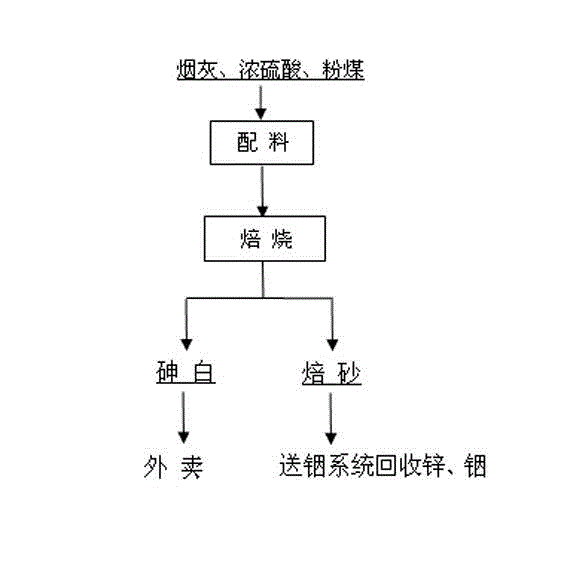

Arsenic-containing soot dearsenication method

A technology for soot and arsenic removal, which is applied in the direction of improving process efficiency, can solve problems such as indium loss, and achieve the effects of improving leaching rate, facilitating recovery, and eliminating hidden dangers of environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] use equipment

[0023] 1. Mixer φ1.5m: 1 set

[0024] 2. Electric rotary furnace φ1.2m*4m: 1 set

[0025] 3. Bag dust collection system: 1 set

[0026] See Table 1 for the composition of soot used

[0027] Table 1 Composition table of soot (%)

[0028] element As In(g / t) Zn Pb Implementation column 1 4.85 3907 12.63 19.21 Implementation column 2 20.31 2356 18.41 18.77 Implementation column 3 35.99 2135 14.65 21.15

[0029] The implementation steps are as follows:

[0030] 1. For batching, calculate the amount of concentrated sulfuric acid and pulverized coal required for batching per ton of soot according to the arsenic content. The batching ratio is (weight ratio): As: concentrated sulfuric acid: pulverized coal = 1: 1.3: 0.32. , concentrated sulfuric acid and pulverized coal mixing; each embodiment batching scheme is shown in Table 2

[0031] Table 2 Ingredients S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com