Semi-automatic machine for turning gloves outside in

A semi-automatic and tipping machine technology, which is applied in mechanical cleaning, textile and paper making, high-pressure cleaning, etc., can solve the problems of waste of resources and low efficiency, and achieve the effect of improving efficiency, convenient operation and reducing manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

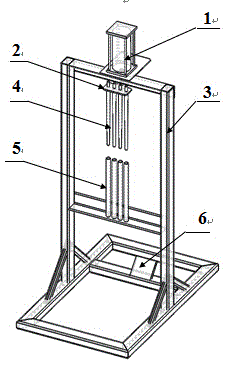

[0013] A semi-automatic glove tipping machine is composed of a cylinder 1, a cylinder connector 2, a bracket 3, an upper sleeve rod 4, a lower sleeve tube 5 and a control pedal 6. The bracket is welded with 50×25 square steel, and the upper casing rod and the lower casing are made of stainless steel. Cylinder, cylinder connector, upper bushing rod, lower bushing and control pedal are installed on the bracket. The cylinder is located on the top of the bracket and is connected to the upper sleeve rod through the cylinder connection head; the lower sleeve tube adapted to the upper sleeve rod is fixedly arranged under the upper sleeve rod; the control pedal for controlling the cylinder is arranged at the bottom of the bracket. Use the control pedal to control the cylinder, and then control the up and down movement of the upper sleeve rod.

[0014] When using, put the finished glove on the lower sleeve, each finger corresponds to a sleeve, at this time, the glove is reversed (the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com