Patents

Literature

86results about How to "Excellent preparation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

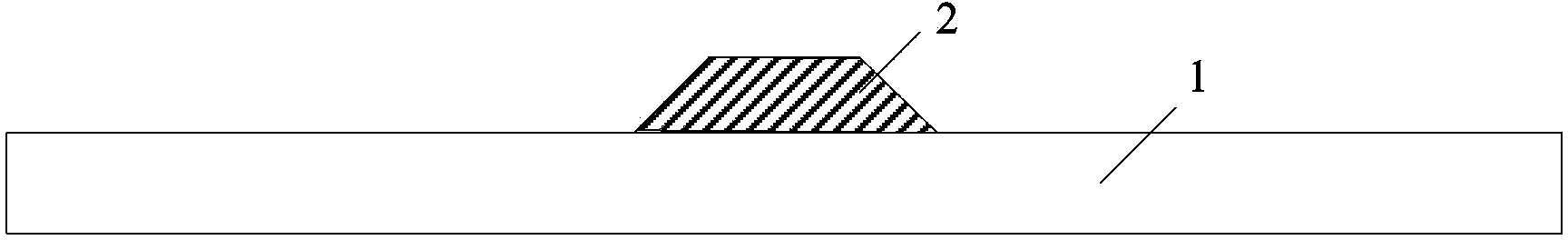

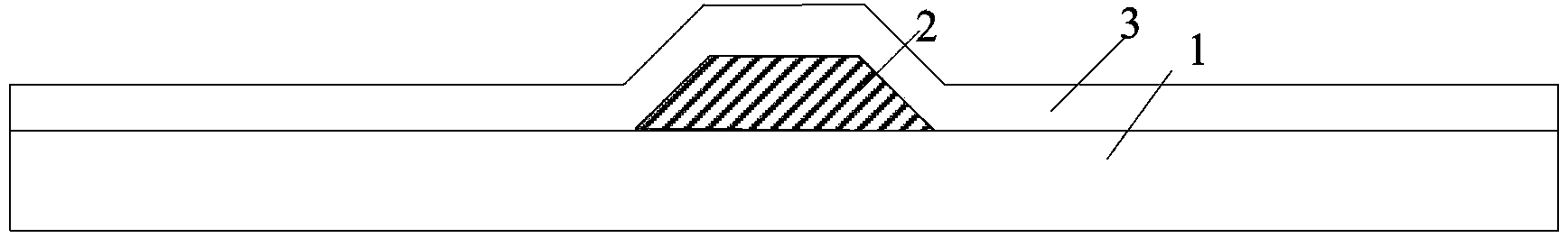

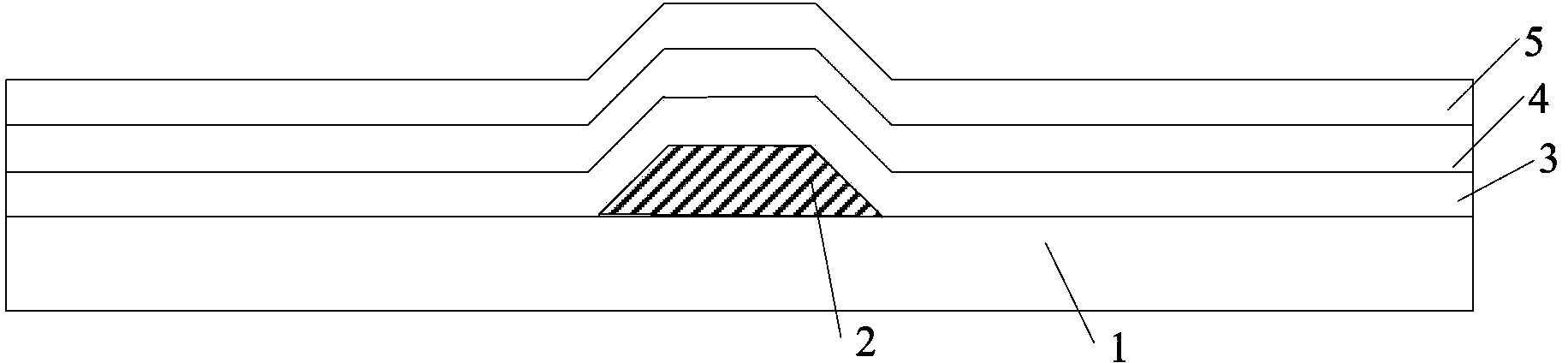

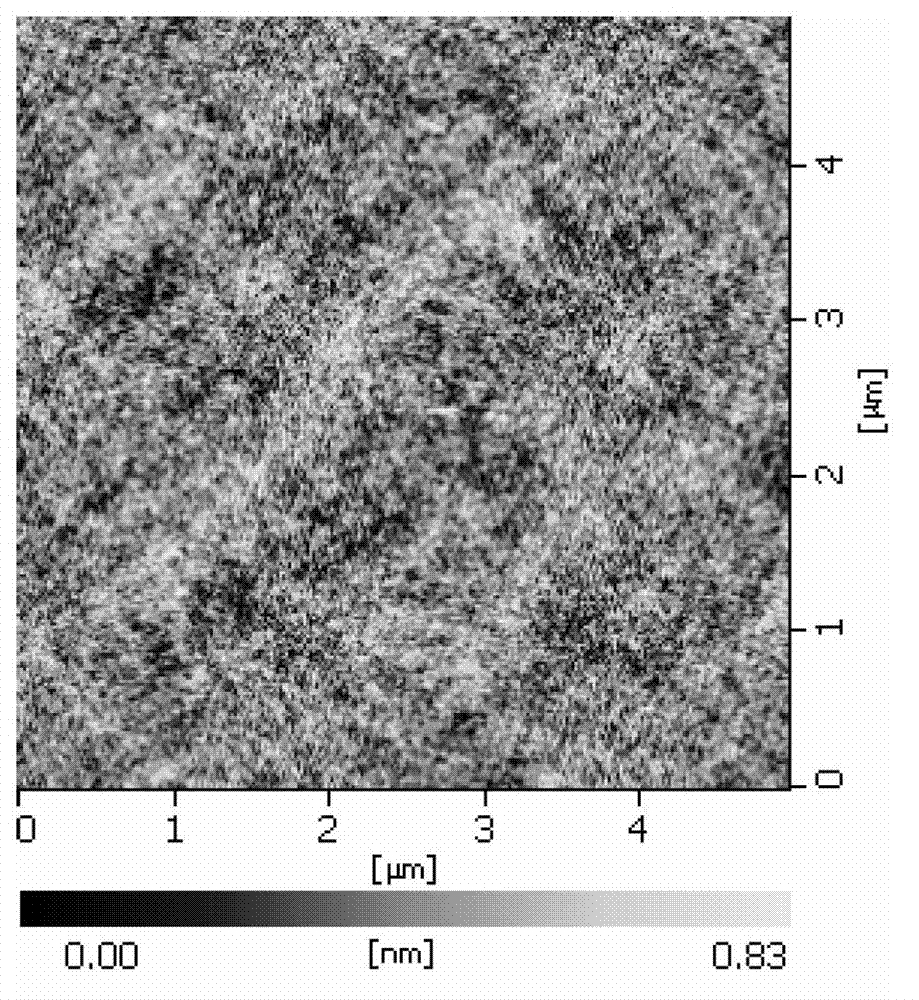

Preparation method and application of separation film with nano composite cortical layer

ActiveCN102908906AImprove throughputImprove interception effectSemi-permeable membranesDesalinationNanofiltration

The invention provides a preparation method and application of a separation film with a nano composite cortical layer. The separation film comprises a non-woven fabric layer, two porous support layers and a desalination layer, and is characterized in that the lower layer of the two porous support layers is a porous body layer containing polymers and / or nano particles, and the upper layer of the two porous support layers is a porous cortical containing polymers and nano particles. The preparation method includes coating the upper layer and the lower layer of the non-woven base material by means of a double-layer coating technology. An ultrafilter support layer of the composite separation film prepared by the preparation method is good in surface evenness, hight water flux is kept in the meantime of keeping higher cutoff rate, and the separation film can be directly used as an ultrafiltration film or can be used as a basic porous support layer to further prepare a composite forward osmosis, reverse osmosis and nanofiltration film. The preparation method can be applied to preparing the reverse osmosis film and the nanofiltration film which are good in performance, and a composite ultrafiltration film with low molecular weight cutoff.

Owner:VONTRON TECH CO LTD

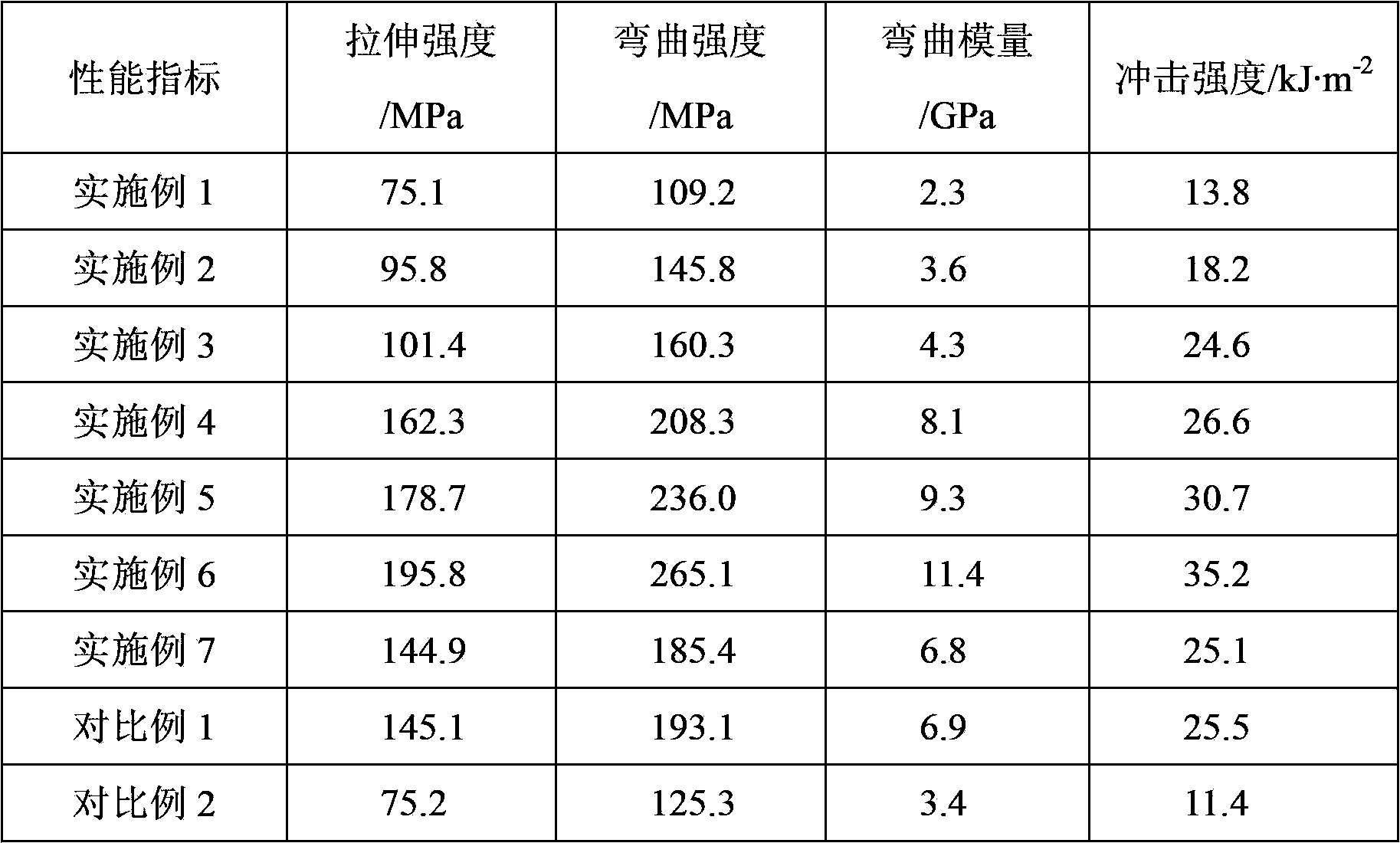

Long glassfiber reinforced nylon composite material and preparation method thereof

The invention belongs to the technical field of high-molecular composite materials, and relates to a long glassfiber reinforced nylon composite material and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 100 parts of nylon, 2 to 10 parts of compatilizer, 0.1 to 0.5 part of antioxidant, 0.2 to 1.0 part of lubricant and 10 to 40 parts of glassfibers. Compared with the short glassfiber reinforcement mode, according to the composite material provided by the invention, abrasions among short glassfibers, a screw rod and a feed cylinder are decreased during a double-screw extruding process, namely, the minimum fiber retained in an injection-molding product is large in length, so that the glassfiber reinforced nylon composite material with excellent performance is prepared. Thus, the applications of the glassfiber reinforced nylon composite material in the fields of automobiles, electric appliances, machinery, military industry and the like are enlarged.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Method for preparing hollow fiber nanofiltration membrane by using thermally induced phase separation/interface cross linking synchronization method

InactiveCN102824859AThickness is easy to controlAvoid the difficulty of high adhesiveness requirementsSemi-permeable membranesHollow filament manufactureFiberCross-link

The invention discloses a method for preparing a hollow fiber nanofiltration membrane by using a thermally induced phase separation / interface cross linking synchronization method; the preparation method comprises the following steps: 1) mixing polymer, a diluting agent and a cross linking agent to form a homogeneous phase membrane casting solution; 2) extruding the membrane casting solution and core solution, or the membrane casting solution and nitrogen by a ring-shaped spinning head, then conducting the thermally induced phase separation in a cooling bath so as to obtain a hollow primary membrane; 3) soaking the hollow primary membrane in extracting solution containing cross linking pre-polymer, conducting the interface cross linking at the same time with removing diluting agent, thereby obtaining a hollow fiber nanofiltration membrane. According to the method provided by the invention, the preparations of holing and separation layer is finished, and the difficulty point of high require of bonding property between a separation layer and a supporting layer of a combining method in the prior art can be avoided, and meanwhile the thickness and the evenness of the separation layer are easy to control; the simple new method for preparing the hollow fiber nanofiltration membrane with excellent property by using the thermally induced phase separation / interface cross linking synchronization method is provided; and the prepared nanofiltration membrane is little in defect, high in stability and high in controllability.

Owner:ZHEJIANG UNIV

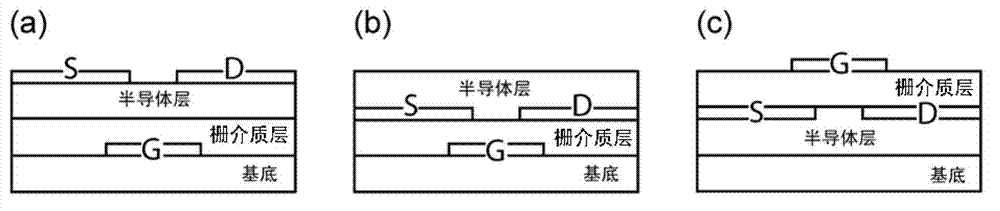

Array substrate, manufacturing method thereof and display device

InactiveCN103412450AExcellent preparation performanceImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerDisplay device

The invention provides an array substrate, a manufacturing method thereof and a display device, and belongs to the display technical field. An active layer of the array substrate comprises at least two metal-oxide semiconductor layers, wherein the mobility ratio of a first metal-oxide semiconductor layer close to a gate insulation layer is larger than that of a second metal-oxide semiconductor layer close to a source drain metal layer. According to the technical scheme, the active layer which is stable, good in performance and high in mobility ratio can be manufactured.

