove, heating the deionized water to 50-60 DEG C, taking out the LCD screen from the second groove, putting the LCD screen into the third groove, and cleaning the LCD screen for 3-5 min by matching the ultrasonic wave; (3) spraying the cleaned LCD screen with the deionized water with the temperature of 50-60 DEG C for 2-4 min; and drying the LCD screen after spraying.

Owner:HEFEI HUIKE PRECISION DIE CO LTD

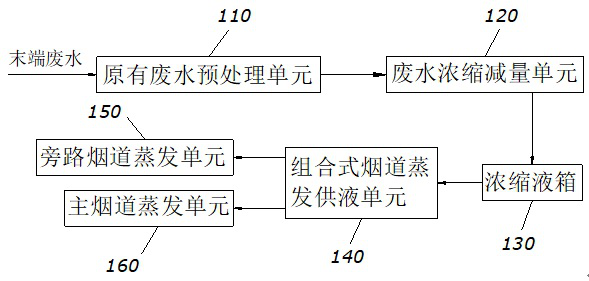

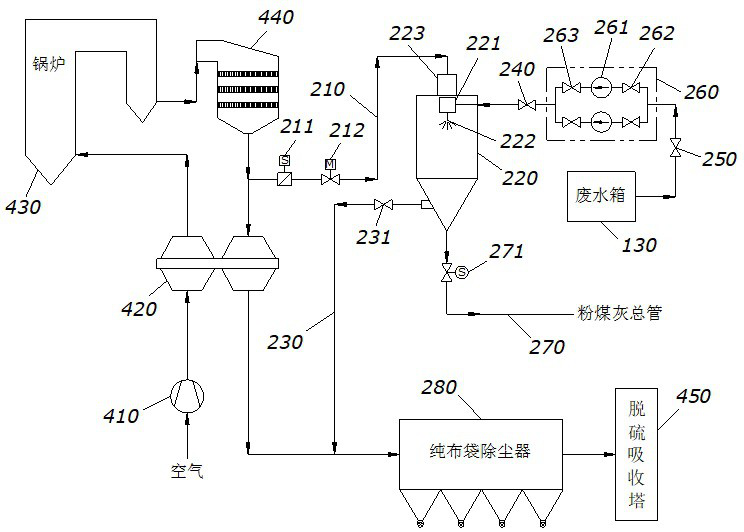

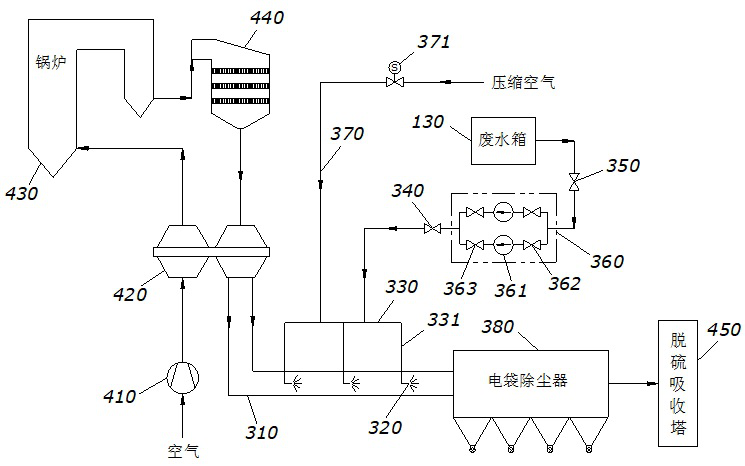

Coal-fired power plant wastewater zero-discharge combined flue evaporation system and method thereof

PendingCN112062376AReduce sensitivityAvoid Low Temperature CorrosionCombination devicesScale removal and water softeningAir preheaterAtomizer nozzle

The invention discloses a coal-fired power plant wastewater zero-discharge combined flue evaporation system and a method thereof. For a unit using a pure bag-type dust collector, a smoke inlet of a bypass flue evaporator is communicated with a pipeline between an SCR reactor and an air preheater through a bypass smoke inlet flue; the smoke outlet is communicated with a pipeline between the air pre-heater and the pure bag-type dust remover through a bypass smoke outlet channel; the spray buffer tank is communicated with the wastewater tank through a first double-fluid atomizer; for a unit of the electric bag dust collector, the same ends of a plurality of atomizing branch pipes with atomizing nozzles are respectively communicated with an atomizing main pipe in parallel, the atomizing main pipe is communicated with a waste water tank through a second double-fluid atomizer, a main flue is communicated between an air preheater and the electric bag dust collector, and the atomizing nozzlesare positioned in the main flue at intervals; due to the adoption of a transformation scheme of concentration decrement and combined flue evaporation, zero discharge of wastewater in the whole plant is achieved, the hidden danger of environmental protection is thoroughly eliminated, the environmental benefit is obvious, the process technology is stable and reliable, and the transformation cost iseconomic and reasonable.

