Novel multifunctional inorganic paint, and preparation method and application thereof

An inorganic coating and multi-functional technology, applied in the field of coatings, can solve the problems of single function and low formaldehyde adsorption efficiency, and achieve the effect of good coating effect, efficient sterilization and sterilization ability, and enhanced water retention ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In one embodiment, the preparation method of the novel multifunctional inorganic coating specifically includes the following steps:

[0041] Step S01, weighing each component according to the formula of the novel multifunctional inorganic coating as described above;

[0042] Step S02, performing the first mixing and grinding treatment on the weighed photocatalyst, plant extract, calcium carbonate, high-alumina white cement, quartz sand, and amylase to obtain the first mixed material;

[0043] Step S03, performing a second mixing treatment on the weighed diatom ooze and the first mixed material to obtain the dry powder of the inorganic coating, and then adding deionized water accounting for 15-45% of the dry powder mass, Wet mixing to obtain inorganic coatings.

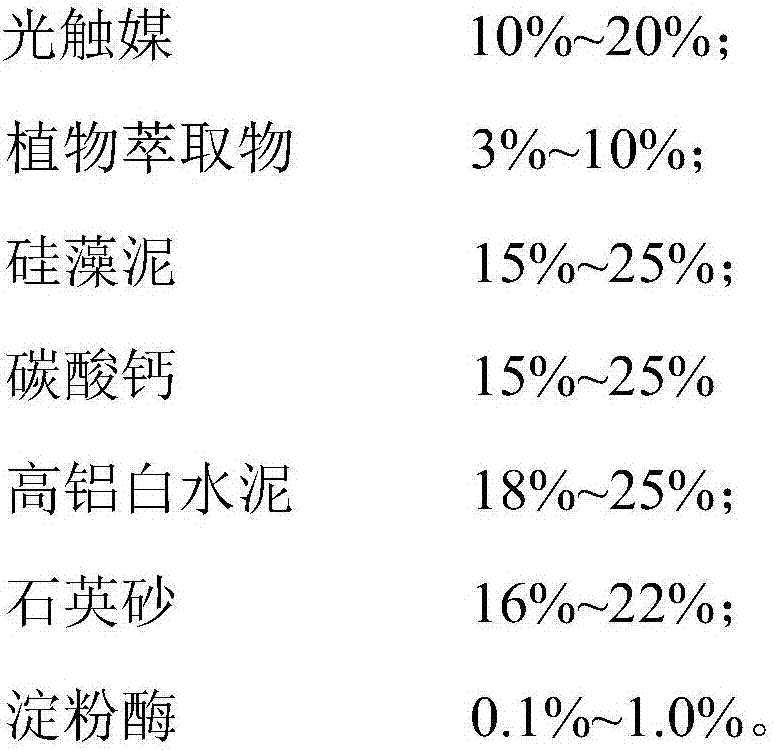

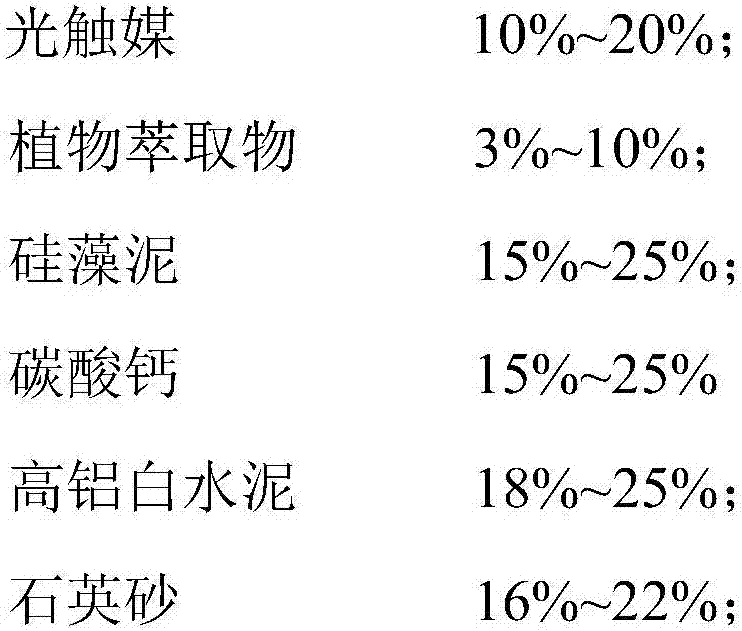

[0044] Specifically, the formulation components of the novel multifunctional inorganic coating weighed in the above step S01 are the formulation components of the novel multifunctional inorganic coating describ...

Embodiment 1

[0052] A novel multifunctional inorganic coating and a preparation method thereof. Among them, the dry powder of the new multifunctional inorganic coating is calculated according to 100% by mass, and includes the following components:

[0053]

[0054] The preparation method of this novel multifunctional inorganic coating comprises the steps:

[0055] Step S01. According to the novel multifunctional inorganic coating formula provided in Example 1, weigh 7kg of nano-titanium dioxide, 3kg of plant extract, 25kg of diatom mud, 17kg of calcium carbonate, 25kg of high alumina white cement, 22kg of quartz sand, and 1kg of amylase;

[0056] Step S02. Perform the first mixing and grinding treatment on the weighed photocatalyst, plant extract, calcium carbonate, high-alumina white cement, quartz sand, and amylase to obtain the first mixed material. The stirring speed is 300rpm and stirred for 45min ;

[0057] Step S03. Perform a second mixing treatment on the weighed diatom ooze a...

Embodiment 10、11

[0072] Examples 10 and 11 have almost no bactericidal effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com