Owner:BOE TECH GRP CO LTD

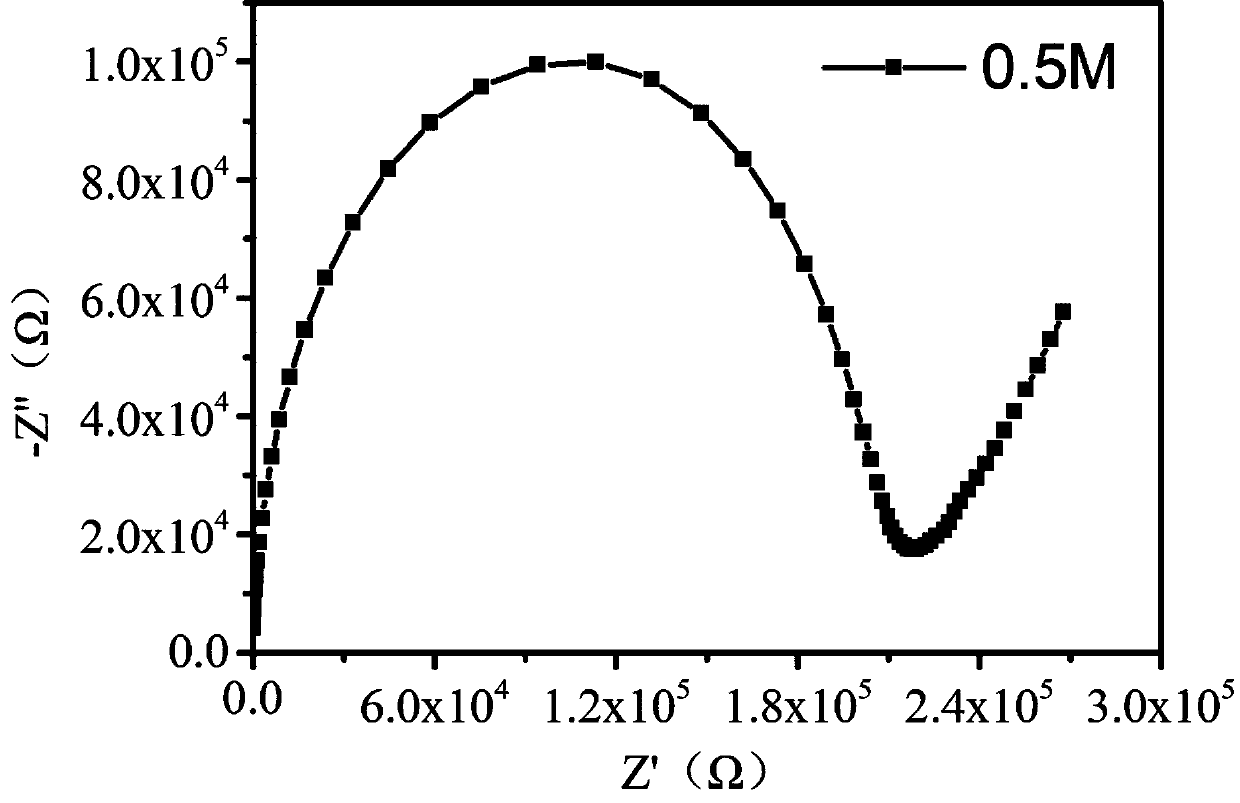

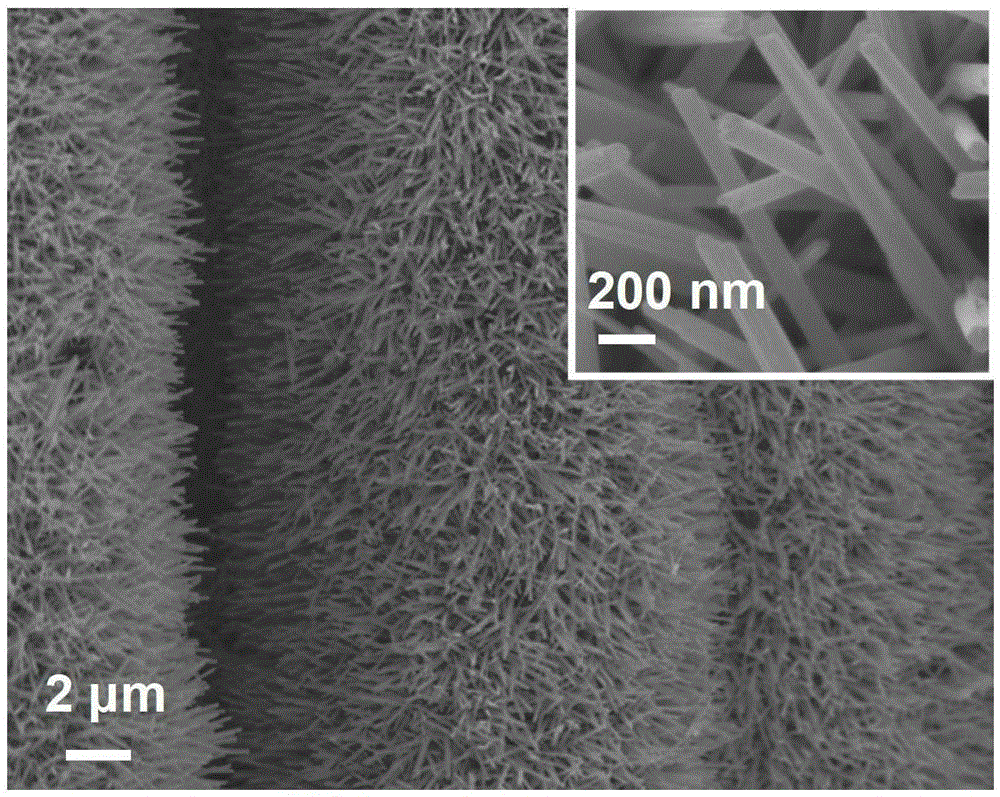

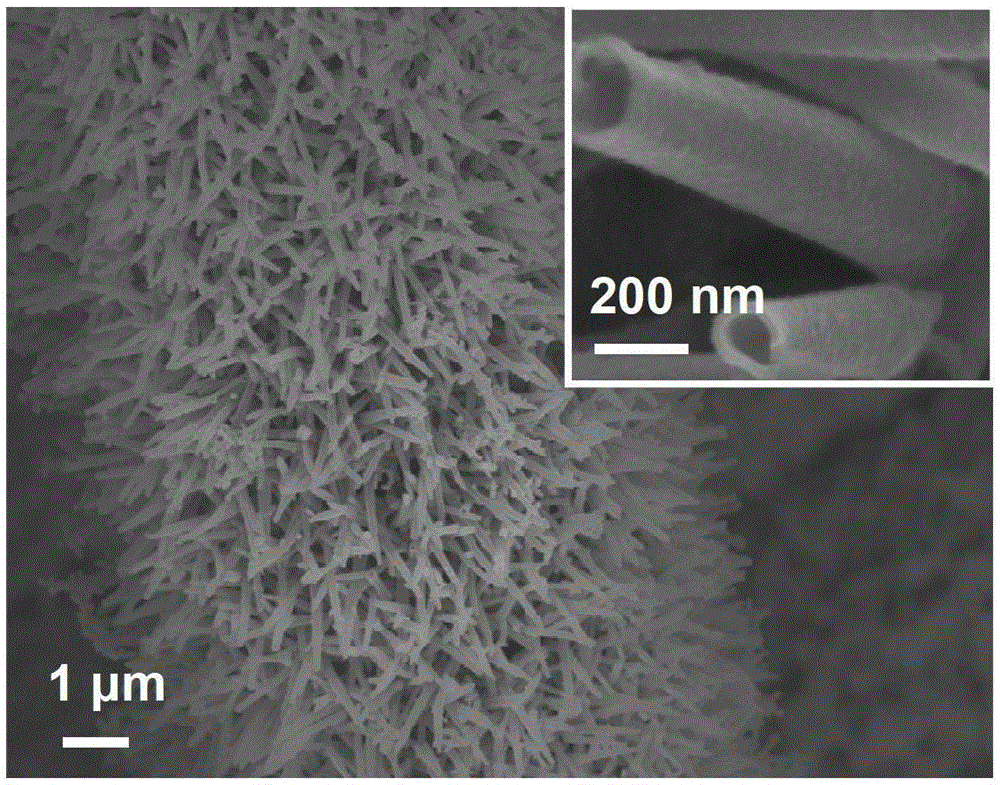

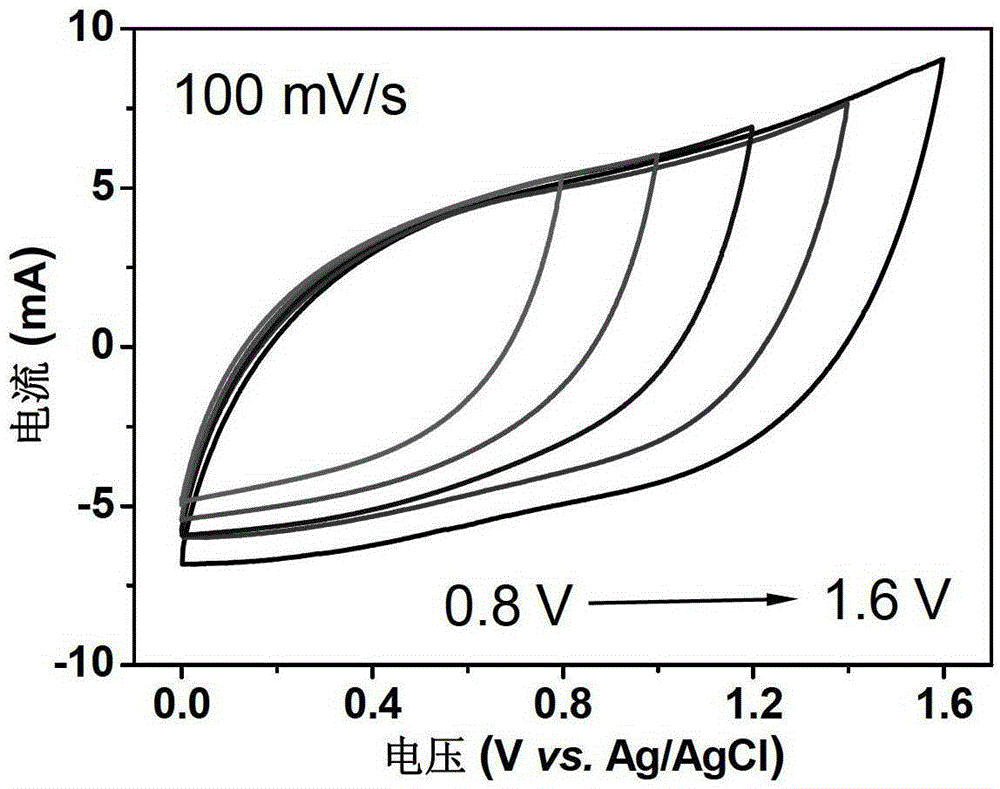

MnO2 and Fe2O3 nanostructure-based flexible asymmetric super-capacitor and preparation method as well as application thereof

ActiveCN103366970AReduce complexityExcellent preparation performanceHybrid capacitor electrodesNanowireNon symmetric

The invention belongs to the field of super-capacitor design, and discloses a MnO2 and Fe2O3 nanostructure-based flexible asymmetric super-capacitor and a preparation method as well as application thereof. The preparation method comprises the following steps: preparing a MnO2 nanowire positive electrode and a Fe2O3 nanotube negative electrode; and assembling the positive electrode, the negative electrode, electrolyte and a diaphragm into an asymmetric super-capacitor. According to the method, complexity for manufacturing the asymmetric super-capacitor is reduced, and energy density of the obtained super-capacitor reaches 0.47 mWh / cm<3>. The method is simple and practicable, MnO2 nanowires and Fe2O3 nanotubes can be grown on a large scale, and the asymmetric super-capacitor with superior performance is prepared.

Owner:JINAN UNIVERSITY

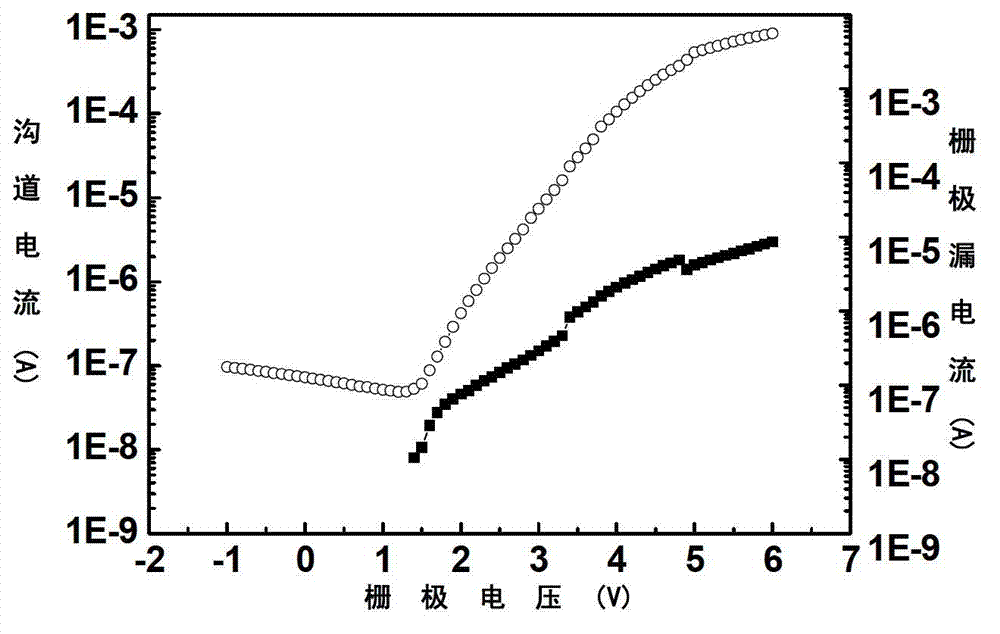

Alumina thin film and preparation method and application thereof

ActiveCN102787309ALow thermal decomposition temperatureLow heat treatment temperatureTransistorSolid/suspension decomposition chemical coatingIonDissolution reaction

The invention discloses a preparation method of an alumina thin film in the field of a thin film transistor. The preparation method comprises the following steps of: preparing aluminium precursor solution, i.e., dissolving a precursor material containing aluminium metal ions and a stabilizer in solution and sufficiently stirring to sufficiently dissolve the precursor material and the stabilizer to obtain the precursor solution; and preparing the alumina thin film, i.e., coating the prepared reaction solution on a coating surface to form a film and carrying out heat treatment program to obtain the alumina thin film. The invention also relates to the alumina thin film prepared by the preparation method and application of the alumina thin film in the transistor. The application comprises the thin film transistor of the alumina thin film and a preparation method of the thin film transistor. According to the preparation method of the alumina thin film, which is disclosed by the invention, by adding a right amount of stabilizer for stabilizing an alumina precursor material, a metal organic complex is formed by the precursor material of aluminium through the coordination dissolution reaction; the complex can be well dissolved in the solution and has low thermal decomposition temperature; and the heat treatment temperature in the preparing process is reduced.

Owner:TSINGHUA UNIV +2

Wood-silicon-plastic net floor and preparation method thereof

InactiveCN101224966AExcellent preparation performanceLow priceSolid waste managementFlooringPolypropyleneScrap

The invention pertains to the technical field of net floor prepared by utilizing waste resources to recycle, which relates to a wood-silicon-plastic net floor and a preparation method. The invention fully applies fly ash of solid waste, crop straw, wood flour and plastic scraps such as secondary polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC) and acrylonitrile-butadiene-styrene copolymer (ABS), by adding right amount of surface treating agent, flame retardant agent, anti-static agent, anti-aging agent, lubricant, plasticizing agent etc. for blending, the granulation is extruded to inject for production of a novel wood-silicon-plastic net floor having compressive strength of 22 to 36 MPa, the bending strength of 15 to 28 MPa, the impact strength 9 to 15 KJ / m<2>, the oxygen index is more than or equal to 28 and the service temperature ranges from -10 DEG C to 55 DEG C. The net floor can be applied to business building, office building, large-scale instrument repository and internet club, etc.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

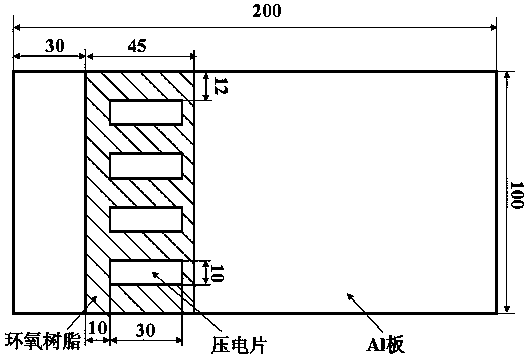

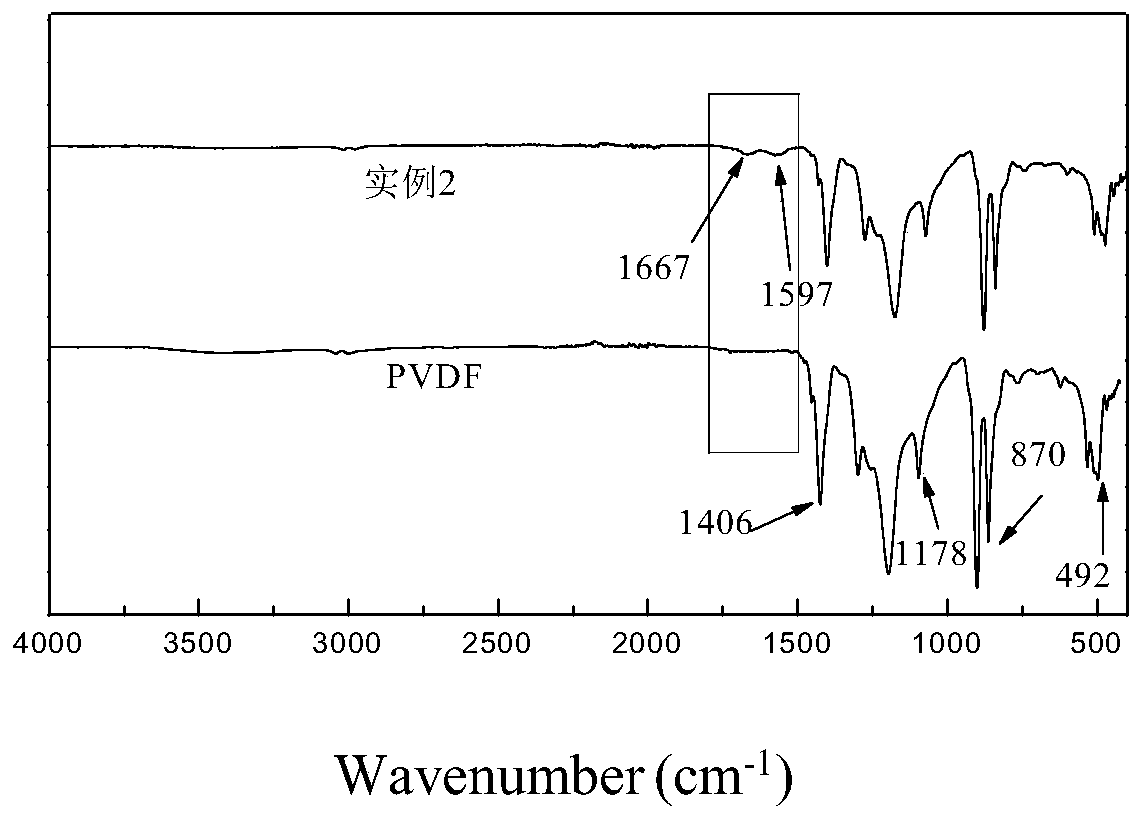

Method for preparing PVDF-TrFE/graphene high performance composite material

InactiveCN108264710AExcellent preparation performanceIncrease power generation capacityFlat articlesElectricityPvdf trfe

The invention discloses a method for preparing PVDF-TrFE high performance piezoelectric film. The method is divided into the following steps of 1, evenly stirring PVDF-TrFE powder and graphene nanoparticles in a DMF solution by using an ultrasonic stirrer and a mechanical stirrer; 2, initially crystallizing an obtained mixed solution in a drying oven; 3, axially stretching film after initial crystallization on a stretching machine; 4, conducting heat treatment on the film after stretching; 5, performing polarization on the film after the heat treatment. The method has advantages of low cost, high piezoelectric performance, simple operation and low process requirements.