Owner:湛江电力有限公司

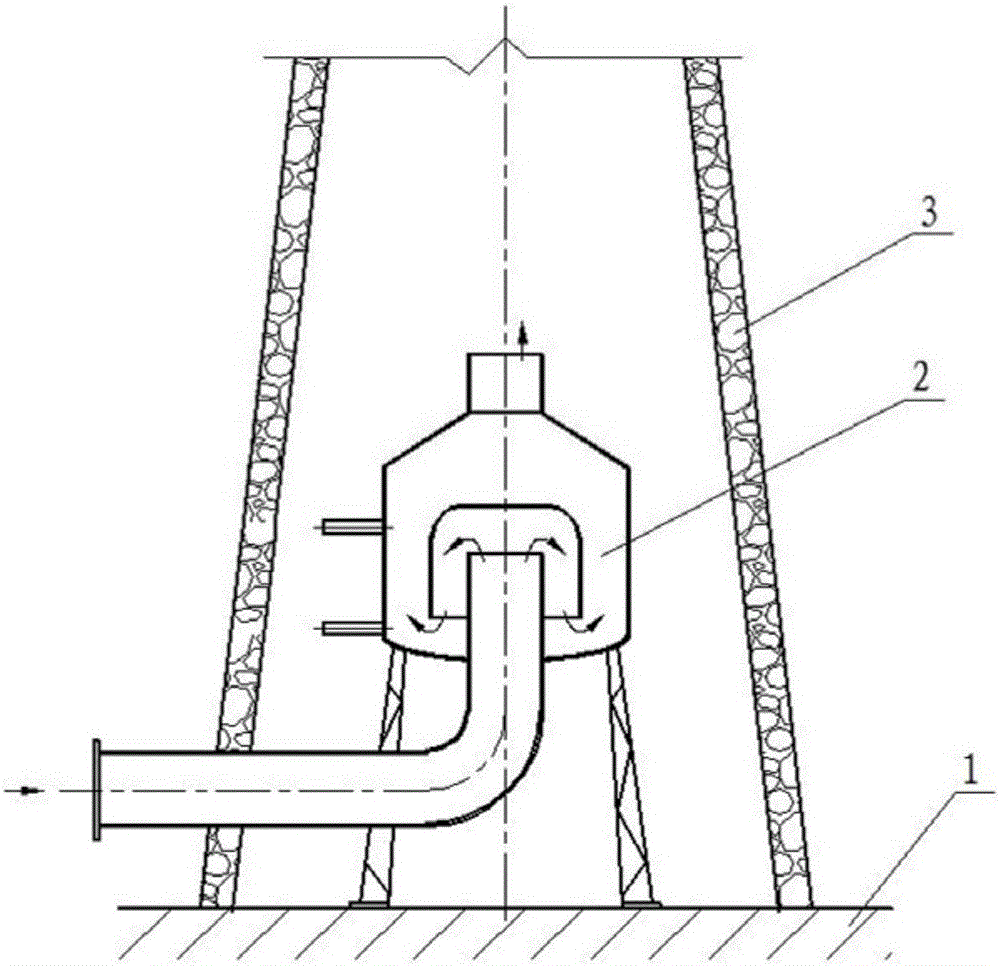

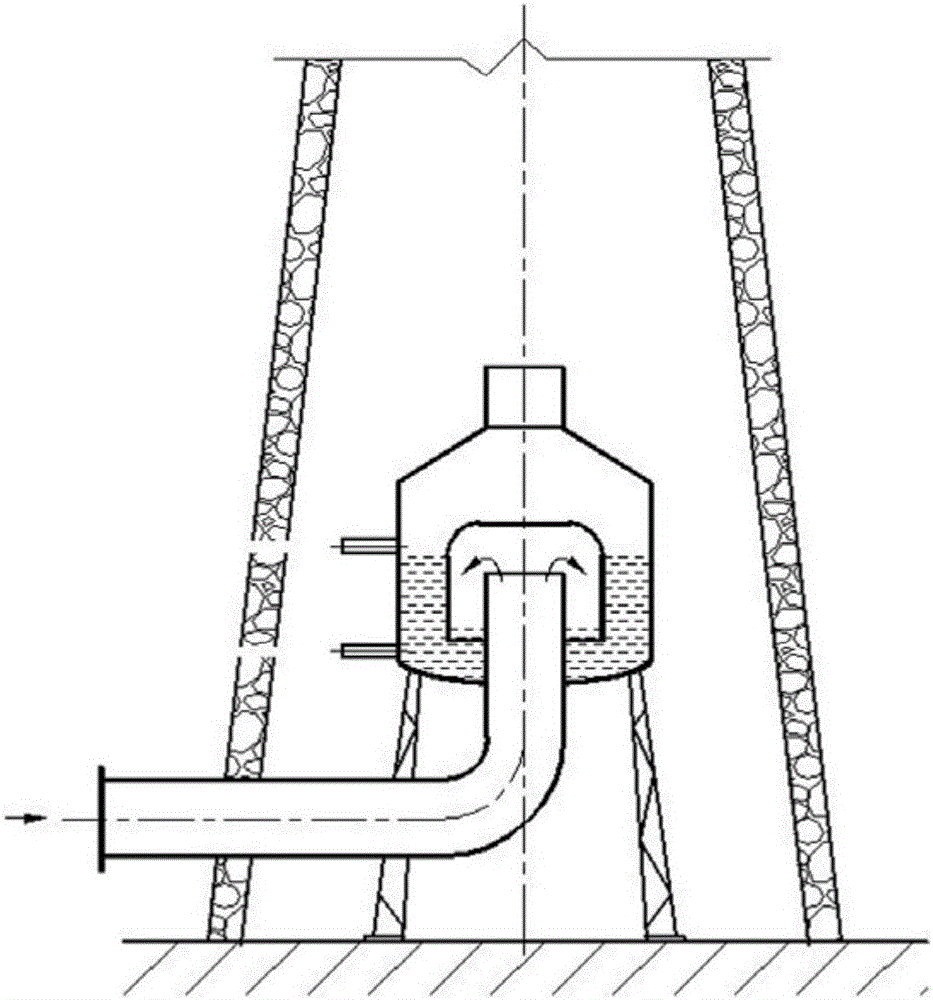

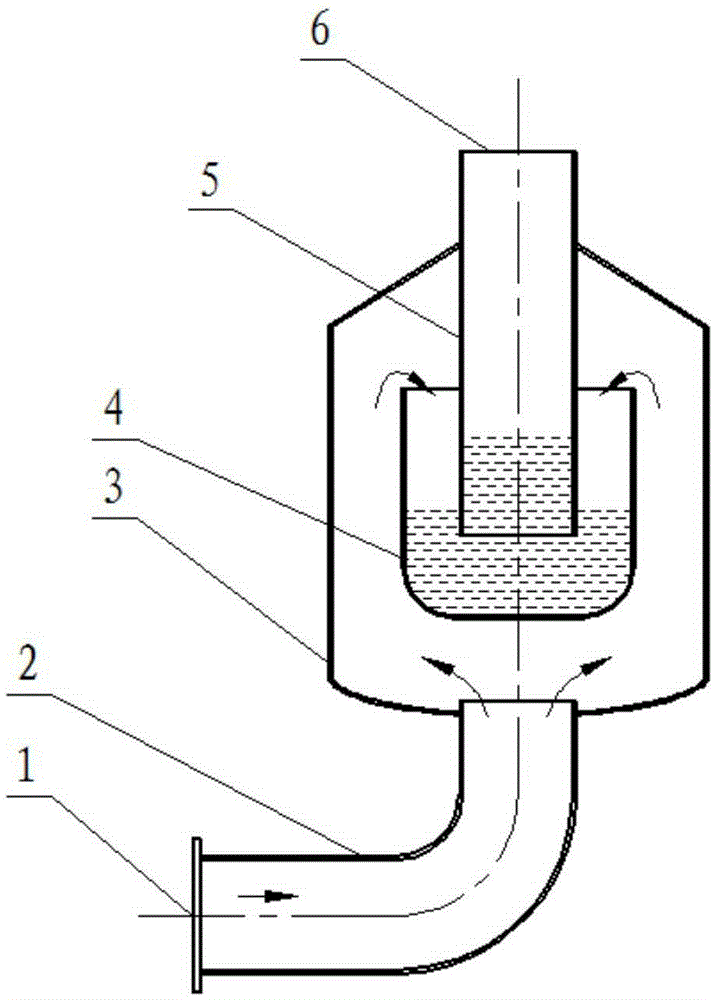

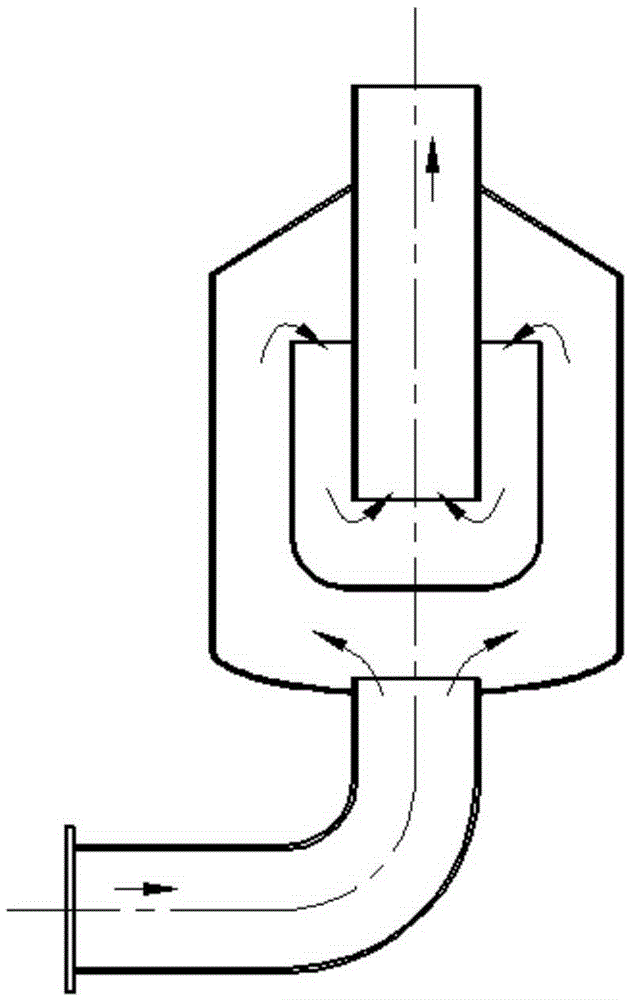

Water-sealed valve device arranged in chimney and use method for water-sealed valve device

ActiveCN105135003ADoes not occupy site spaceEliminate the risk of leakageValve arrangementsButterfly valveFlue

The invention relates to a water-sealed valve device arranged in a chimney and a use method for the water-sealed valve device. When the water-sealed valve device is in a water-sealed cap type, the water-sealed valve device is arranged in the chimney (3) and comprises a smoke inlet (21), a water inflow and outflow port (22), an overflow port (23), a smoke outlet (24), a cone section (25), a water-sealed cap (26), an inner barrel (27), an outer barrel (28), an outer barrel bottom board (29) and a support (210). When the water-sealed valve device is in a conventional type, the water-sealed valve device is arranged in a chimney (3') and fixed to a foundation (1') through a support (210'), and a smoke inlet of the chimney (3') serves as a smoke inlet (21') of the water-sealed valve device. By the adoption of the technical scheme, the space at the bottom of the chimney can be fully used for containing a water-sealed tank, and the space of a site is not occupied. The sealing effect of the water-sealed valve device is better than that of a flue butterfly valve, and the smoke leakage risk existing during long-term operation of a device and the hidden environment protection danger caused by leakage are eliminated.

