Aluminum-scandium intermediate alloy and preparation technology thereof

A master alloy, aluminum scandium technology, applied in the field of aluminum scandium master alloy and its preparation technology, can solve the problems of easy segregation, high cost of aluminum scandium master alloy, etc., and achieve the effect of excellent comprehensive performance, high recovery rate and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

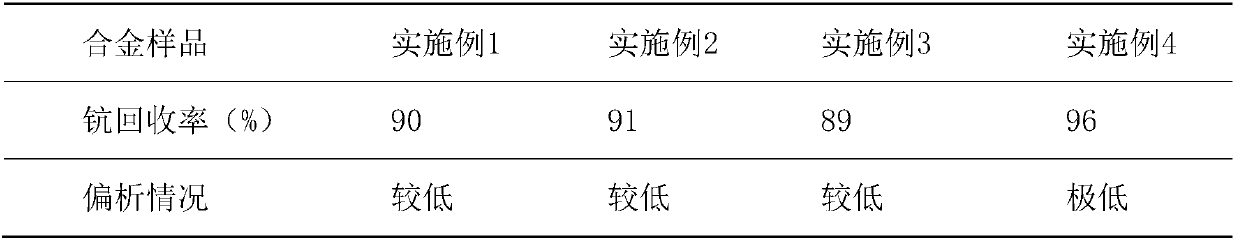

Examples

preparation example Construction

[0024] A method for preparing the above-mentioned aluminum-scandium master alloy is characterized in that it comprises the following steps:

[0025] A. Prepare nano-scandium powder with a diameter of 50-100nm, high-purity aluminum ingots, high-purity aluminum foil, and high-purity argon as a protective gas according to weight percentage;

[0026] B. First put the high-purity aluminum ingot into a graphite crucible, use a resistance furnace to heat it to 950°C to melt, and pass high-purity argon on the surface of the melt for protection;

[0027] C. Put nano-scandium powder with a diameter of 50-100nm into high-purity aluminum foil and wrap it tightly, press it into the liquid aluminum melt after vacuuming, and keep it for 10 minutes;

[0028] D. Use electromagnetic stirring technology to uniformly stir the melt for 5-10 minutes to make the scandium evenly distributed;

[0029] E. Pour the qualified aluminum-scandium alloy melt into the preheated water-cooled iron mold, the pouring tempe...

Embodiment 1

[0033] An aluminum-scandium master alloy. The components and weight percentages of the aluminum-scandium master alloy are: Sc: 2.0%; C: 0.03%; Cu: 0.02%; Fe: 0.08%; Si: 0.004%; the balance is Al .

[0034] A method for preparing the above-mentioned aluminum-scandium master alloy is characterized in that it comprises the following steps:

[0035] A. Prepare nano-scandium powder with a diameter of 50nm, high-purity aluminum ingot, high-purity aluminum foil, and high-purity argon as a protective gas according to weight percentage;

[0036] B. First put the high-purity aluminum ingot into a graphite crucible, use a resistance furnace to heat it to 950°C to melt, and pass high-purity argon on the surface of the melt for protection;

[0037] C. Put the nano-scandium powder with a diameter of 50nm into high-purity aluminum foil and wrap it tightly, press it into the liquid aluminum melt after vacuuming, and keep it for 10 minutes;

[0038] D. Use electromagnetic stirring technology to homogen...

Embodiment 2

[0042] An aluminum-scandium master alloy. The components and weight percentages of the aluminum-scandium master alloy are: Sc: 3.0%; C: 0.05%; Cu: 0.03%; Fe: 0.06%; Si: 0.003%; the balance is Al .

[0043] A method for preparing the above-mentioned aluminum-scandium master alloy is characterized in that it comprises the following steps:

[0044] A. Prepare nano-scandium powder with a diameter of 60nm, high-purity aluminum ingot, high-purity aluminum foil, and high-purity argon used as a protective gas according to weight percentage;

[0045] B. First put the high-purity aluminum ingot into a graphite crucible, use a resistance furnace to heat it to 950°C to melt, and pass high-purity argon on the surface of the melt for protection;

[0046] C. Put the nano-scandium powder with a diameter of 60nm into the high-purity aluminum foil and wrap it tightly, press it into the liquid aluminum melt after vacuuming, and keep it for 10 minutes;

[0047] D. Use electromagnetic stirring technology t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com