Owner:海宁盛台材料科技有限公司

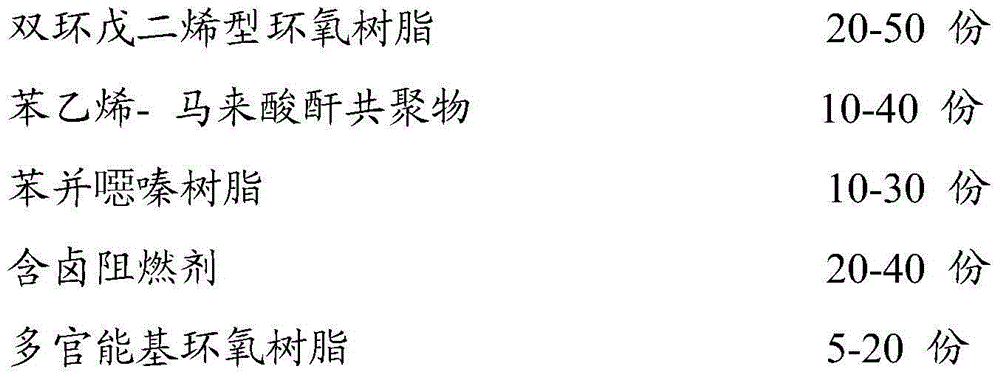

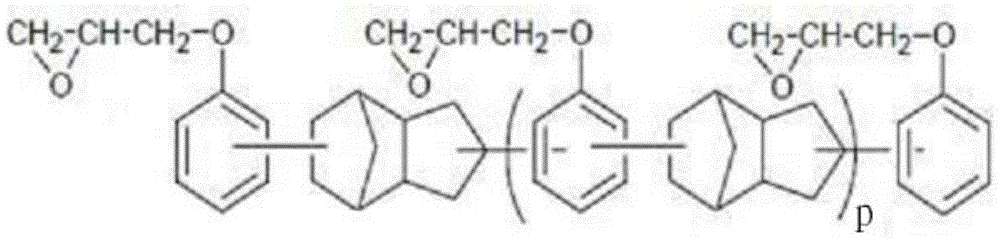

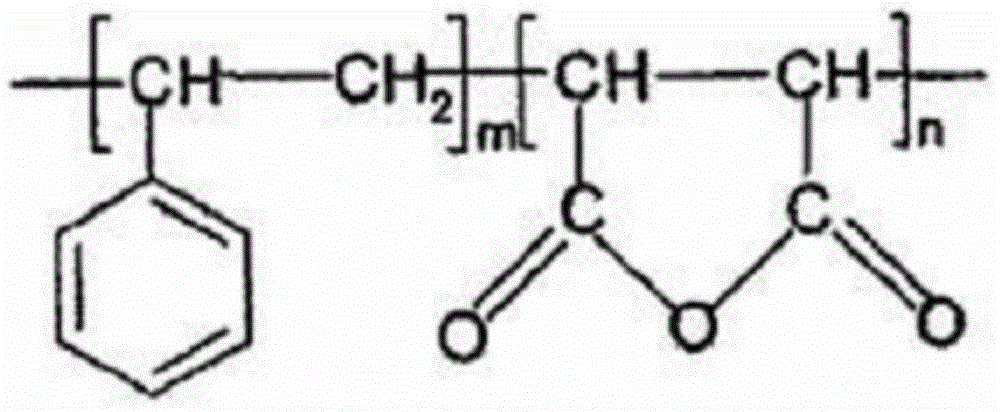

Halogen resin composition and application thereof

The invention relates to a halogen resin composition and an application thereof. The halogen resin composition is prepared from the following raw materials in parts by weight: 20-50 parts of dicyclopentadiene epoxy resin, 10-40 parts of styrene-maleic anhydride copolymer, 10-30 parts of benzoxazine resin, 20-40 parts of halogenous fire retardant, and 5-20 parts of multi-functional group epoxy resin, wherein the halogenous fire retardant is at least one of the decabrominated dipheny ethane, tri(tribromophenyl) triazine, brominated polyolefin, brominated polystyrene, ethyl-di(tetrabromobenzene o-dicarboximide), decabromodiphenyl ether, hexabromocyclododecane, eight bromo ether, tetrachlorophthalic anhydride, Hexachlorocyclopentadiene and perchlorinated cyclopentyl decane. A metal foil substrate made of the halogen resin composition has the advantages of low dielectric constant and dielectric loss, excellent heat resistance, good machinability and low swelling coefficient and can be well applied to a composite board.

Owner:GUANGZHOU GRACE ELECTRON CORP

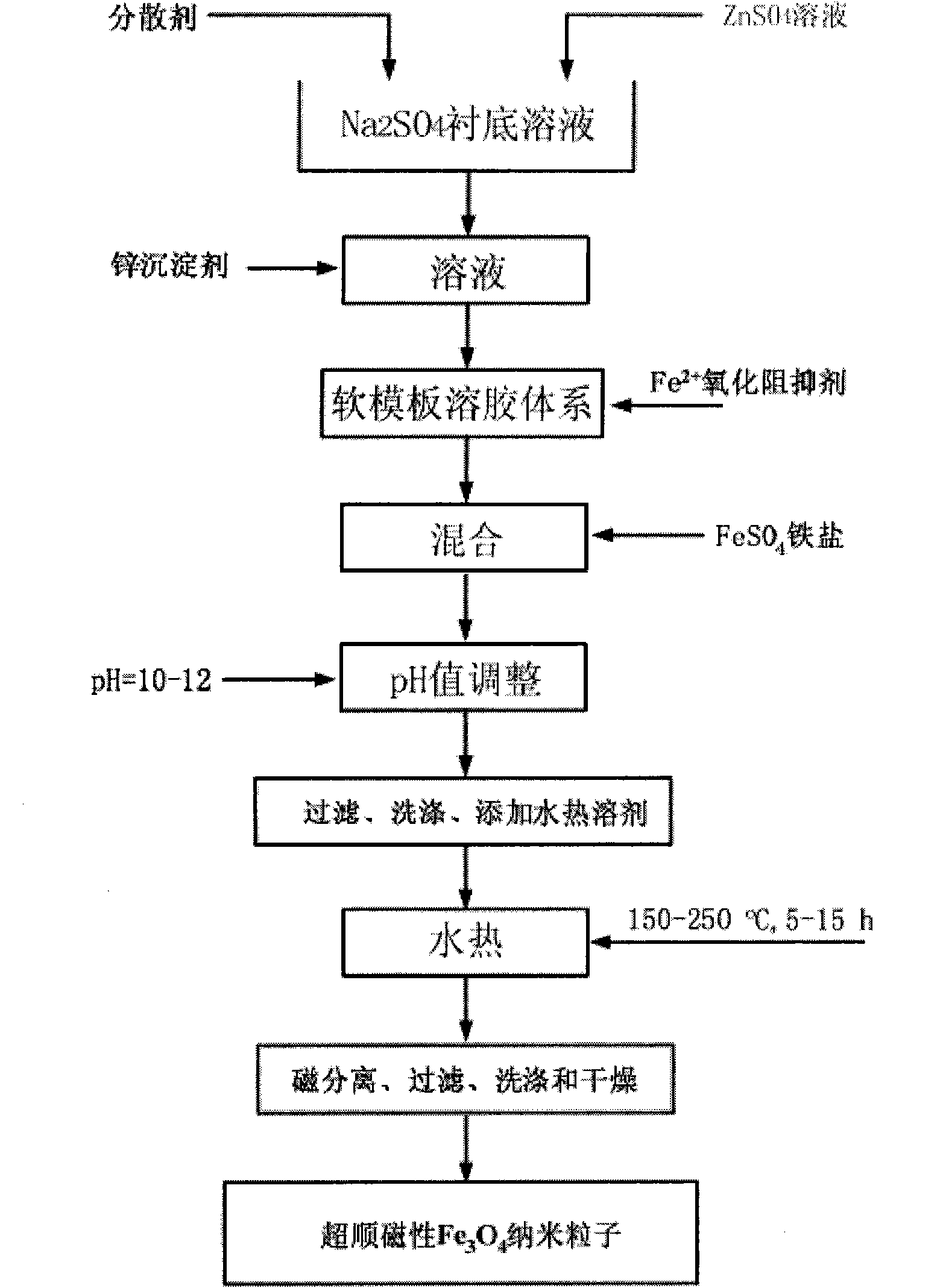

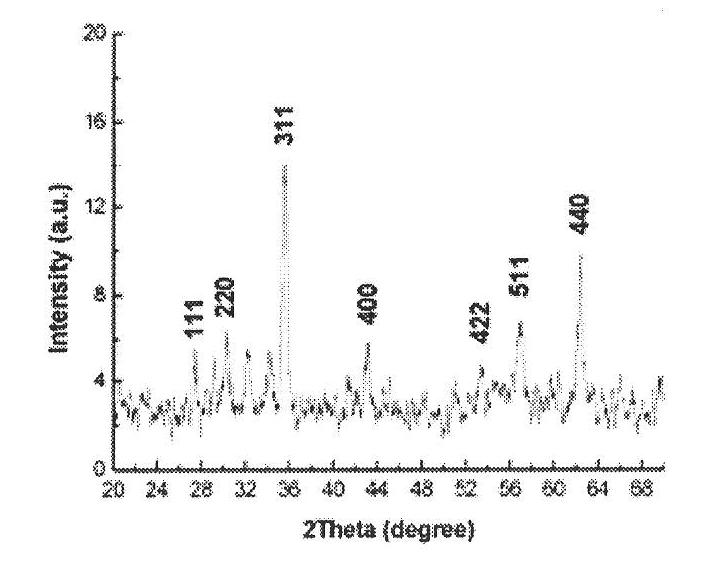

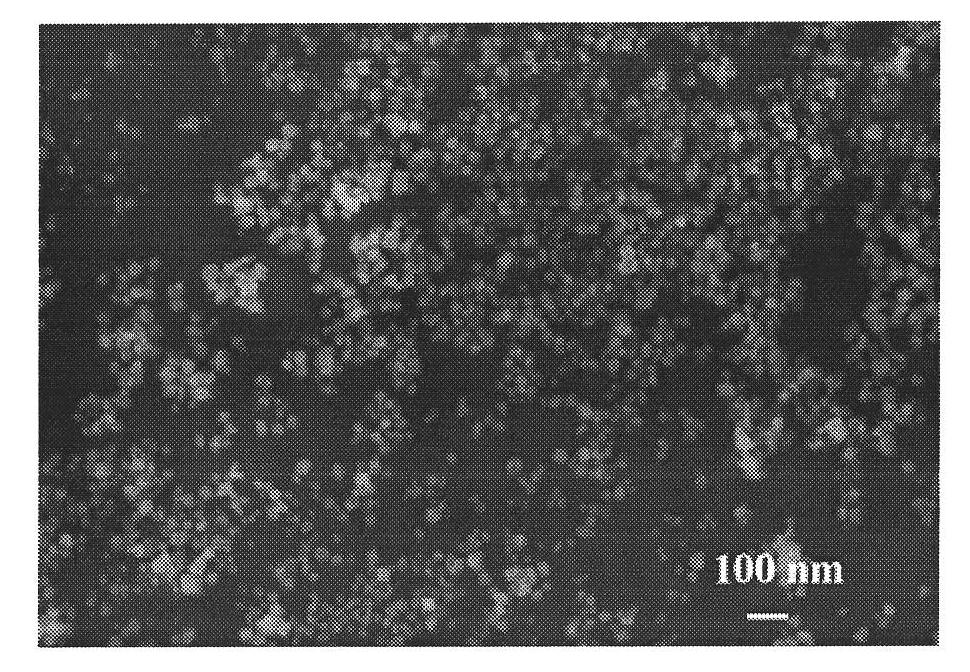

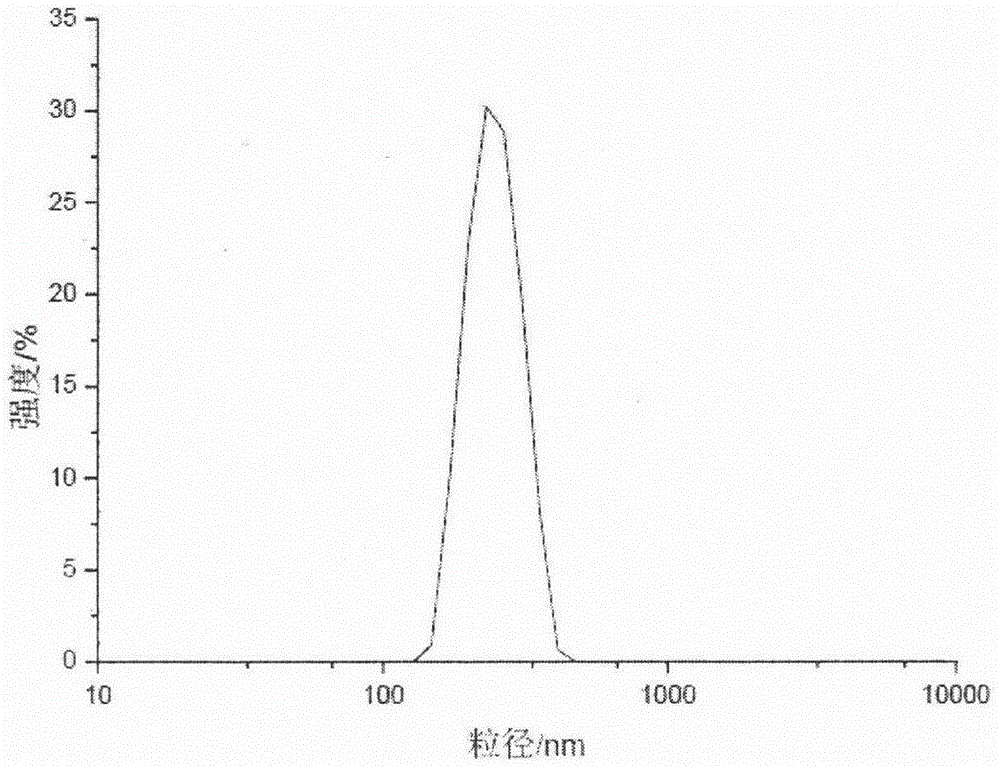

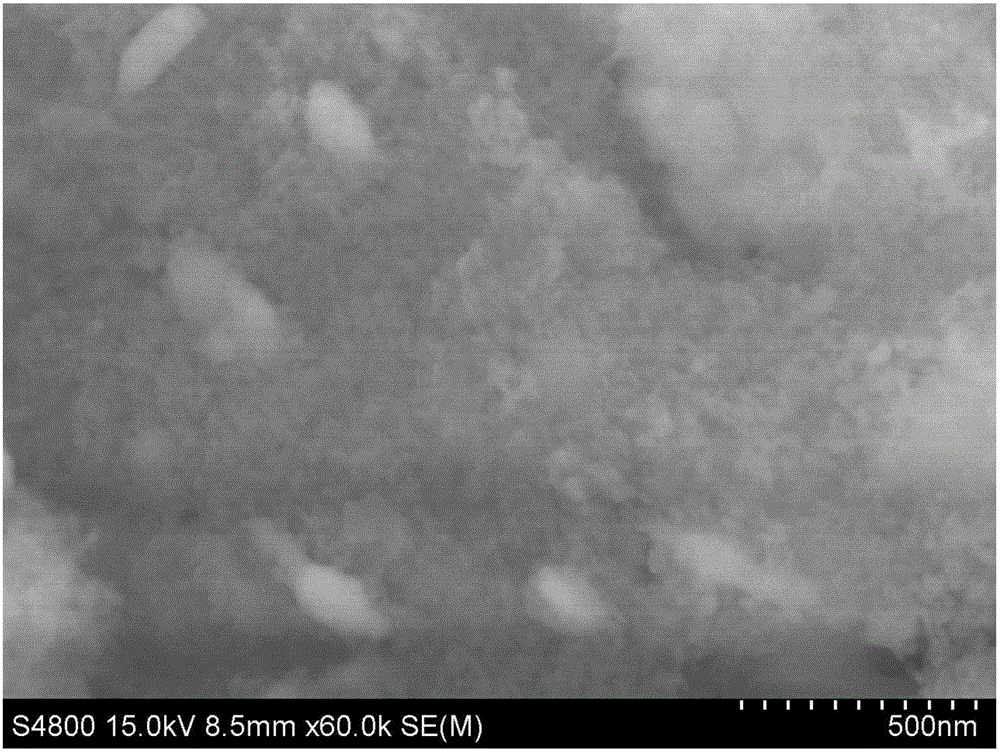

Method for preparing superparamagnetic Fe3O4 nano particle based on thermal decomposition of template

InactiveCN102001712AShape is easy to controlParticle size controllableFerroso-ferric oxidesInorganic ChemicalSuperparamagnetism

The invention relates to a method for preparing a superparamagnetic Fe3O4 nano particle based on the thermal decomposition of a template, belonging to the filed of preparation of an inorganic chemical material. The method comprises the following steps: preparing a sol soft template of which the surface contains -OH radicals by a liquid deposition reaction, using low-cost iron salt as raw materials, solidifying Fe<2+> ions in the liquid phase by means of the -OH radicals on the surface of the soft template, and performing a hydrothermal reaction at 150-2500 C for 5-15 hours to obtain a magnetic Fe3O4 nano particle having a regular appearance, a controllable particle diameter and monodispersity, wherein the particle can present superparamagnetism when the particle diameter is less than 50 nm. The synthesized magnetic nano material can be widely used in fields of biological separation, diathermic therapy on tumors, release of targeted drugs, magnetic suspensions, vacuum sealing, aerospace, sensors and the like.

Owner:SUZHOU KANG NAMI BIOLOGICAL ENG

Tin-based composite oxide material as well as preparation method and application thereof

InactiveCN102024948AUniform particle sizeGood lookingElectrode manufacturing processesCapacitor electrodesMicrosphereCrystallinity

The invention provides a tin-based composite oxide material comprising a tin-based composite oxide with a structure of porous micro balls, wherein the micro balls are formed by mutually connecting nanosheets as construction units; the diameters of the micro balls are 1-3mu m; the chemical formula of the tin-based composite oxide is SnPxOy; X is more than 1 and less than 1.5, and y is more than 3.5 and less than 4.5. The invention also provides a preparation method and application of the tin-based composite oxide material. The tin-based composite oxide has perfect structure, high crystallization degree and excellent electrochemical performance, is not easy to aggregate and can improve the circulating performance, high multiplying power discharge performance, safety performance and capacity of the battery. The preparation method is simple and easy to realize.