Owner:LUOYANG MINGYUAN PETROCHEM IND TECH +1

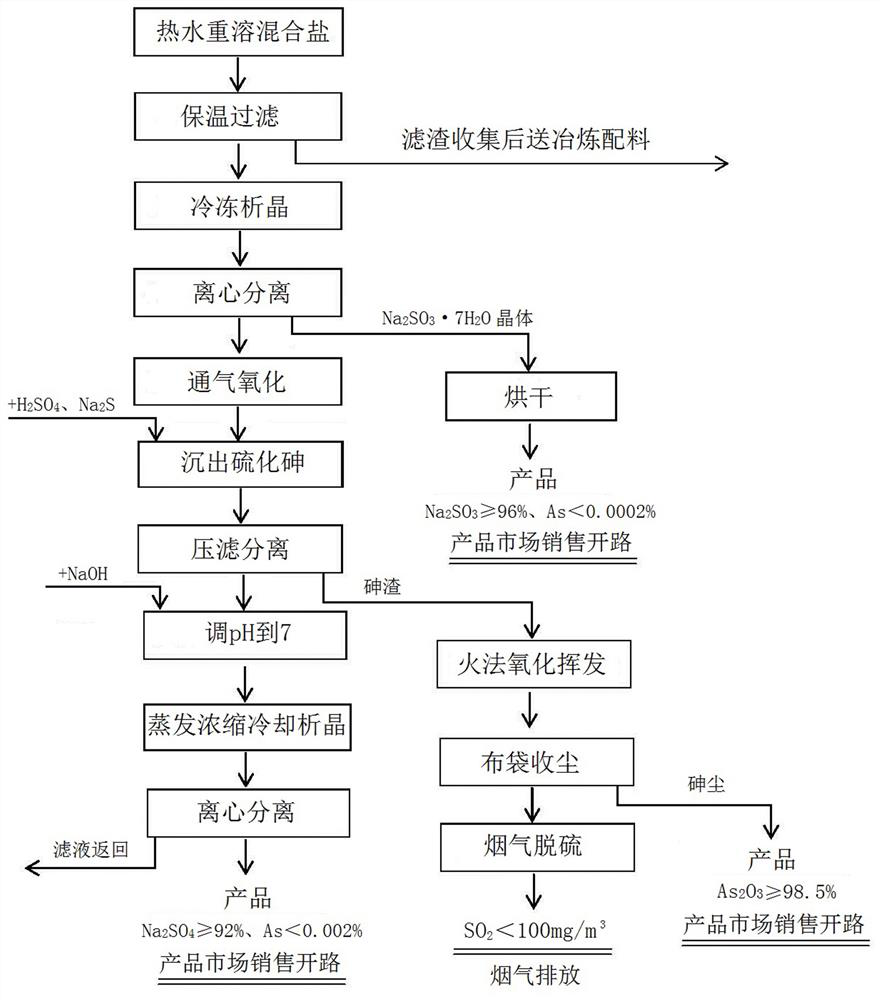

Method for redissolving, freezing and purifying mixed salt containing arsenic, sodium sulfite and sodium sulfate

ActiveCN112607751AEasy to open the way for market salesEliminate environmental hazardsArsenic oxides/hydroxides/oxyacidsAlkali metal sulfite/sulfate purificationSulfite saltPhysical chemistry

The invention relates to a method for purifying mixed salt containing arsenic, sodium sulfite and sodium sulfate by redissolving and freezing, and the method comprises the following steps: redissolving the mixed salt, carrying out filtering, freezing the filtrate to precipitate sodium sulfite crystals, carrying out filtering, drying the separated crystals to obtain a Na2SO3 product, introducing air into the filtrate to oxidize the residual sodium sulfite into sodium sulfate, precipitating arsenic, and carrying out filter pressing to separate As2S5 filter residues and filtrate, performing pyrogenic process on As2S5 filter residues to obtain an As2O3 product, evaporating and concentrating filtrate to supersaturation, carrying out cooling to separate out Na2SO4 crystals, carrying out centrifuging, and drying the obtained crystals to obtain a Na2SO4 product. According to the method, the mixed salt can be separated and enriched at a lower production cost, so that the mixed salt which cannot be directly utilized generates market values according to respective contents, and more importantly, the harmful substance arsenic with lower content can be enriched at a high rate to form a high-quality arsenic trioxide product, thereby facilitating market sale and development, and achieving the harmless and resourceful treatment on the environment-friendly strictly-controlled arsenic.

