Method for preparing building insulation material employing straws and bamboo poles

A technology for building insulation and bamboo poles, applied in the field of building insulation materials, can solve the problems of weak mechanical properties, poor folding performance, increased process costs, etc., and achieve the effects of improving mechanical strength, flexural strength, and improving bonding ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

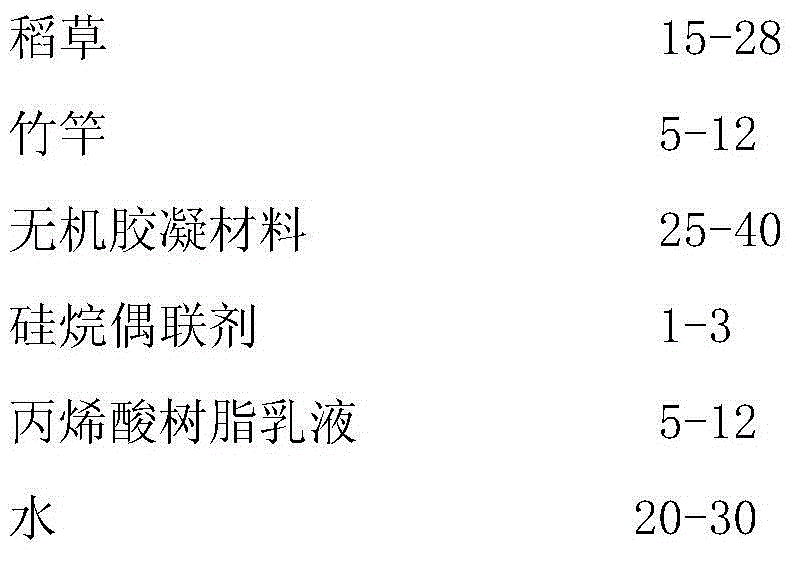

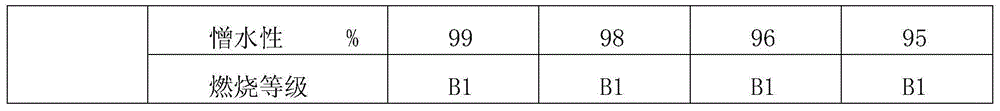

[0048] Convert the proportioning of formula 1 in Table 1 into kilogram unit for batching, prepare 100 kilograms of the above-mentioned raw materials, and its proportioning is respectively: 28 kilograms of straw, 12 kilograms of bamboo poles, and inorganic cementitious materials include 15 kilograms of ordinary portland cement and gypsum 10 kg, 3 kg of silane coupling agent, 12 kg of acrylic resin emulsion, 20 kg of water.

[0049] The size of the plastic mold used in this embodiment is 600*900*90mm, and the mold is divided into upper, middle and lower layers, and the thickness of each layer is 30mm. The bamboo poles are 10mm in diameter, and the lengths are cut to 940mm and 640mm respectively. The straw needs to be cut and processed, and the straw with a length of 3-10mm, 10-20mm, and 20-30mm is mixed according to the volume 2:3:4.

[0050] Mix the silane coupling agent and acrylic resin emulsion together to form a mixed solution, then turn on the straight-through drum mixer,...

Embodiment 2

[0056] Convert the proportioning of formula 2 in Table 1 into kilogram units for batching, and prepare 100 kilograms of the above-mentioned raw materials, and the proportioning is respectively: 23 kilograms of straw, 8 kilograms of bamboo poles, and inorganic cementitious materials including 15 kilograms of aluminosilicate cement and gypsum 15 kg, 3 kg of silane coupling agent, 10 kg of acrylic resin emulsion, 26 kg of water.

[0057] In this embodiment, the size of the plastic mold used is 600*1200*120mm, and the mold is divided into upper, middle and lower layers, and the thickness of each layer is 30mm, 60mm, and 30mm respectively. The bamboo poles are 15mm in diameter, and the lengths are cut to 1240mm and 640mm respectively. The straw needs to be cut and processed, and the straw with a length of 3-10mm, 10-20mm, and 20-30mm is mixed according to the volume of 2:3:5.

[0058] Mix the silane coupling agent and acrylic resin emulsion together to form a mixed solution, then ...

Embodiment 3

[0064] Convert the proportioning of formula 3 in Table 1 into kilogram unit for batching, prepare 100 kilograms of the above-mentioned raw materials, and its proportioning is respectively: 20 kilograms of rice straw, 5 kilograms of bamboo poles, inorganic cementitious material comprises 35 kilograms of magnesium oxide cement, silane even 2 kg of joint agent, 9 kg of acrylic resin emulsion, and 29 kg of water.

[0065] In this embodiment, an aluminum alloy mold with a size of 900*1500*150mm is used, and the mold is divided into upper, middle and lower layers, and the thickness of each layer is 30mm, 90mm, and 30mm, respectively. The bamboo poles are selected with a diameter of 20mm, and the lengths are cut to 1540mm and 940mm respectively. The straw needs to be cut and processed, and the straw with a length of 3-10mm, 10-20mm, and 20-30mm is mixed according to the volume of 2:3:6.

[0066] Mix the silane coupling agent and acrylic resin emulsion together to form a mixed soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com