Owner:BYD CO LTD

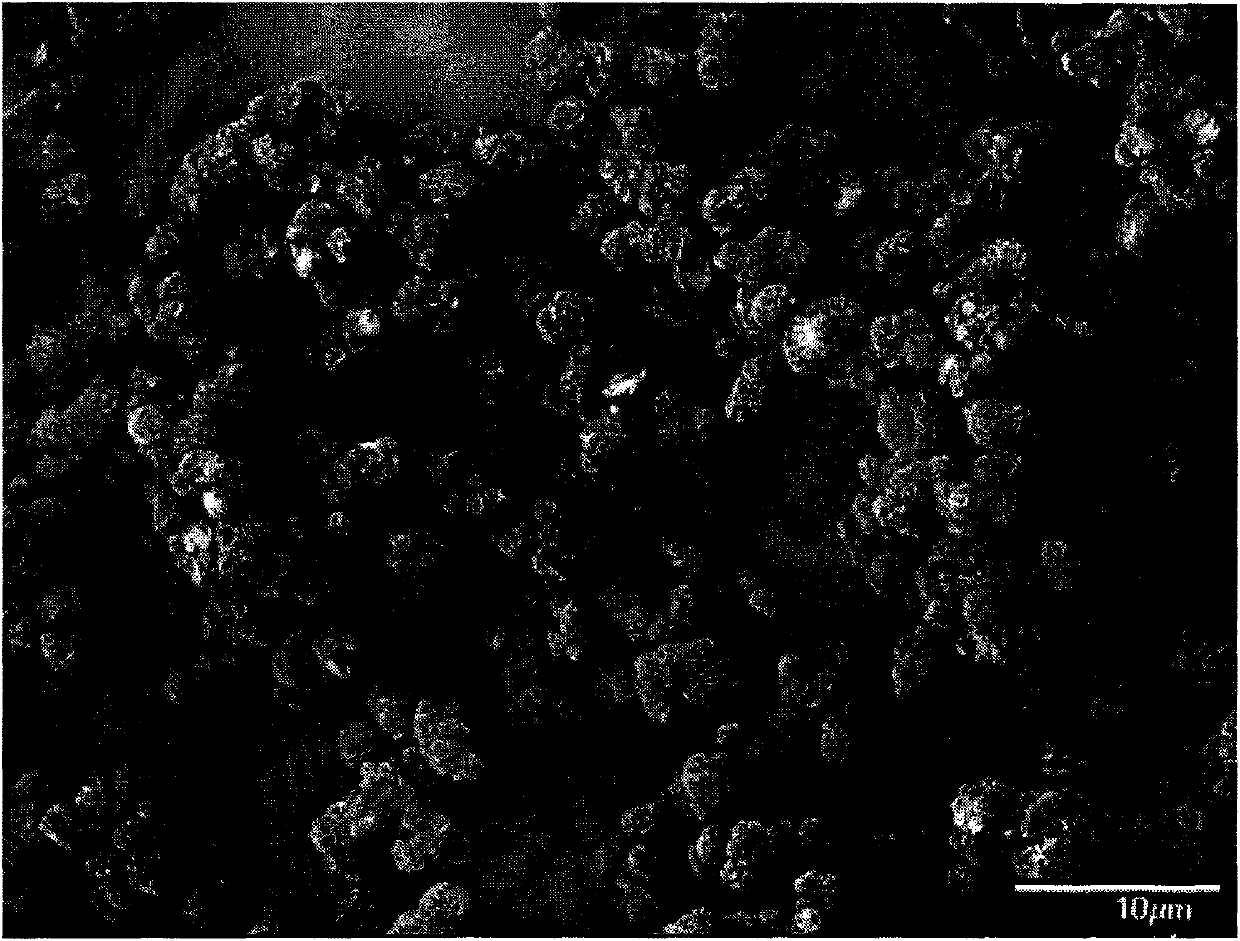

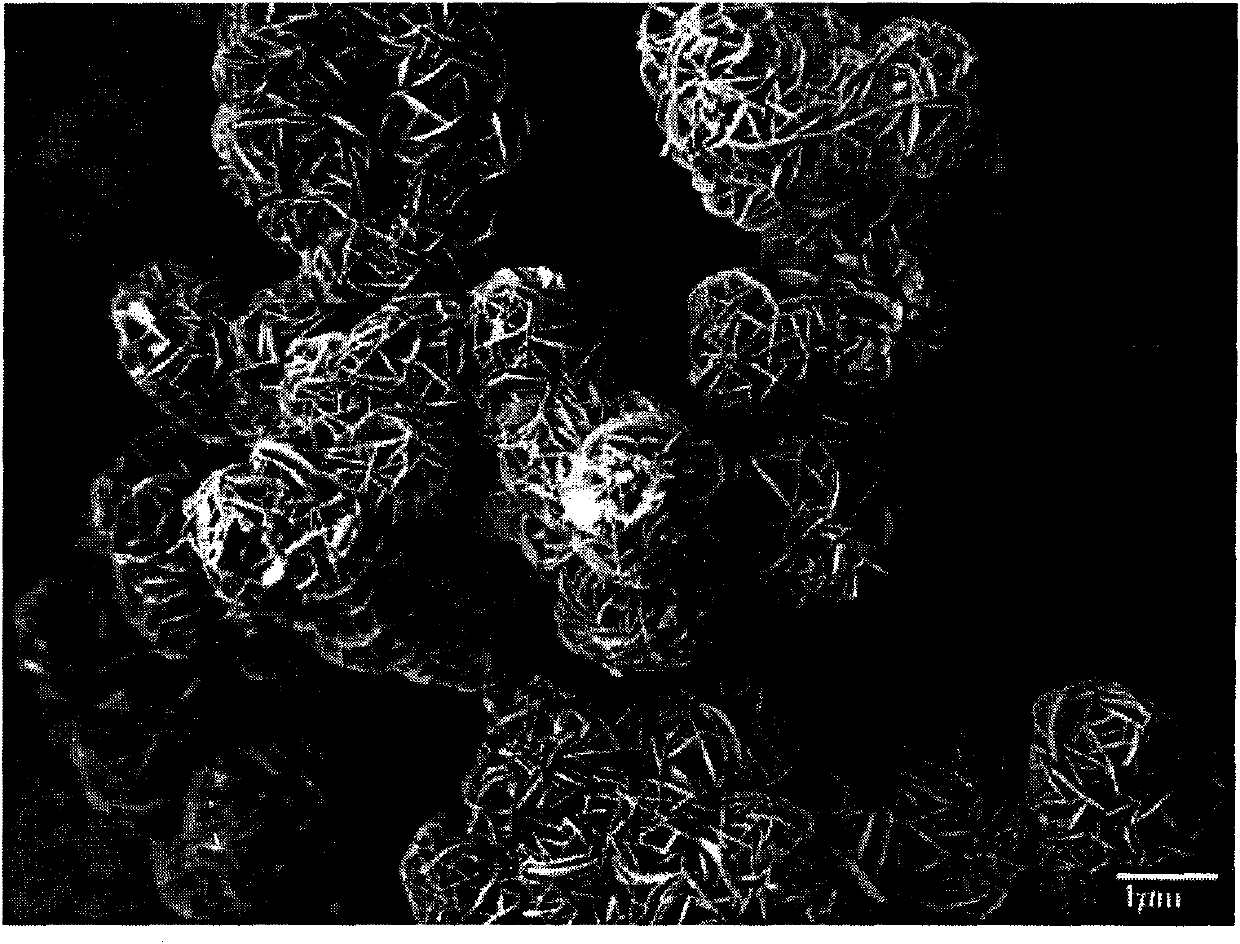

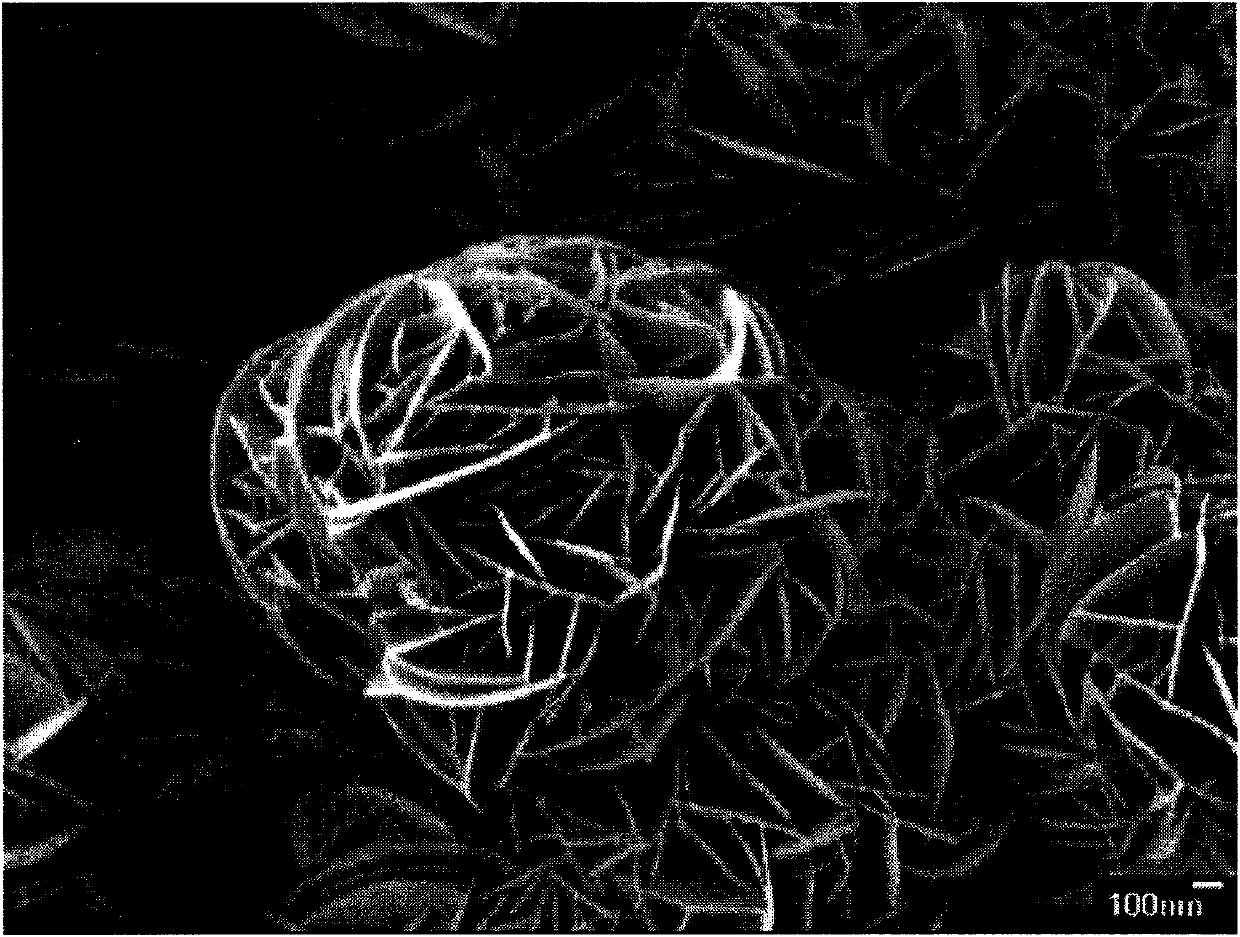

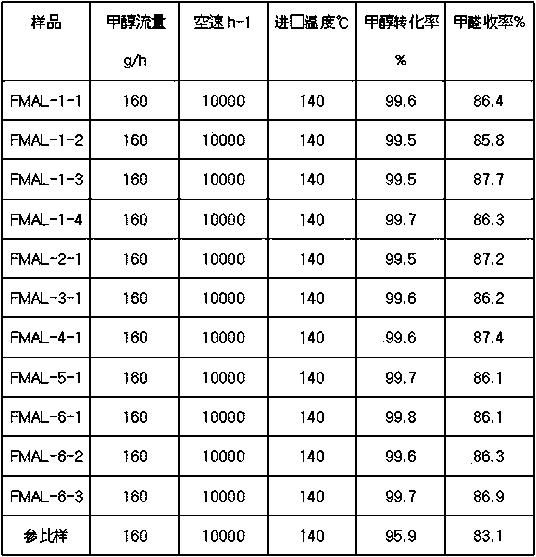

Preparation method for formaldehyde catalyst through adopting iron molybdenum method and methanol oxidation

PendingCN108816241AHigh activityHigh selectivityOrganic compound preparationCarbonyl compound preparationSlurryHigh activity

The invention relates to the technical field of manufacture of formaldehyde catalysts, and particularly to a preparation method for a formaldehyde catalyst through adopting an iron molybdenum method and methanol oxidation. The preparation method for the formaldehyde catalyst through adopting the iron molybdenum method and methanol oxidation includes the following steps: step I: slurry preparation;step II, filter cake preparation; step III, precursor preparation, step IV, smashing, step V, pressing and step VI, preparation of a finished product. According to the preparation method for the formaldehyde catalyst through adopting the iron molybdenum method and methanol oxidation, the hydro-thermal synthesis reaction is carried out at higher temperature and pressure, so as to obtain the precursor with uniform grain sizes and larger grain sizes, and the catalyst prepared through adopting the precursor can be used for methanol oxidation for preparation of the formaldehyde, and in the reaction, high activity and selectivity are obtained.

Owner:常州新日催化剂股份有限公司

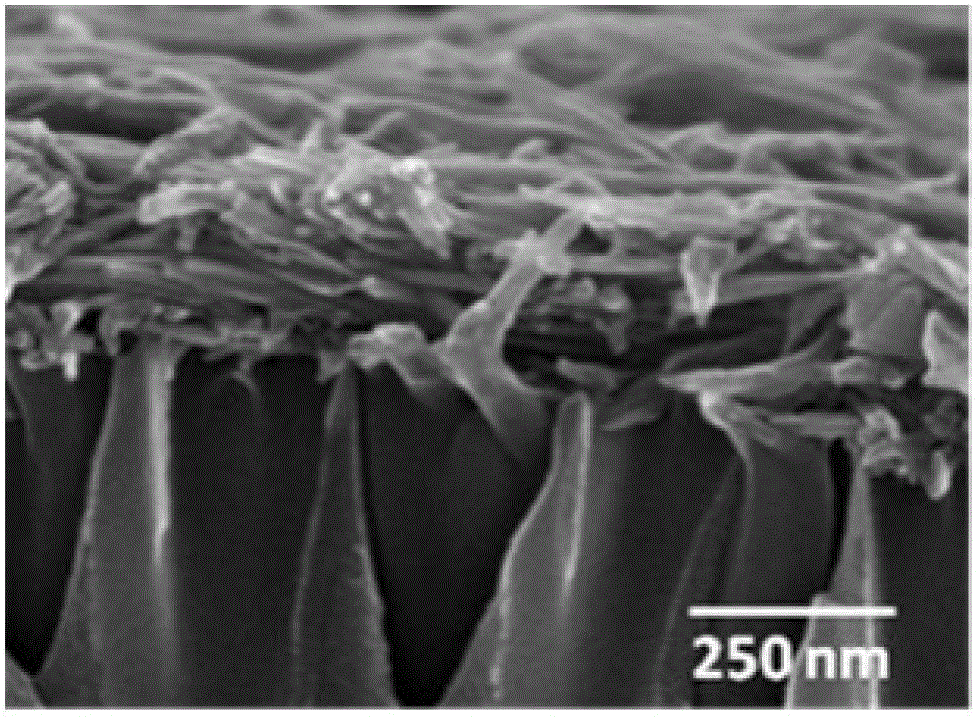

Preparation method of carbon nanotube dispersed in ionic liquid and application thereof

InactiveCN106495131AExcellent preparation performanceSimple processCarbon compoundsBulk chemical productionDispersityMultiwalled carbon

The invention relates to a preparation method for enhancing dispersity of multiwalled carbon nanotube in an ionic liquid and application thereof. The method for preparing uniformly dispersed multiwalled carbon nanotube suspension comprises the following steps: using a choline chloride-based ionic liquid as a solvent, mixing multiwalled carbon nanotube and the solvent in proportion, adding a small amount of an additive, heating and dissolving, and carrying out ultrasonic treatment. The invention aims to enhance dispersity of the multiwalled carbon nanotube in the choline chloride-based ionic liquid. The technology of the invention is simple and green and environment friendly. By the technology, the structure of the multiwalled carbon nanotube is basically not destroyed, and stability of the multiwalled carbon nanotube dispersion liquid is good. The invention is especially suitable for preparation a metal-based composite material from the multiwalled carbon nanotube and metal ion in the ionic liquid.

Owner:TIANJIN AGRICULTURE COLLEGE

Preparation method of waterborne epoxy resin-based asphalt heat-reflection heat-insulation weather-proof coating

InactiveCN110698951AReduce reunionImprove reflectivityAnti-corrosive paintsEpoxy resin coatingsZinc phosphateFirming agent

The invention discloses a preparation method of a waterborne epoxy resin-based asphalt heat-reflection heat-insulation weather-proof coating. The preparation method comprises the following steps: adding water, a substrate wetting agent, a defoaming agent, an anti-flash-rust agent and a coalescing agent into a paint mixing tank and carrying out dispersing; adding waterborne bisphenol A epoxy resinand performing dispersing; adding a pH regulator to regulate a pH value and carrying out dispersing; adding anionic emulsified asphalt and carrying out dispersing; adding an inorganic bentonite thickener to regulate viscosity; and carrying out dispersing to obtain a component A of the coating; adding water, a defoaming agent, a dispersing agent and an anti-settling agent into another paint mixingtank and carrying out dispersing; adding dry-process modified sericite powder and zinc phosphate, and carrying out sanding and dispersing; adding a waterborne modified amine curing agent and carryingout dispersing to obtain a component B; and mixing inorganically coated rutile titanium dioxide, precipitated phase silicon dioxide, hollow microspheres, a dispersing agent, a waterborne epoxy curingagent and a waterborne epoxy emulsion, carrying out grinding and dispersing, and mixing the formed mixture with the component A of the coating, the component B and chemically surface-modified shell powder to obtain the waterborne coating.