Owner:LEIYANG YANXIN NON FERROUS METALS

Ferrous metal tailing comprehensive treatment method

InactiveCN107790477AEliminate potential safety hazardsEliminate environmental hazardsSolid waste disposalFilling materialsBuilding material

The invention discloses a ferrous metal tailing comprehensive treatment method. The ferrous metal tailing comprehensive treatment method comprises the following steps: (1) size mixing of tailing and impurity removal; (2) recleaning and roughing of the tailing; (3) regrinding of rough concentrate; (4) concentration of the rough concentration to output a concentrate product; (5) coarse fraction dehydration of secondary tailing; (6) fine fraction dehydration of the secondary tailing to prepare cakes; and (7) dehydration to prepare cakes. The invention relates to two process courses: (1) recleanining (flotation and reselection and the like) of old tailing and new tailing of non metals, and selection and output of residual target minerals and other valuable mineral concentrate products from thetailing, wherein the comprehensive utilization ratio of resources is improved; and (2) comprehensive treatment of the secondary tailing, wherein coarse fraction is converted into building materials or agricultural land remolding and constructional engineering filling materials and fine fraction is dehydrated to output mud cakes as the building materials or agricultural land remolding and constructional engineering filling materials, so that the hazard of the mine tailing on the environment and occupation of land resources are eliminated fundamentally.

Owner:乔静梅

Freon treated by premixed combustion and method for producing said resource

InactiveCN100416162CImprove mixing uniformityImprove decomposition rateIncinerator apparatusFurnace temperatureFreon

Owner:KUNMING UNIV OF SCI & TECH

Stainless steel cold rolling sludge recycling method

InactiveCN112499815AEliminate environmental hazardsAchieve source reductionSludge treatmentWater contaminantsSteelmakingSludge cake

The invention relates to the technical field of industrial harmful waste recycling, and discloses a stainless steel cold rolling sludge recycling method which comprises the following steps of: (1) carrying out distinguishing treatment; (2) carrying out mixing treatment; (3) carrying out primary precipitation; (4) obtaining heavy metal sludge; (5) carrying out secondary precipitation; and (6) obtaining calcium salt sludge. According to the stainless steel cold rolling sludge recycling method, through two-stage treatment and segmented recovery, a heavy metal sludge cake and a calcium salt sludgecake are obtained conveniently, the heavy metal sludge cake is mainly composed of hydroxides of heavy metals such as Fe, Cr and Ni, the heavy metal sludge cake can be returned to a metallurgy processand utilized as a steelmaking slag former or sinter or pellet ore and other raw materials after being dried, the calcium salt sludge cake can be used as a cement mineralizer, a building material rawmaterial or a metallurgical auxiliary material, and can also fill up the landfill or be stacked as common industrial waste due to low heavy metal content, and practice shows that after the stainless steel cold rolling pickling wastewater is subjected to segmented treatment, mixed sludge source reduction is realized, and two sections of sludge are easier to comprehensively utilize.

Owner:SHANDONG HONGWANG INDUSTRY CO LTD

Environment-friendly RH refining furnace lining brick and preparation method thereof

InactiveCN103601508AExcellent preparation performanceAchieve chrome-free liningEnvironmental resistanceBrick

