High-temperature-resistant nano light ceramic material and preparation method thereof

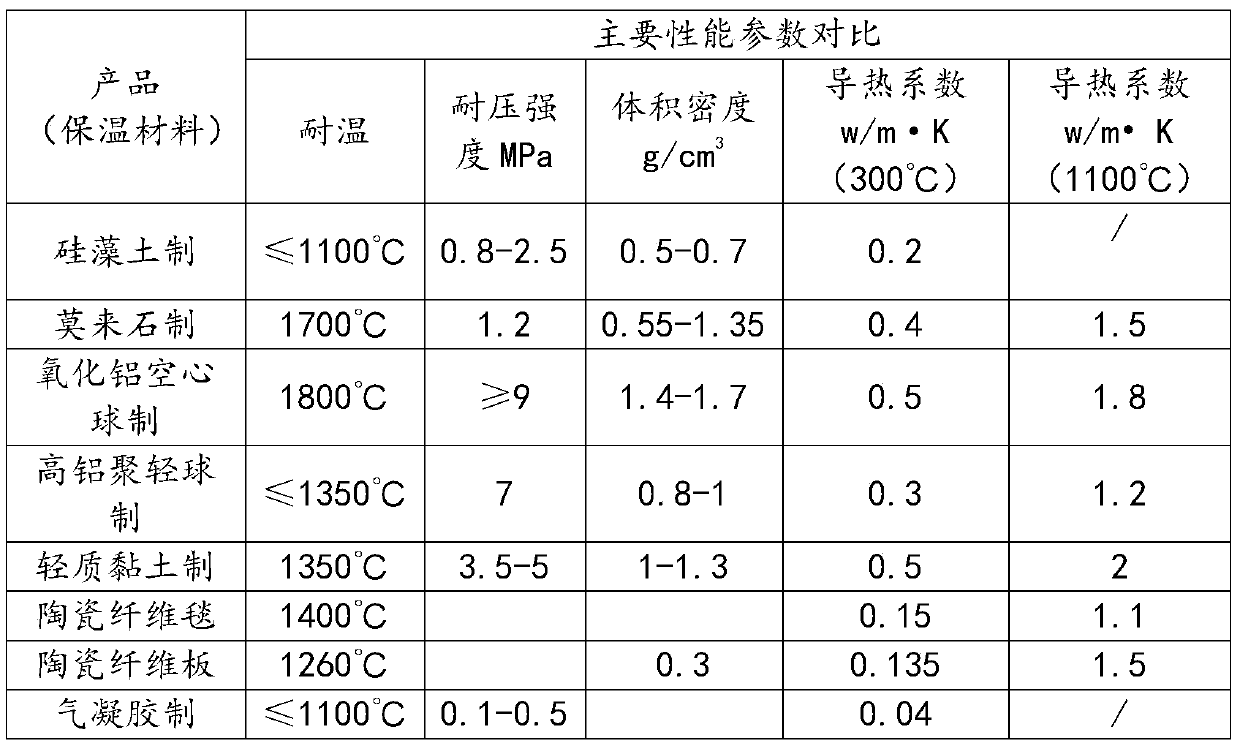

A lightweight ceramic, high-temperature-resistant technology, applied in the field of thermal insulation, can solve the problems of high density, low thermal conductivity, and high thermal conductivity of high-temperature thermal insulation materials, and achieve the effects of low density, low thermal conductivity, and high-efficiency thermal insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