Owner:萧县金虹新型防水建材有限公司

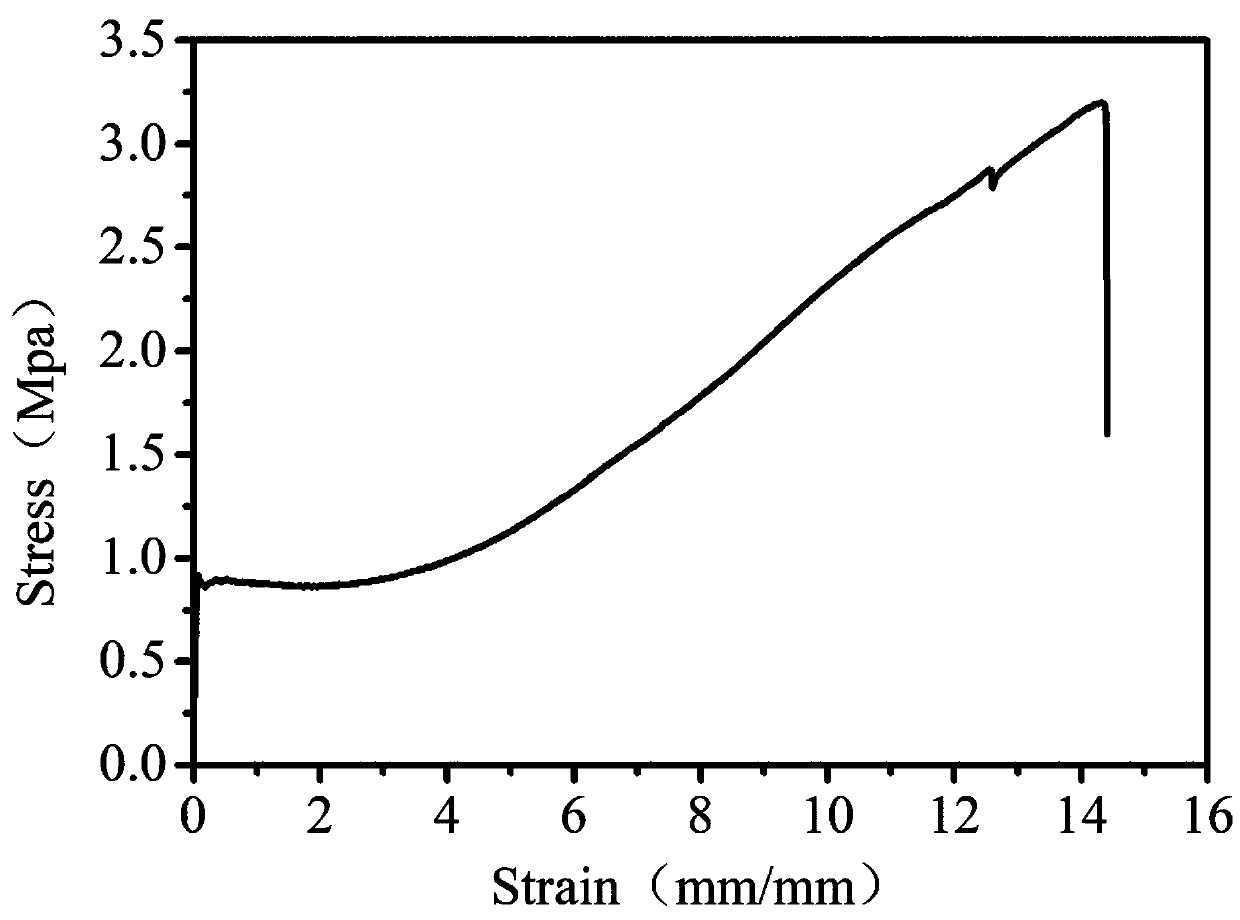

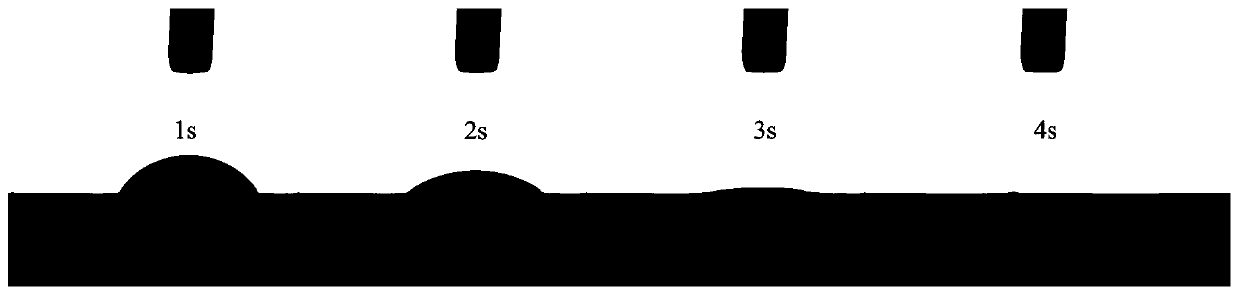

Self-healing solid electrolyte film as well as preparation method and application thereof

ActiveCN111574734AImprove conductivityImprove tensile propertiesForce measurement using piezo-resistive materialsMaterial impedanceSolid state electrolytePolymer science

The invention relates to a self-healing solid electrolyte film. The self-healing solid electrolyte film is prepared from the following raw materials: a monomer, a cross-linking agent, an initiator andan electrolyte salt; the molar ratio of the cross-linking agent to the monomer is 0.1%, the molar ratio of the initiator to the monomer is 1%, and the concentration of the electrolyte salt in a mixedsolution of all the raw materials is 0.1 mol / L-0. 9 mol / L. The preparation method of the film comprises the following steps: (1), measuring a monomer, respectively adding a cross-linking agent, an initiator and an electrolyte salt, and performing stirring to fully dissolve the materials to obtain a transparent solution; and (2), putting the solution obtained in the (1) into a sheet-shaped mold, and performing irradiating under ultraviolet light to crosslink and solidify the monomer in the sheet-shaped mold, thereby obtaining a self-healing solid electrolyte film. The high-tensile and self-healing solid electrolyte film is good in preparation performance and simple in process, and has the broad application prospects in the field of flexible stretchable electronic devices.

Owner:NANJING UNIV OF POSTS & TELECOMM

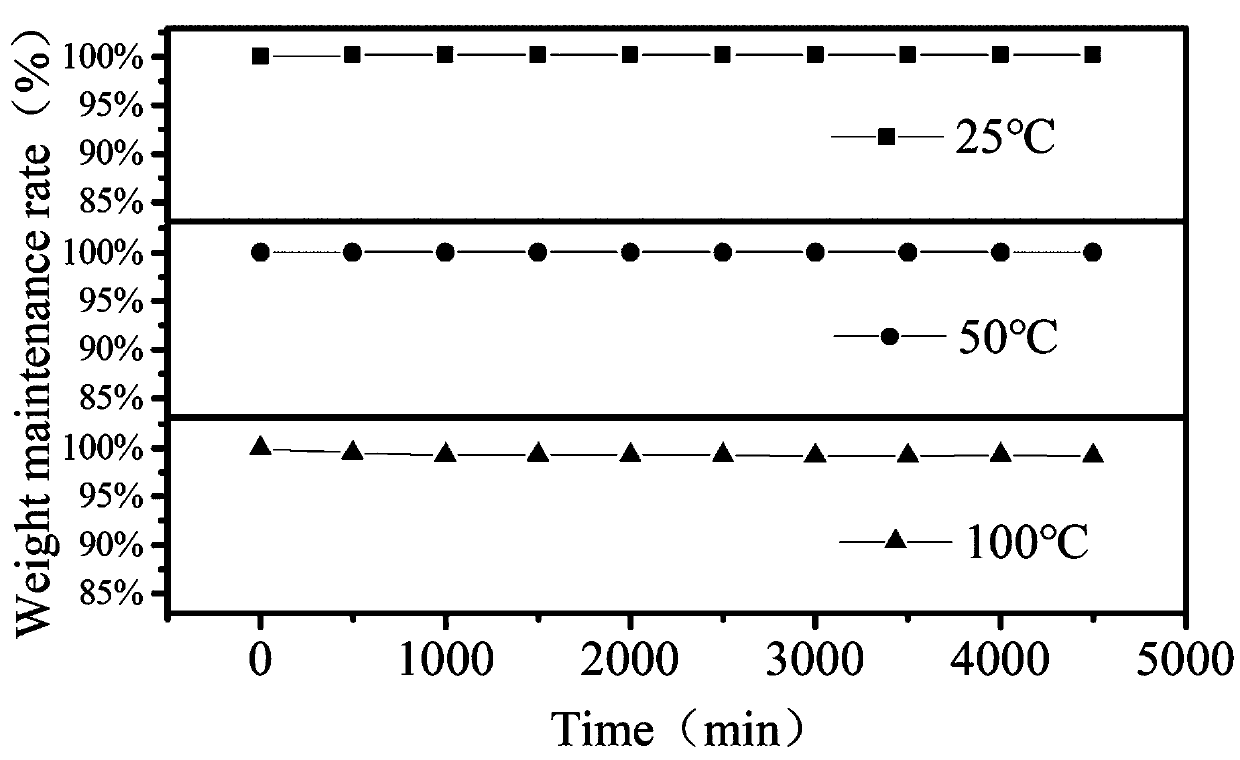

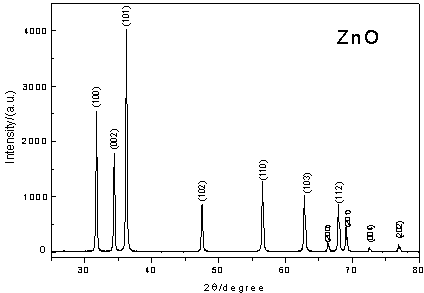

Method for preparing monodisperse spherical nano ZnO

InactiveCN103482681AThe materials are cheap and easy to getNo need for calcinationMaterial nanotechnologyZinc oxides/hydroxidesWater bathsDispersity

The invention belongs to the field of semiconductor inorganic materials, and particularly relates to a method for preparing monodisperse spherical nano ZnO. The method particularly comprises the following steps: weighing and dissolving PEG-6000 in distilled water, adding 0.75g of PEG-6000 per 1 ml of distilled water, heating and stirring to enable the PEG-6000 to be completely dissolved; mixing the PEG-6000 solution with 0.4 M of a zinc salt solution, heating in water bath at the temperature of 95 DEG C, and stirring at the same time so as to enable the solutions to be fully mixed; weighing 4 M of a NaOH aqueous solution, adding the aqueous solution into the mixed solution quickly, stirring fiercely at the same time, performing constant temperature bath at the temperature of 95 DEG C, and continuously stirring for 2-4 hours; cooling the mixture to the indoor temperature after completion of reaction, filtering, washing by adopting ethyl alcohol and distilled water, and placing the obtained mixture into a drying oven for drying so as to obtain white ZnO powder. The method has the advantages that the zinc salt, NaOH and the PEG-6000 are used as the raw materials, a one-step method is adopted to prepare spherical nano ZnO with the particle diameter of 30 nanometers, the ZnO is good in dispersity and narrow in particle size distribution, and the method has the excellent prospect for preparing ZnO voltage-dependent functional materials.

Owner:CHANGZHOU UNIV

Rare earth cerium-added high-strength dispersion-strengthened copper, and preparation method thereof

The present invention provides rare earth cerium-added high-strength dispersion-strengthened copper, and a preparation method thereof. The method comprises the following specific steps: mixing rare earth cerium and nano Al2O3 according to a ratio, and grinding the mixture with copper powder in a planetary ball mill to obtain mixed powder with uniform components; performing high-temperature sintering on the mixed powder to obtain a high-temperature sintering blank, performing hot processing and quenching on the high-temperature sintering blank to obtain a tubular bar blank, and performing cold deformation or thermal deformation on the tubular bar blank to obtain the dispersion-strengthened copper of a finished product tubular bar. In the present invention, a new element, the rare earth cerium, is added to form a new phase. The dispersion-strengthened copper comprises following components in percentage by mass (wt.%): 98.20-99.0% of copper, 0.5-0.9% of nano Al2O3, 0.5-0.9% of cerium, and the balance of impurity elements. In the present invention, a new element, rare earth cerium, is added, so that the strength and the hydrochloric acid corrosivity resistance can be obviously improved. Compared with a material prepared by using a conventional method, for the copper disclosed by the present invention, the extension strength is improved by 24.03%, and the electric conductivity is reduced only by 7.38%. Compared with powder at other mixed ratios, the copper disclosed by the present invention has the most strength.

Owner:付亚波

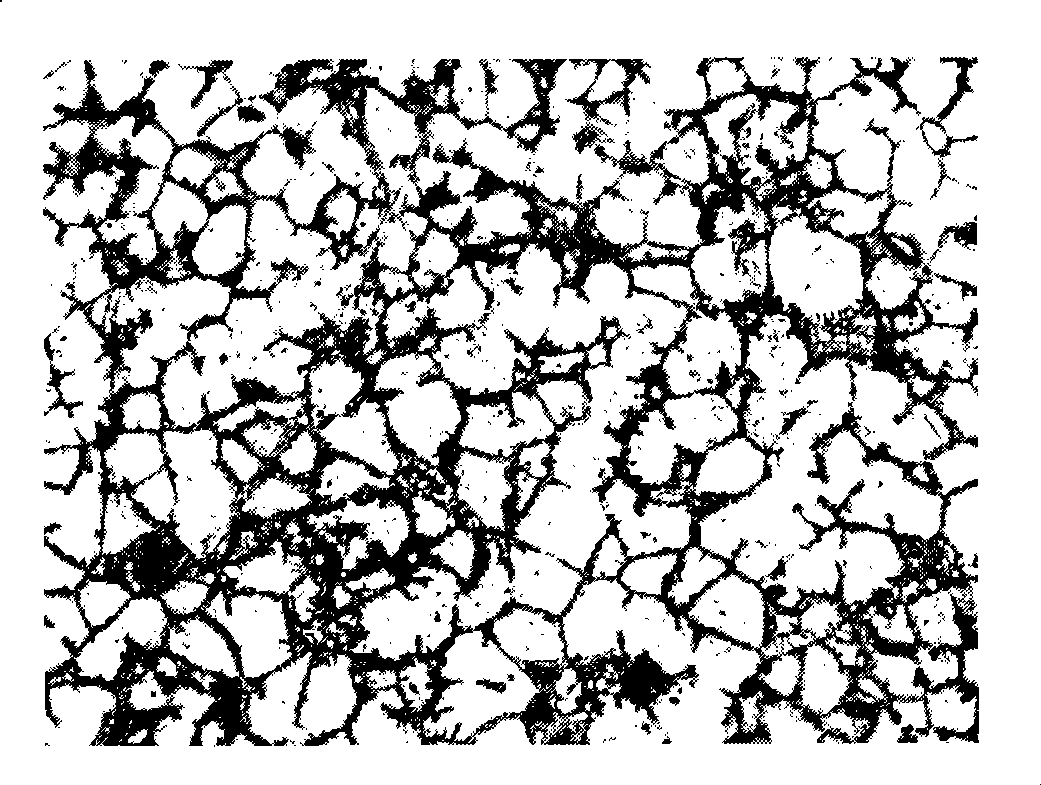

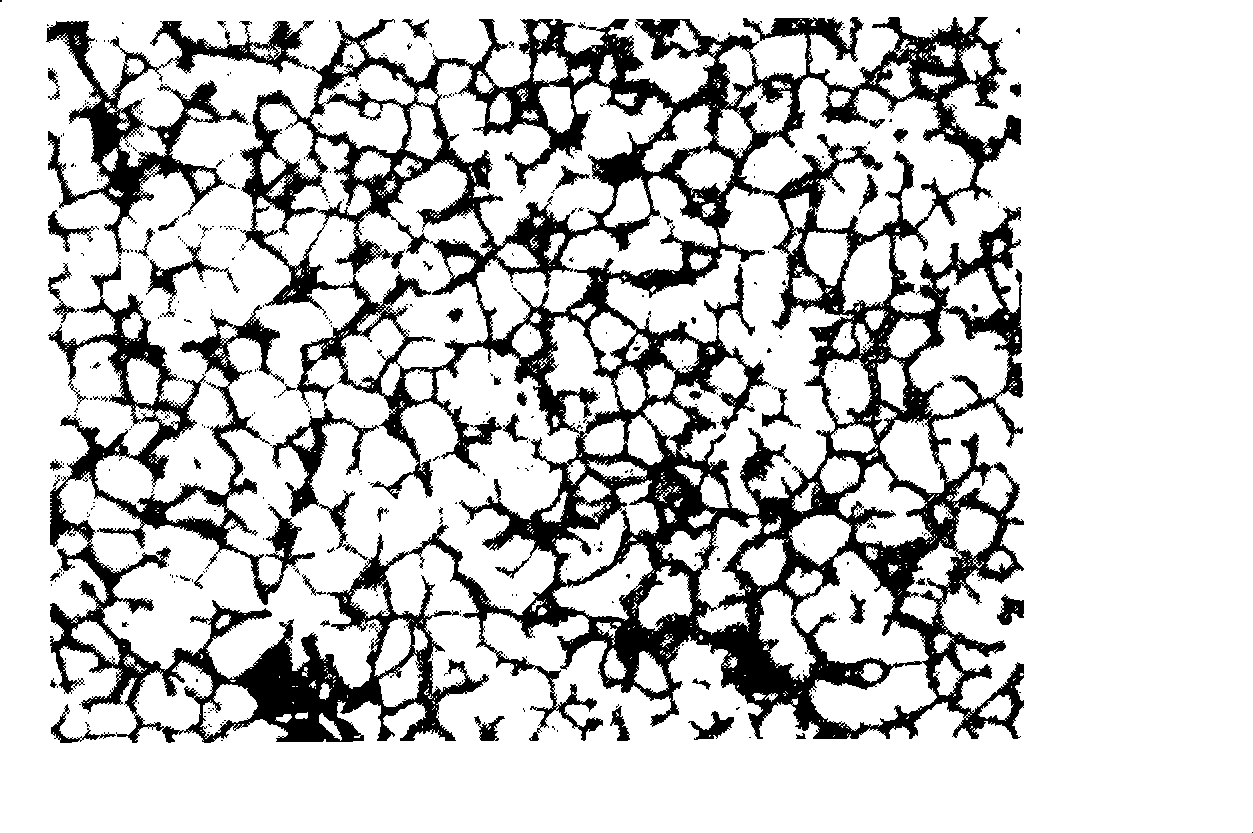

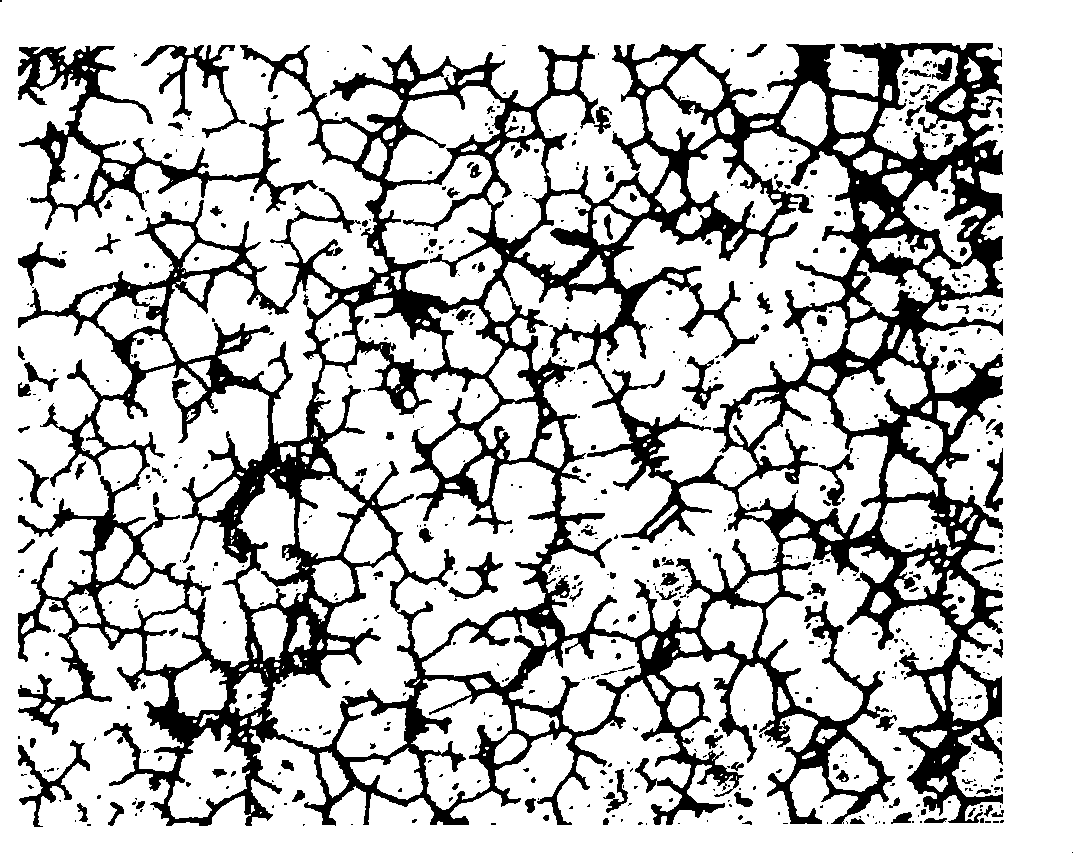

Rotary pouring manufacture method of AZ91D magnesium alloy semisolid slurry

The invention relates to a method for preparing AZ91D magnesium alloy semi-solid sizing agent by rotating pouring, which is characterized in that AZ91D magnesium alloy is melted and refined in a smelting maintaining furnace, then cooled to 630-650 DEG C, and insulated for 10-30 minutes; a stainless steel rotating pouring tube is preheated to 60-80 DEG C, with the rotating speed of the pouring tube controlled at 0-105r / min, and the inclination of the rotating pouring tube being 20-30 degrees; then the AZ91D magnesium alloy melt is poured into the rotating tube through a deflection tube; a crystallizer is preheated to 470-500 DEG C; the AZ91D magnesium alloy melt enters the crystallizer through the rotating pouring tube, and insulated for 5-15 minutes. The method for preparing the AZ91D magnesium alloy semi-solid sizing agent by rotating pouring has a simple device, low cost, convenient operation, high practicality; the prepared AZ91D magnesium alloy semi-solid sizing agent has fine grain organization and even distribution; in addition, the process flow is short, the energy consumption is low, the efficiency is high, the equipment is simple, the structure is compact, the applicability is high, and the method is especially applicable to small and medium-sized enterprises of China.