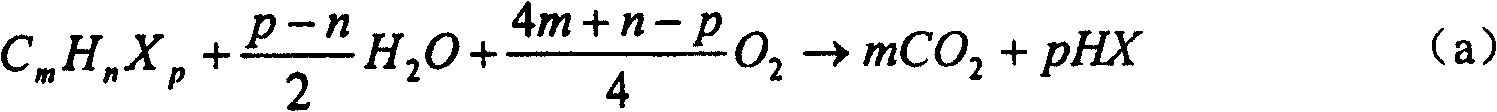

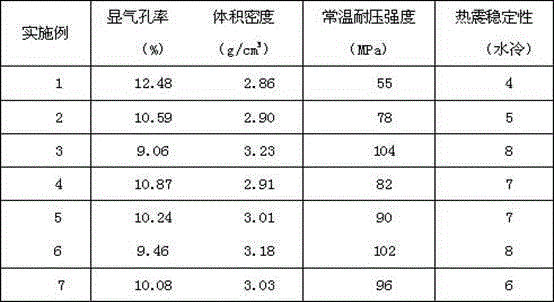

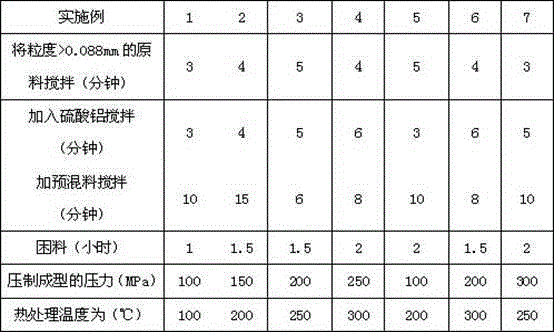

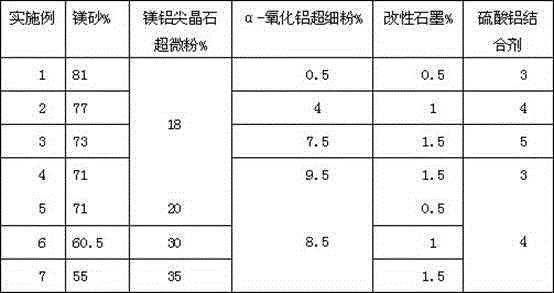

The invention relates to an environment-friendly RH refining furnace lining brick and a preparation method thereof. The environment-friendly RH refining furnace lining brick is prepared from the following raw materials in percentage by weight: 54-81% of magnesite, 18-35% of magnesium aluminate spinel ultra-fine powder, 0.5-9.5% of alpha-aluminium oxide ultra-fine powder and 0.5-1.5% of modified graphene, wherein the sum of the percentage by weight of the raw materials is 100%; in addition, the environment-friendly RH refining furnace lining brick also comprises 3-5% by weight of aluminium sulfate serving as a binding agent. The preparation method comprises the following steps: weighing the raw materials in proportions, and premixing the raw materials with the particle size of less than or equal to 0.088mm so as to obtain a premixed material; then stirring the raw materials with the particle size of more than 0.088mm for 3-5 minutes, adding the aluminium sulfate binding agent and stirring for 3-6 minutes, adding the premixed material and stirring for 6-15 minutes, carrying out compression molding under the pressure of 100-300MPa, and finally carrying out heat treatment in an electric heating dry kiln at the temperature of 100-300 DEG C, thus forming the RH vacuum furnace lining brick. The preparation method has the advantages that the non-chromizing of a lining of RH vacuum smelting equipment is realized, the environment hidden danger caused by a chrome-containing refractory lining is eliminated, and the environment-friendly RH refining furnace lining brick with the good performance can be prepared.

Owner:鞍山市量子炉材集团有限公司

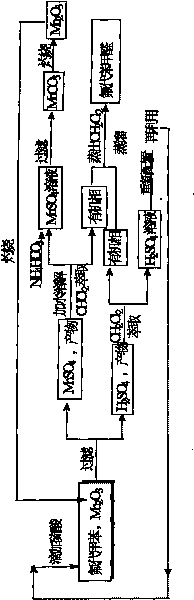

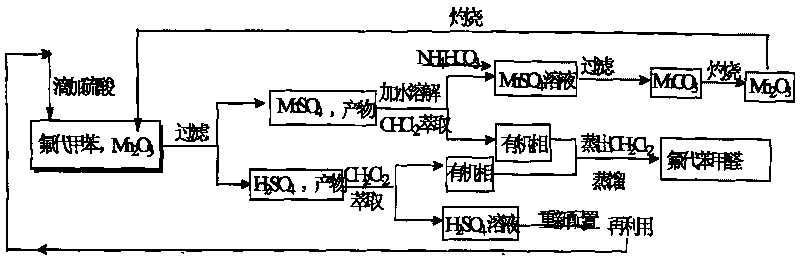

Oxidation preparation method of fluorobenzene formaldehyde

InactiveCN101735028AHigh yieldEliminate environmental hazardsCarbonyl compound preparation by oxidationContinuous operationHeavy metals

The invention discloses an oxidation preparation method of fluorobenzene formaldehyde, comprising the following steps: adding Mn2O3 and fluorotoluene in a reaction device; heating the reaction device, and beginning to dropwise add sulfuric acid; and after the reaction, purifying the product fluorobenzene formaldehyde through processing. The invention has high synthetic product yield which can reach 90%; the generated heavy metallic salt can be effectively converted into Mn2O3, thus eliminating the harm to the environment; the invention has easily obtained reaction raw materials, simple process flow and low production cost; the waste acid generated by oxidation can be recycled, thus improving the utilization rate of the device, realizing continuous operation and satisfying the requirement of industrialization.