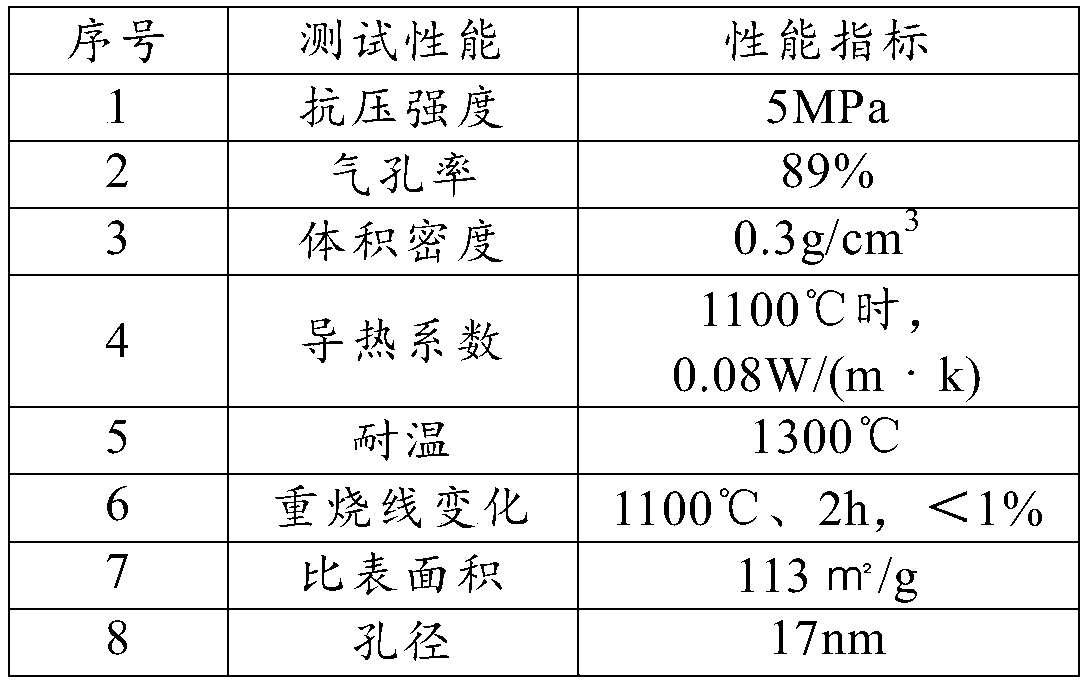

Examples

Embodiment 1

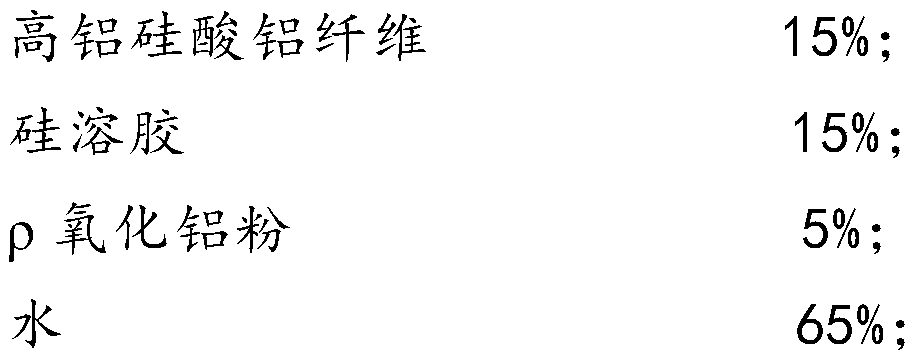

[0036] High temperature resistant nano light ceramic material, the unit is mass percentage.

[0037] Main material system:

[0038]

[0039] Admixture (0.901% of the main material system):

[0040] Cetyltrimethylammonium bromide 0.001%

[0041] Methylcellulose 0.2%;

[0042] Ammonia 0.7%

[0043] The preparation process of the high temperature resistant nano light ceramic material in this embodiment is as follows:

[0044] S1. Dissolve cetyltrimethylammonium bromide and methyl cellulose in water, place in a fiber disperser and add silica sol to stir, set the speed at 600 rpm, and stir for 3 minutes to obtain nano-scale bubble solution to stabilize the bubbles;

[0045] S2. Add rho-alumina powder to the solution in step S1, keep the rotational speed at 600 rpm, stir for 1 min, and the solution becomes a suspension of bubbles wrapped in white ceramic powder.

[0046]Continue to add fibers, increase the speed of the fiber disperser to 800 rpm, and stir for 8 minutes to o...

Embodiment 2

[0054] High temperature resistant nano light ceramic material, the unit is mass percentage.

[0055] Main material system:

[0056]

[0057] Admixture (0.802% of the main material system):

[0058]

[0059]

[0060] The preparation process of the high temperature resistant nano light ceramic material in this embodiment is as follows:

[0061] S1. Dissolve sodium dodecylbenzenesulfonate, sulfurous acid pulp waste liquid and gum arabic in water, place in a fiber disperser and add silica sol to stir, set the speed at 700 rpm, and stir for 4 minutes to obtain a nanometer bubble solution with stable bubbles;

[0062] S2. Add aluminum nitrate nonahydrate to the solution in step S1, keep the speed at 600 rpm, stir for 1 min, and the solution becomes a viscous suspension of air bubbles.

[0063] Continue to add fibers, increase the speed of the fiber disperser to 1000 rpm, and stir for 8 minutes to obtain a high-viscosity suspension solution in which the chopped fibers are...

Embodiment 3

[0071] High temperature resistant nano light ceramic material, the unit is mass percentage.

[0072] Main material system:

[0073]

[0074] Admixture (0.752% of the main material system):

[0075]

[0076] The preparation process of the high temperature resistant nano light ceramic material in this embodiment is as follows:

[0077] S1. Dissolve sodium dodecylbenzenesulfonate, sulfurous acid pulp waste liquid and gum arabic in water, place in a fiber disperser and add silica sol to stir, set the speed at 700 rpm, and stir for 4 minutes to obtain a nanometer bubble solution with stable bubbles;

[0078] S2. Add aluminum chloride and aluminum sulfate to the solution in step S1, keep the rotation speed set at 600 rpm, stir for 1 min, and the solution becomes a viscous suspension of bubbles.

[0079] Continue to add fibers, increase the speed of the fiber disperser to 1000 rpm, and stir for 8 minutes to obtain a high-viscosity suspension solution in which the chopped fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com