Owner:NANCHANG UNIV

Method for preparing hollow fiber nanofiltration membrane by using thermally induced phase separation/interface cross linking synchronization method

InactiveCN102824859BThickness is easy to controlAvoid the difficulty of high adhesiveness requirementsSemi-permeable membranesHollow filament manufactureFiberNitrogen

The invention discloses a method for preparing a hollow fiber nanofiltration membrane by using a thermally induced phase separation / interface cross linking synchronization method; the preparation method comprises the following steps: 1) mixing polymer, a diluting agent and a cross linking agent to form a homogeneous phase membrane casting solution; 2) extruding the membrane casting solution and core solution, or the membrane casting solution and nitrogen by a ring-shaped spinning head, then conducting the thermally induced phase separation in a cooling bath so as to obtain a hollow primary membrane; 3) soaking the hollow primary membrane in extracting solution containing cross linking pre-polymer, conducting the interface cross linking at the same time with removing diluting agent, thereby obtaining a hollow fiber nanofiltration membrane. According to the method provided by the invention, the preparations of holing and separation layer is finished, and the difficulty point of high require of bonding property between a separation layer and a supporting layer of a combining method in the prior art can be avoided, and meanwhile the thickness and the evenness of the separation layer are easy to control; the simple new method for preparing the hollow fiber nanofiltration membrane with excellent property by using the thermally induced phase separation / interface cross linking synchronization method is provided; and the prepared nanofiltration membrane is little in defect, high in stability and high in controllability.

Owner:ZHEJIANG UNIV

High-stability neutral ink

In order to solve the stability problem of the existing neutral ink, the invention discloses high-stability neutral ink. The high-stability neutral ink comprises the following components in percentage by weight: 0.1%-0.2% of nonylphenol polyoxyethylene ether, 0.0.3%-0.05% of fluorocarbon surfactant, 50%-70% of mill base with 4%-6% of water-soluble pigment, 10%-15% of thickening agent, 5%-20% of moisture-retention lubricant and 0.05%-0.1% of antiseptic antimildew agent. According to the high-stability neutral ink, a plurality of surfactants are used in a matched manner, so that the proportion of materials is optimized, and therefore, the prepared neutral ink is high in stability and capable of greatly improving the writing performance.

Owner:李莉

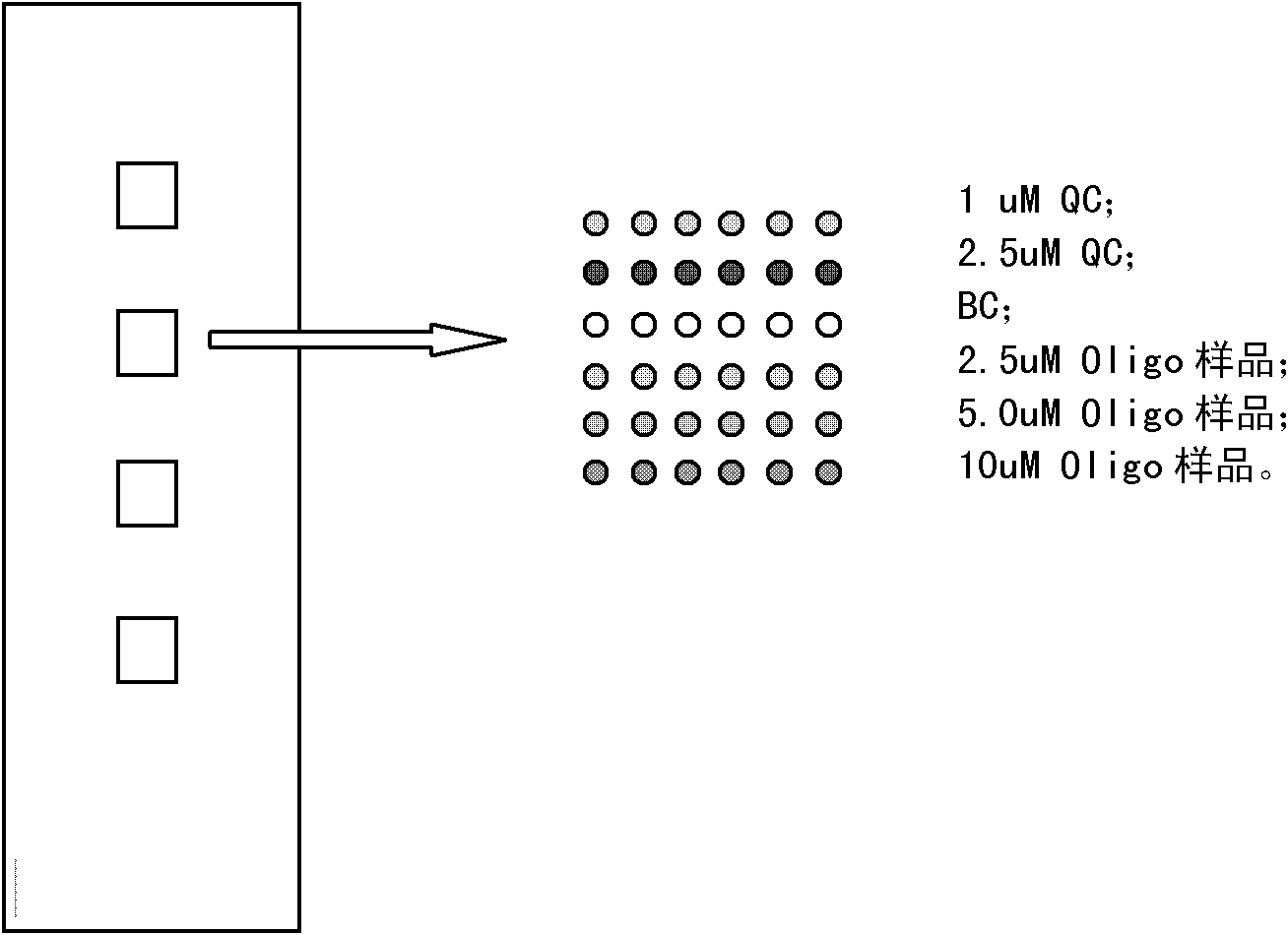

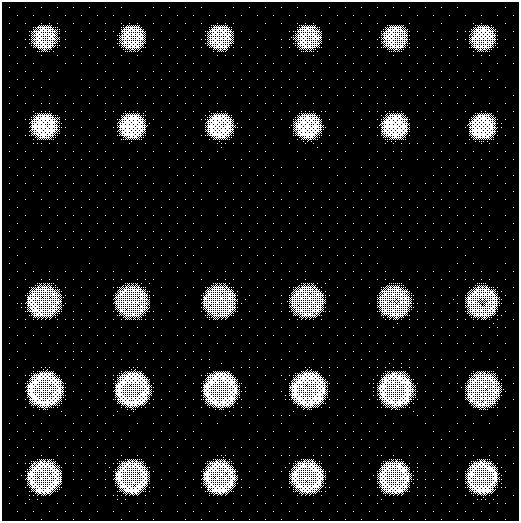

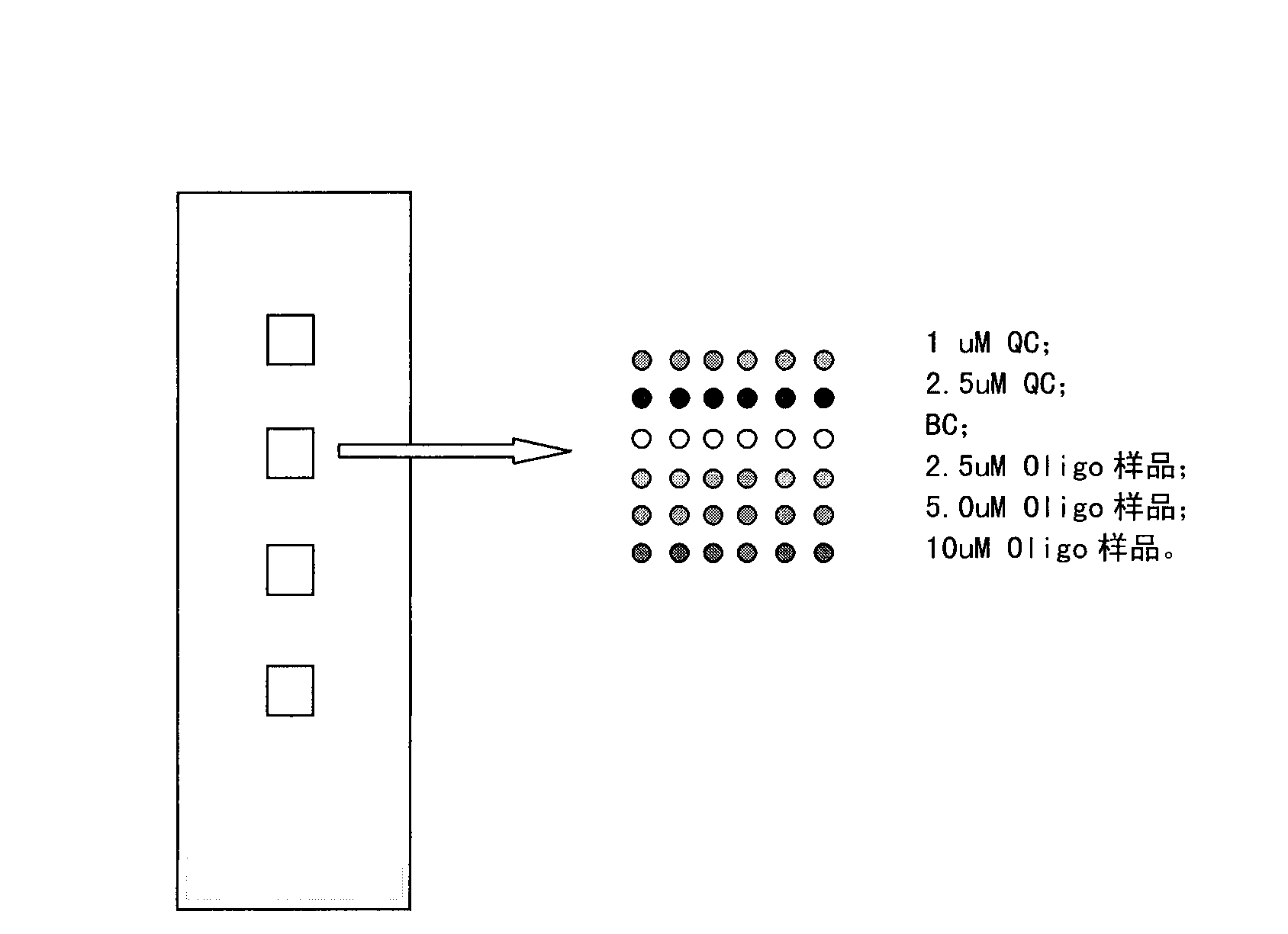

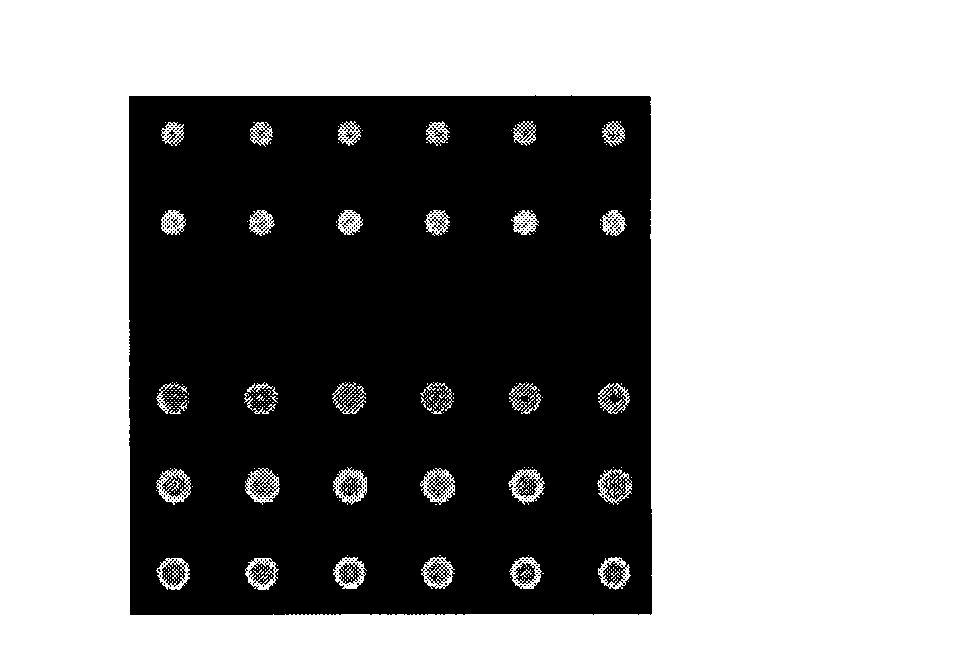

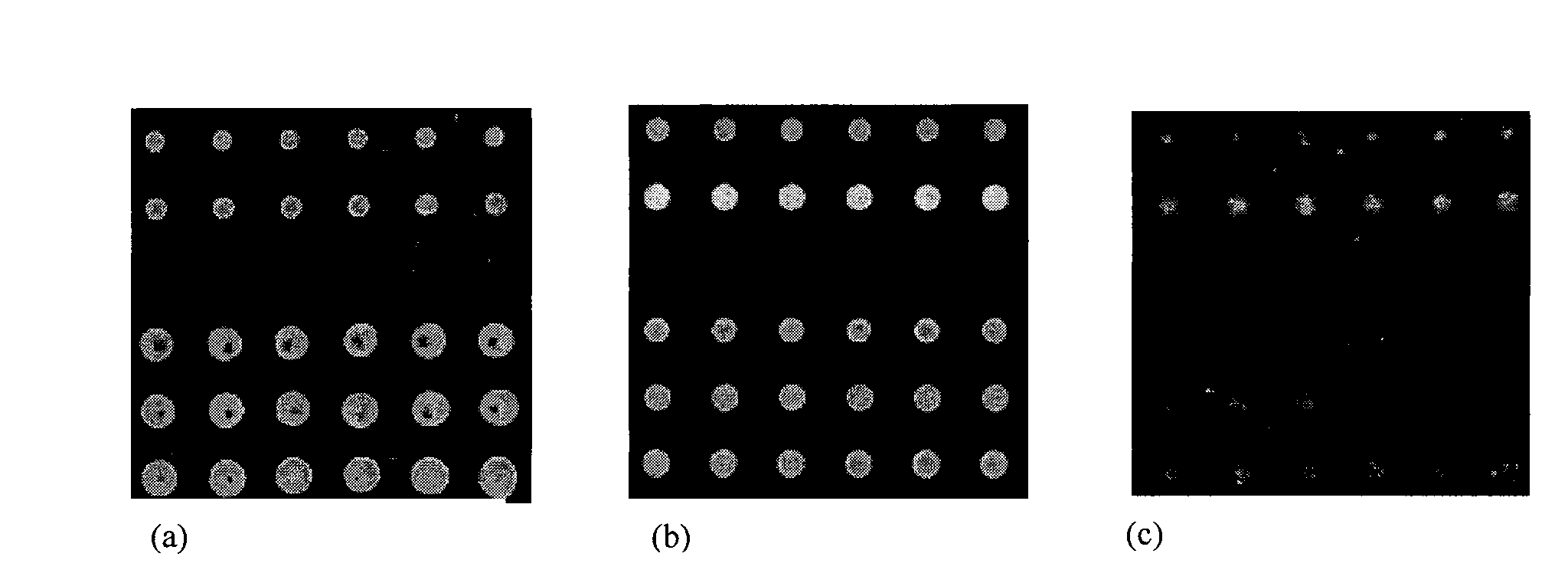

A kind of amino plastic substrate and its preparation method and application

ActiveCN102276863AImprove stabilityImprove plasticityMicrobiological testing/measurementMicro structurePlastic materials

The invention discloses an amino plastic substrate and a preparation method and application thereof. The preparation method of a biochip substrate comprises the following step of: connecting an amino group to the surface of a plastic substrate to obtain the substrate with the amino group connected to the surface. Experiments prove that the preparation of a biochip with excellent performance on a plastic material is achieved through the preparation method disclosed by the invention. Because the plastic has strong plasticity and can be conveniently molded, processed and designed into various micro-structures and functional units, the plastic can be applied to microfluidic chips and other biochip fields.

