Method for preparing building insulation materials using shell powder

A technology of building thermal insulation and fruit shell powder, which is applied in the field of building thermal insulation materials, can solve the problems of limited number of fruit shells, complex and high cost of multifunctional materials, achieve excellent performance, significant technical effects and economic advantages, and avoid environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

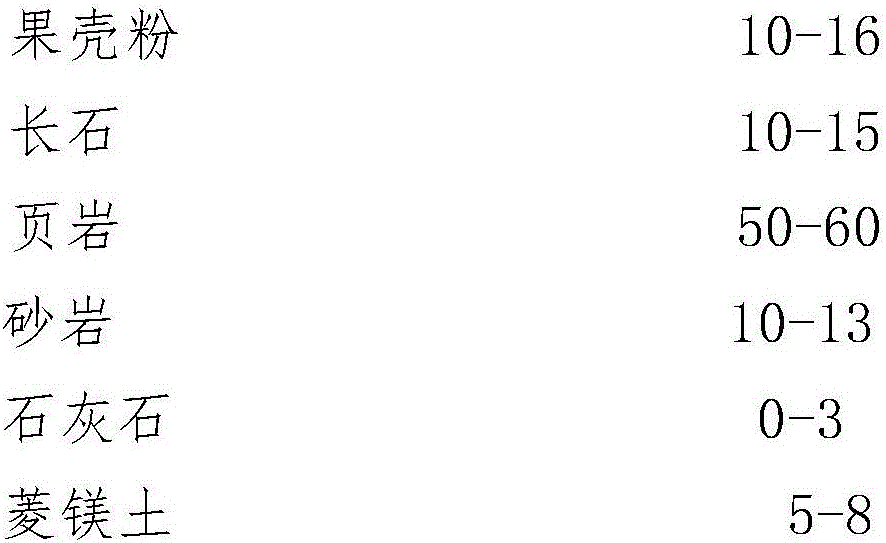

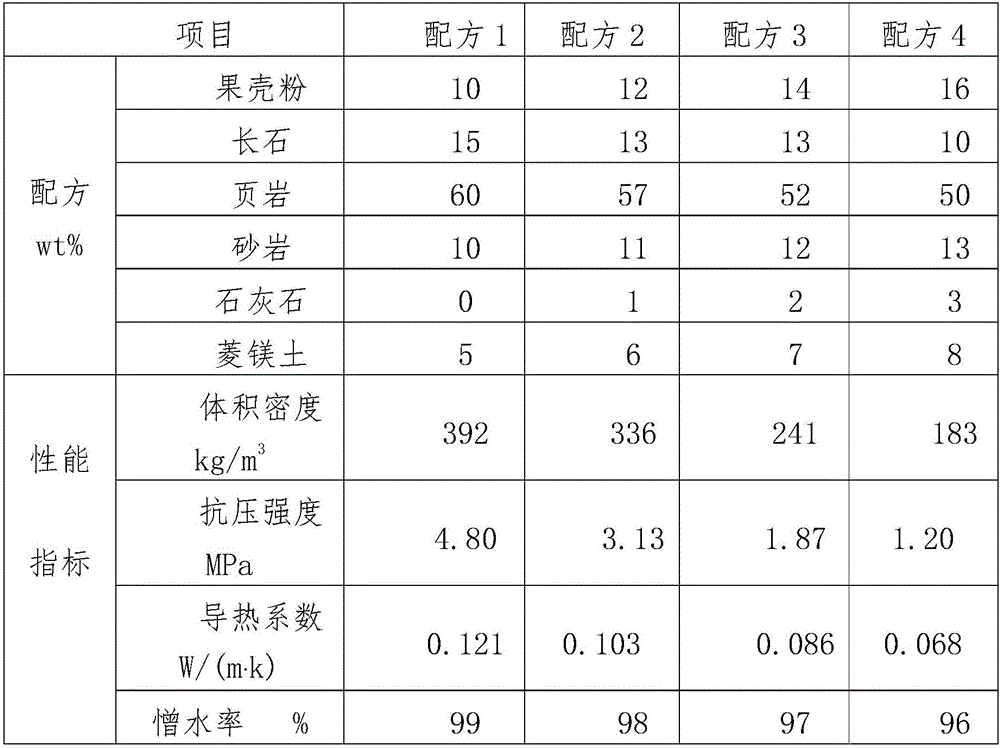

[0042] (1) Ingredients: Weigh the ingredients according to the ratio of formula 1 in Table 1. The ratios are: feldspar powder 15kg, shale 60kg, sandstone 10kg, limestone 0kg, magnesite 5kg, water 61.2kg, control the particle size of raw materials less than 5cm;

[0043] (2) Ball mill mixing: Put the raw materials in (1) into a ball mill lined with 200 kilograms of corundum ceramics, stop the ball mill for 8 hours, discharge the slurry, put it into a 200L mixing drum, the slurry is 200-400 mesh, and mix 40 - 10kg of 120 mesh fruit shell powder is put into the mixing drum and stirred to obtain the evenly mixed slurry of the fruit shell;

[0044] (3) Granulation: use a laboratory-grade centrifugal granulator for the mixed slurry in (2), and granulate the slurry. The particle size range of the granulated powder is 1-3mm, and the moisture content is 8%;

[0045] (4) Firing: Place the granulated powder in (3) in a silicon carbide refractory mold, spread out flat, with a thickness o...

Embodiment 2

[0048] (1) Ingredients: Weigh the ingredients according to the ratio of formula 2 in Table 1. The ratios are: feldspar powder 13kg, shale 57kg, sandstone 11kg, limestone 1kg, magnesite 6kg, water 57.2kg, control the particle size of raw materials less than 5cm;

[0049] (2) Ball mill mixing: Put the raw materials in (1) into a ball mill lined with 200 kg of corundum ceramics, stop the ball mill for 10 hours, discharge the slurry, put it into a 200L mixing drum, and sieve the slurry with 200-400 mesh. Put 12kg of 120-160 mesh fruit shell powder into the mixing drum and stir to obtain a uniformly mixed slurry of fruit shells;

[0050] (3) Granulation: use a laboratory-grade centrifugal granulator for the mixed slurry in (2), and granulate the slurry. The particle size range of the granulated powder is 1-3mm, and the moisture content is 6%;

[0051] (4) Firing: Place the granulated powder in (3) in a silicon carbide refractory mold, spread out flat, with a thickness of 40 mm, he...

Embodiment 3

[0054] (1) Ingredients: Weigh the ingredients according to the ratio of formula 3 in Table 1. The ratios are: feldspar powder 13kg, shale 52kg, sandstone 12kg, limestone 2kg, magnesite 7kg, water 56.76kg, control the particle size of raw materials less than 5cm,

[0055] (2) Ball mill mixing: put the raw materials in (1) into a ball mill lined with 200 kg of corundum ceramics, stop the ball mill for 12 hours, discharge the slurry, put it into a 200L mixing drum, the slurry is 200-400 mesh, and mix 120 -14kg of 200 mesh fruit shell powder is put into the mixing drum,

[0056] (3) Granulation: use a laboratory-grade centrifugal granulator for the mixed slurry in (2), and granulate the slurry. The particle size range of the granulated powder is 1-1mm, and the moisture content is 5%.

[0057] (4) Firing: Place the granulated powder in (3) in a silicon carbide refractory mold, spread out flat, with a thickness of 50mm, heat, sinter and anneal in a heating furnace. The preheating, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com