Owner:NANJING UNIV OF SCI & TECH

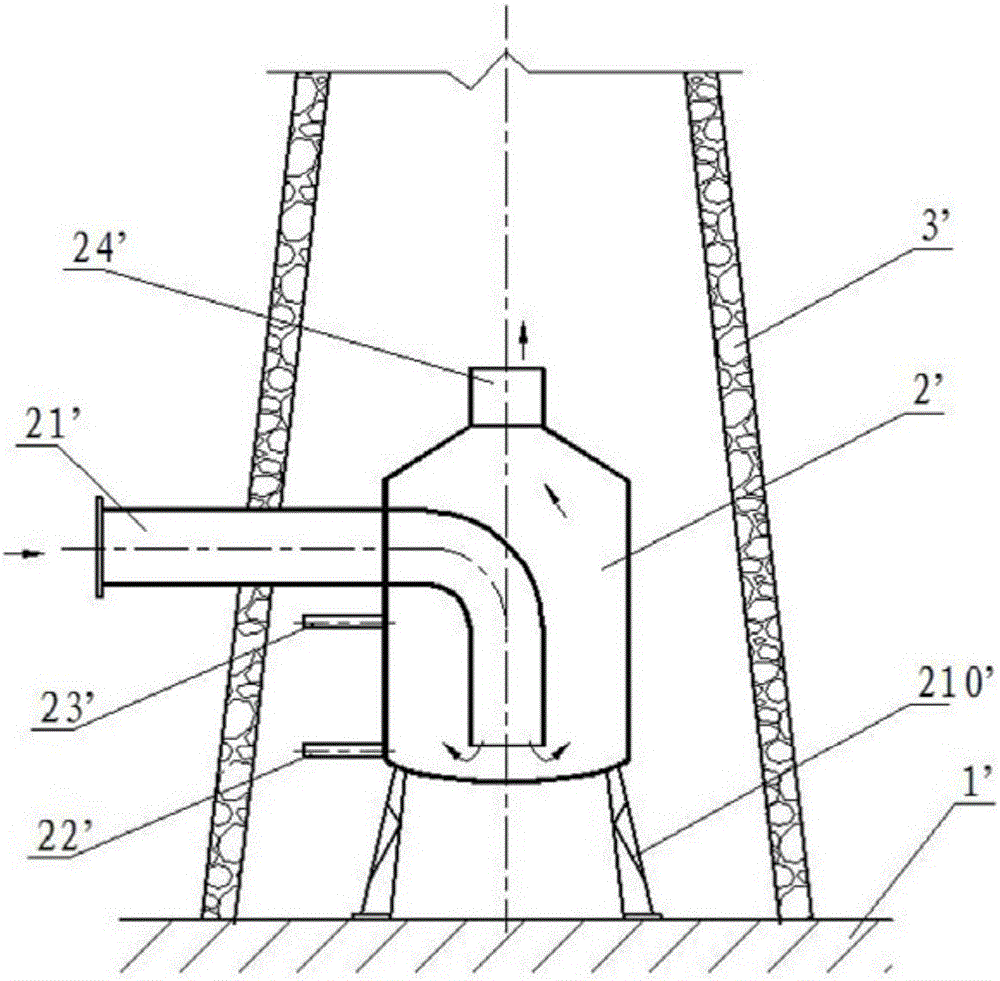

Water-sealed valve

InactiveCN105276239ALow costImprove sealingValve arrangementsEngine sealsChinese charactersEngineering

The invention relates to a water-sealed valve which comprises a smoke inlet, a smoke inlet connecting pipe, a smoke outlet pipe, a shell, a water-sealed basin and a smoke outlet, wherein the smoke inlet is communicated with the shell by virtue of the smoke inlet connecting pipe; the water-sealed basin is arranged in the shell, the water-sealed basin is a container with an upward opening, the interior of the water-sealed basin is concave downwards, and the cross section of the water-sealed basin is in a shape like the Chinese character ao; the smoke outlet pipe is inserted into the shell, the low end of the smoke outlet pipe is inserted into the water-sealed basin, and the upper end of the smoke outlet pipe is communicated with the smoke outlet. When the water-sealed valve provided by the invention is placed in a chimney, the bottom space of the chimney is fully used, and the spot space is not occupied; when the water-sealed valve is placed outside the chimney, the smoke inlet can be directly connected with an inlet pipeline which is low or even close to the ground, so that the inlet pipeline is simplified, and the cost is greatly saved; for a long-sealed chimney, the sealing effect is better than that of a flue butterfly valve, and the smoke leakage risk which occurs during long-period operation of the device and the environmental hazard caused by leakage are eliminated.

Owner:LUOYANG MINGYUAN PETROCHEM IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com