A kind of tundish multifunctional liner and its preparation method and application

A tundish and multi-functional technology, applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of sintering and adhesion between the working layer and the permanent layer, and achieve easy turning and peeling, good thermal insulation function, and less smoke Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the multifunctional lining of the tundish of the following embodiments comprises the following steps:

[0044] (1) Preparation of film-forming substance solution: According to the technical requirements for the use of film-forming substances, first prepare a film-forming substance solution of a specified concentration, measure the film-forming substance, water and / or organic solvent according to the proportion, disperse, dissolve, and set aside.

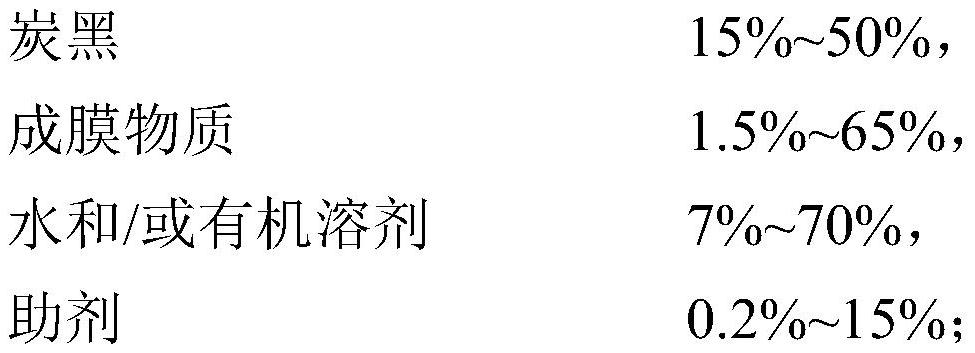

[0045] (2) Preparation of multi-functional lining paint: the preparation of paint can be made by general water-based polyester paint. According to the design ratio, weigh carbon black, film-forming substance solution and additives, first add the film-forming substance solution into the mixer, start the agitator, and add carbon black and various additives into the film-forming substance solution one by one according to the order of feeding , full and high-speed stirring, and finally add water to adjust...

Embodiment 1

[0049] A tundish multifunctional lining coating, the mass parts of raw materials are: carbon black 19-45 parts, 3wt% polyvinyl alcohol aqueous solution 50-70 parts, tributyl phosphate is 0.1% of the total mass of carbon black and polyvinyl alcohol aqueous solution ~0.4%. Glycerin and polyethylene glycol are added in 10% to 15% of the mass of the polyvinyl alcohol aqueous solution in a compounding ratio of 4:1. Amino alcohol alkali-free solution organic decoagulant, Sima chemical PEPTAPON71S suspension stabilizer for glaze, Sima chemical GLYDOL N2002 carbon material wetting agent are respectively 0.1%~0.5%, 0.3%~0.6%, 0.5%~ of carbon black mass 1%. The amount of carbon black and polyvinyl alcohol varies slightly according to the construction method. The amount of carbon black can be increased appropriately for hand coating, while the fluidity of the slurry must be taken into account when spraying.

[0050] According to the above design ratio, weigh carbon black, film-forming ...

Embodiment 2

[0055] A tundish multifunctional lining coating, the mass parts of raw materials are: 30-50 parts of carbon black, 40-70 parts of styrene-acrylic emulsion (solid content 40wt%-50wt%), 0.2-0.5 parts of tributyl phosphate defoamer , 0.4-0.8 parts of alcohol ester twelve film-forming aids, 10-30 parts of water. The decondenser amino alcohol solution and the wetting agent Sima Chemical GLYDOL N2002 carbon material are respectively 0.1% to 0.5% and 0.5% to 1% of the carbon black mass.

[0056] First, add decoagulant and wetting agent to water, add carbon black for pre-dispersion, and stir at high speed to obtain slurry. Then, under low-speed stirring, slowly add styrene-acrylic emulsion to the slurry, keep stirring, and then add film-forming aids, defoamers, etc. to prepare a coating.

[0057] The performance index of slurry is: bulk density (25°C) 1.1~1.4g / cm 3 , Solid content 30wt% ~ 50wt%.

[0058] The slurry has a high viscosity and is suitable for hand-painted construction,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com