Owner:CAPITALBIO CORP +1

A kind of three-component composite fiber with high resistance to pilling and high wear resistance and preparation method thereof

ActiveCN105908268BSimple processExcellent preparation performanceFilament forming substance formingFilament/thread formingFiberSOCKS

The invention relates to a preparation method of a three-component composite fiber with high fuzzing and pilling resistance and high wear resistance. The method comprises the following steps: drying a slice A, a slice B and a slice C; correspondingly feeding the slices into corresponding screw extruders to smelt and extrude; then transferring into a spinning box body to spin through a spinning assembly; feeding melts of the slice A, the slice B and the slice C into corresponding spinning micropores; forming a smelt on the surface of a spinning plate in a smelt form; slowly cooling and coating with oil to obtain the three-component composite fiber. According to the method, a melt distributing plate is designed in an asymmetric melt running channel form; the spinning micropores in the spinning plate are three-leaf shaped; the micropore corresponding to each component is different in length to diameter ratio; a multi-oiling device is adopted for coating the oil; the fuzzing and pilling resistance level of a fabric prepared through the fiber is up to 5 level, and the wear resistance reaches more than two hundred thousand times; the fabric prepared through the fiber can be widely applied to the fields of middle-level and high-level one-piece trousers, one-piece socks, underwear, sports and leisure fabrics, fitness clothing, school uniforms, battle dress uniforms and training uniforms of army and armed police.

Owner:苏州泰森高分子材料有限公司

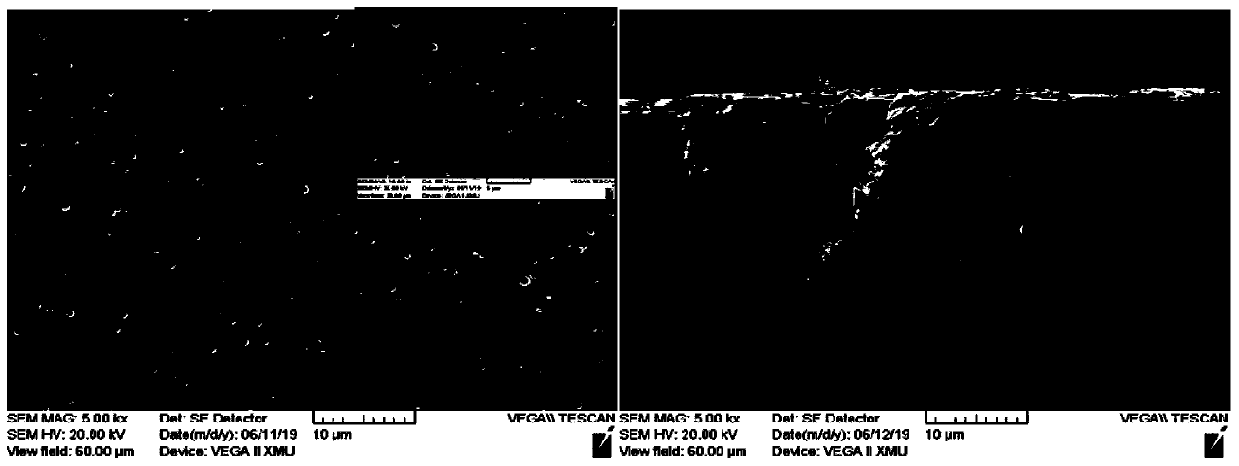

Method for preparing super-hydrophilic PVDF ultrafiltration membrane through one-pot process

InactiveCN110975650AImprove hydrophilicityImprove wettabilityMembranesUltrafiltrationHydrophilic monomerLithium chloride

The invention discloses a method for preparing a super-hydrophilic PVDF ultrafiltration membrane through a one-pot process. The method comprises the following steps: mixing and dissolving 3%-9% of hydrophilic monomer acrylic acid, 10%-14% of alkalized polyvinylidene fluoride, 2%-8% of a high-molecular compatibilizer, 1%-5% of anhydrous lithium chloride and 68%-80% of an organic solvent, adding 1%of an initiator, carrying out heating for polymerization, standing and defoaming to prepare a grafting reaction mixed solution; preparing a polymer solution film with a certain thickness from the mixed solution; and performing pre-evaporation at room temperature, carrying out phase splitting treatment in a coagulating bath so as to obtain the super-hydrophilic PVDF ultrafiltration membrane prepared through the one-pot process. The super-hydrophilic PVDF ultrafiltration membrane has higher hydrophilicity and stronger anti-pollution performance, can be applied to industrial application of separation of water bodies with high contents of hydrophobic pollutants such as oil-water mixtures and secondary effluent of domestic sewage, and is a scientific and efficient super-hydrophilic PVDF ultrafiltration membrane production technology.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

Amino plastic substrate, and preparation method and application thereof

ActiveCN101633742AImprove stabilityImprove plasticityMicrobiological testing/measurementMicro structurePlastic materials

The invention discloses an amino plastic substrate, and a preparation method and application thereof. The preparation method of a biochip substrate comprises the following steps: connecting an amino group with the surface of the plastic substrate and obtaining the substrate. The surface of the substrate is connected with the amino group. Proved by tests, a biochip with excellent performance is prepared on plastic material by the preparation method. The plastic material has strong plasticity and convenient forming, and processing and various micro-structures and functional units can be designed; therefore, the preparation method can be applied to the field of the biochip, such as micro-fluidic control, and the like.

Owner:CAPITALBIO CORP +1

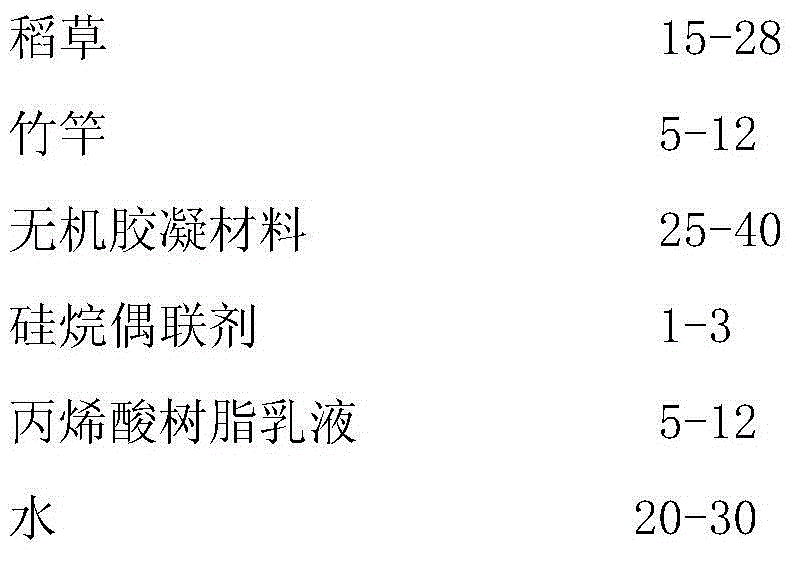

Method for preparing building insulation material employing straws and bamboo poles

InactiveCN104671724AGood low thermal conductivityGood thermal conductivitySolid waste managementIsolation effectAcrylic resin

The invention discloses a method for preparing a building insulation material employing straws and bamboo poles, and belongs to the field of building insulation materials. The agricultural wastes straws and bamboo poles are utilized to the maximal extent; and the building insulation material has heat preservation and insulation properties, fireproof and flame-retardant properties and antiseptic and mildew-proof effects, and can be applied to the requirements of urbanization and new rural construction. The mechanical strength is improved by virtue of the bamboo poles; the breaking strength is improved; in addition, the heat conductivity coefficient can be effectively reduced; the bamboo is a hollow material has relatively small heat conductivity coefficient, and the straws and the bamboo poles are compounded together, so that the heat conductivity coefficient of a building material product is reduced. The problems of interface characteristics, corrosion prevention and water absorption of the straws and the bamboo poles are solved by a silane coupling agent and an acrylic resin emulsion; and an inorganic cementing material and the combining capacity thereof are improved by the coated isolation effect. Through technological innovation and innovation of a preparation method, the straw-bamboo pole-inorganic composite building insulation material with excellent performance is prepared; the volume usage of the straws in the building material can reach 50%-80%; and full utilization of the straws is realized.

Owner:SHENYANG JIANZHU UNIVERSITY +1

Flexible asymmetric supercapacitor based on mno2 and fe2o3 nanostructures and its preparation method and application

ActiveCN103366970BReduce complexityExcellent preparation performanceHybrid capacitor electrodesNanowireNon symmetric

The invention belongs to the field of super-capacitor design, and discloses a MnO2 and Fe2O3 nanostructure-based flexible asymmetric super-capacitor and a preparation method as well as application thereof. The preparation method comprises the following steps: preparing a MnO2 nanowire positive electrode and a Fe2O3 nanotube negative electrode; and assembling the positive electrode, the negative electrode, electrolyte and a diaphragm into an asymmetric super-capacitor. According to the method, complexity for manufacturing the asymmetric super-capacitor is reduced, and energy density of the obtained super-capacitor reaches 0.47 mWh / cm<3>. The method is simple and practicable, MnO2 nanowires and Fe2O3 nanotubes can be grown on a large scale, and the asymmetric super-capacitor with superior performance is prepared.

Owner:JINAN UNIVERSITY

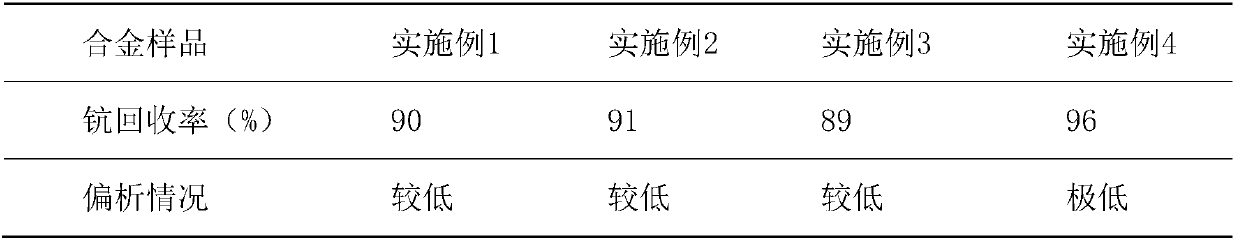

Aluminum-scandium intermediate alloy and preparation technology thereof

InactiveCN107587005AExcellent preparation performanceInhibition of segregationRoom temperatureEconomic benefits

The invention discloses an aluminum-scandium intermediate alloy, which comprises the following components in percentage by weight: 2.0 to 4.0% of Sc, not more than 0.05% of C, not more than 0.03% of Cu, not more than 0.08% of Fe, not more than 0.005% of Si, and the balance being Al. The invention also discloses a preparation method of the aluminum-scandium intermediate alloy. The preparation method comprises the following steps: preparing nano scandium powder with a diameter of 50-100 nm, high purity aluminum ingots, high purity aluminum foils, and high purity argon according to weight percentage; at first, adding high purity aluminum ingots into a graphite crucible, heating the graphite crucible to a temperature of 950 DEG C by a resistance furnace so as to melt aluminum ingots; tightly wrapping nano scandium powder by high purity aluminum foils, then pressing aluminum foils into liquid aluminum melt, keeping the aluminum foils in the aluminum melt for 10 minutes; uniformly stirring the melt for 5 to 10 minutes by an electromagnetic stirring technology so as to evenly distribute scandium; pouring qualified aluminum-scandium alloy melt into a preheated water-cooling iron mould, carrying out casting at a temperature of 800 DEG C, and cooling to the room temperature after casting. The preparation method has the advantages that segregation is overcome, the scandium loss is little,the recovery rate is high, compared with a conventional doping method, the cost is lower, and the economic benefit is good.

Owner:深圳市中金环保科技有限公司

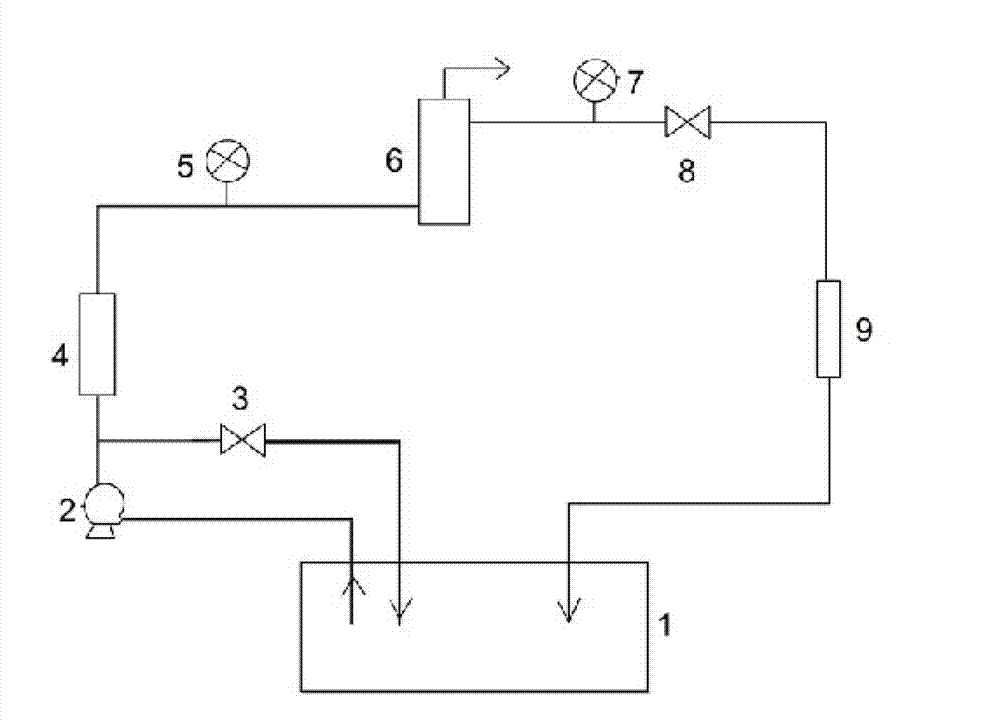

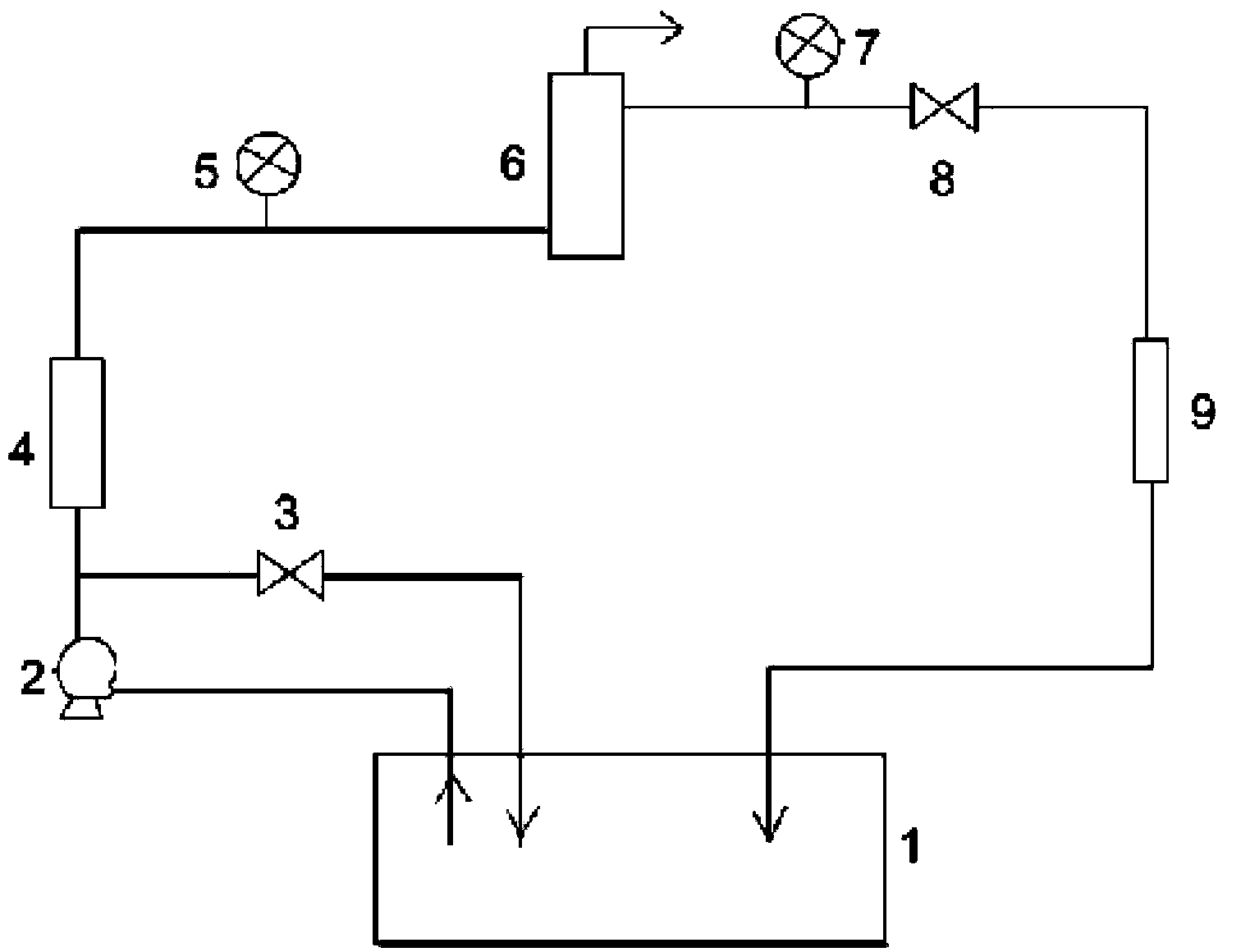

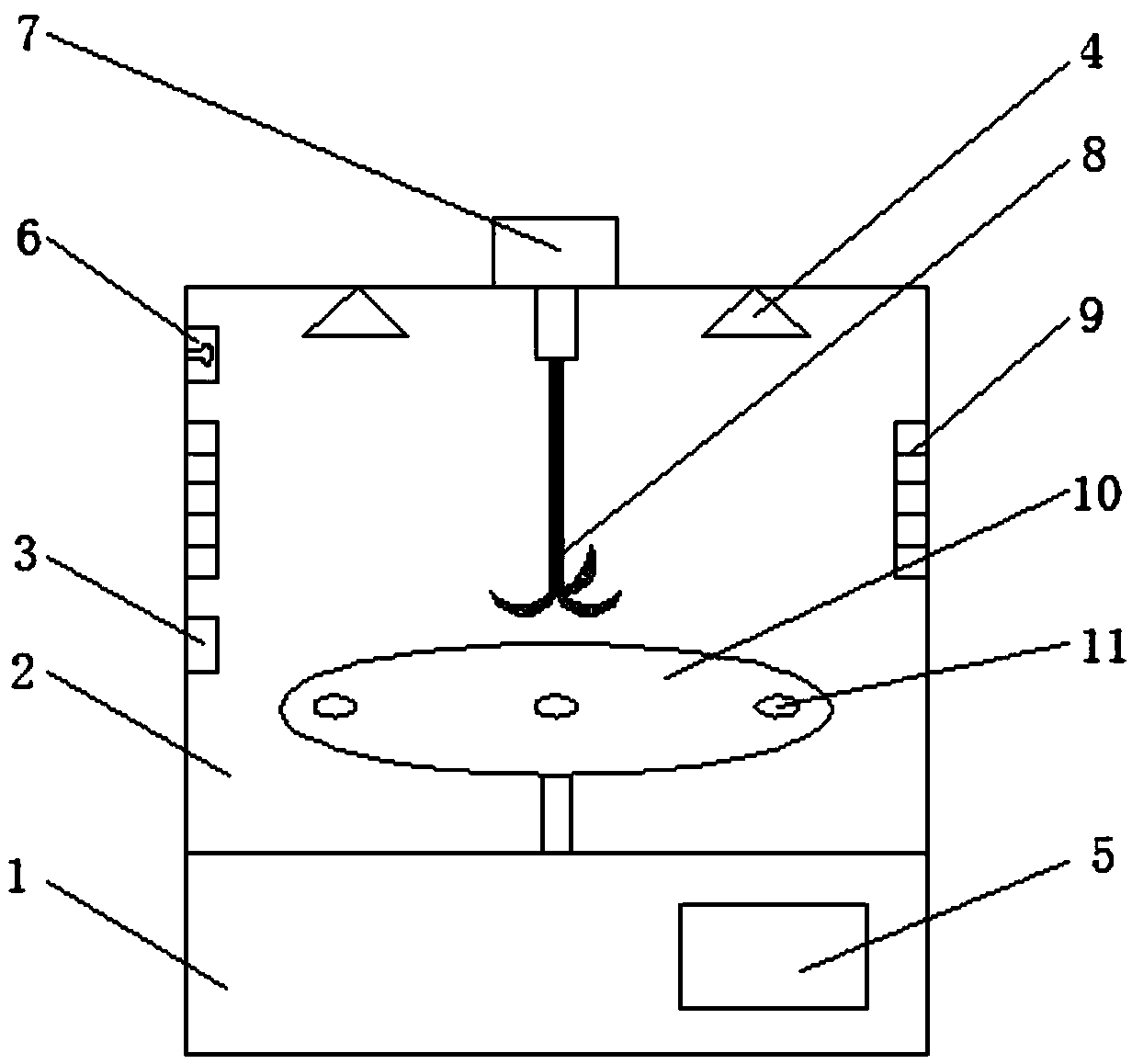

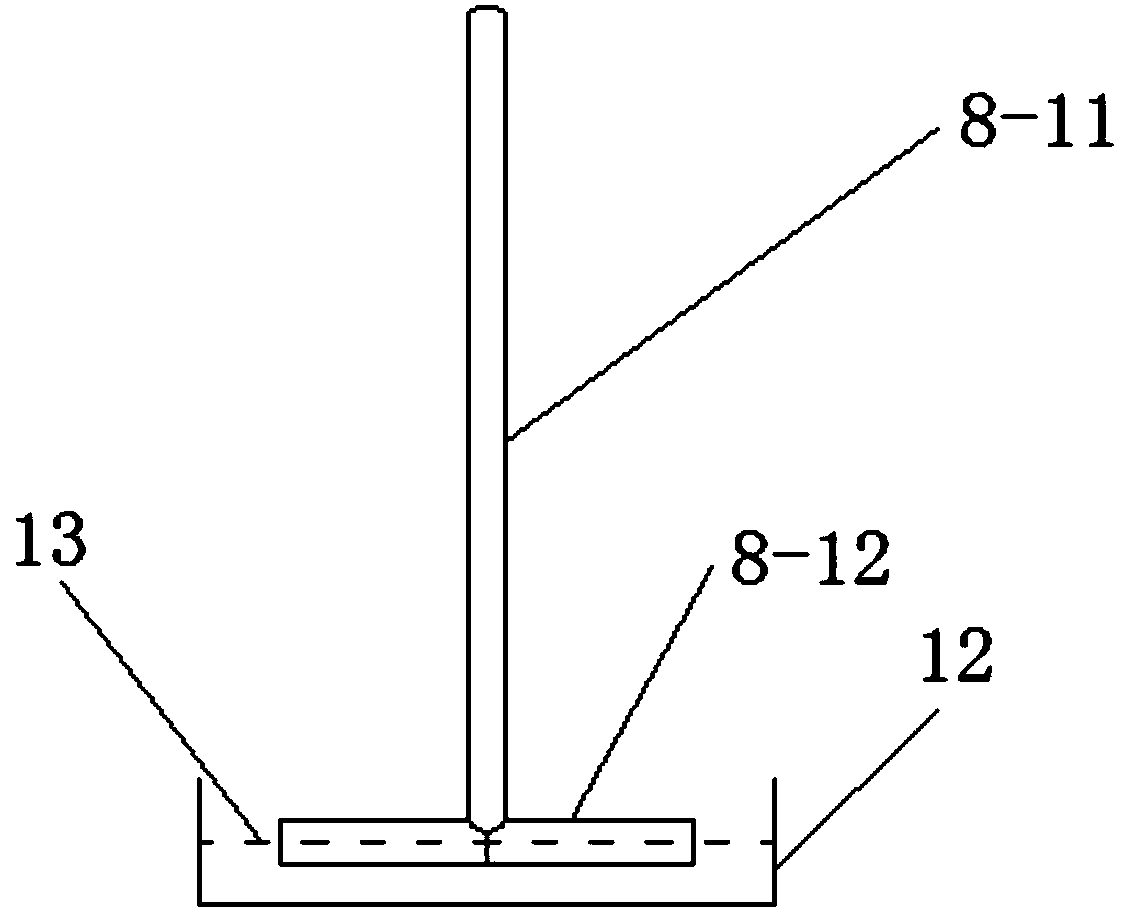

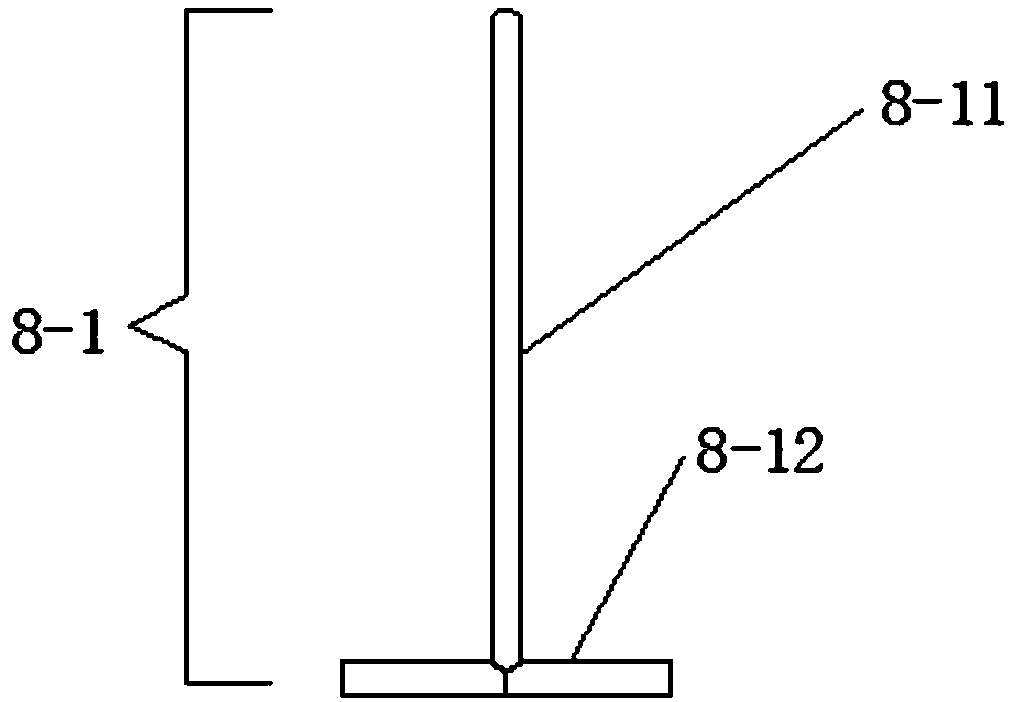

Multifunctional testing device and method for asphalt stirring, preparation and microwave aging

InactiveCN108918242APrecise temperature controlPrecise control of microwave radiation intensityWeather/light/corrosion resistancePreparing sample for investigationTemperature controlMicrowave

The invention discloses a multifunctional testing device and method for asphalt stirring, preparation and microwave aging. The device comprises a temperature control system, a stirring system, an objective table and an air blowing system; the temperature control system comprises a control box, an environment box, an infrared temperature probe, a microwave generator and a control panel, the stirring system comprises an illuminating lamp, a motor and a rotor; the rotor comprises a first rotor and a second rotor, and the air blowing system comprises an air blowing window, a draught fan, a filter,a heater and a cooler; in a process of performing microwave aging on the asphalt by using the testing device, a test mold is arranged on the objective table, the test mold is used for holding a testsample, the test sample is heated by the microwave generator, and the temperature of the test mold is monitored in real time by the infrared temperature probe. When the above testing device is used for stirring the asphalt and preparing modified asphalt, the rotor adopts the second rotor, and the second rotor is controlled to stir the test sample through the control panel. By adoption of the multifunctional testing device and method provided by the invention, the preparation efficiency and the output of the aged asphalt are improved, and the multifunctional test requirements are met.

Owner:CHANGAN UNIV

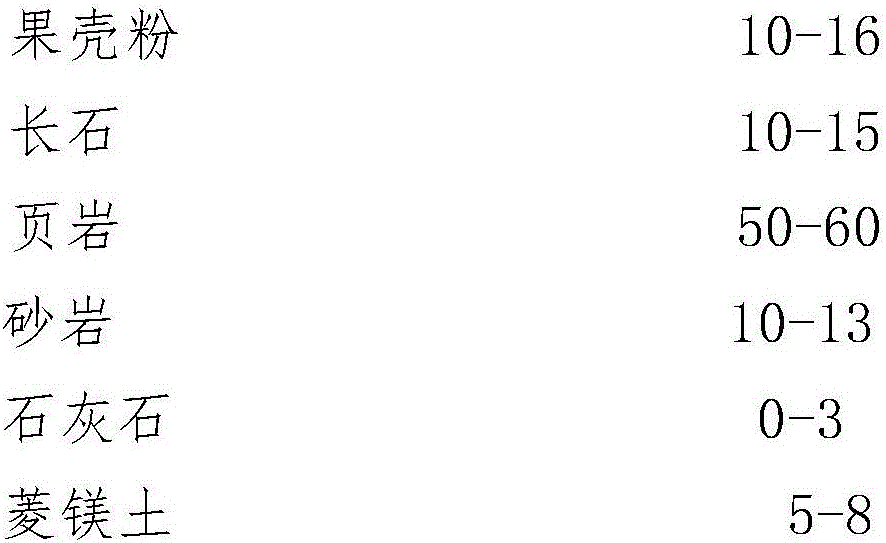

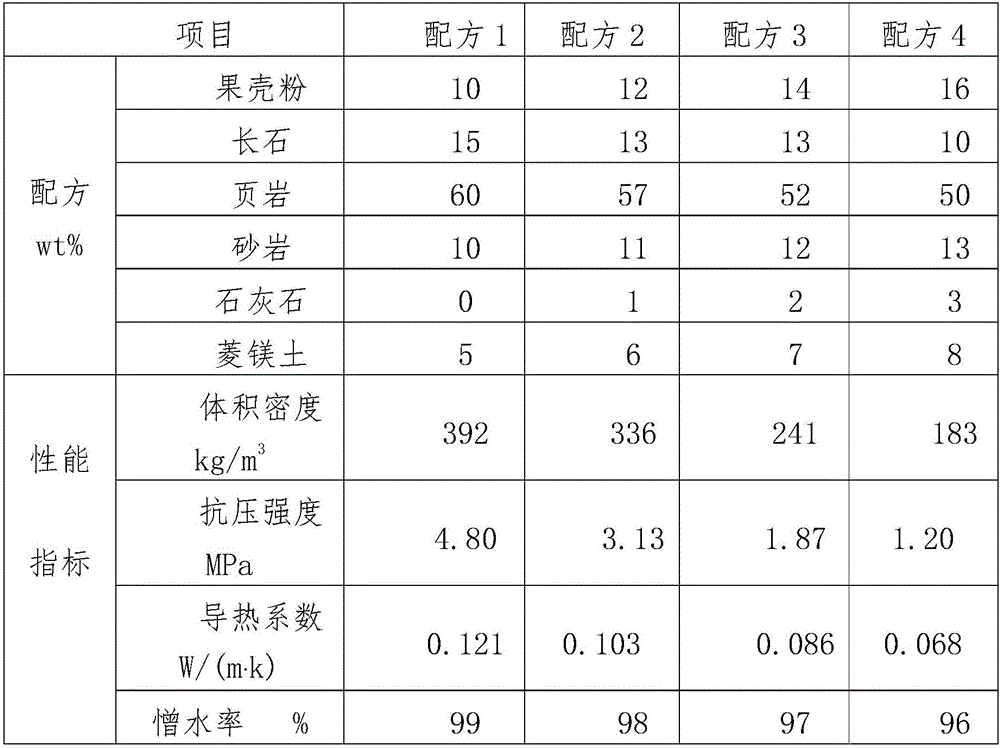

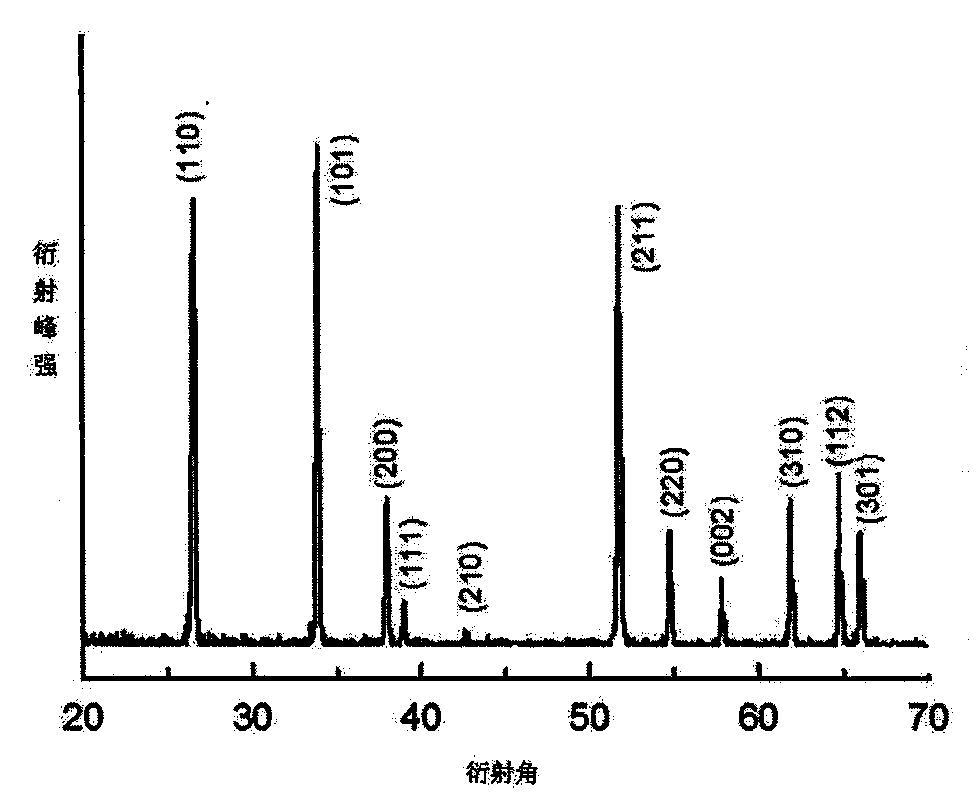

Method for preparing building insulation materials using shell powder

ActiveCN106348782ASatisfy the use of heat preservationGood thermal insulation functionCeramic materials productionCeramicwareBuilding insulation materialsMechanical property

The invention discloses a method for preparing building insulation materials using shell powder, wherein the building insulation materials are obtained by mixing the following raw materials and admixtures by mass percentage and stirring for slurrying, granulation by spray and high temperature firing: 50-60% of shale, 10-15% of feldspar, 10-13% of sandstone, 0-3% of limestone, 5-8% of magnesite and 10-16% of shell powder.The method for preparing building insulation materials not only utilizes the mine raw material and the waste shell powder to achieve the comprehensive utilization of the resources, and the product has fairly good mechanical property and heat preservation performance with low manufacturing cost and little environmental pollution.

Owner:BEIJING UNIV OF TECH +1

Stannic oxide pressure sensitive resistor composite powder material and preparation method thereof

The invention relates to a stannic oxide pressure sensitive resistor composite powder material with excellent properties, and a preparation method thereof. The powder material is prepared from SnO2, Co2O3, Bi2O3, Pr2O3 and Y2O3. The preparation method comprises the following steps: by adopting a chemical coprecipitation method and by taking absolute ethyl alcohol as an organic solvent and polyethylene glycol as a dispersing agent, adding stannic chloride, tribismuth chloride, tricobalt chloride, praseodymium nitrate and yttrium nitrate, dissolving the components into a transparent solution in a constant temperatue water bath environment, dropwise adding an ammonia water solution used as a precipitator into the transparent solution at a uniform speed, precipitating, filtering, washing, drying, grinding and calcining, thereby obtaining the stannic oxide pressure sensitive resistor composite powder material. The stannic oxide composite powder with excellent properties is essential to manufacturing of high-performance pressure sensitive resistors. The stannic oxide composite powder prepared by using the method disclosed by the invention has the advantages of small particle size, uniform modified oxide distribution and narrow particle size distribution. The stannic oxide pressure sensitive resistor composite powder material disclosed by the invention is simple in preparation method, precise and controllable in component, relatively good in product morphology consistence and excellent in electric property.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com